Carbon dioxide exploder

A carbon dioxide and detonator technology, applied in blasting and other directions, can solve problems affecting production efficiency, poor sealing, troubles, etc., and achieve the effects of prolonging service life, convenient handling, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

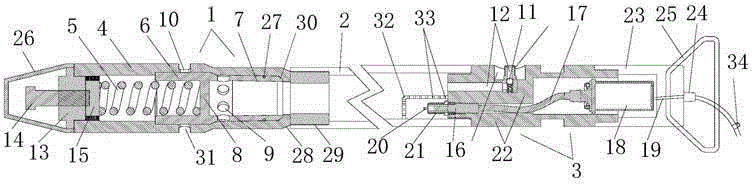

[0021] This embodiment includes an energy relief valve 1, a main body pipe 2 and a starting mechanism 3, the energy relief valve 1 and the starting mechanism 3 are respectively fixed at both ends of the main body pipe 2, and the energy relief valve includes an energy relief valve sleeve 4 , energy release spool, spring 5, described energy release spool is the ladder cylindrical shape of two ends open, comprises the compression cylinder 6 of large external diameter, the energy discharge cylinder 7 of small external diameter, between compression cylinder, energy discharge cylinder There is a partition 8 in between, and the inner cavity of the energy relief valve sleeve 4 is a stepped inner cavity, including a compression chamber with a large inner diameter and an energy release chamber with a small inner diameter. One end of the energy relief valve sleeve 4 is sealed with the main pipe 2 The other end is a closed end, the spring 5 is set in the energy release valve sleeve 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com