Magnetic guide synchronous type sewing machine feeding mechanism and using method thereof

A feeding mechanism and sewing machine technology, applied in the field of sewing machines, can solve the problems of reducing sewing quality, fabric wrinkling, etc., and achieve the effects of reducing contact area, reducing resistance, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

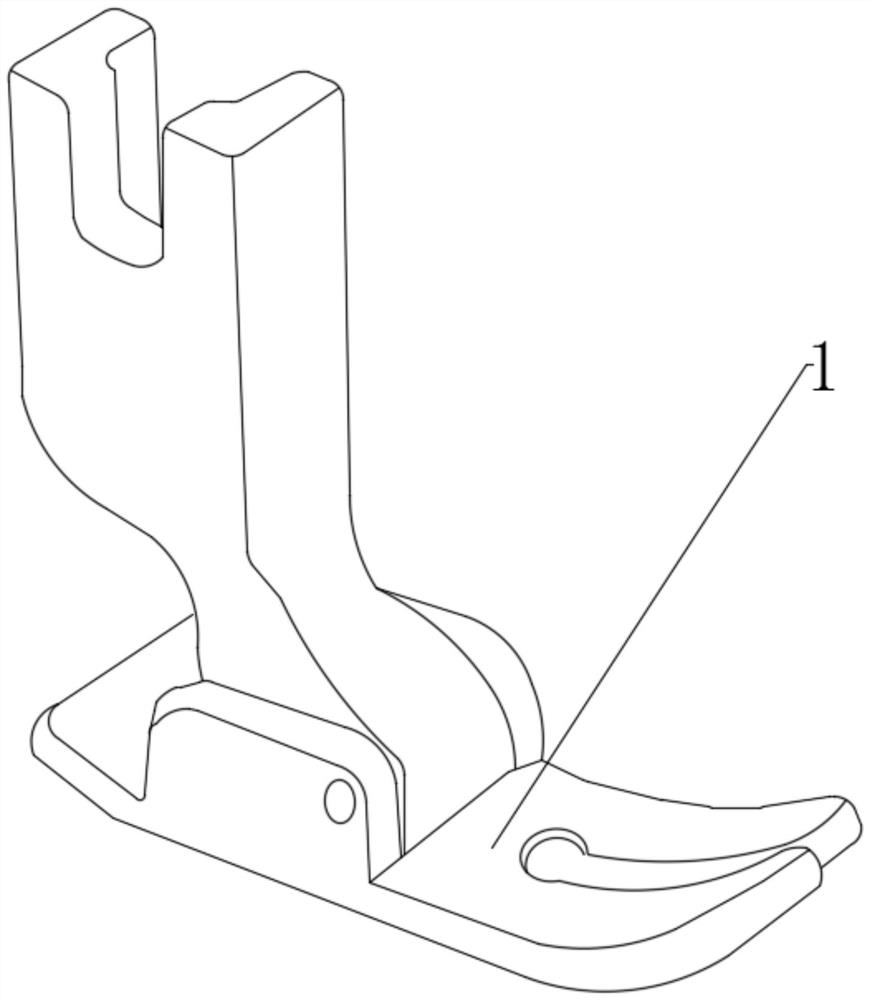

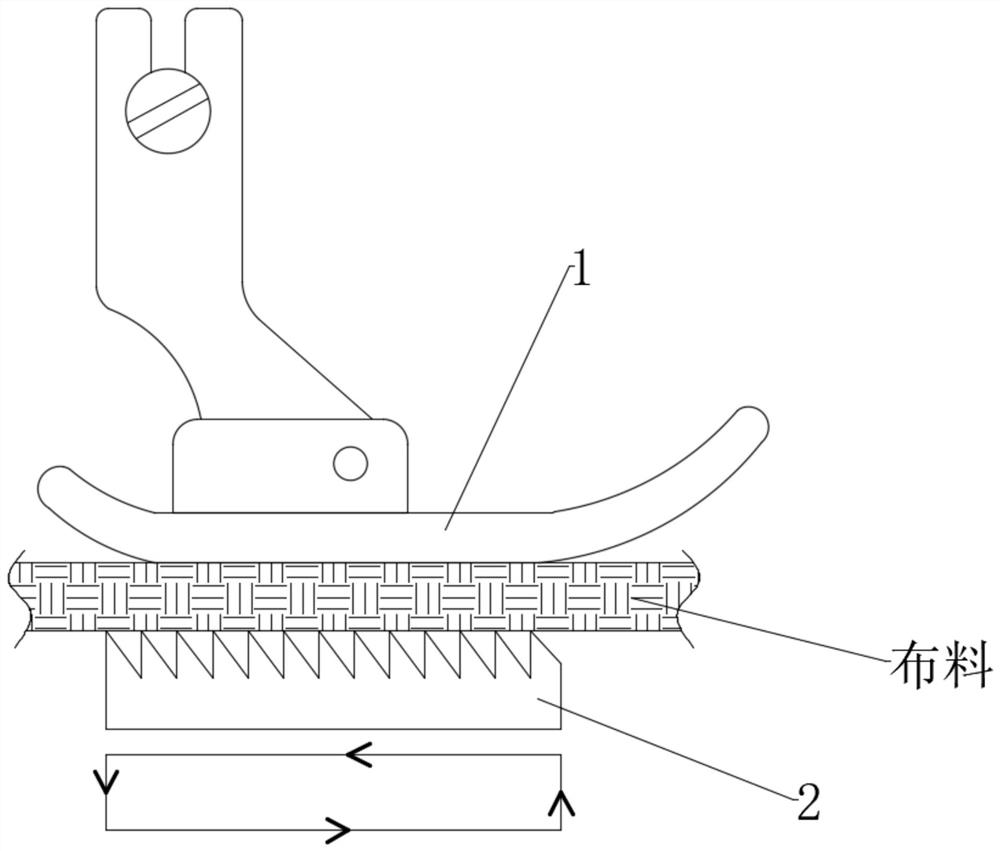

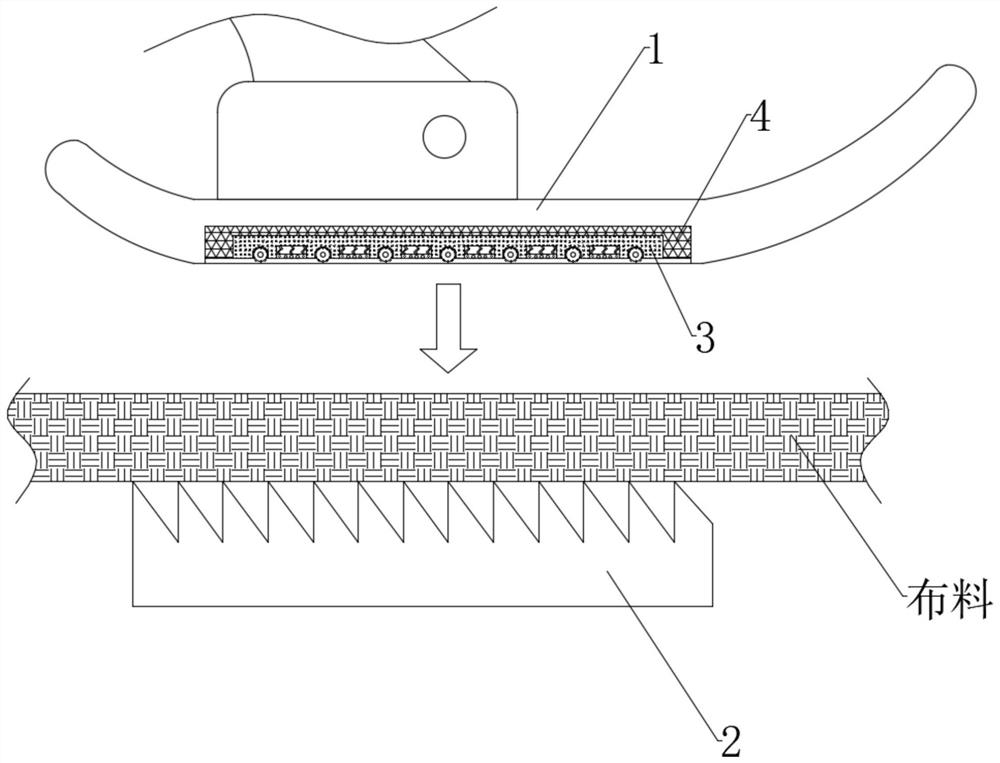

[0048] see Figure 1-9 , a magnetic synchronous sewing machine feeding mechanism, please refer to Figure 1-2 , including matching presser foot body 1 and feed dog 2, which is magnetic, see Figure 9 , the feed dog 2 is composed of a plurality of non-magnets 201 and permanent magnets 202, a plurality of non-magnets 201 and permanent magnets 202 are arranged alternately, and the widths of each non-magnet 201 and permanent magnet 202 are equal, in order to allow the feeding dog 2 When moving forward, it can drive the roller feeding cylinder 5 to roll on the cloth, so the magnetism of the cloth feeding dog 2 must be discontinuous, otherwise the continuous magnetic force will keep the roller feeding cylinder 5 still;

[0049] see image 3 , the side wall of the lower end of the presser body 1 is provided with an installation groove, and a pressure plate 3 matching the cloth feed dog 2 is arranged in the installation groove. The pressure plate 3 is made of hard magnetic material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com