Injection molding device capable of conducting even cooling

A technology of uniform cooling and packaging, applied in the field of injection molding devices that can be uniformly cooled, can solve the problems of uneven cooling and poor quality of molded products, and achieve the effect of uniform cooling and avoiding uneven cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

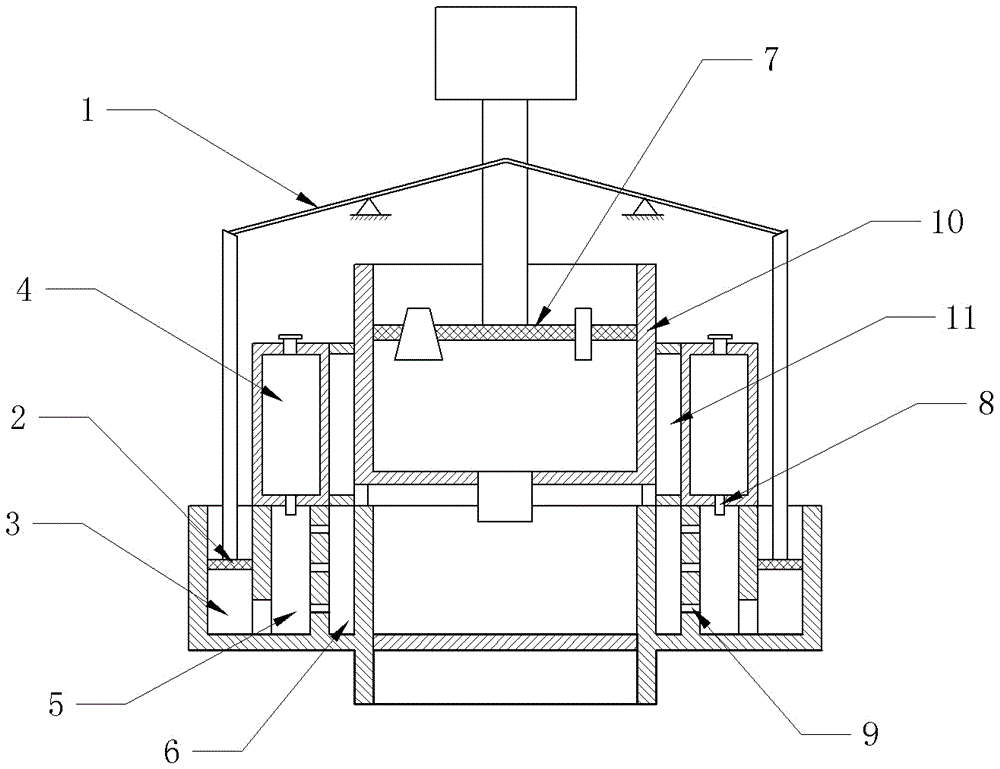

[0019] The reference signs in the drawings of the description include: lever 1, second piston 2, power chamber 3, liquid storage tank 4, storage chamber 5, cooling chamber 6, first piston 7, pressure valve 8, capillary hole 9, material storage Bucket 10, isolation cavity 11.

[0020] Such as figure 1 As shown, including the mold, the side wall of the mold is provided with three concentric annular cavities, from the inside to the outside are the cooling cavity 6, the storage cavity 5 and the power cavity 3, and these three annular cavities are all set in the inner cavity of the mold outside. The top of the inner cavity of the mold is provided with a material storage barrel 10, and the material storage barrel 10 has a support foot, and the material storage barrel 10 is set on the top of the mold inner cavity by the support foot, and the bottom end of the material storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com