Anti-cracking method for butt joint of prefabricated immersed tube concrete members

A technology of concrete and new concrete, which is applied in the direction of caisson, heating element shape, and basic structure engineering, etc., can solve problems such as cracking of new concrete components, achieve the effects of increasing contact area, high thermal efficiency, and improving heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

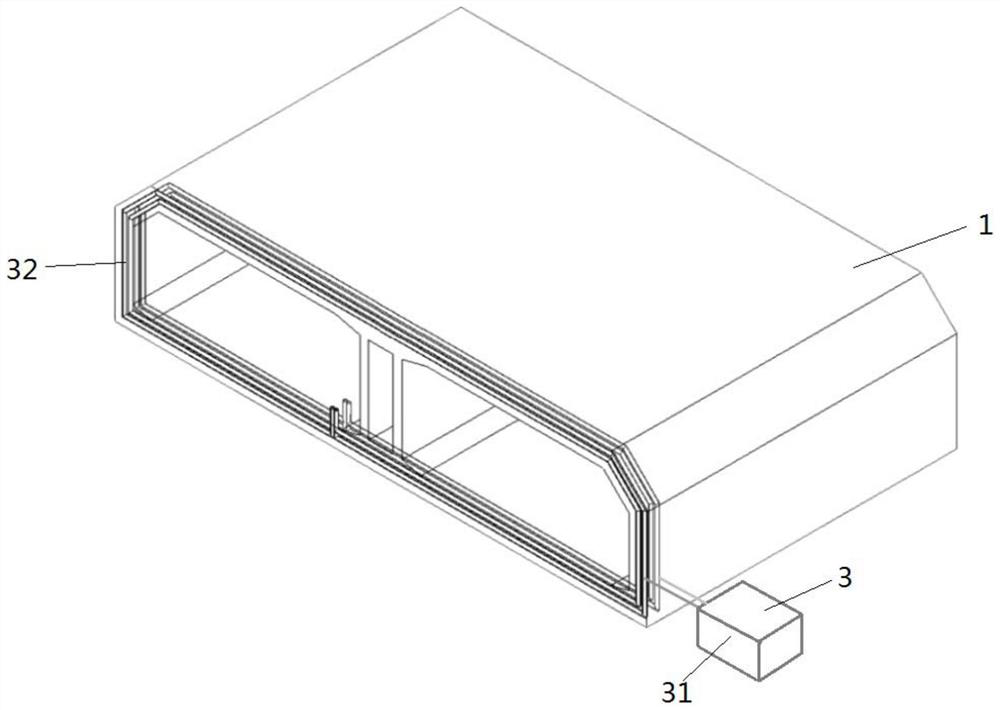

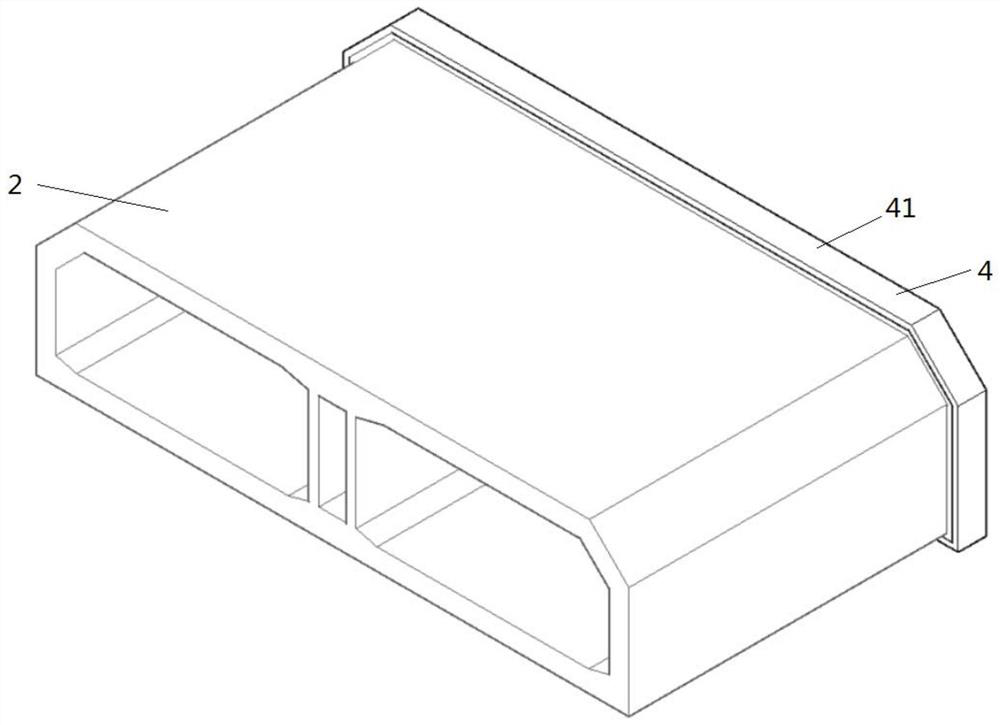

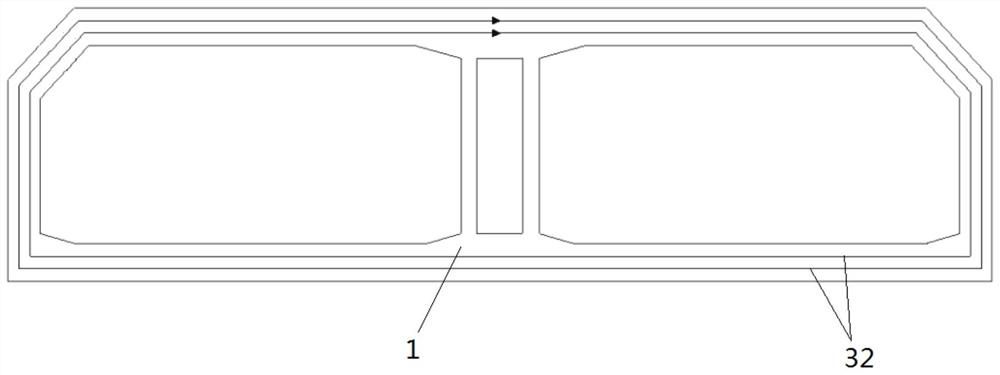

[0081] Such as Figure 1-Figure 4 As shown, there is also provided a crack-proof structure for the butt joint of prefabricated immersed tube concrete components, including a heating mechanism 3 for heating the old concrete component 1; the heating mechanism 3 includes interconnected adjustable temperature heaters 31 and a heating wire 32; the heating wire 32 is pre-embedded in the side wall of the old concrete member 1 for docking with the new concrete member 2, and the temperature-adjustable heater 31 is used to control the switch and output temperature of the heating wire 32 .

[0082] Through the above scheme, the present invention at least obtains the following technical effects:

[0083] The heating mechanism 3 heats the end of the old concrete component 1 to be connected with the new concrete component 2, so that the temperature of the end of the old concrete component 1 is raised to the peak value of the pouring temperature of the new concrete component 2, or higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com