Device for hoisting equipment racks

A hoisting equipment and racking technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of poor stability, the influence of the levelness and verticality of the whole machine, and achieve the effect of ensuring stability and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The device for hoisting equipment of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

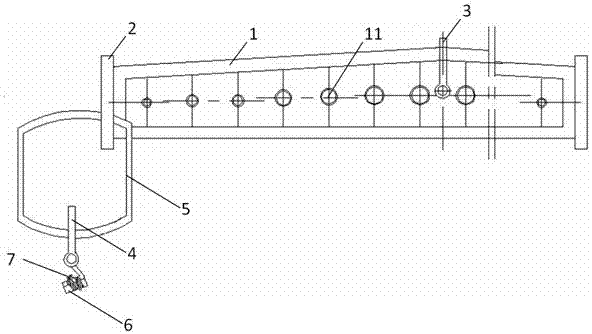

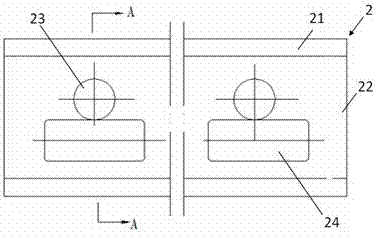

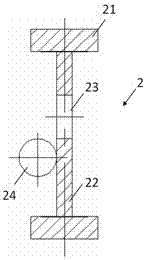

[0028] Such as Figure 1~3 As shown, a device for hoisting equipment racks includes a beam 1, a spreader arm 2 is welded at one end of the beam 1, the beam 1 is a rectangular structure, and the upper top surface forms a "︿"-shaped curved surface; No. 1 hook 3 and The highest point of the "︿"-shaped curved surface of the beam 1 is connected; the spreader arm 2 is an I-shaped structure composed of two long beams 21 and a short beam 22, and a plurality of connecting holes 23 are formed on the short beam 22, and a plurality of The anti-wear rod 24 is horizontally fixed on the short beam 22, and is located directly below the connecting hole 23 and corresponds one by one; the hoisting rope 5 passes through any connecting hole 23 on the short beam 22, and the No. Ⅱ hook 4 is connected below it, No. II hook 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com