Stretching device capable of continuously stretching PVC (polyvinyl chloride) film

A technology of stretching device and driving roller, which is applied in the field of PVC film sustainable stretching stretching device, can solve the problems of inability to realize continuous work of PVC film and low work efficiency, and achieve ingenious structural design, time saving and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

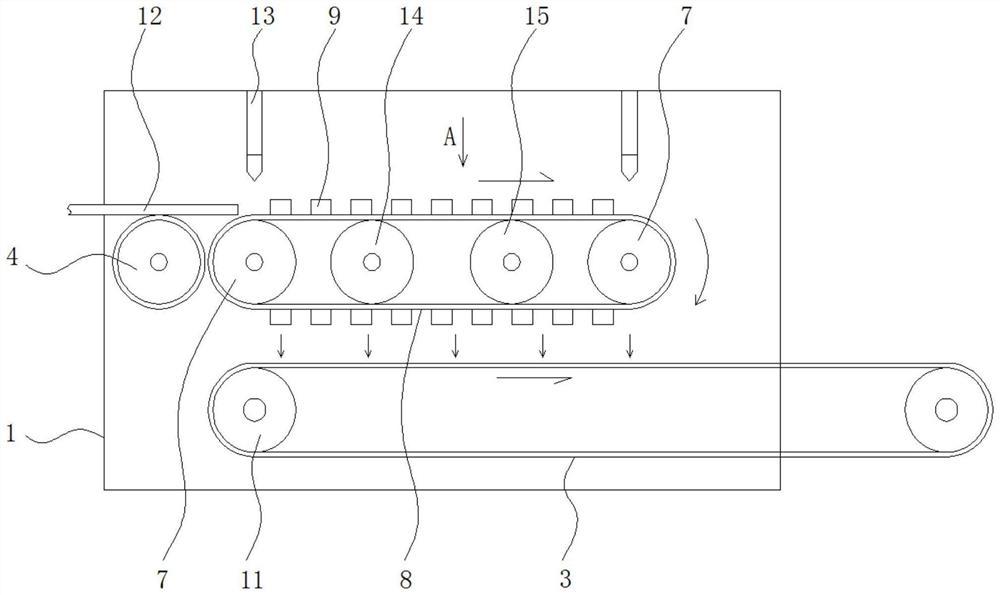

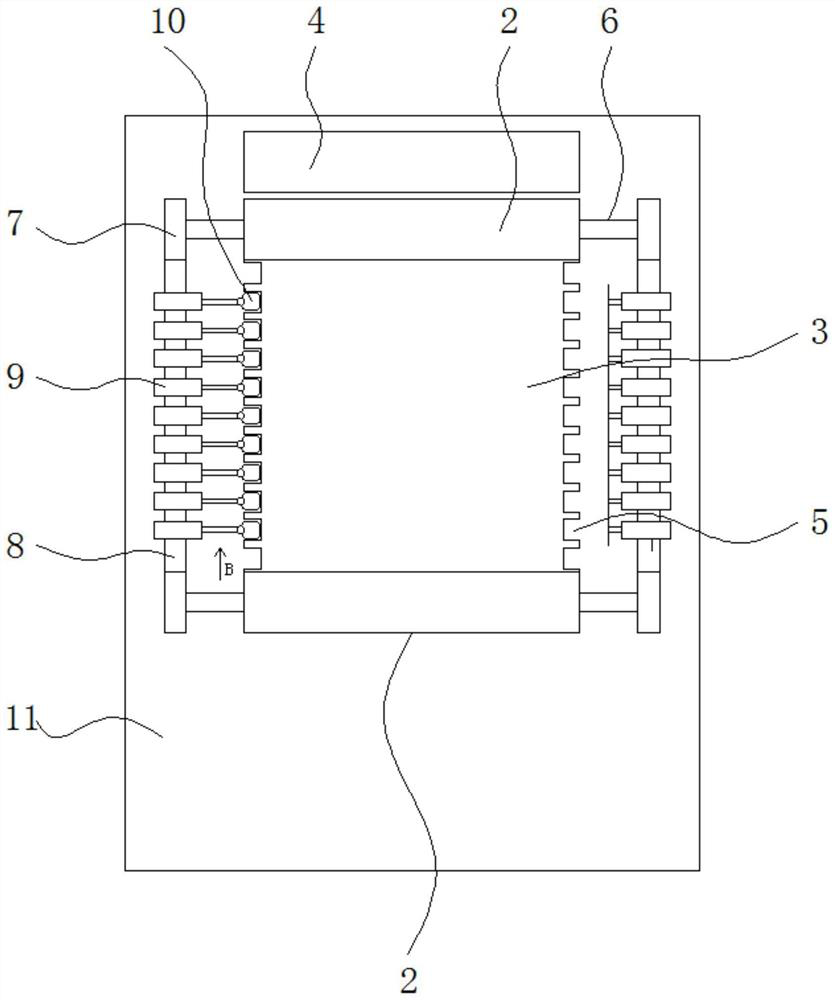

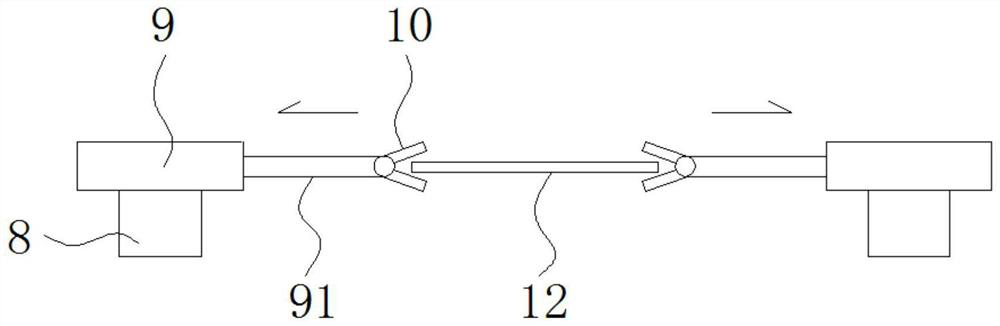

[0031] like figure 1 , figure 2 and image 3 As shown in the figure, a PVC film can be continuously stretched and stretched, including a drying chamber 1, and two driving rollers 2 are also arranged in the drying chamber 1, and a conveyor belt 3 is correspondingly installed between the two driving rollers 2. The width of the belt 3 corresponds to the width of the transmission roller 2, and the left side of the drying chamber 1 is also installed with a feeding roller 4 corresponding to the height of the conveyor belt 3. The feeding roller 4 can transfer the PVC film 12 to the conveyor belt 3. , the PVC film 12 is transported forward with the conveyor belt 3 .

[0032] The edge positions on both sides of the conveyor belt 3 are also provided with evenly spaced clamping gaps 5, the roller shafts 6 of the two drive rollers 2 are extended to both sides, and the ends of the roller shafts 6 are also equipped with corresponding drive sprockets 7. , a transmission sprocket 7 is cor...

Embodiment 2

[0041] like figure 1 , figure 2 and image 3 As shown in the figure, a PVC film can be continuously stretched and stretched, including a drying chamber 1, and two driving rollers 2 are also arranged in the drying chamber 1, and a conveyor belt 3 is correspondingly installed between the two driving rollers 2. The width of the belt 3 corresponds to the width of the transmission roller 2, and the left side of the drying chamber 1 is also installed with a feeding roller 4 corresponding to the height of the conveyor belt 3. The feeding roller 4 can transfer the PVC film 12 to the conveyor belt 3. , the PVC film 12 is transported forward with the conveyor belt 3 .

[0042] The edge positions on both sides of the conveyor belt 3 are also provided with evenly spaced clamping gaps 5, the roller shafts 6 of the two drive rollers 2 are extended to both sides, and the ends of the roller shafts 6 are also equipped with corresponding drive sprockets 7. , a transmission sprocket 7 is cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com