Drive device and application of blade star wheel in roadheader

A driving device and roadheader technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of coal slime accumulation, unfavorable production, viscous transportation efficiency, etc., to prevent coal slime from sticking and improve transportation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The accompanying drawings disclose the specific structure of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

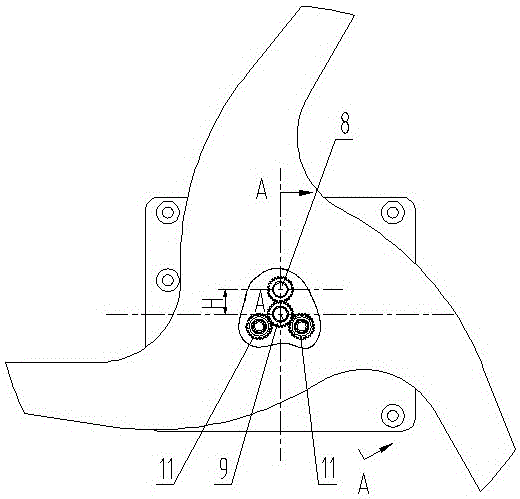

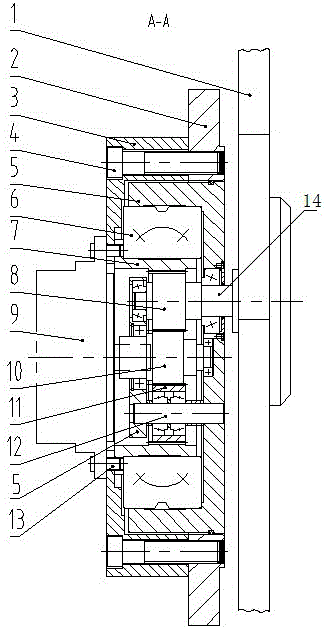

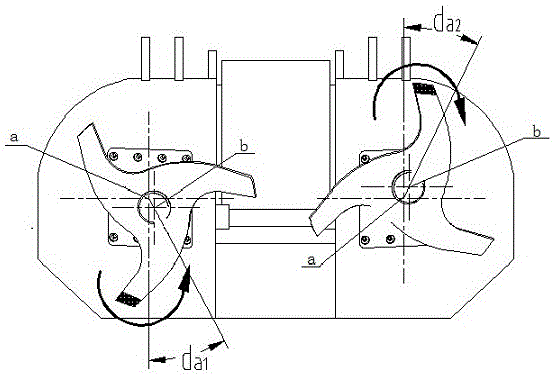

[0016] Depend on figure 1 , figure 2 It can be seen that the present invention includes that the gear transmission mechanism is a planetary gear train, which contains three evenly distributed planetary gears 11, and the inner ring gear 7 of the planetary gear train is fixedly connected with the fastening flange 3 through bolts 13. The fastening method The blue 3 is fixedly connected with the mirror plate 2 through the bolt 4, and the rotating bearing 6 is arranged between the ring gear 7 and the planet carrier 5; the sun gear shaft 10 of the planetary gear system is the input shaft; one of the three planetary gears 11 is Drive planetary gear 8, the shaft pin of driving planetary gear 8 is the output shaft 14, the output shaft 14 is supported on the planet carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com