Driving face temporary support equipment and working method thereof

A technology for excavation work and equipment, applied in the direction of temporary shield, mining equipment, shaft equipment, etc., can solve the problems of long time, large labor demand, cumbersome process, etc., and achieve the effect of improving productivity, reducing labor, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

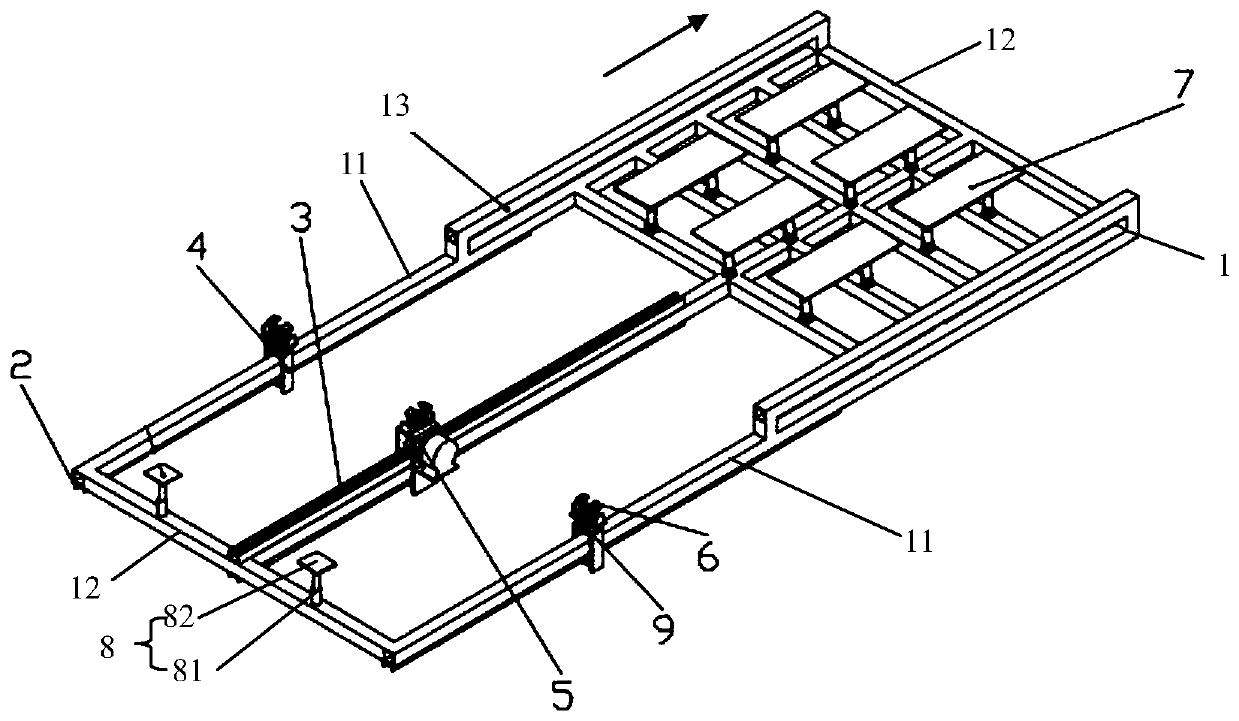

[0044] A kind of temporary support equipment for excavation work, such as Figure 1-6 As shown, it includes a front beam frame 1, which includes three square steel pipes 11 along the roadway direction and a connecting rod 12 for connecting the three square steel pipes 11 and perpendicular to the roadway direction. The front end of the front probe beam frame 1 is provided with at least Four sets of connecting rods, and one set of connecting rods at the rear end;

