A coated aluminum alloy formwork

A technology of aluminum alloy formwork and formwork, which is applied in card reinforcement boards, provision of connectors and printed circuit boards, cooling/ventilation/heating transformation, etc., and can solve multi-space, occupation of electronic components, and easily damaged electronic components, etc. problem, to achieve the effect of preventing short circuit, preventing separation or damage, not easy to shift or entangle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

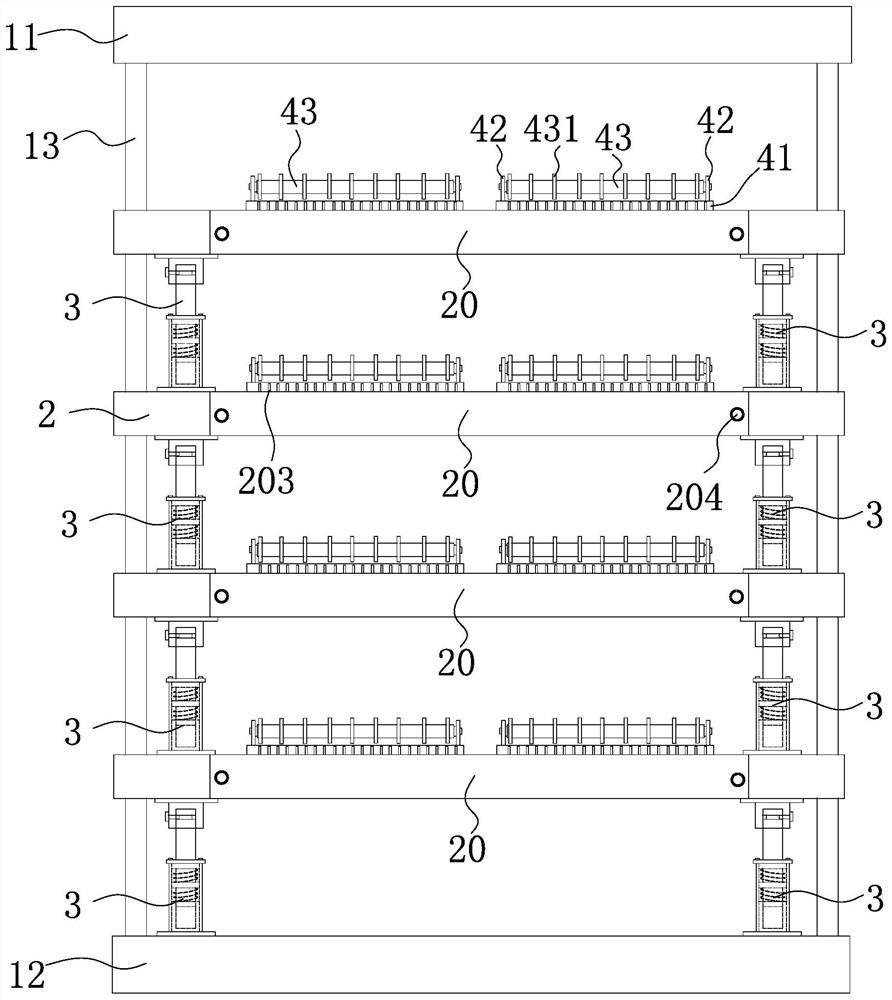

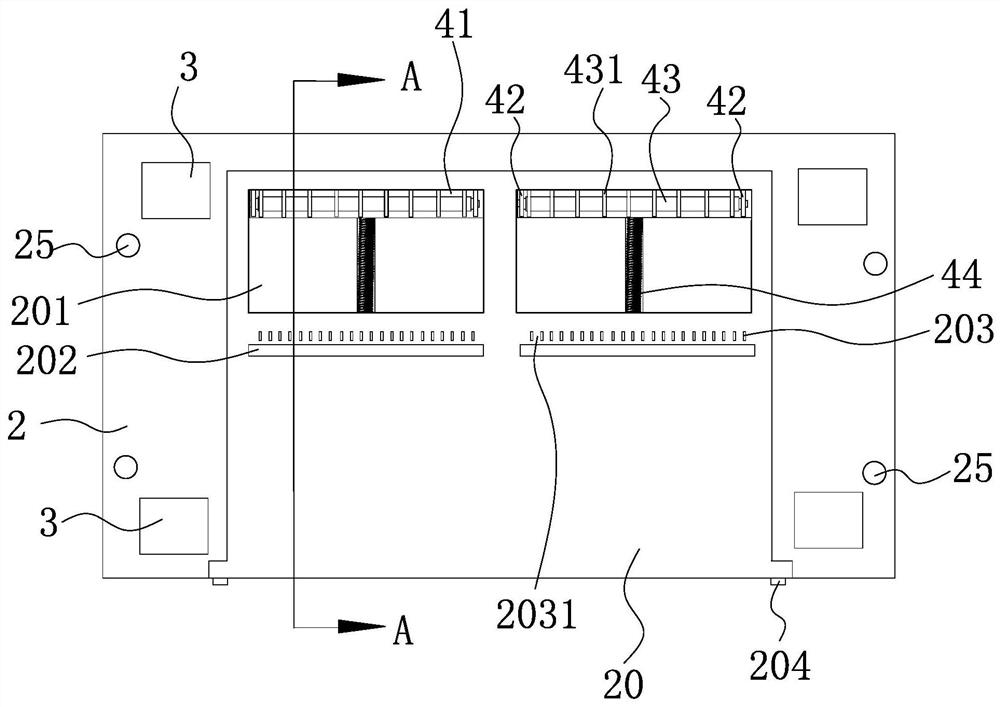

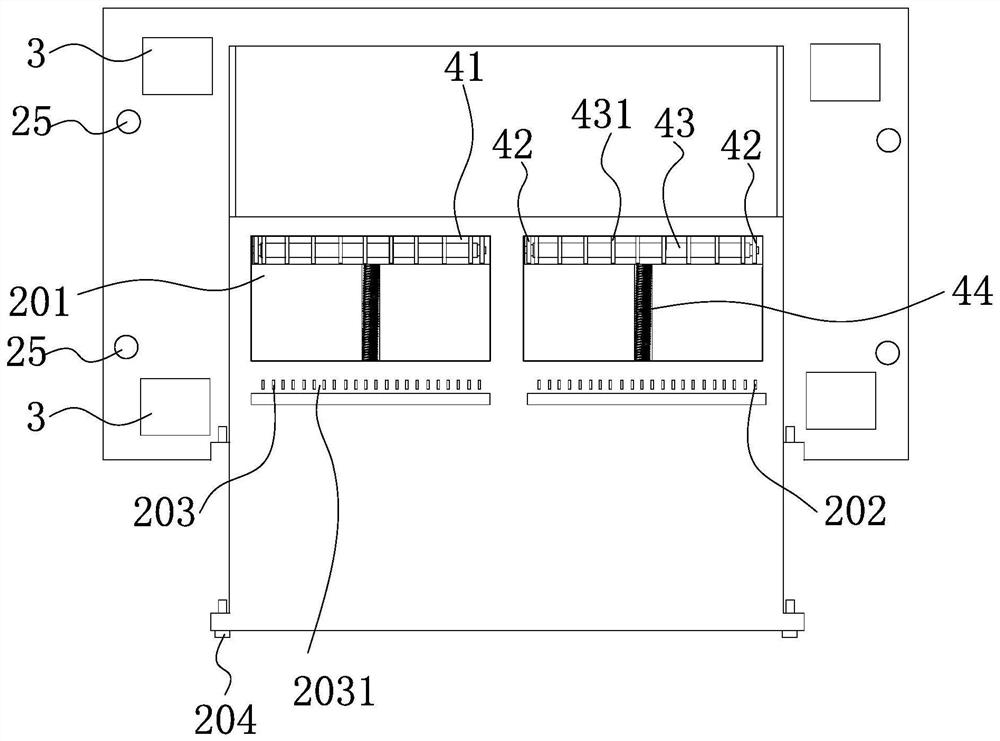

[0026] refer to Figure 1 to Figure 8, the present embodiment provides a coated aluminum alloy formwork, including an upper plate 11, a lower plate 12, four guide rods 13 connected between the upper plate 11 and the lower plate 12, and four guide rods that can be lifted horizontally along the guide rods 13. Template 2, the number of guide rods 13 is four, respectively located at the four corners of the upper plate 11 and the lower plate 12, the template 2 is provided with guide holes 25 sleeved on the guide rods 13; Between the lower plate 12 and the formwork 2 adjacent to the lower plate 12, four connecting mechanisms 3 are respectively provided. The connecting mechanism 3 includes a first mounting seat 31, a set The second mounting seat 32 at the bottom of the upper formwork 2, the shock absorbing mechanism located between the first mounting seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com