Power transmission tower stay wire rust removal robot

A technology of transmission poles and robots, which is applied in the direction of manipulators, welding equipment, laser welding equipment, etc., can solve the problems of low rust removal efficiency, inability to remove rust and paint in all directions, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

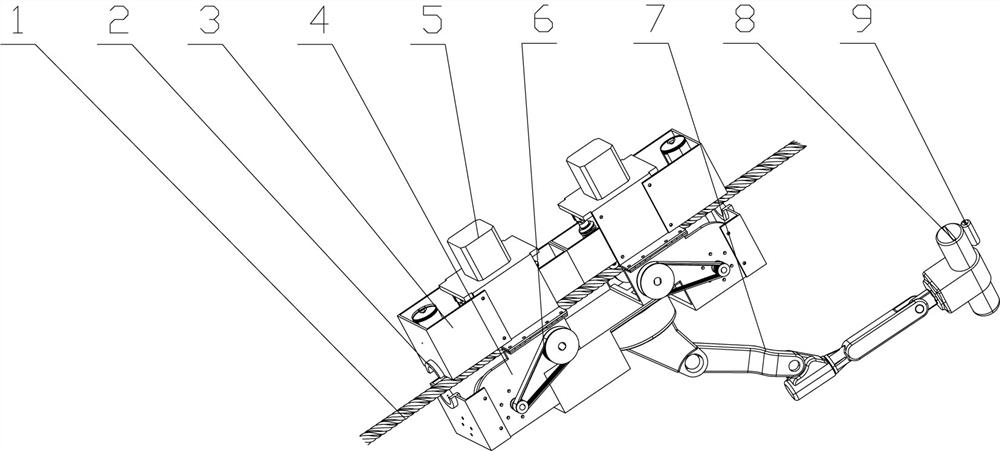

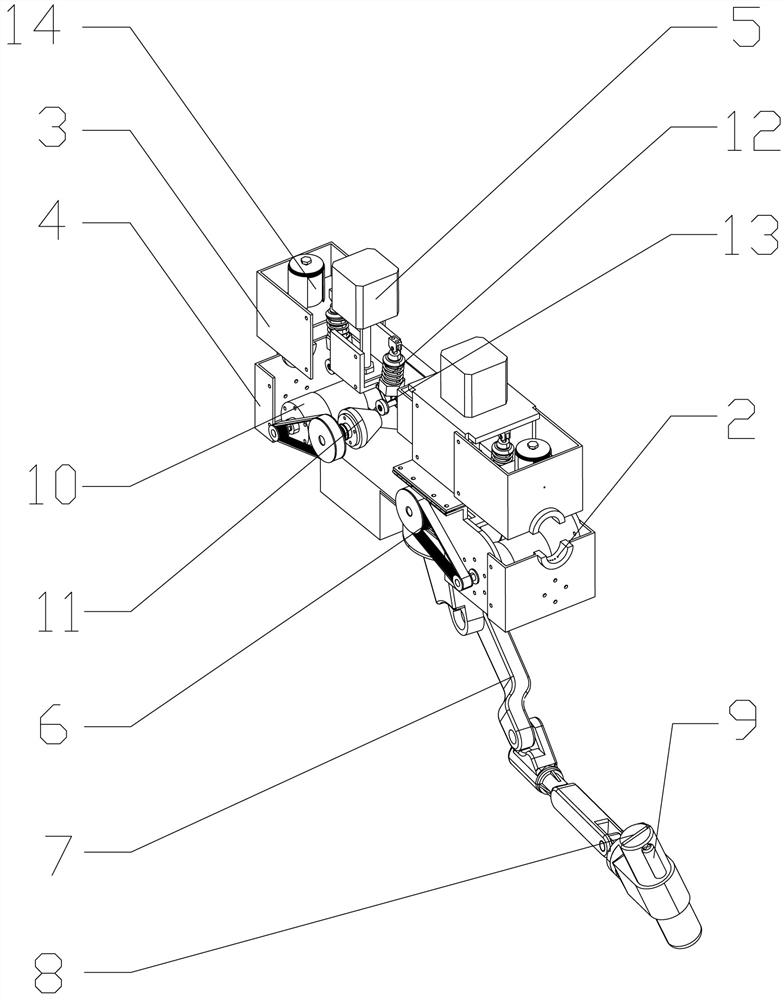

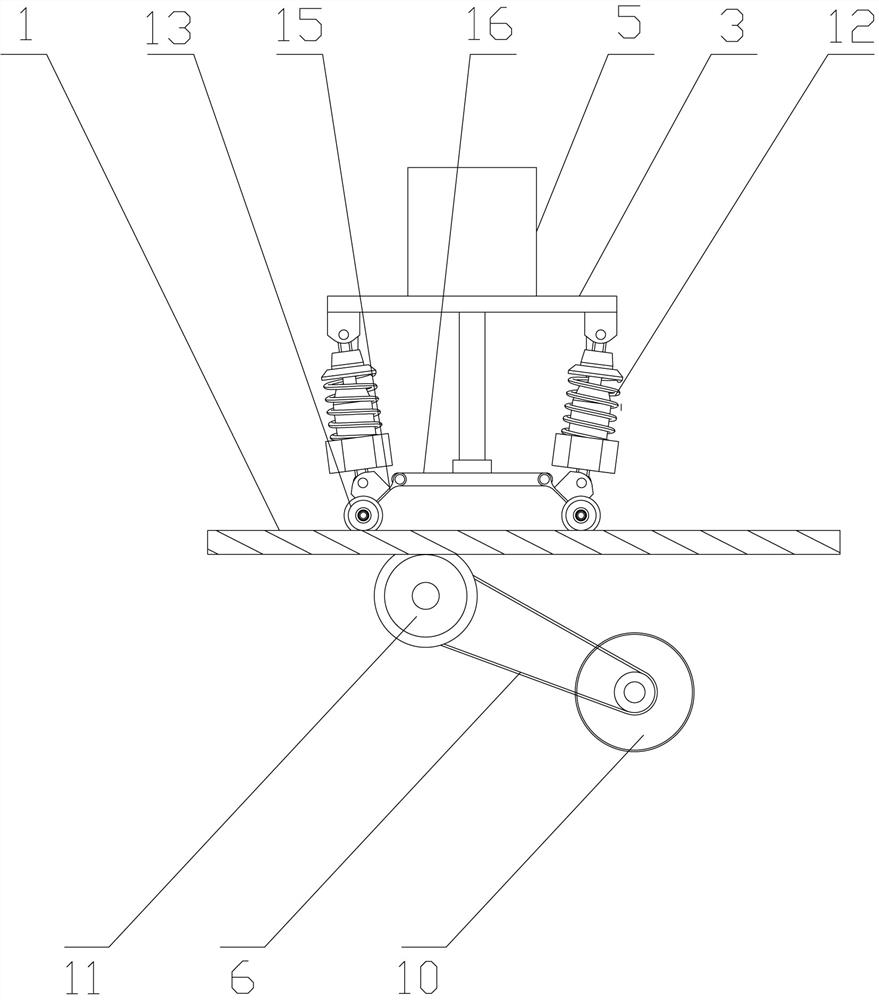

[0026] Such as Figures 1 to 6 As shown, a transmission pole pull wire derusting robot includes an upper casing 3 and a lower casing 4 that are detachably connected, and a plurality of clamping mechanisms are installed in the upper casing 3, and multiple clamping mechanisms are installed in the lower casing 4. a driving device and install a derusting device;

[0027] The clamping mechanism includes an electric cylinder 5 installed on the upper casing 3, the piston rod of the electric cylinder 5 is fixedly connected with the load cell 16 arranged in the upper casing 3, and the two ends of the load cell 16 are connected to the The first sheave 13 is hinged, and each top plate 15 is hinged with the upper casing 3 through the shock absorber 12;

[0028] The driving device includes a reduction motor 10 installed in the lower casing 4 and a second sheave 11 installed in the lower casing 4, the reduction motor 10 is connected to the second sheave 11 through a synchronous belt transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com