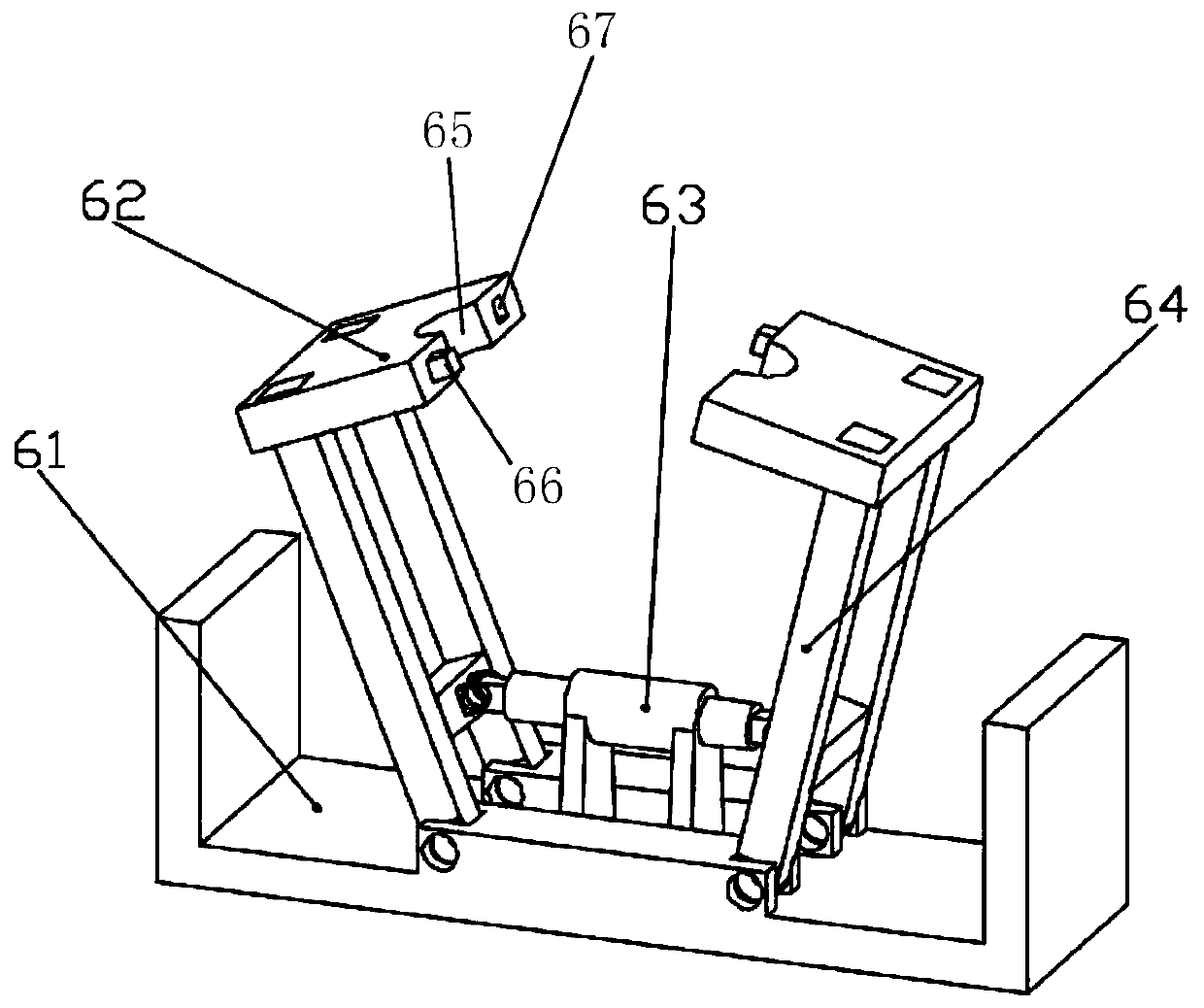

[0045] Three square steel pipes 11 are evenly arranged along the roadway width, the middle square steel pipe is provided with a drive mechanism 5, the square steel pipes 11 on both sides are provided with a guide mechanism 4, and the upper part of the drive mechanism 5 is fixedly provided with a clamping device 6 and a guide mechanism 4 The upper part is also equipped with a clamping mechanism 6 through the landing gear 9, and the clamping mechanism 6 is used to clamp the existing anchor rod in the roadway;

[0046] ...

Embodiment 2

[0048] A kind of excavation work face temporary support equipment, its structure is as shown in embodiment 1, the difference is, as shown in Figure 5, the quantity of lifting platform 7 is 6, and lifting platform 7 comprises two lifting hydraulic cylinders 71 and The lifting top plate 72 located on the upper part of the two lifting hydraulic cylinders 71 and the lifting hydraulic cylinder 71 of the lifting platform can keep synchronous elongation, and the elongation can also be adjusted according to the complex situation of the roadway. The bottom of the lifting hydraulic cylinder 71 is fixed on the connecting rod 12 , the top of the extension rod of the lifting hydraulic cylinder 71 is connected with the lifting roof 72 through a multi-degree-of-freedom connector 73 to ensure that the lifting roof 72 is self-adjusting to adapt to the complex shape of the roadway top. The multi-degree-of-freedom connector 73 here is a connector composed of a pair of ordinary hinges with a relat...

