The installation method and support system of synchronous side expansion in fully mechanized mining face

A fully mechanized mining face and installation method technology, which is applied to mining equipment, earthwork drilling, mine roof support, etc., can solve the problems of unminable coal seams and waste of resources, so as to avoid empty top operations, save resources, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

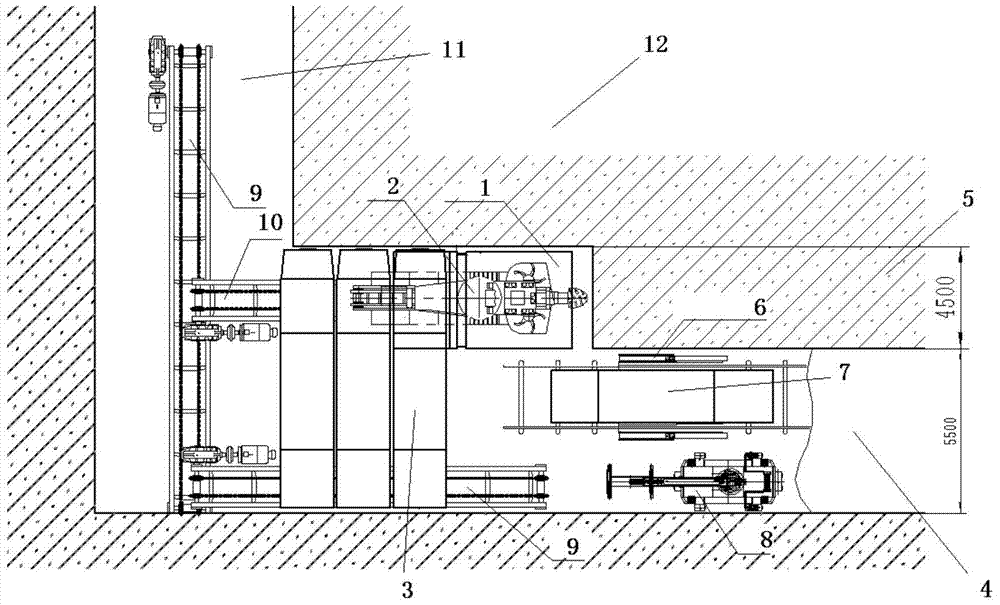

Embodiment 1

[0047] Lay 600 or 900-gauge track in Huishun roadway, working face and Yunshun roadway; lay 2-meter-gauge track on the working face.

[0048] In the Yunshun roadway, use a crane to install the tail of the belt conveyor; install the nose of the loader and the bridge of the loader; install the crusher; install the middle slot and tail frame of the loader.

[0049] Install the end bracket at the end of the working surface.

[0050] Use a crane to install the rear scraper nose and transition slot, and install the front scraper nose and transition slot.

[0051] The crane moves to the return air triangle point.

[0052] Use the crane to assemble the lifting truck, and then use the lifting truck to install the middle slot of the rear scraper machine. After the installation is completed, withdraw the lifting truck.

[0053] Use a crane to install the four-corner road; hoist the hydraulic support to install the forklift, expand the hydraulic support to install the forklift, and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com