Connector post of refrigeration compressor

A technology of refrigeration compressors and terminal posts, which is applied in the direction of connection, conductive connection, inorganic insulators, etc., which can solve the problems of insulators such as poor chemical performance stability, voltage resistance, insulation reduction, and air tightness reduction in electrical performance, etc., to achieve durable physical and chemical properties, reduce the chance of air leakage, and enhance the expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

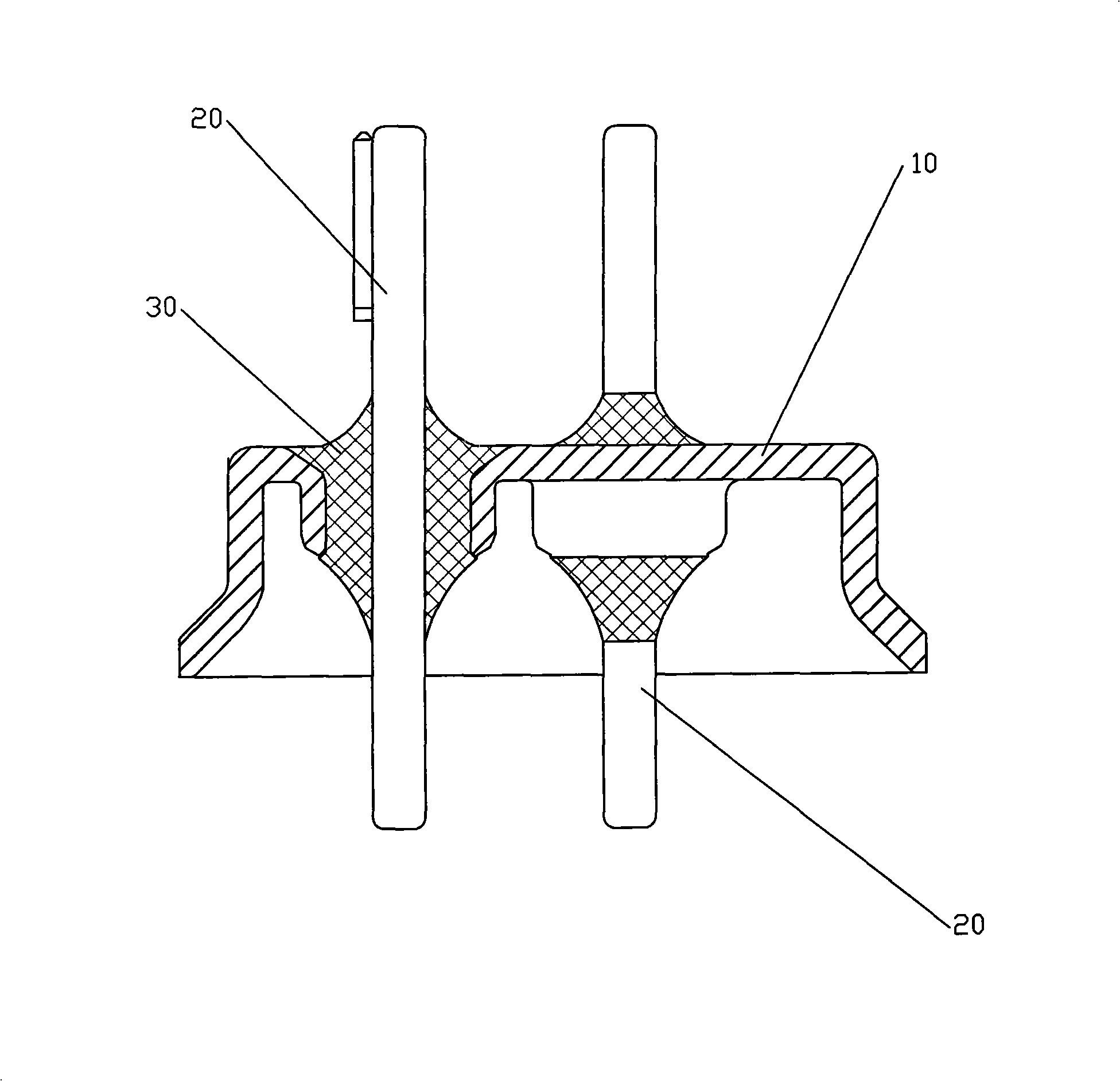

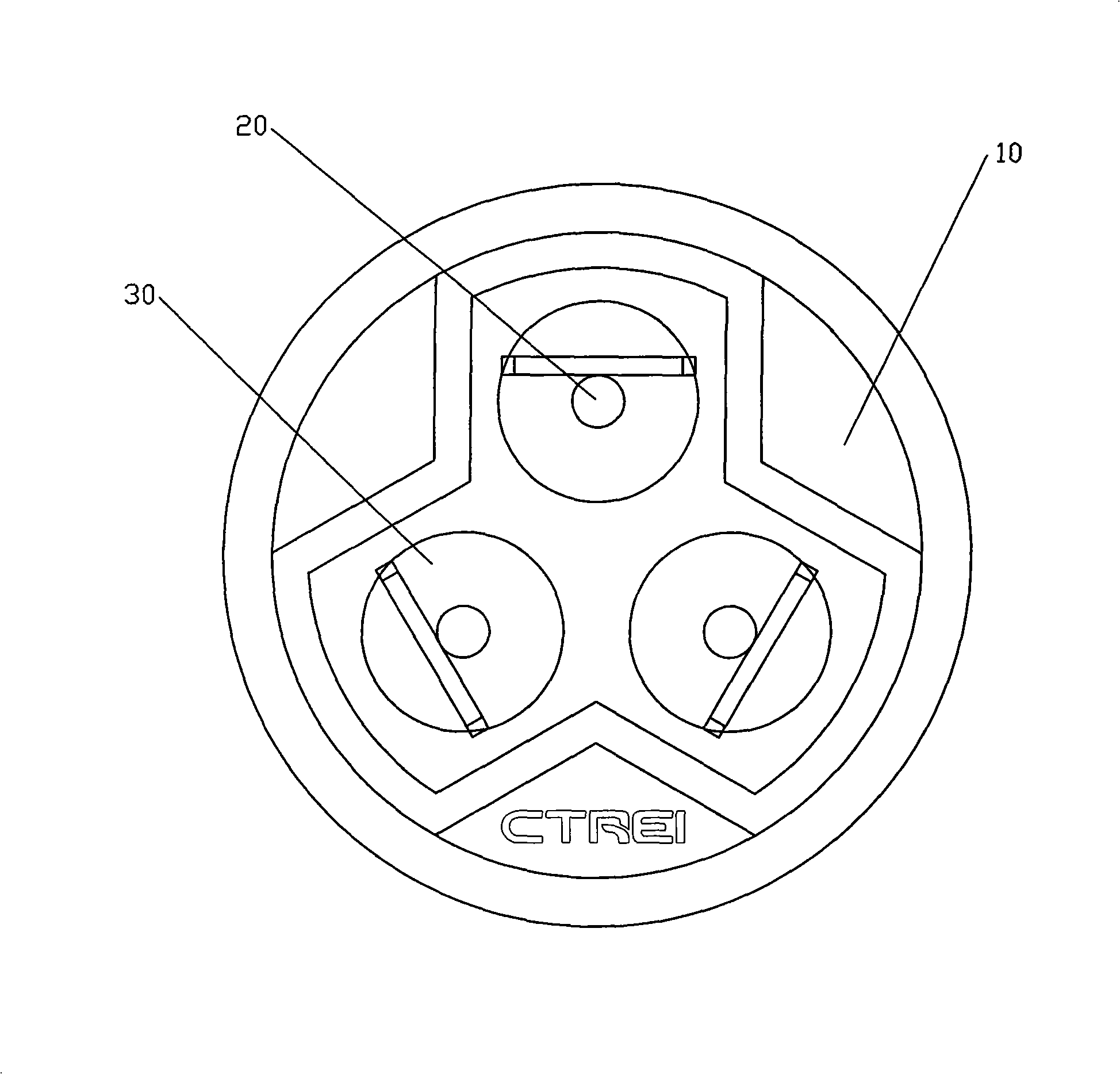

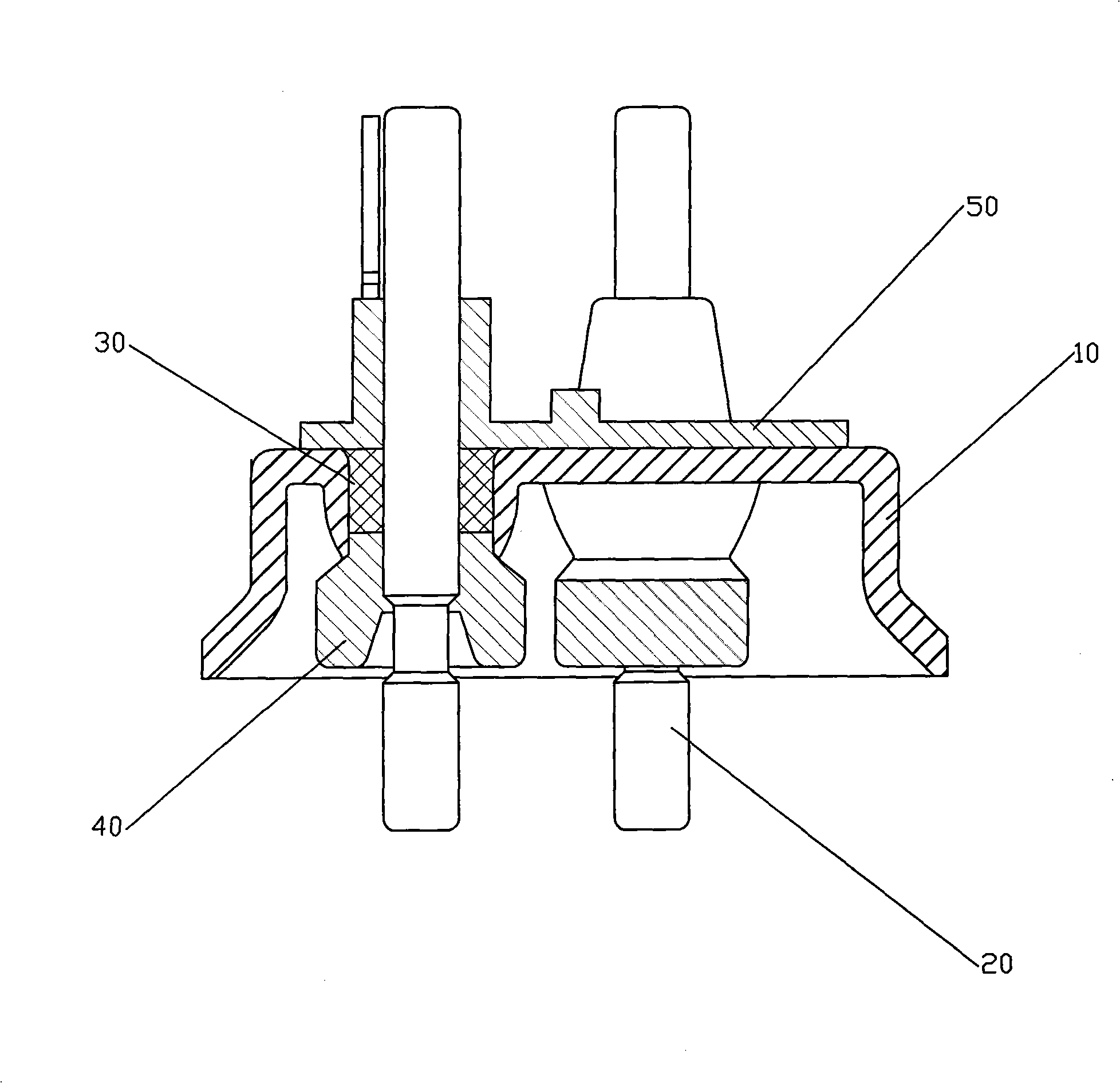

[0030] refer to image 3 and Figure 4 , the present invention is implemented as follows:

[0031] exist image 3 and Figure 4 Among them, it includes an end cover (10), the end cover (10) and the compressor casing are welded together, the conductive column (20) is sealed together by the glass (30) and the end cover (10), and the glass (30) uses In order to play the role of insulation and sealing, the conductive column (20) is provided with an insulator (40) that separates the surface of the glass (30) from the air, and the upper side of the end cover (10) is provided with an insulator (40) that separates the surface of the glass (30) from the air. Opened silicone rubber (50), the insulator (40) is made of aluminum oxide, the insulator (40) is made of the following materials: aluminum oxide: 92-96%, silicon oxide: 2-3%, calcium oxide: 1- 3%, bismuth oxide: 0.5-1.0%, antimony oxide: 0.5-1.0%. The expansion coefficient of the insulator (40): 8.0±0.5×10^-6 / K (@RT-500℃).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com