Cable Sheath Production Line

A cable sheath and production line technology, applied in the field of cable sheath production line, can solve the problems of cable sheath structure not compact enough, low production efficiency, large floor space, etc., to achieve normal and effective operation, small site and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

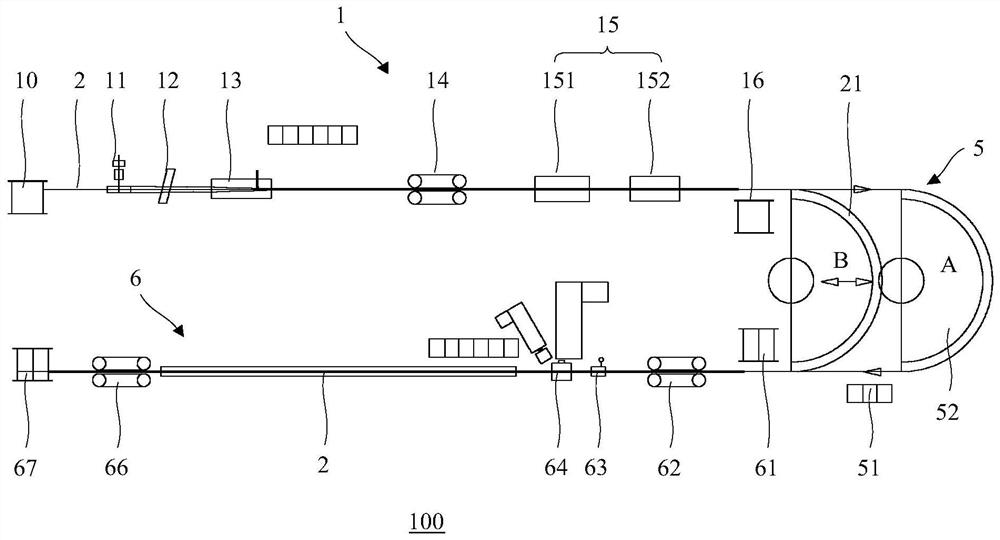

[0037] figure 1 It is a schematic structural diagram of the cable sheath production line provided in the embodiment of the present application.

[0038] The cable sheath production line is used to make the cable semi-finished products into a complete sheath, such as a smooth aluminum sheath. The product obtained at the end of the production line is the high-voltage cable. During the production process of the production line, the cable may have different forms due to the different production positions. In this application, for the convenience of explanation, the form of the cable before the end of the production line is collectively referred to as cable semi-finished products 2. It can be understood that the cable semi-finished product 2 may have different structures and shapes at different stages of the production line.

[0039] refer to figure 1 , the cable sheath production line 100 of the present embodiment includes a metal sheath installation assembly 1, a non-metal she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com