Two-edge double margin drill

A technology of drill bits and margins, which is used in repair drills, twist drills, drilling tool accessories, etc., can solve problems such as unstable steering and difficulty in improving hole drilling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

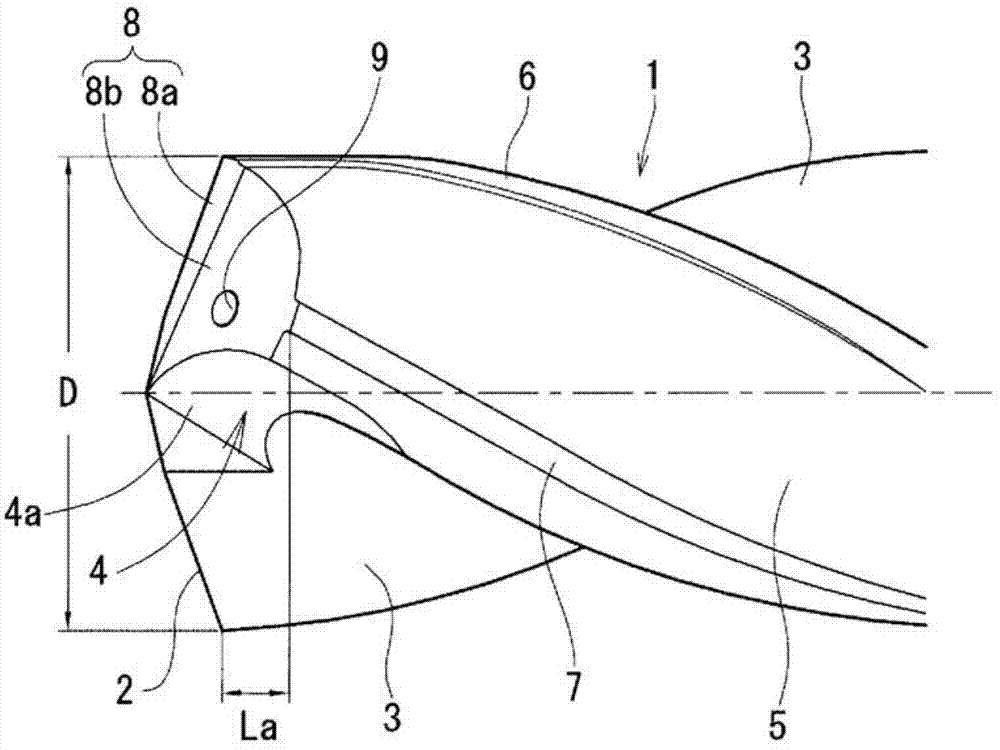

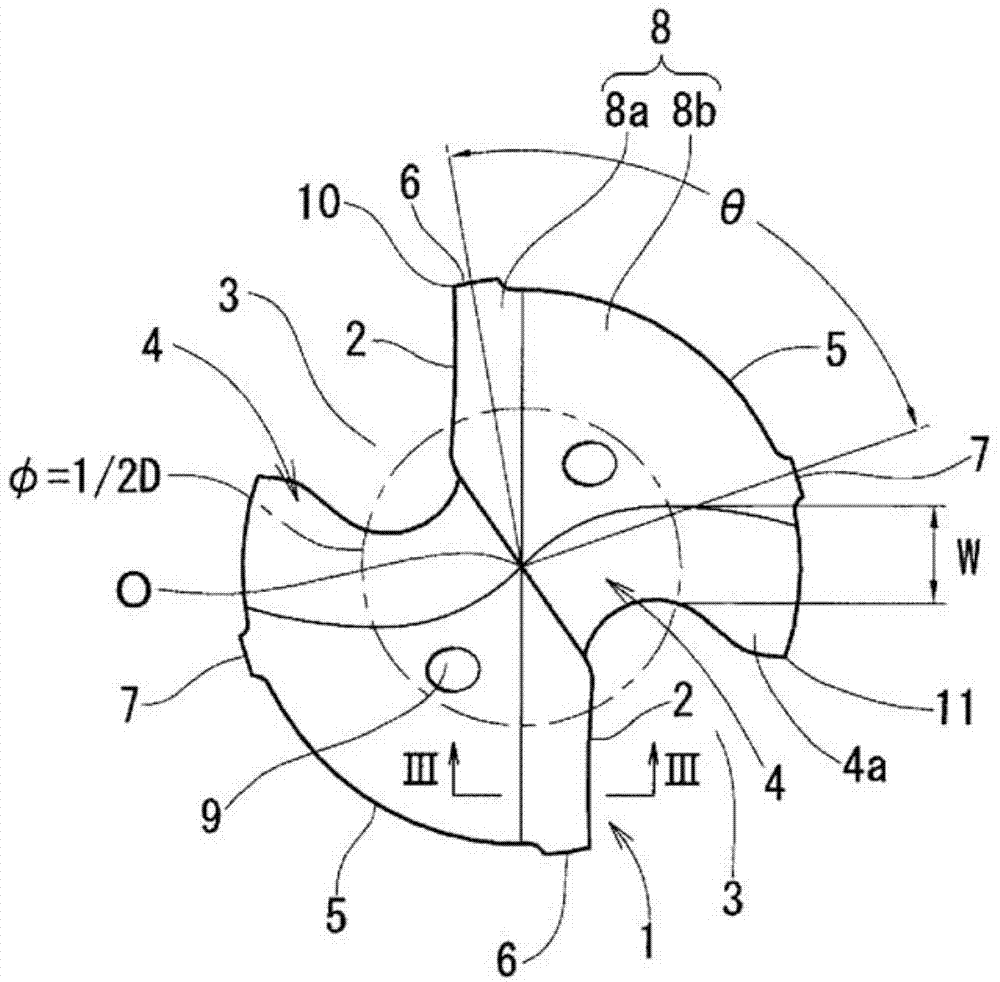

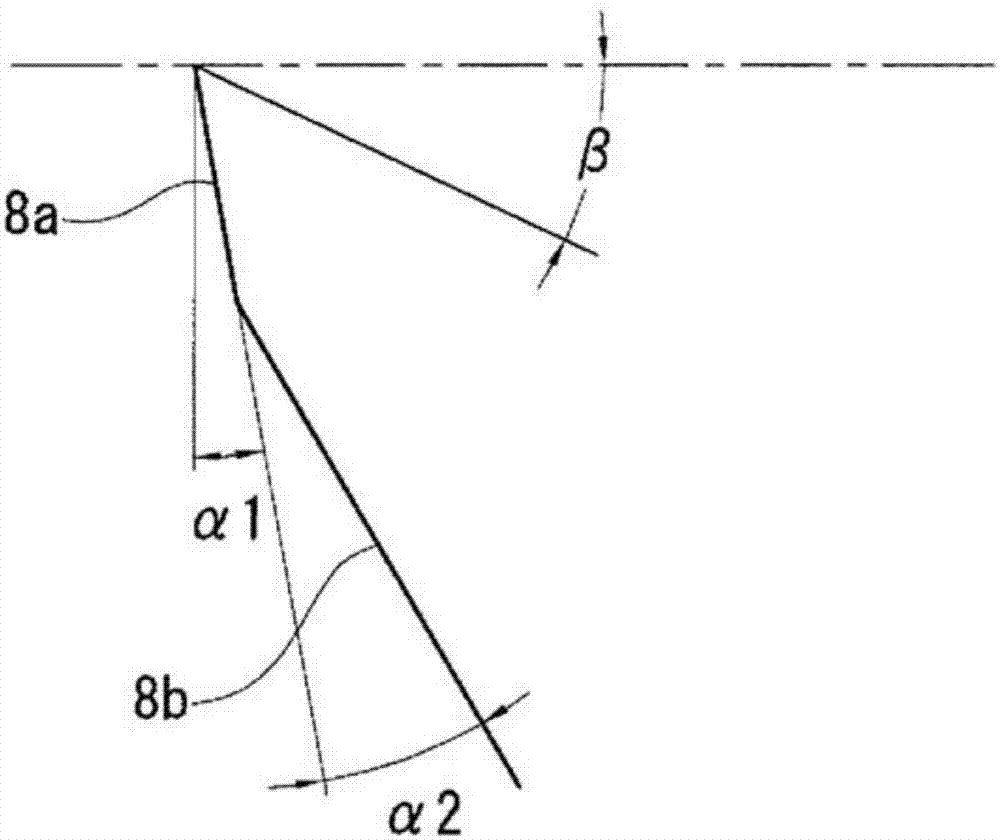

[0049] Trial out with Figure 4 and Figure 5 Bits of the shape shown. The size of the drill bit is: diameter D=13mm, center thickness=4.6mm, helix angle β=30° of each helical chip flute, clearance angle α1=9° of each second flank, and α1=9° of each third flank The clearance angle α2 = 15°, and at a distance equal to (1 / 2)D from the center of rotation, the width W of each ground chisel surface in the end view of the drill bit = 2.3mm.

[0050] The trial-manufactured drill provides the R-shaped chisel edge part shown in the figure, which prevents the chisel edge from being cut to the end of the secondary margin, and can be connected from the outer end of each cutting edge to the corresponding secondary margin. The axial distance La is shortened to 0.4mm. Furthermore, it is possible to set the circumferential interval θ between the primary land and the corresponding secondary land to 90°. Therefore, even if the drilling operation (workpiece: cast iron) is performed under the...

example 2

[0053] The drills I to III were used, and the difference in the positional accuracy of the hole caused by the difference between the clearance angles of the third flank was checked. For drill bits I to III, set according to table 1 Figure 6A The shown clearance angle α1 of the second flank and clearance angle α2 of the third flank, Figure 6B Shown are the axial distance La from the outer end of the cutting edge to the secondary land and the distance Lb from the position where the primary land acts to the secondary land (the section where the secondary land does not function).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com