Embodiment 3

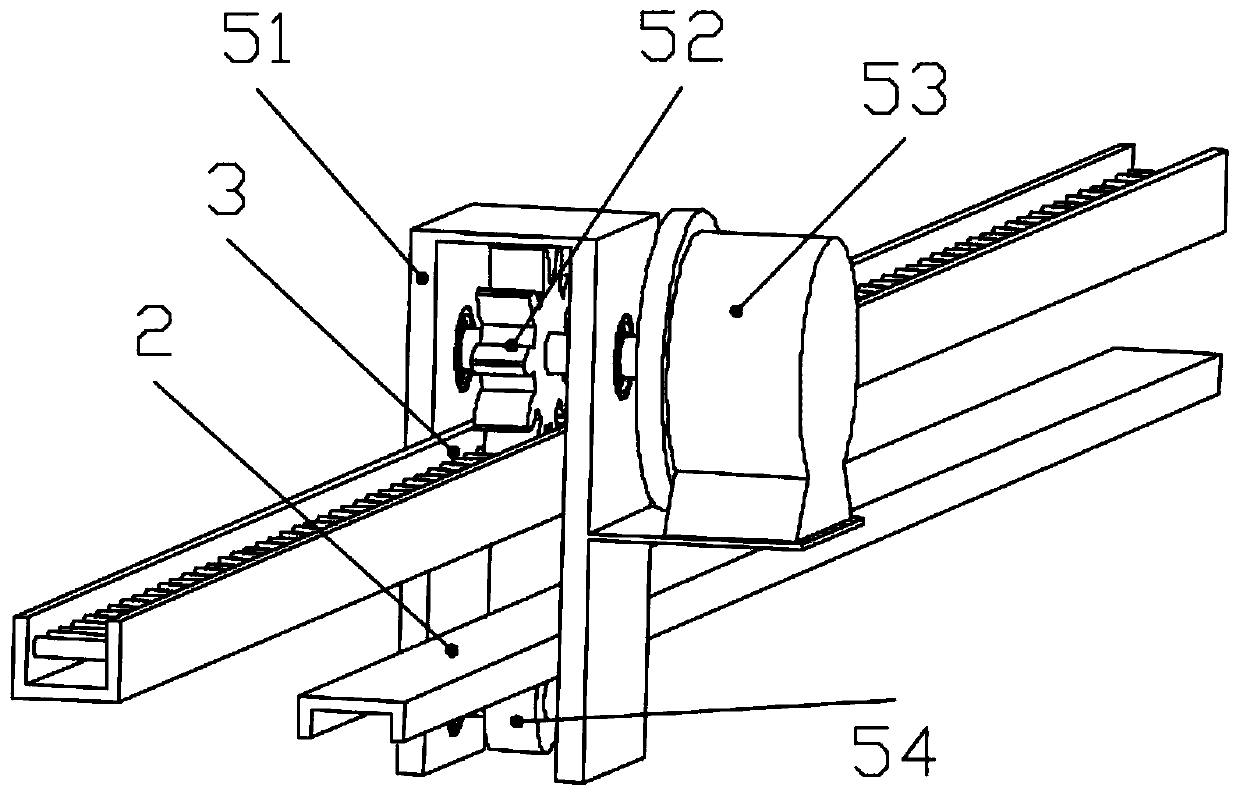

[0052] A kind of temporary support equipment for excavation work, its structure is as shown in embodiment 2, the difference is, as figure 1 , 2 As shown, the bottoms of the three square steel pipes without connecting rods are fixedly provided with an inverted U-shaped guide rail 2, as the walking track of the guide mechanism 4 and the drive mechanism 5, and a pin rail 3 is fixedly installed above the square steel pipe in the middle position. Used to cooperate with the drive gear 52 inside the drive mechanism;

[0053] Such as figure 2 As shown, the drive mechanism 5 includes a drive box body 51, a drive gear 52 cooperating with the pin track 3 is installed on the top of the drive box body 51, a motor 53 is arranged on the outside of the drive box body 51, and the output shaft of the motor 53 is connected to the drive gear 52. connected to drive the drive gear 52 to rotate, thereby realizing the relative movement between the pin rail 3 and the drive gear 52;

[0054] The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com