Self-adaptive elastic laminating device for carton forming

A lamination device and self-adaptive technology, applied in the field of adaptive elastic lamination device, can solve the problems of easy occurrence of wrinkles, substandard quality, inability to carry out comprehensive wrapping, etc., and achieve the effect of avoiding wrinkles and preventing re-rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

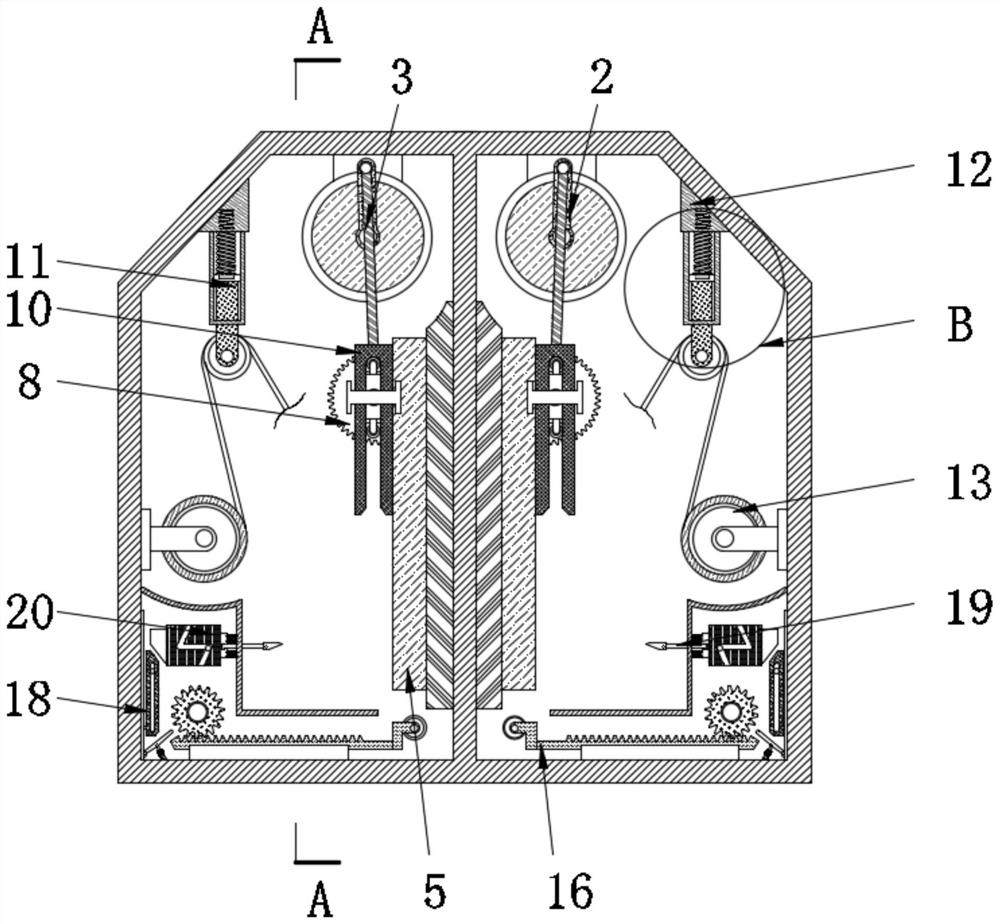

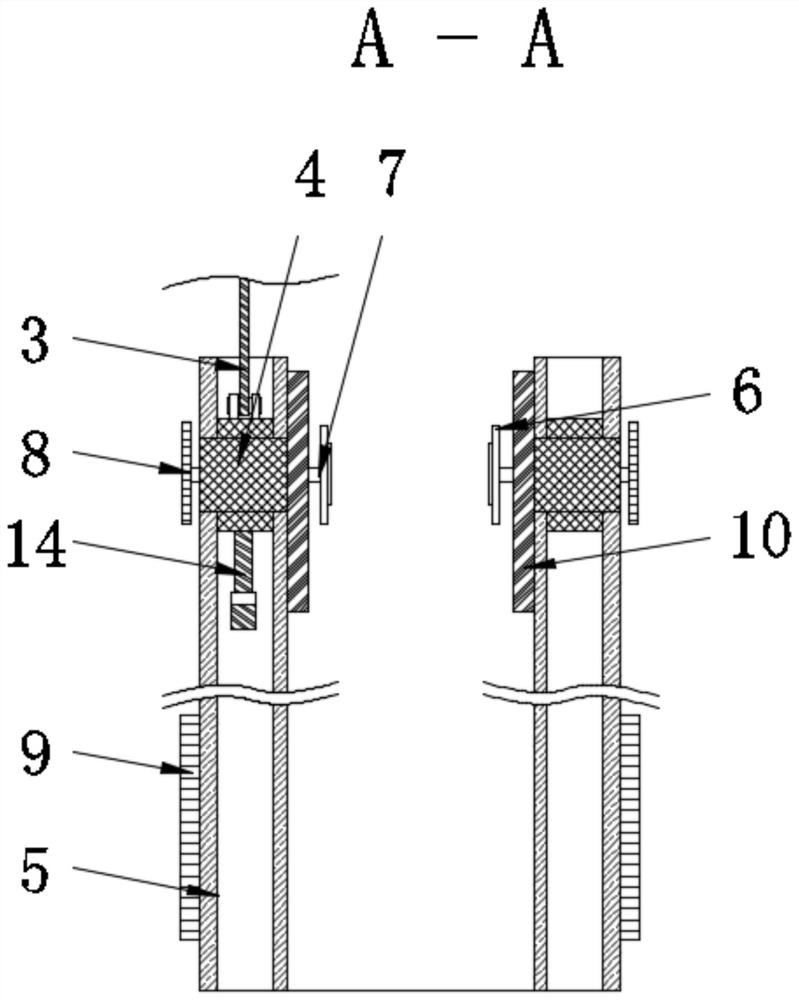

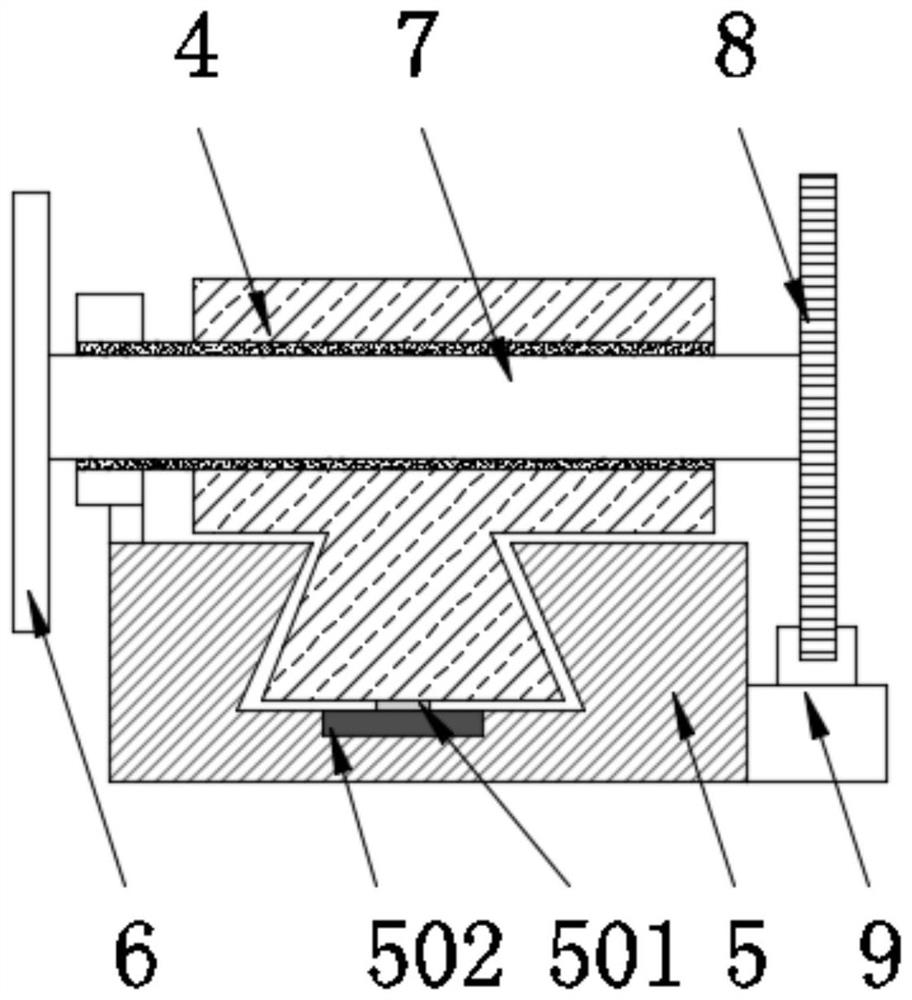

[0022] The invention provides an adaptive elastic coating device for carton forming, as attached figure 1 to attach Figure 5 Shown: including the processing chamber 1, the interior of the processing chamber 1 is installed with the main rod 2, the top of the main rod 2 is fixedly connected to the output end of the motor, the end of the main rod 2 is movably connected with the movable rod 3, and the bottom of the movable rod 3 The movable seat 4 is installed at the end, and the movable seat 4 is slidably installed in the inside of the guide rail 5. The connection between the movable seat 4 and the guide rail 5 is provided with a variable resistor 502, and the surface of the variable resistor 502 is provided with a Corresponding to the metal sheet 501, the inside of the moving seat 4 is rotatably equipped with a connecting rod 7, the front end of the connecting rod 7 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com