Fragile coal seam rapid excavation and anchor protection matching device

A technology of breakable coal seams, applied in cutting machinery, earthwork drilling, cutting machinery, etc., can solve problems such as easy broken roof coal seams, easy broken roof rock layers, and difficult support, achieving a simple and reasonable technical structure, The effect of ensuring safe production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

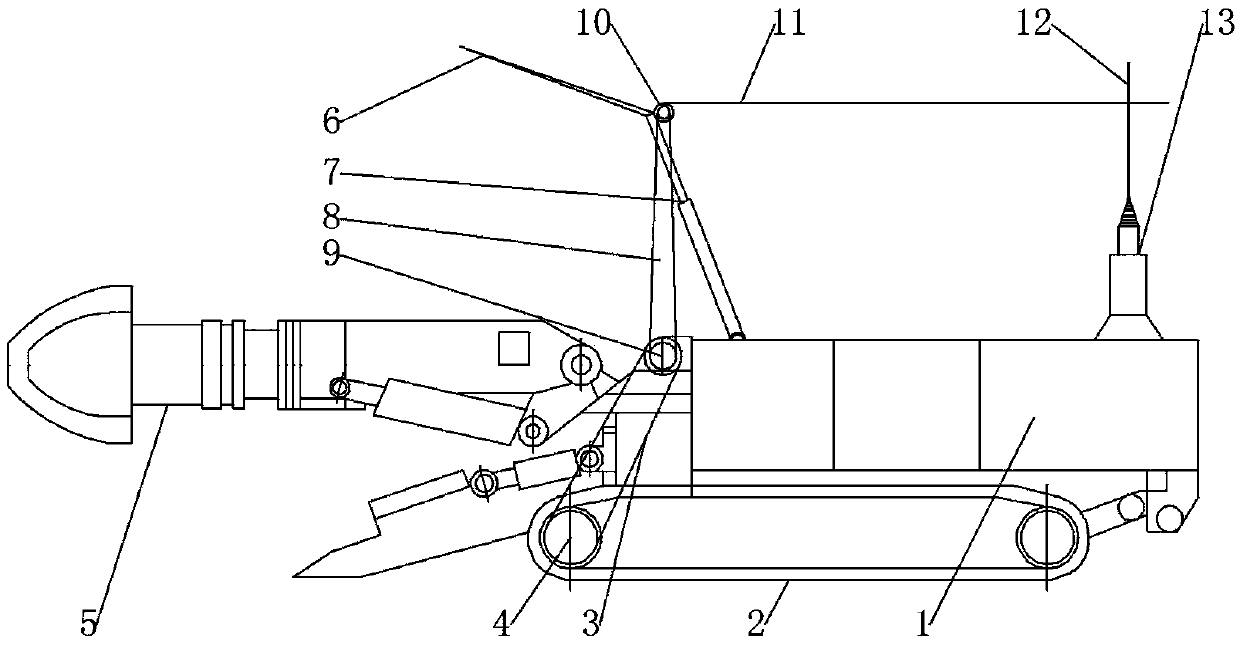

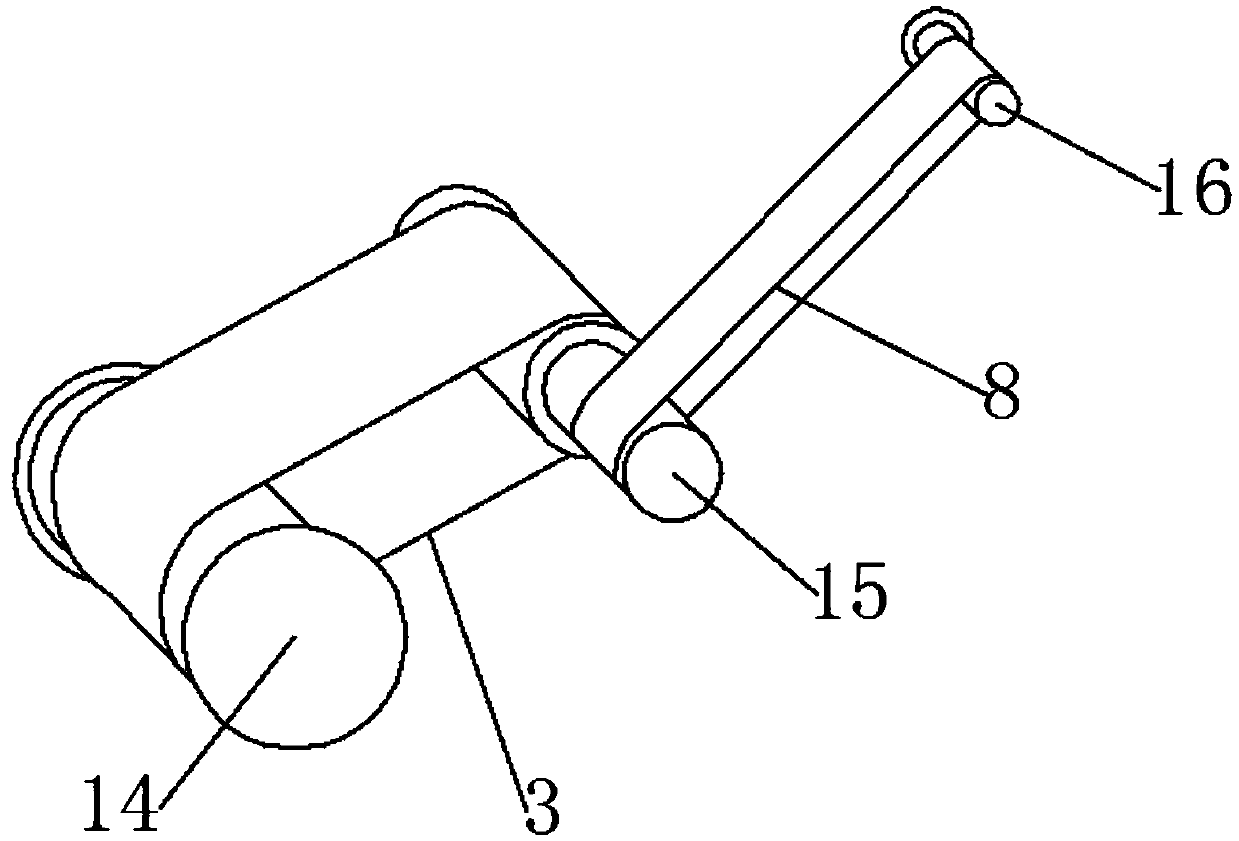

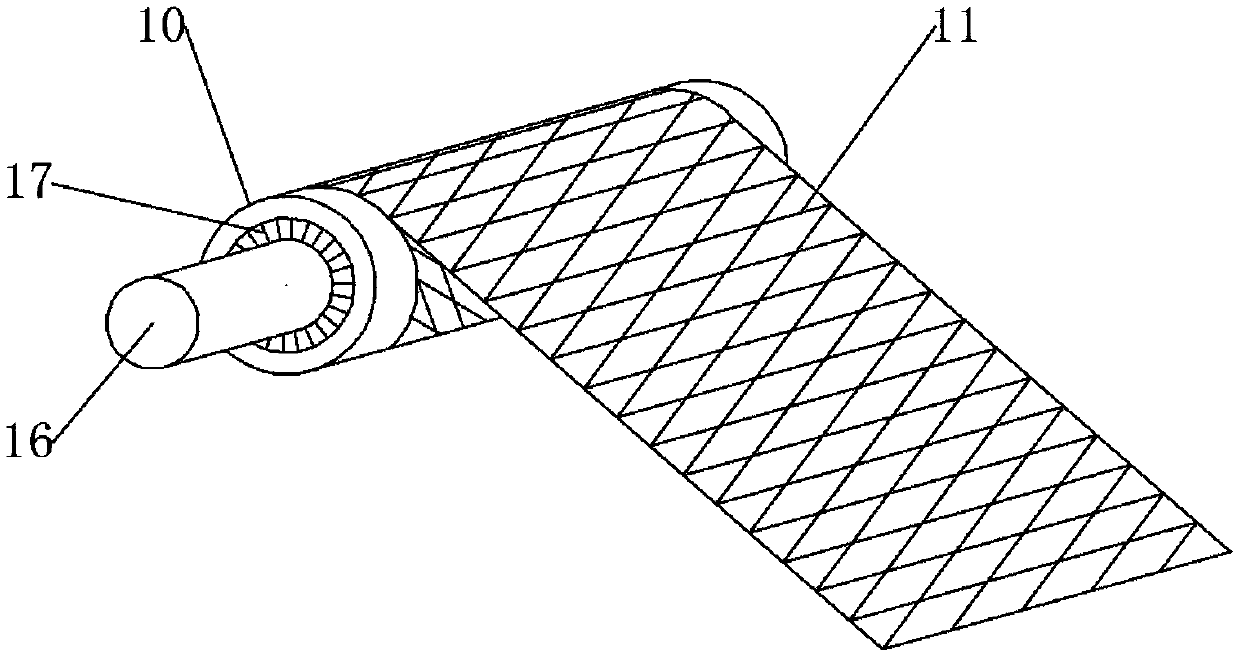

[0015] The present invention will be further described below in conjunction with accompanying drawing: as figure 1 As shown, a supporting device for rapid excavation and anchor protection of fragile coal seams, the device is mainly composed of fuselage (1), cutting device (5), hydraulic device (7), cover beam (6), etc., such as figure 2 As shown, the transmission shaft I (14) is added outside the crawler guide tensioning device (4) at the lower part of the roadheader, and the belt guide tensioning device (9) is installed on the fuselage (1), and the hydraulic device (7) and The roller (10) that can install barbed wire (11) is set at the junction of shield beam (6), as image 3 As shown, the drum (10) is installed on the transmission shaft III (16), and the transmission shaft I (14) is connected to one side of the transmission shaft II (15) on the belt guide tensioning device (9) through the belt I (3) , the other side of the transmission shaft II (15) is connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com