Aluminum profile extrusion die for cooling in die

A technology for extrusion die and aluminum profile, which is applied in the field of aluminum profile extrusion die, aluminum profile extrusion production die cooling field, and can solve the problem that it is difficult to avoid extrusion product defects, the temperature control ability is not strong, and the die surface is not detachable, etc. The problem is to reduce the defects of extruded products, the cooling method is directly effective, and the cooling method is efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention provides an aluminum profile extrusion die with in-mold cooling.

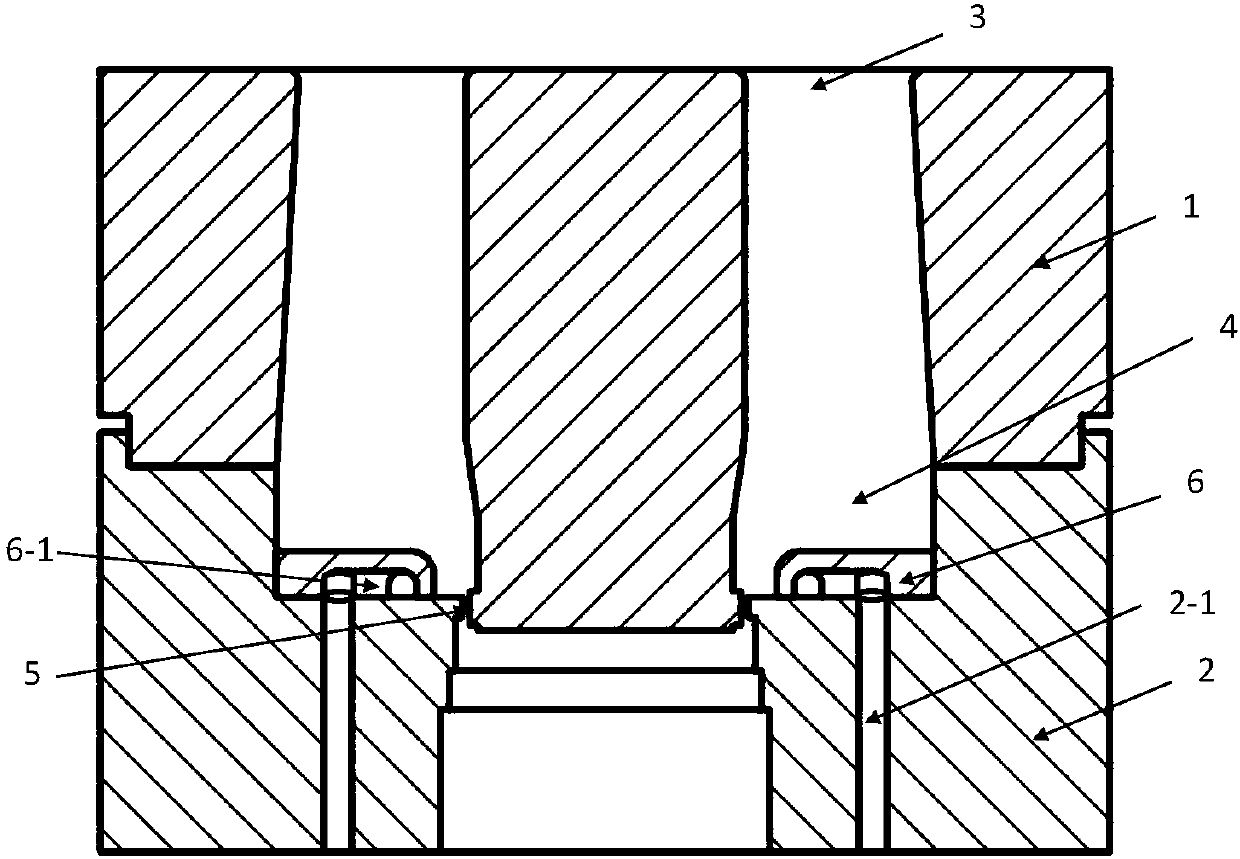

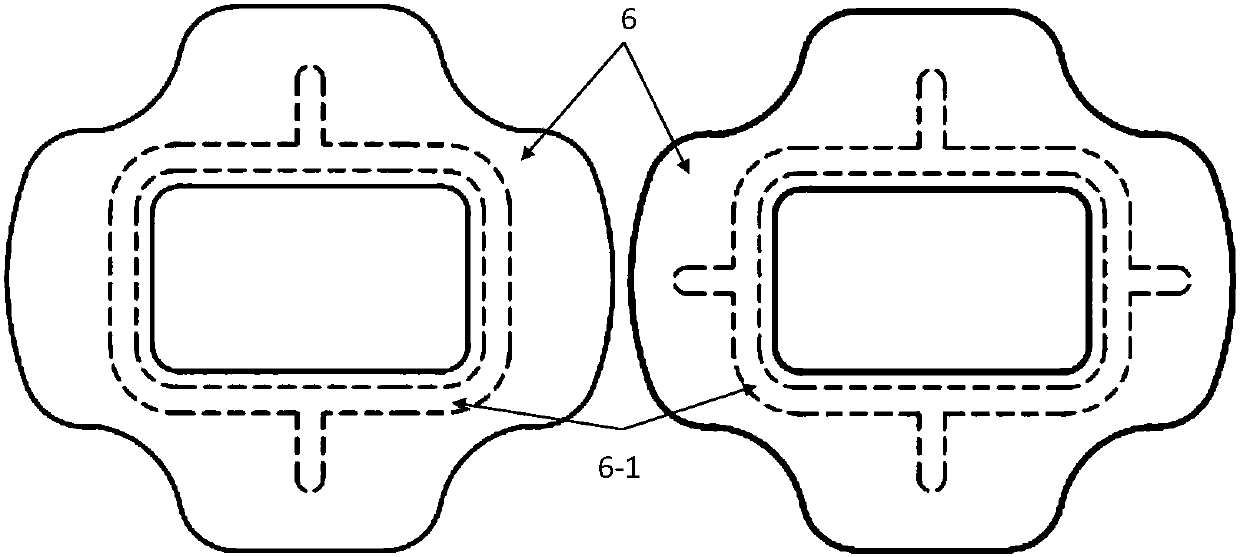

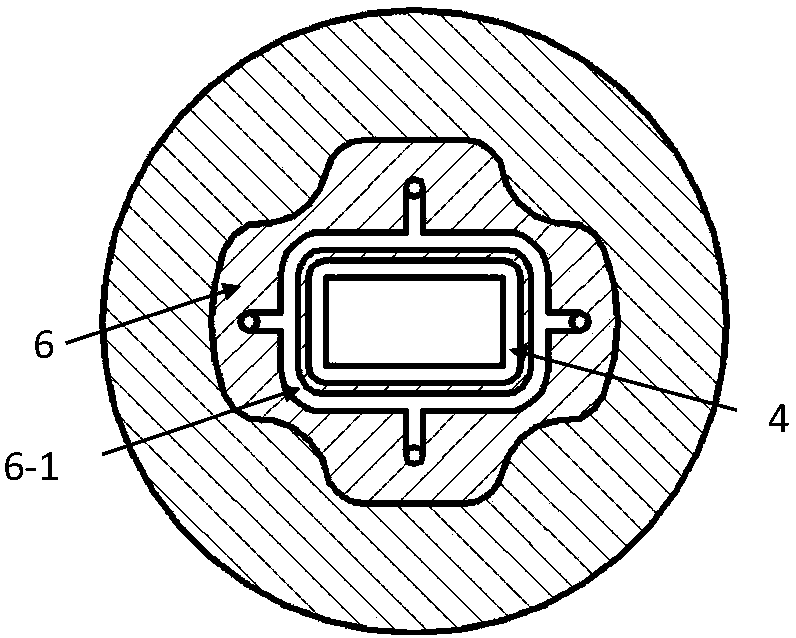

[0046] The traditional aluminum profile extrusion splitting combination die consists of an upper die 1 and a lower die 2. The present invention adds a layer of cooling pad 6 at the bottom of the welding chamber 4 of the extrusion die, and the top view of the cooling pad 6 is as follows: figure 2 As shown, when the cooling pad 6 is placed in the upper mold 1 and the lower mold 2, the overall cross-sectional view of the mold is as follows Figure 1-9 shown.

[0047] An aluminum profile extrusion die that can realize in-mold cooling, comprising an upper die 1, a lower die 2, a distribution hole 3, a welding chamber 4, a working belt 5, and a profile outlet 7, and the upper die 1 and the lower die 2 are installed together, The upper end surface of the upper mold 1 is formed with a split hole 3, the below of the split hole 3 is a welding chamber 4, and the bottom of the welding chamber 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com