Planar mask production line

A production line and mask technology, applied to clothing, tools for sewing clothes, clothing, etc., can solve problems such as affecting the bridge of the nose, transmission error of the power transmission mechanism, and low adjustment efficiency, so as to reduce the difficulty of adjustment, ensure synchronous movement, and improve The effect of positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

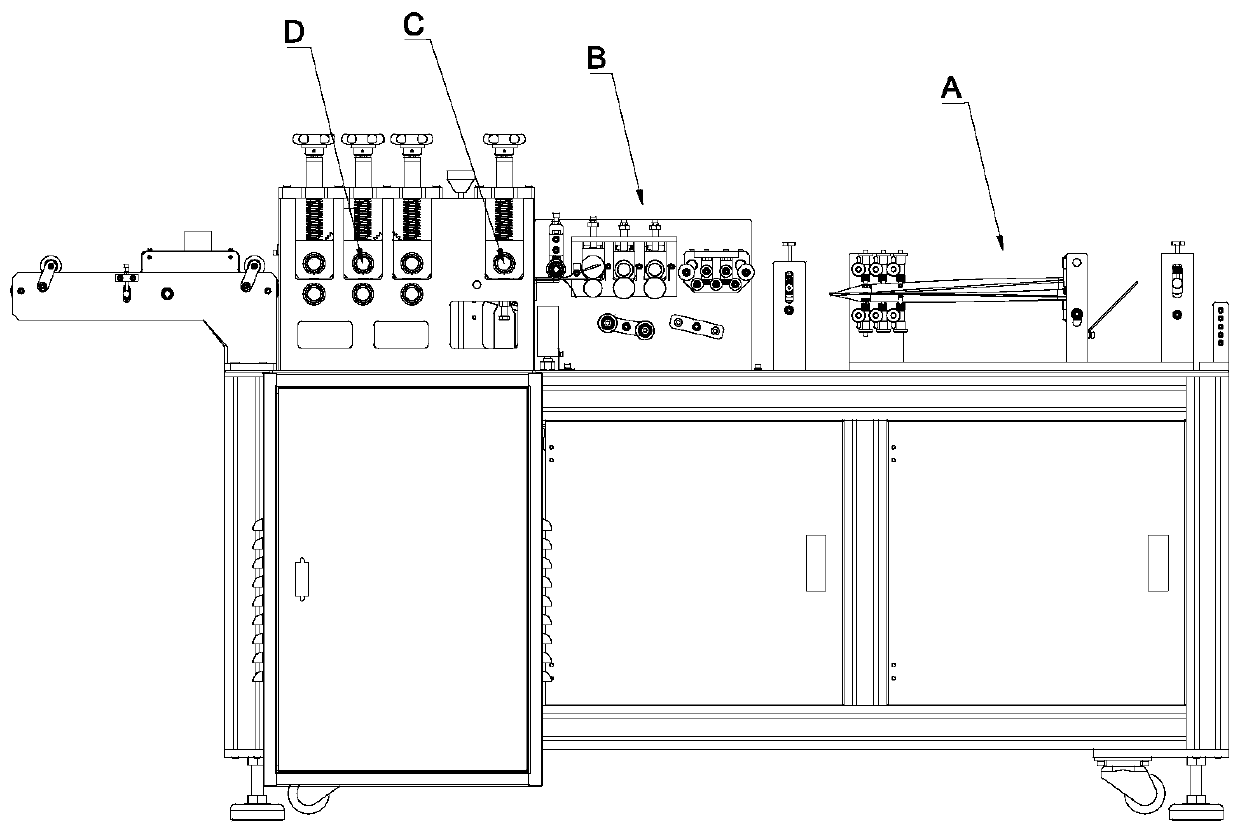

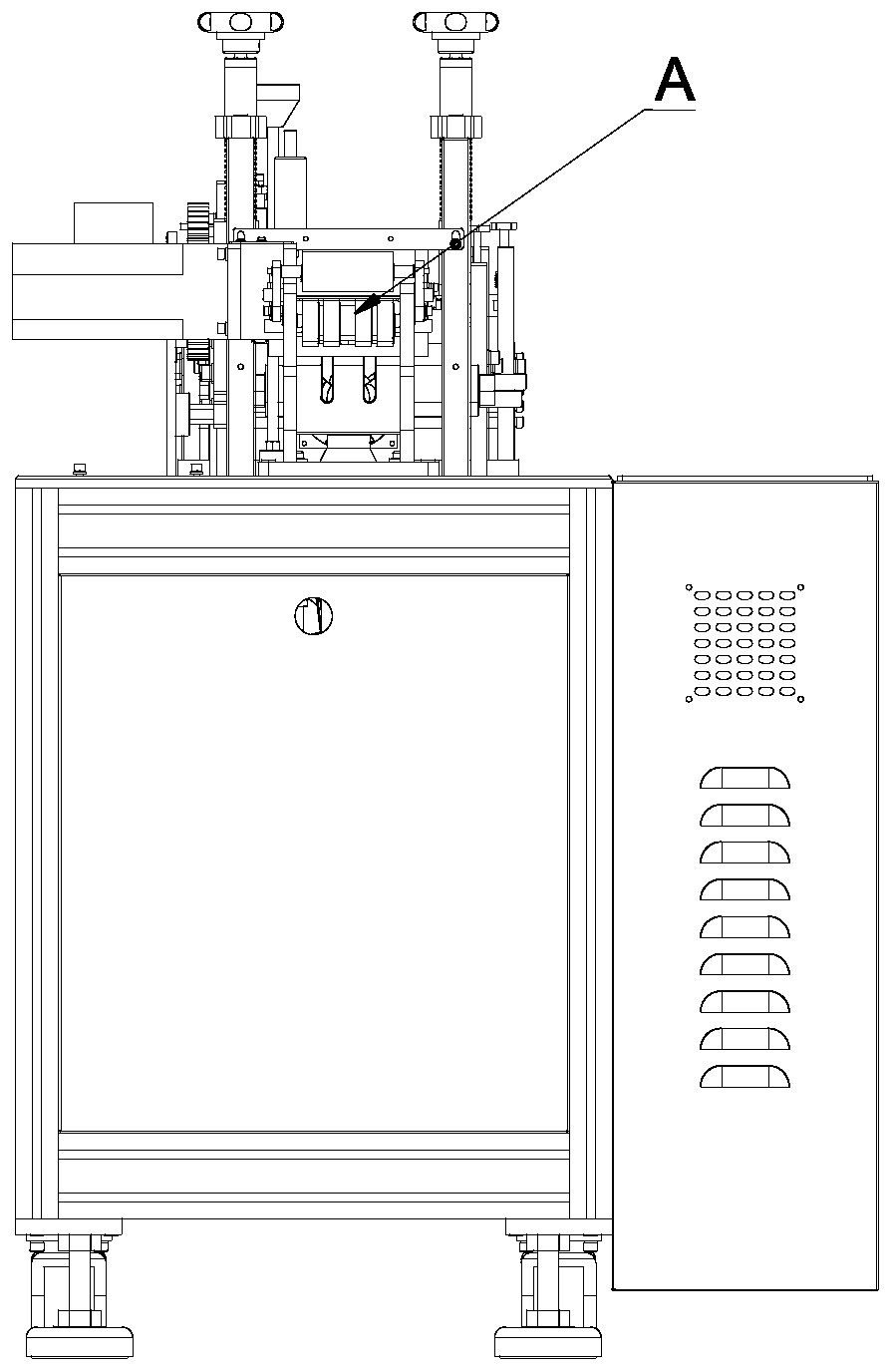

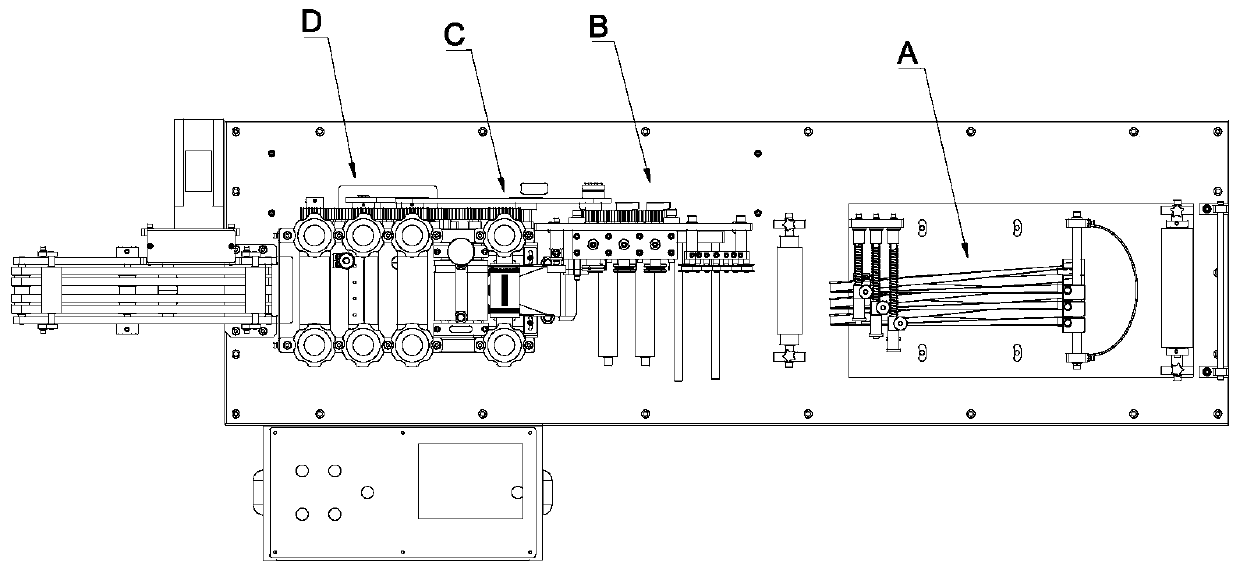

[0048] The flat mask production line of this embodiment includes a cloth roll feeding module, a fold forming module A, a nose wire feeding module B, a welding module C, a slicing module D, and a power source. Along the movement direction of the mask cloth, the cloth roll The feeding module, the fold forming module A, the nose wire feeding module B, the welding module C, and the slicing module D are arranged on the frame in sequence; the cloth roll feeding module includes a plurality of cloth rolls, and the plurality of cloth rolls rotate Connected to the frame; the fold forming module A includes a mounting frame and several sets of fold components arranged on the mounting frame, and the mask cloth is wound on the fold components along the width direction; the welding module C includes a welding roller , A welding table and an ultrasonic device, the welding table is connected with the ultrasonic device, the circumferential surface of the welding roller is provided with welding bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com