Packing bag heat seal mechanism and rubber plug/aluminum cover discharge device based on same

A technology of discharging device and packaging bag, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problem that the translation of both ends of the second connector is out of synchronization, affecting the appearance of cleanliness and aesthetics, and the thermal sealing of packaging bags. Equal problems, to achieve the effect of improving cleanliness and aesthetics, optimizing circuit layout, and improving heat sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

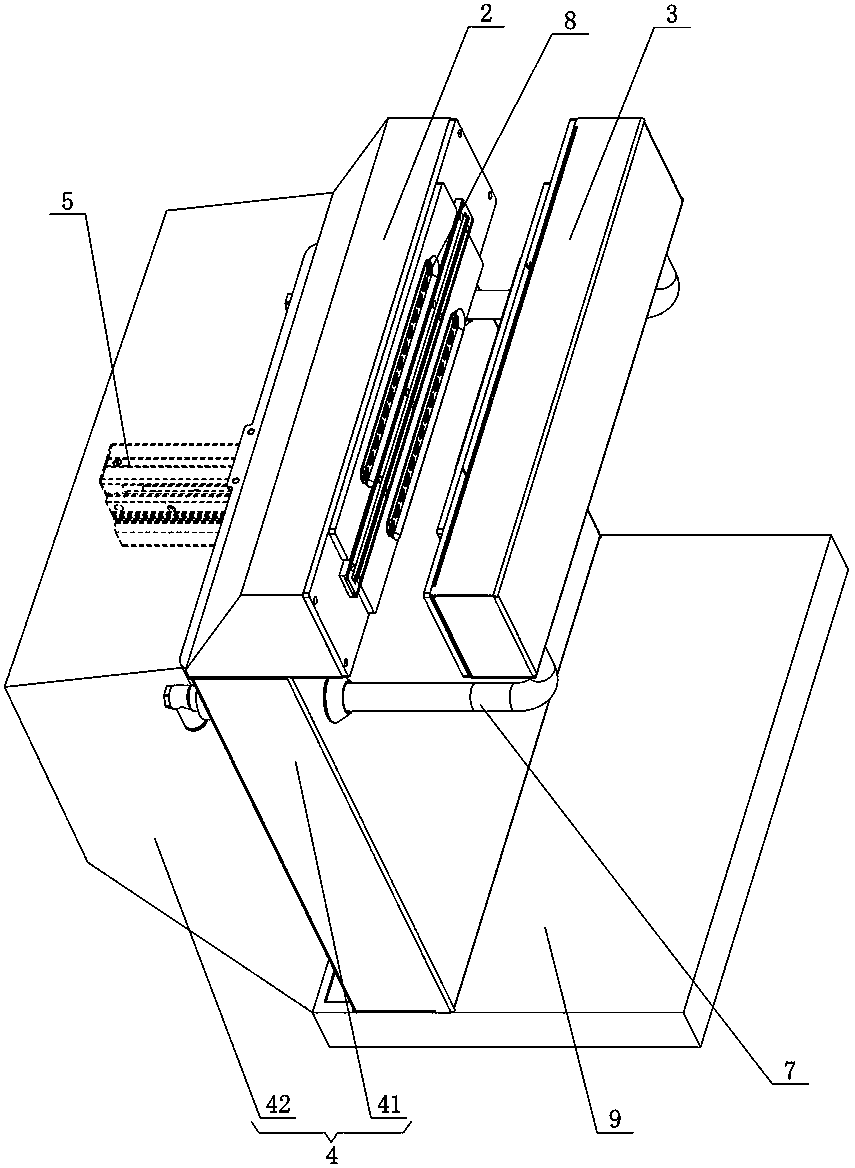

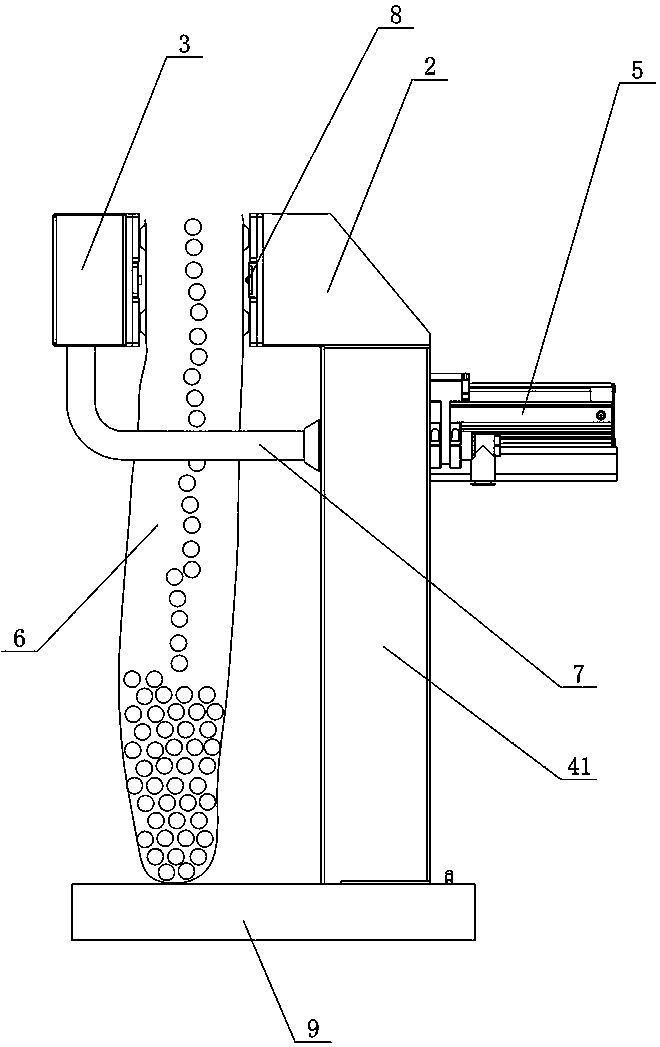

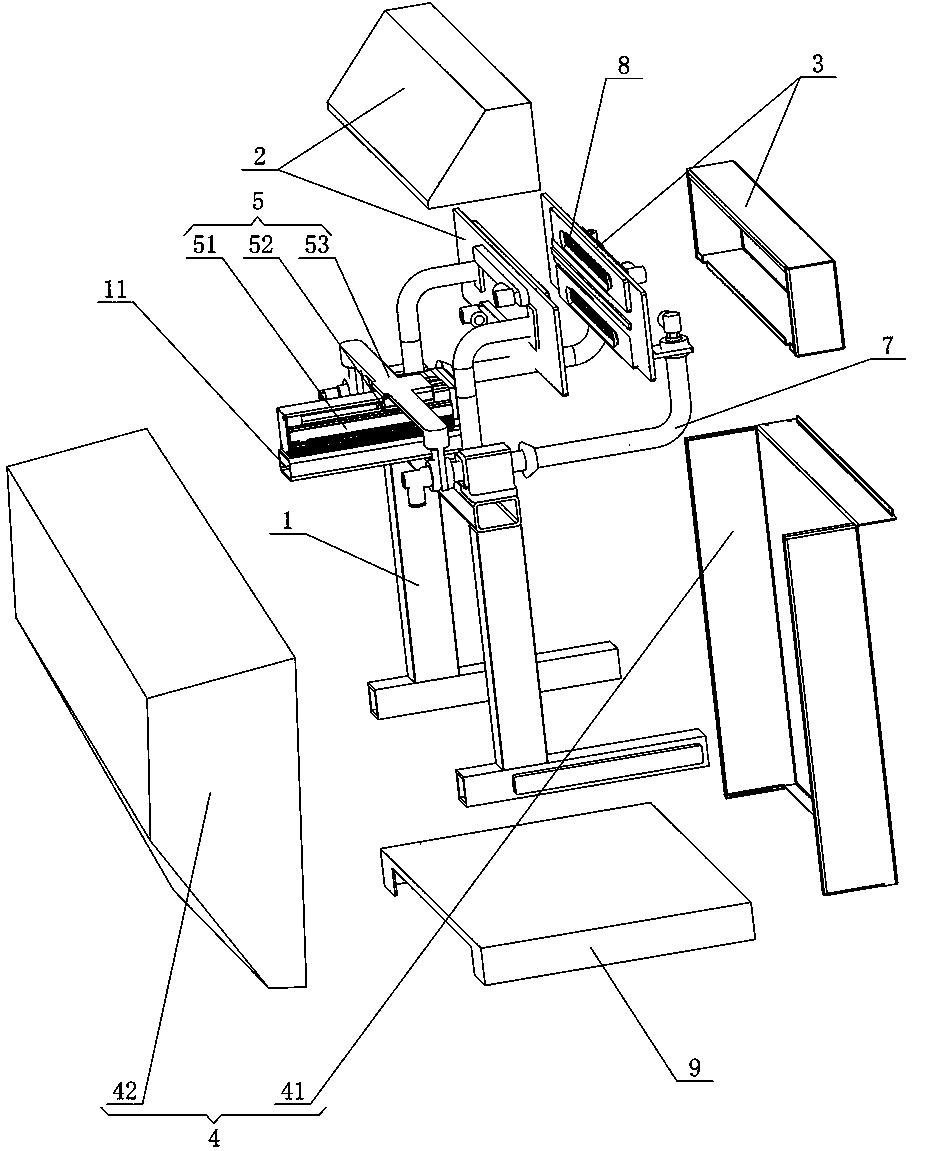

[0025] Figure 1 to Figure 3 Shown is an embodiment of the heat sealing mechanism of the packaging bag, the heat sealing mechanism includes a bracket 1, a first heat sealing plate 2 and a second heat sealing plate 3, the first heat sealing plate 2 is installed on the bracket 1, and a bracket is installed on the periphery of the bracket 1 Cover 4, the bracket cover 4 is provided with a drive assembly 5 installed on the bracket 1, the drive assembly 5 is connected with at least one through the bracket cover 4 body wall and connected with the second heat sealing plate 3, and drives the second heat The guide rod 7 that the plywood 3 moves relative to the first heat seal plate 2, through the present invention, the drive assembly 5 is arranged in the bracket cover body 4, and the guide rod 7 passes through the body wall of the support cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com