A rotary detonation combustor

A combustion chamber and detonation technology, which is applied in the field of combustion chambers, can solve the problems that detonation waves are easy to degrade and disappear, detonation waves are only formed at the head of the combustion chamber, and fuel filling space is insufficient, so as to shorten the transition from slow combustion to detonation combustion distance, improve fuel filling efficiency, and improve the effect of overall self-pressurization capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

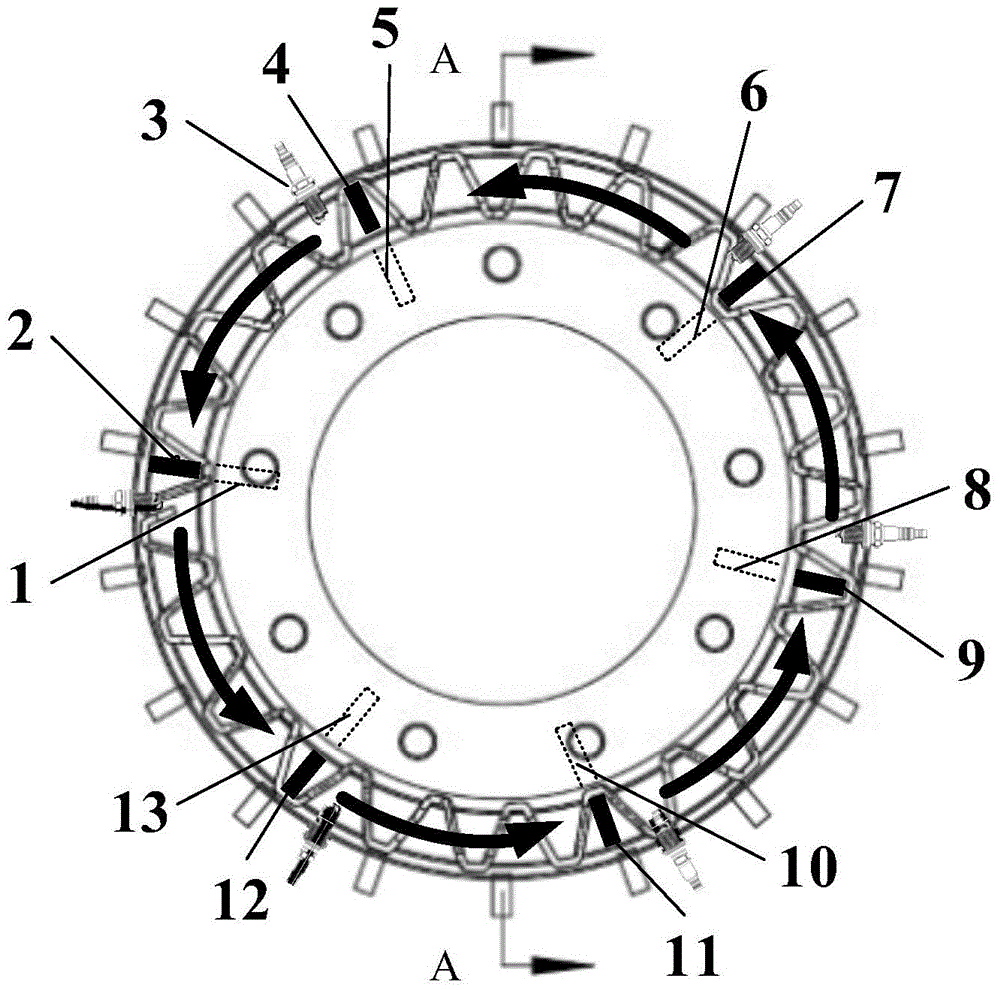

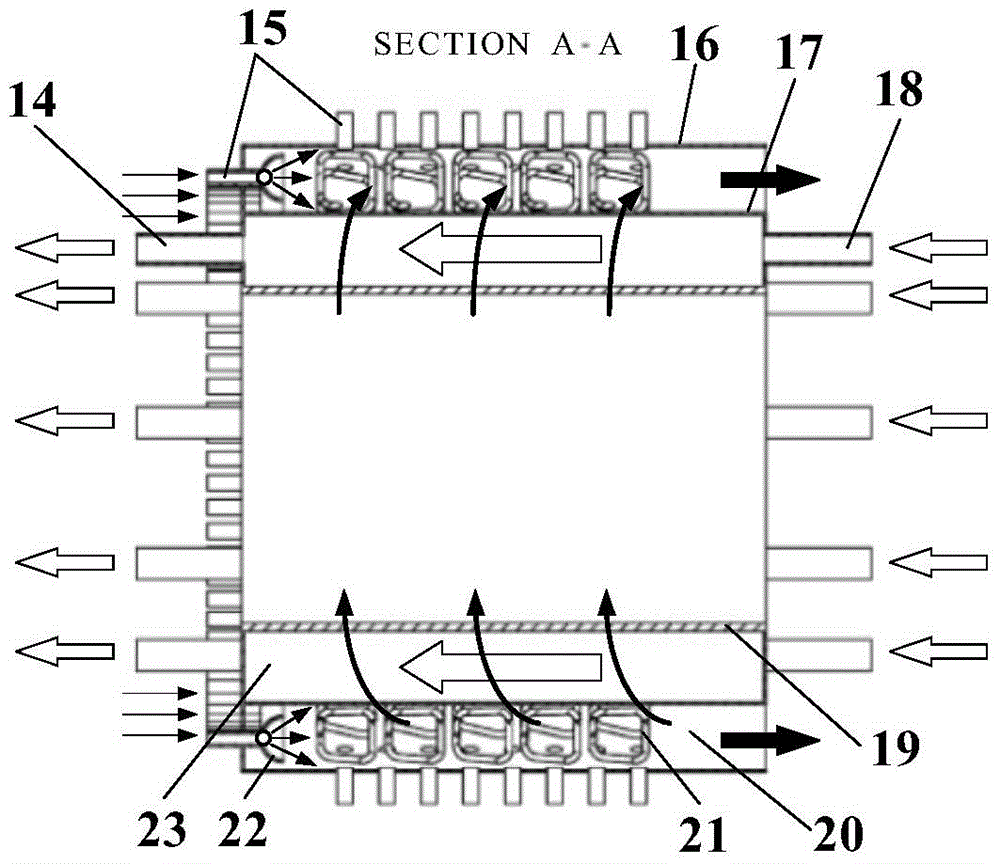

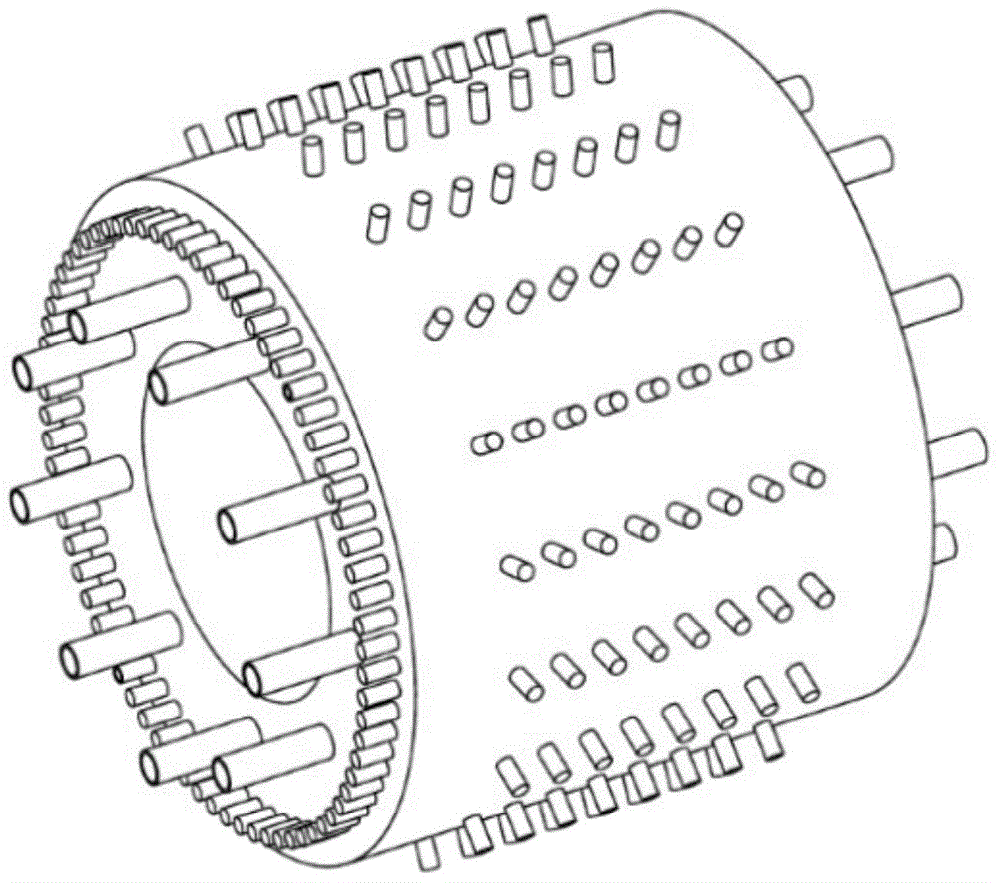

[0031] see figure 1 and figure 2 , a rotary detonation combustion chamber of the present invention, comprising a detonation combustion chamber 20, a fuel preheating chamber 23, a fuel nozzle 15, a spiral obstacle 21, a pre-detonation pressure wave attenuation structure 22, a fuel inlet pipeline 18, a fuel Outlet line 14 and spark plug 3. In this embodiment, the detonation combustion chamber 20 and the fuel preheating chamber 23 are coaxially arranged; the detonation combustion chamber has an outer diameter of 1400 mm, an inner diameter of 1200 mm, and a length of 1100 mm; an outer diameter of the fuel preheating chamber of 1190 mm, an inner diameter of 890 mm, and a length of 1100 mm. The pre-detonation pressure wave attenuation structure 22 is arranged at the head of the detonation combustion chamber 20, and is fixedly connected to the detonation combustion chamber 20 through the fuel nozzle 15. The detonation pre-detonation pressure wave attenuation structure 22 is a semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com