High-performance structure RV reduction machine

A reducer, high-performance technology, applied in the direction of mechanical equipment, geared components, transmission parts, etc., can solve the impact torque of RV reducer, restrict the service life of RV reducer, etc., to improve the load capacity and resistance Impact ability, improved service life, and reduced assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

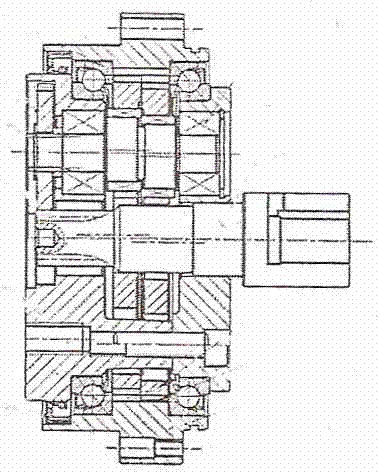

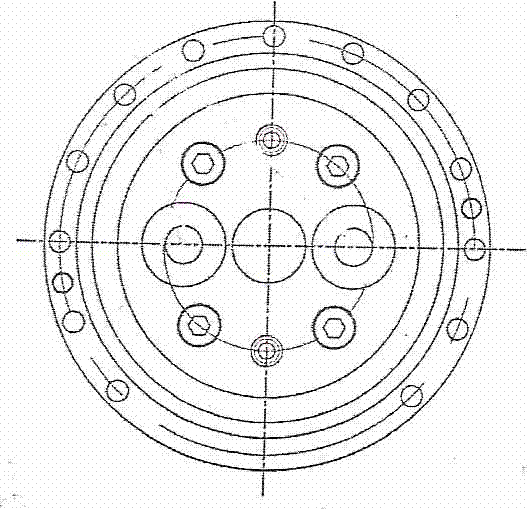

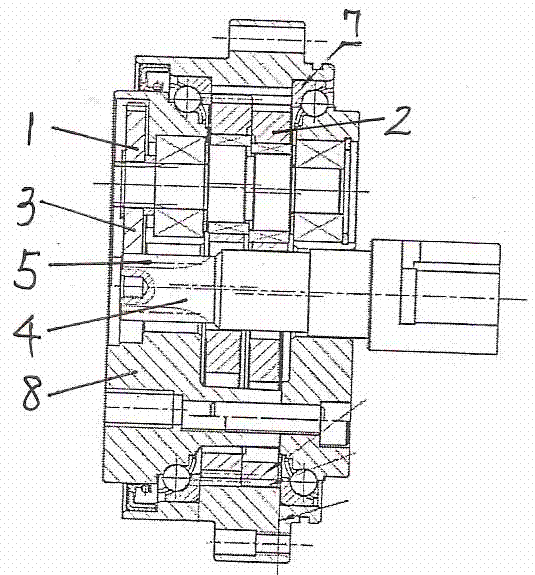

[0027] An RV reducer with a high-performance structure, including a first-stage planetary reduction mechanism 1, a second-stage cycloidal reduction mechanism 2, and an angular contact bearing 7. The planetary gear 3 of the first-stage planetary reduction mechanism meshes with the central gear 5 at one end of the input shaft 4 , the above-mentioned two-stage deceleration mechanism is connected through the eccentric shaft 5, and there are three eccentric shafts 6, and the three eccentric shafts are evenly distributed on the circumference at intervals of 120 degrees; the angular contact ball bearing 7 is a one-piece type, that is, the outer ring is independent, and the inner ring and the output disk Frame 8 integrated structure.

[0028] The planetary gear is a structural form embedded in the reducer, or a structural form exposed outside the reducer.

[0029] The input shaft is installed from the left side of the RV reducer (that is, the side close to the motor), or from the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com