Manufacturing technology of gearbox body casting

A manufacturing process and gear box technology, applied in the direction of manufacturing tools, molds, mold components, etc., to achieve the effect of reducing the occurrence of pinholes in castings and compacting the structure of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

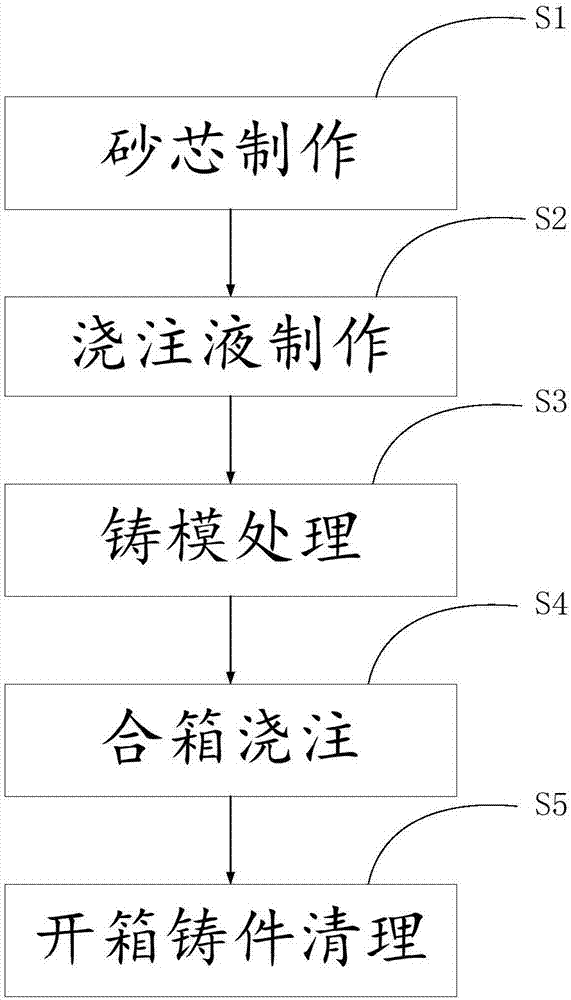

[0044] Such as figure 1 As shown, the present embodiment provides a manufacturing process of a gearbox casing casting, including:

[0045] Step S1, making sand cores, using refractory mud-coated sand combined with sand core box molds to make sand cores for gearbox casings, and baking them for later use.

[0046] In step S2, casting liquid is made, and the cast alloy material used is ZAlSi7MgA.

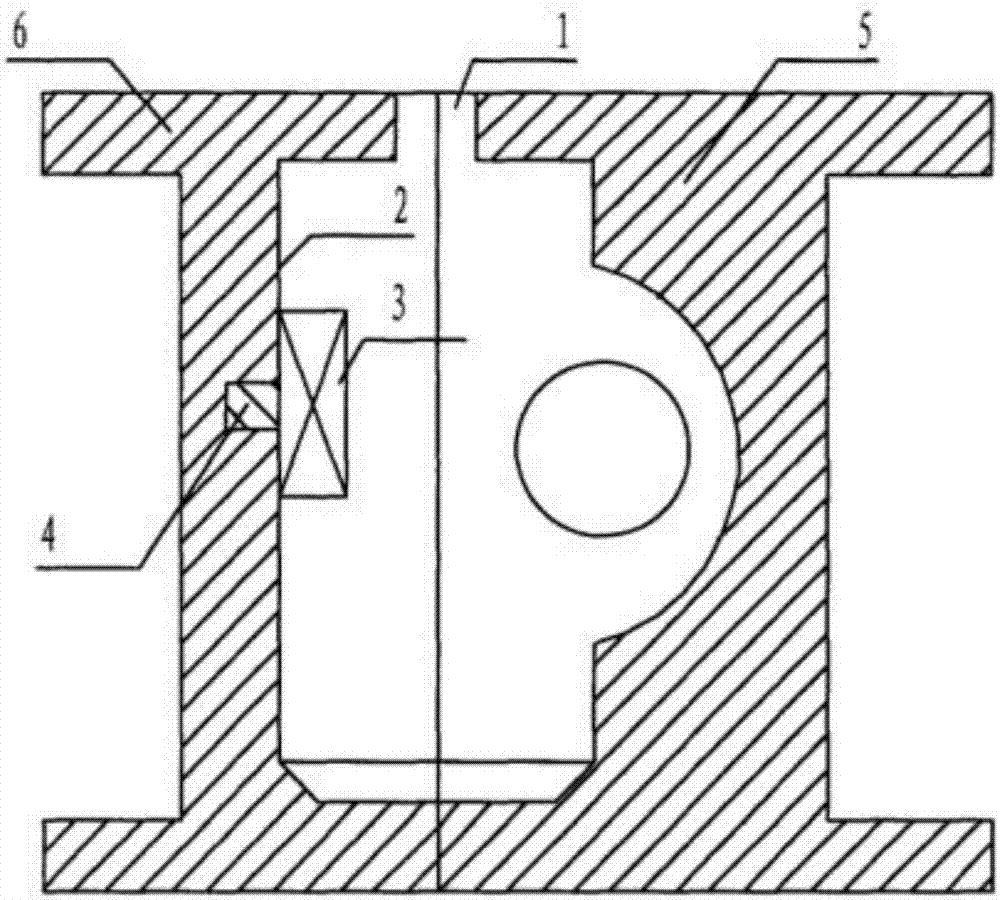

[0047] Step S3, casting mold treatment. The casting mold treatment is to preheat the casting outer mold, and the preheating temperature is controlled within the range of 250-280°C; the sand core prepared in step S1 is assembled in the inner cavity of the casting mold to form a casting mold.

[0048] Step S4, pouring in a box, pouring the pouring solution prepared in step S2 into the casting mold prepared in step S3, controlling the pouring temperature to 710-730°C, and the pouring speed to 0.6-0.8m / s.

[0049] Step S5, unpacking and cleaning the casting, including cutting, rough grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com