Feeding device for metal band sawing machine

A technology of metal strip and sawing machine, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc. It can solve the problems of inability to cut bar material, reprocessing and inclination of the end of bar material, etc., and achieve the effect of increasing cutting diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

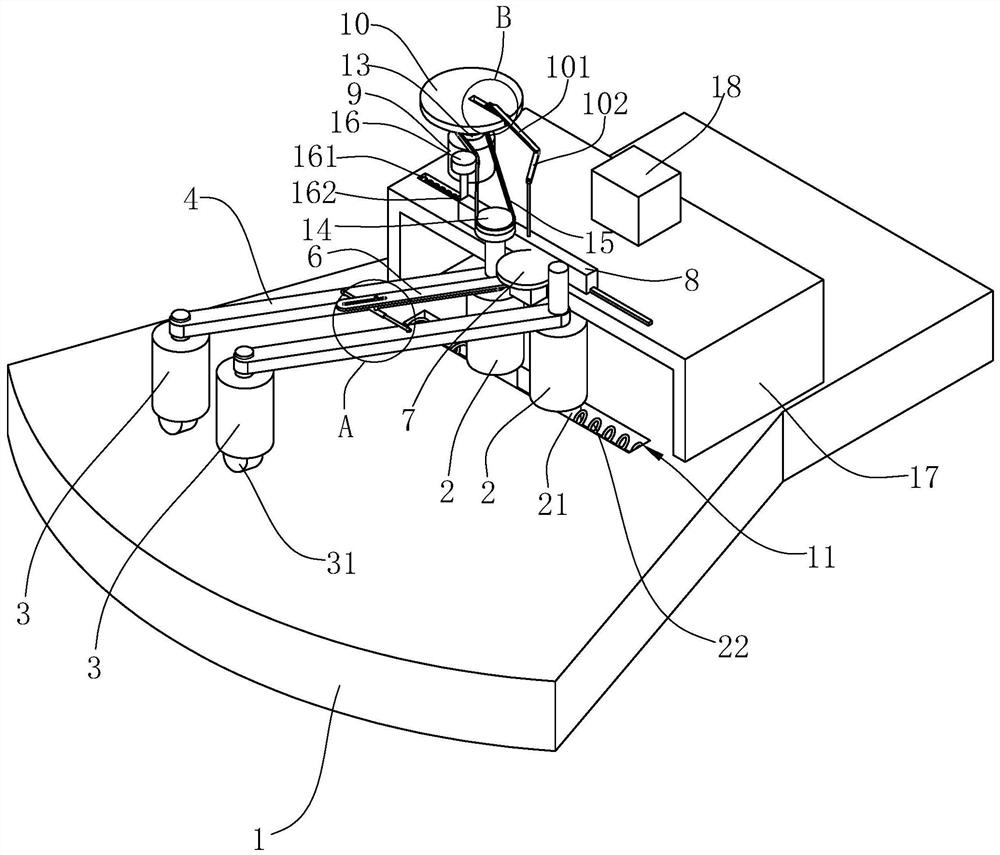

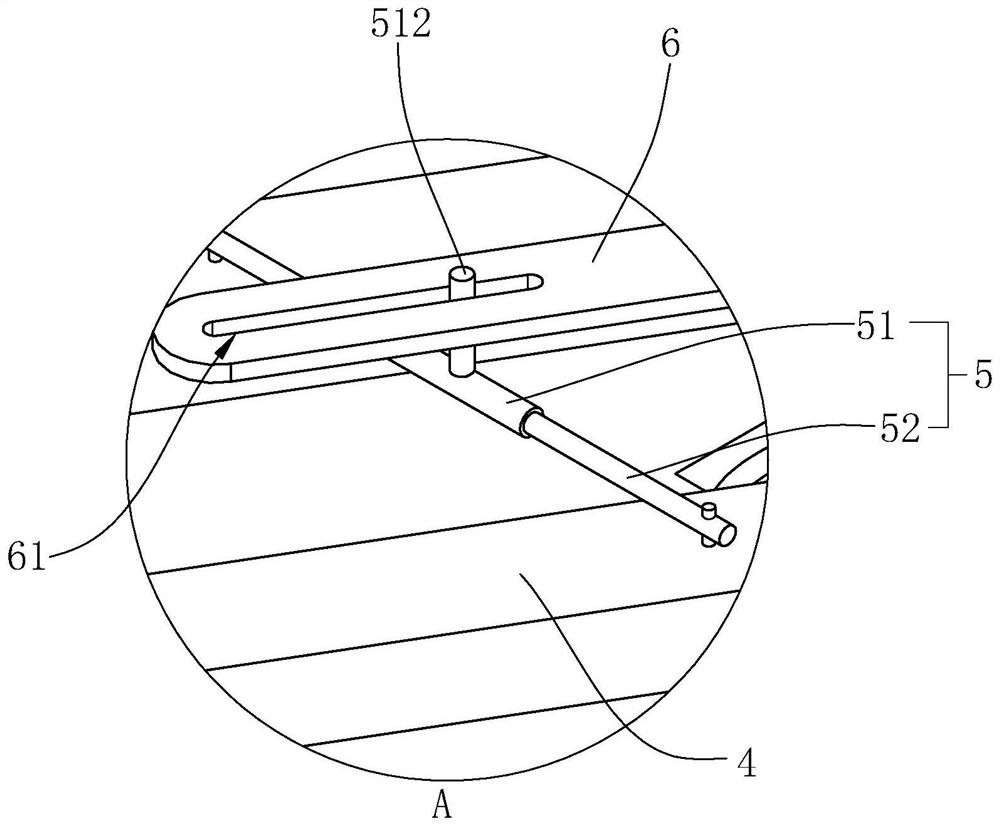

[0038] Such as figure 1 As shown, a feeding device for a metal band sawing machine includes a base 1, a pair of driving rollers 2 and a pair of guide rollers 3 are arranged on the base 1, and the axes of the driving roller 2 and the guide rollers 3 are all extended along the vertical direction , and the driving roller 2 and the guide roller 3 both rotate around their axes, wherein the lower ends between the driving rollers 2 move relative or opposite each other in the horizontal direction, and the two guide rollers 3 rotate around the axis of one of the driving rollers 2 respectively and are installed on the base 1 , and the distance between the axes of the guide rollers 3 is always equal to the distance between the axes of the driving rollers 2;

[0039] Insert the bar between the driving roller 2 and the guide roller 3, and then drive the driving roller 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com