Clamping device for aluminum profile machining

A technology of aluminum profile processing and clamping device, which is applied in the field of aluminum profile processing, can solve the problems of uneven processing surface, damage of processing equipment, vibration of aluminum profile, etc., and achieve the effect of improving dimensional accuracy, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

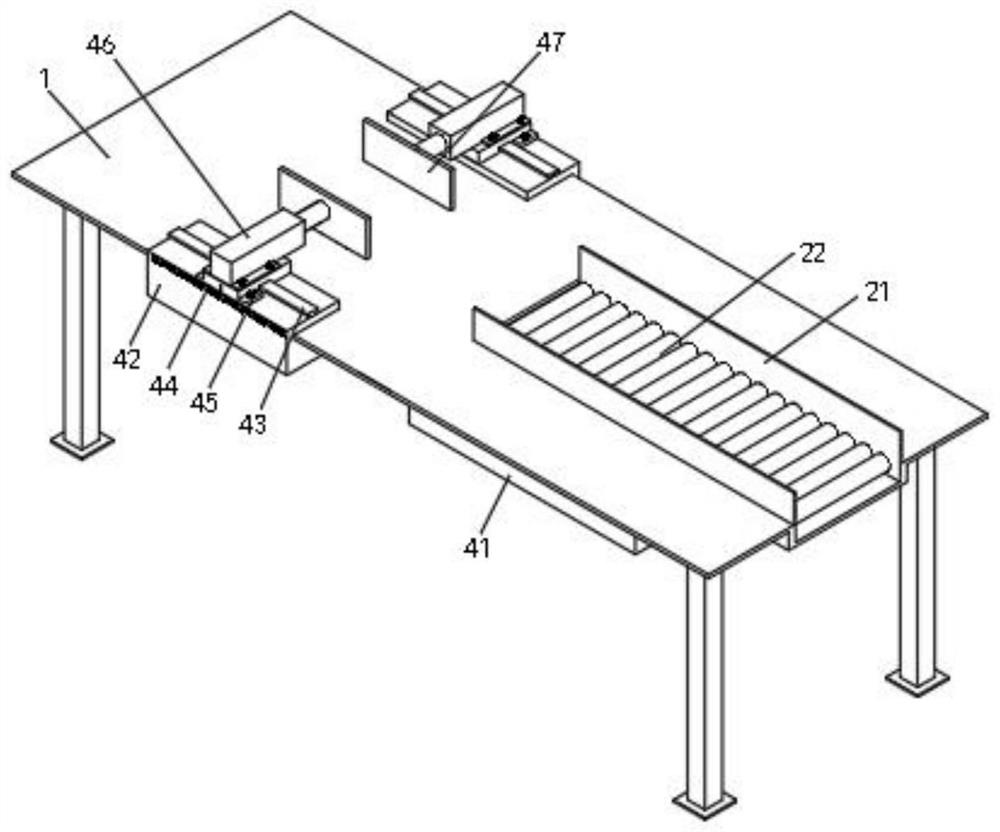

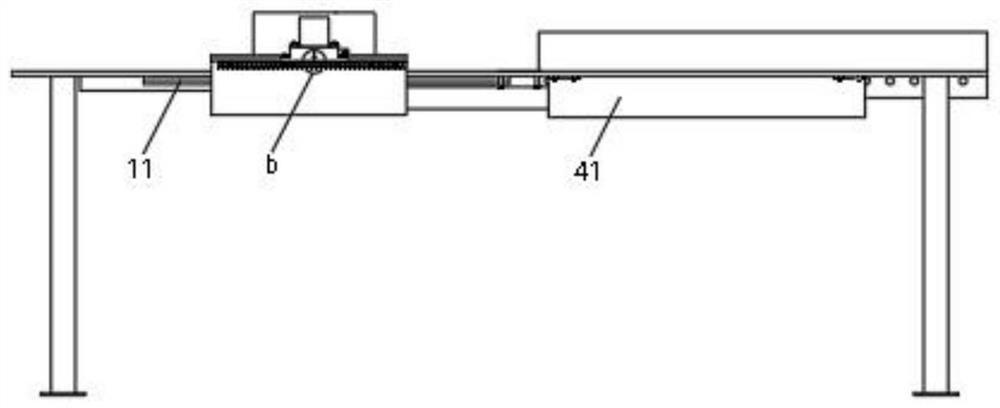

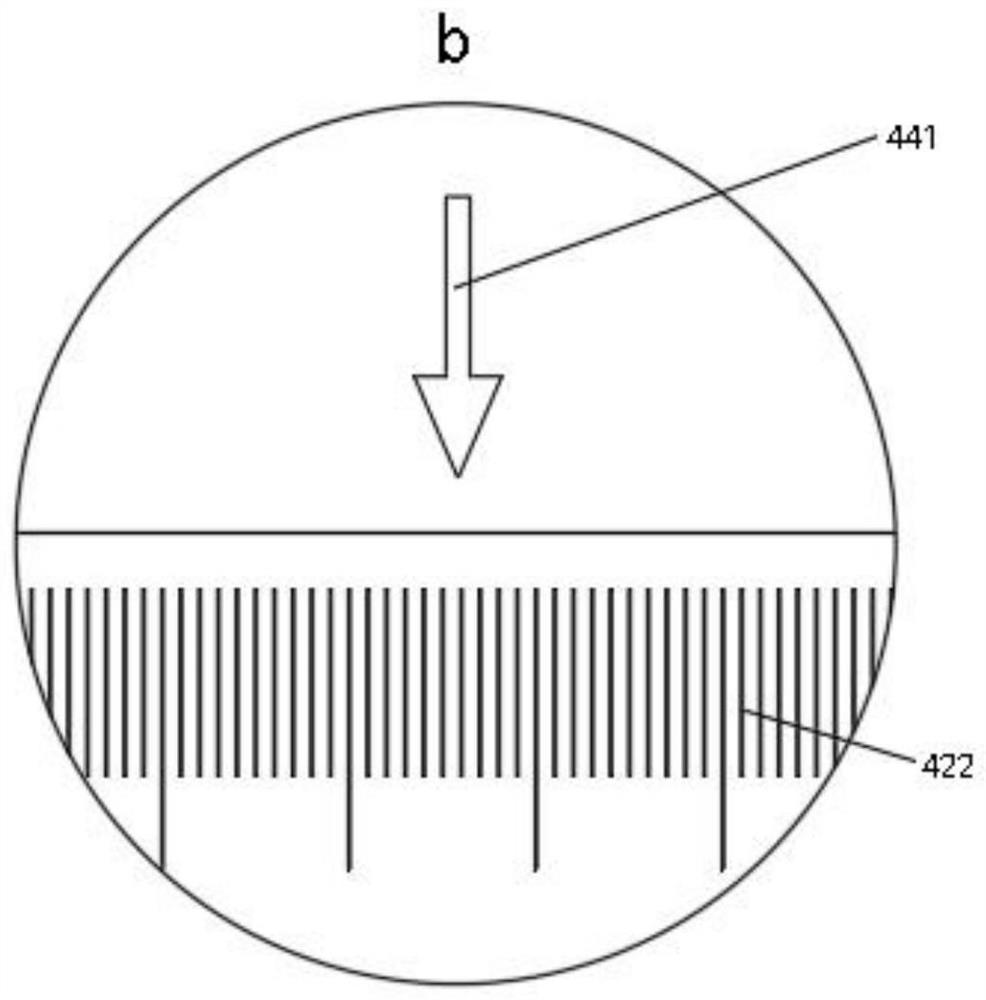

[0033] Such as Figure 1-Figure 3 As shown, in this embodiment, a clamping device for processing aluminum profiles is used to cooperate with aluminum profile processing devices to improve the accuracy of aluminum profile processing, such as aluminum profile cutting devices and punching devices. Conveyor platform 1 of the aluminum profile processing production line. The end of the conveyor platform 1 facing the incoming direction of aluminum profiles is equipped with a roller shaft conveying part. The roller shaft conveying part is composed of the first conveying roller shaft 22 and the limit plate 21, which is used to undertake the upper road. For the aluminum profiles transferred in the process, the conveying track of the aluminum profiles can be preliminarily restricted by the limiting plate 21 .

[0034] Certainly, in this embodiment, the height of the axial surface of the first conveying roller shaft 22 protruding from the upper end surface of the conveying platform 1 is 0...

Embodiment 2

[0040] Such as Figure 4-Figure 8 As shown, in this embodiment, a clamping device for aluminum profile processing, the device is used to cooperate with aluminum profile processing devices to improve the accuracy of aluminum profile processing, such as aluminum profile cutting devices, punching devices, the device includes installation On the conveying table 1 of the aluminum profile processing production line, the end of the conveying table 1 facing the incoming direction of the aluminum profile is equipped with a roller conveying part. The roller conveying part is composed of a first conveying roller 22 and a limit plate 21 for receiving The aluminum profiles transferred in the first working procedure can preliminarily restrict the conveying track of the aluminum profiles through the limiting plate 21.

[0041] Certainly, in this embodiment, the height of the axial surface of the first conveying roller shaft 22 protruding from the upper end surface of the conveying table 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com