A support device applied to coal mine mining face and driving face operation

A technology for supporting devices and mining faces, which is applied to mine roof brackets, roof beams supporting mine roofs, mining equipment, etc., can solve problems such as long time, low efficiency, and affecting the start-up efficiency of fully mechanized excavators, so as to improve efficiency , Improve safety performance, shorten auxiliary working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1:

[0038] This embodiment provides a support device applied to coal mine mining face and driving face operations. In this embodiment, the support device includes n support mechanisms, where n is an integer ≥ 1, and the n support mechanisms distribute The shaft is connected as a whole

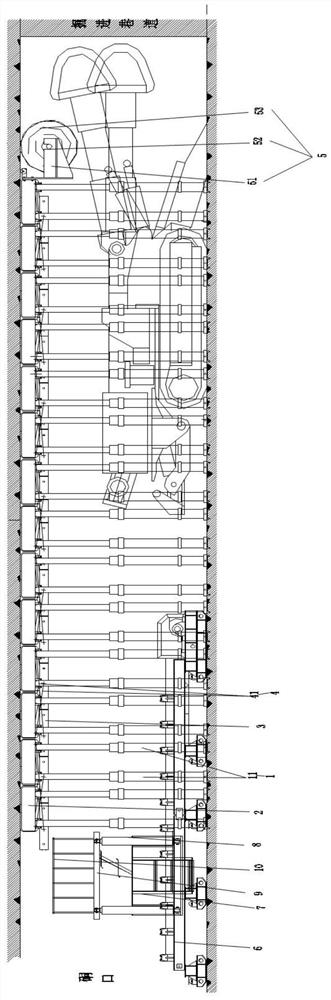

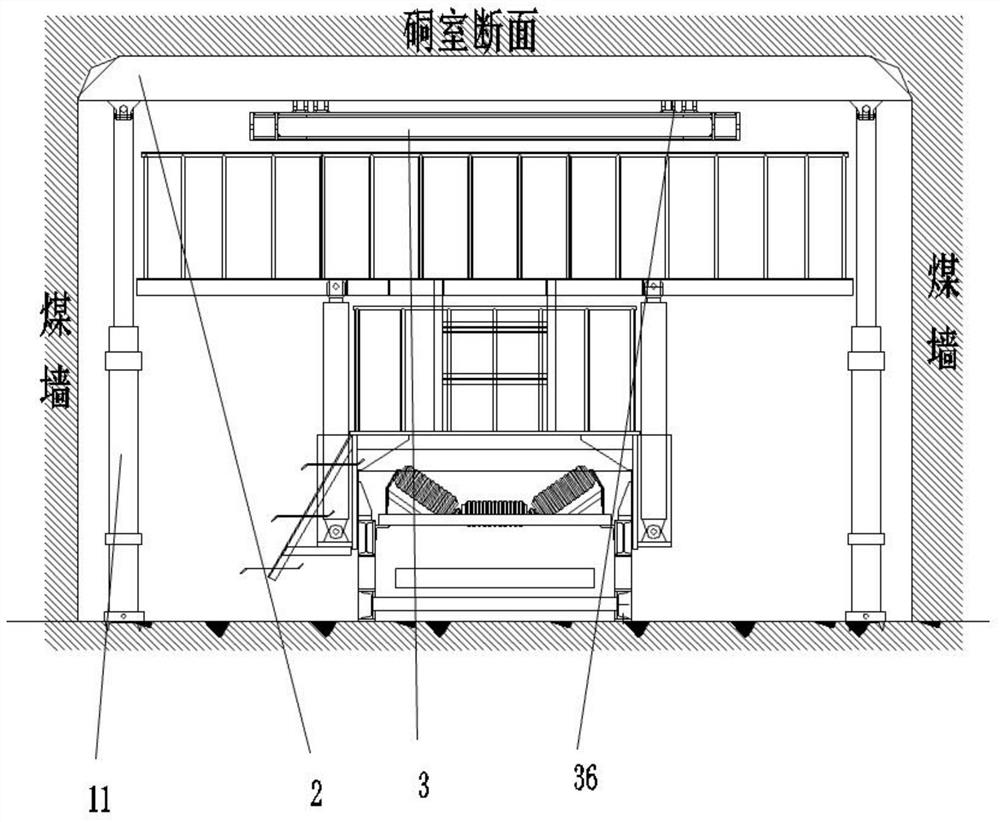

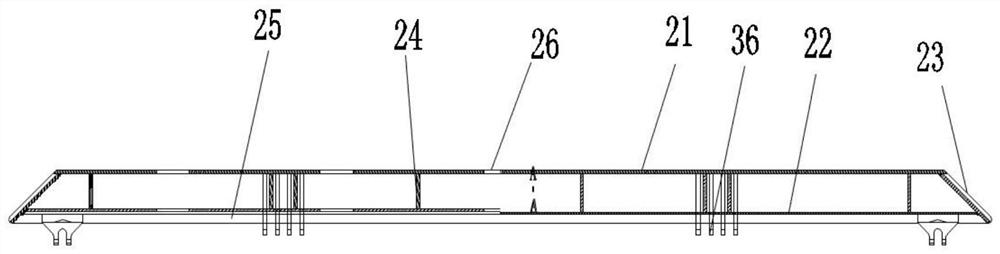

[0039] Please refer to figure 1 and figure 2 as shown, figure 1 is a side view of the support device, figure 2Front view of the support device. Each support mechanism includes a support structure, and the support structure is arranged along the depth direction of the excavation working face. The support structure includes two sets of hydraulic prop assemblies 1, and each set of hydraulic prop assemblies 1 is arranged close to the coal wall wall of the coal mine and along the depth direction of the driving face. Two top beam structures 2 are arranged on the top of the supporting structure, and a tow beam structure 3 is arranged under each top beam structure 2 , and the to...

Embodiment 2

[0044] This embodiment provides a support device applied to coal mining face and excavation face operation. The support device of this embodiment is further improved on the basis of the support device of embodiment 1. In this embodiment, the supporting device includes n supporting mechanisms, where n is an integer ≥ 1, and the n supporting mechanisms are connected as a whole through pin shafts.

[0045] Please refer to figure 1 and figure 2 as shown, figure 1 is a side view of the support device, figure 2 is the front view of the support device, each support mechanism includes a support structure, and the support structure is arranged along the depth direction of the excavation working face. The support structure includes two sets of hydraulic prop assemblies 1, and each set of hydraulic prop assemblies 1 is arranged close to the coal wall wall of the coal mine and along the depth direction of the driving face. Two top beam structures 2 are arranged on the top of the sup...

Embodiment 3

[0052] As a further improvement to the support device in Embodiment 1 and Embodiment 2, in order to facilitate the fixing of the mining face and the roof of the excavation face, such as figure 1 As shown, the front end of the top beam structure 2 of the nth support mechanism is provided with an anchor net structure 5, including an anchor net support 51, and the front end of the anchor net support 51 is fixed with an anchor net shaft 52, and the anchor net 53 is wound around the anchor net shaft 52 superior. During operation, by utilizing the belt conveyor 6 tail guide rails to make the sliding frame 7, with the lifting column 8 attached, the supporting ladder, the working platform 9, and the guardrail 10, the anchor cable and the anchor cable plate are anchored in a safe state, thereby To achieve the fixation of the mining face and the roof of the excavation face.

[0053] As a further improvement to the hydraulic strut assembly 1, each set of hydraulic strut assemblies 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com