Circular blowing polyester spinning cooling device and method

A technology of cooling device and blowing device, which is applied in the field of polyester production, can solve the problems of lack of air uniformity measures, achieve the effects of reducing unevenness of evenness, avoiding uneven cooling, and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

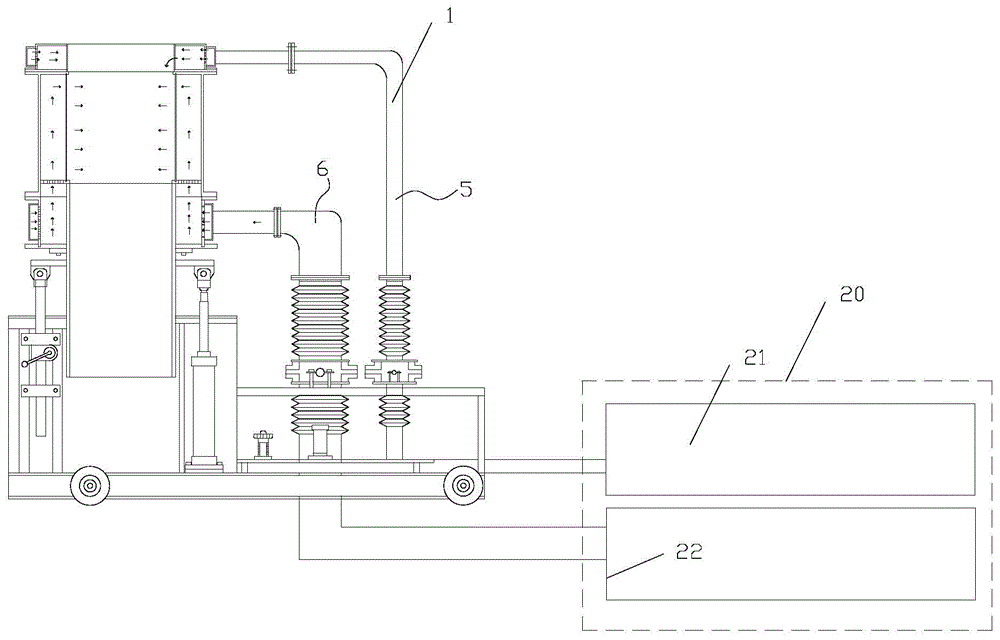

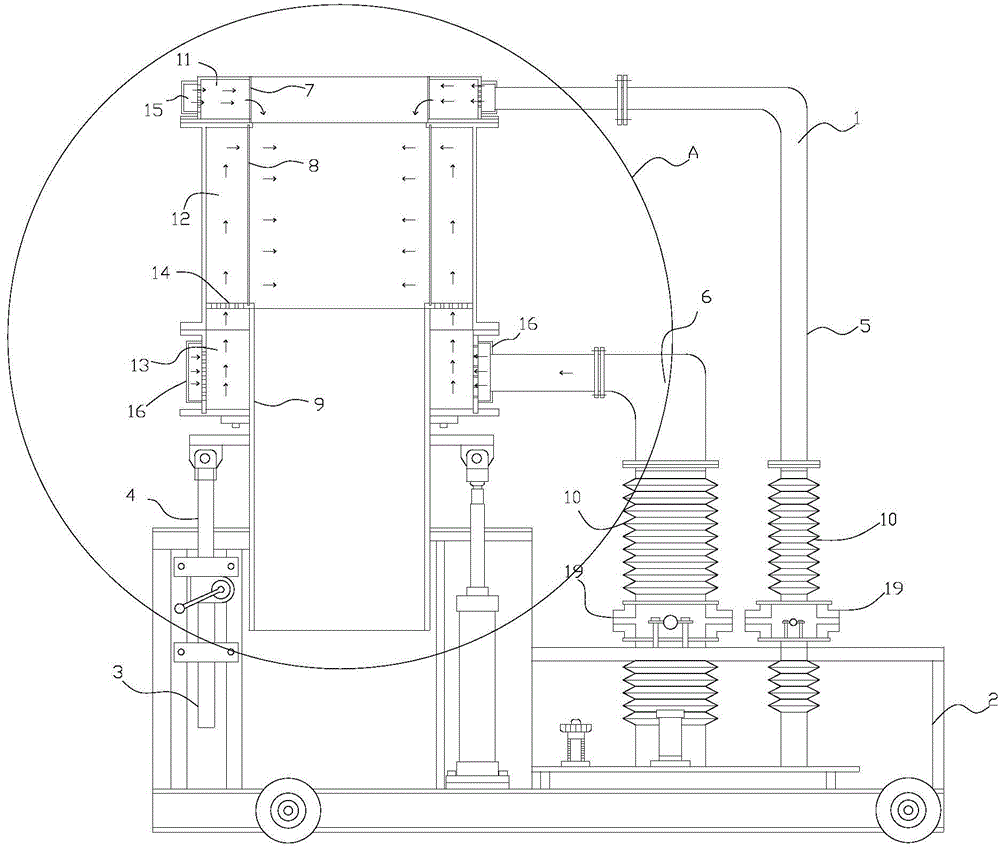

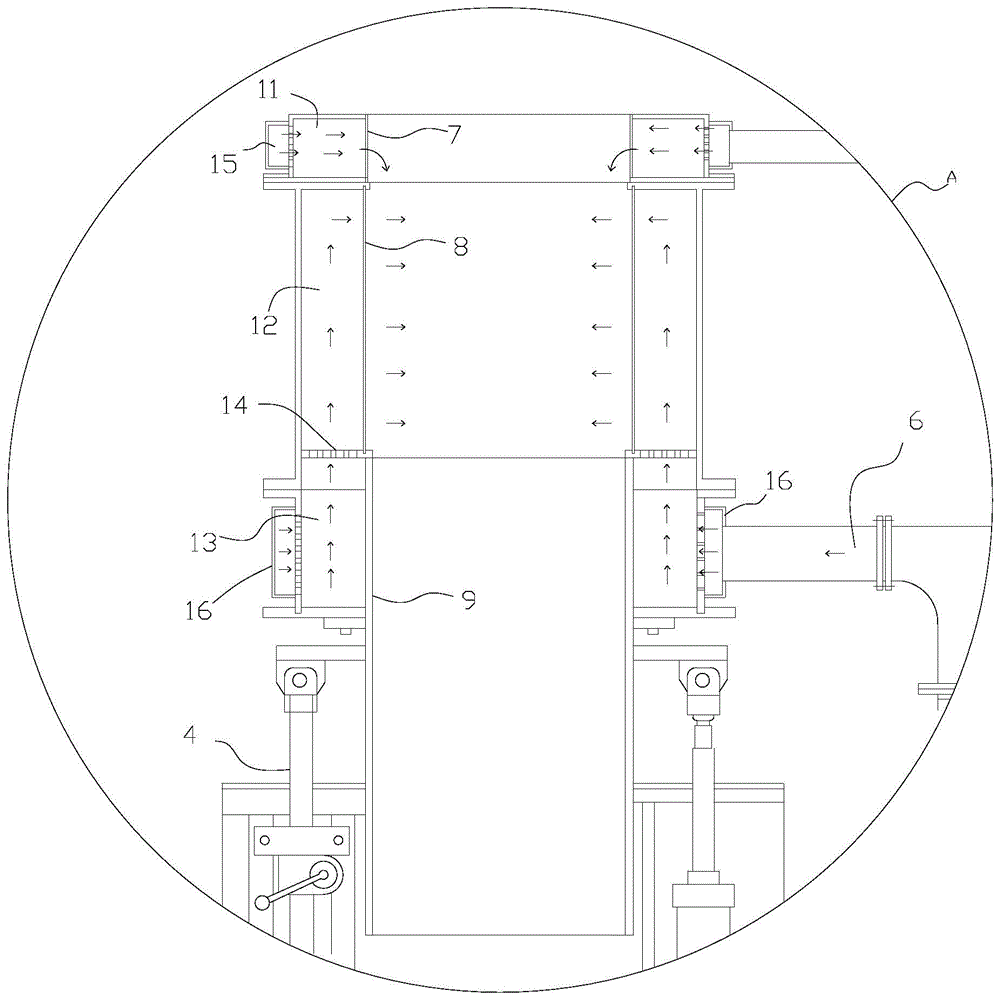

[0028] Such as figure 1 , 2 , 3, and 4, the ring air blowing polyester spinning cooling device described in this embodiment is composed of two parts: a blowing device 1 and an air conditioning system 20, and it is characterized in that the described blowing device 1 includes a frame 2, a lifting cylinder 3. The lifting rod 4, the first air inlet pipe 5, the second air inlet pipe 6, the first air cylinder 7, the second air cylinder 8 and the guide cylinder 9, the first air cylinder 7 and the second air cylinder 8 can be ventilated, The guide cylinder 9 is airtight; the lift cylinder 3 is arranged on the frame 2, the bottom of the lift rod 4 is connected to the lift cylinder 3, the top is connected to the outer wall of the guide cylinder 9, the first air inlet pipe 5 and the second air inlet pipe 6 Also located on the frame 2, the first air inlet pipe 5 and the second air inlet pipe 6 are provided with a deformation section 10 and an air inlet valve 19, and the first air cylind...

Embodiment 2

[0033] Such as Figure 5 As shown, the ring-air blown polyester spinning cooling device described in this embodiment is different from Embodiment 1 in that: the first air conditioning system 21 and the second air conditioning system 22 have the same structural composition, and they are all composed of sequentially connected Air duct 23, air intake fan 24, air intake valve 25, coarse filter 26, preheater 27, front surface cooler 28, spray chamber 29, rear surface cooler 30, rear heater 31, blower 32 , fine filter 33 and air outlet 34 are formed.

Embodiment 3

[0035] Such as Figure 6 As shown, the difference between the circulating blowing polyester spinning cooling device described in this embodiment and the embodiment 1 is that the cooling air blown out by the first air cylinder 7 blows obliquely upwards. The cylinder body of the first air cylinder 7 is covered with through holes 35 inclined inwardly and upwardly, and the angle of inclination of the through holes 35 is 30 degrees (the angle of inclination of the through holes 35 can be selected from 30 degrees to 60 degrees. ), the first air inlet 17 is a horizontal air intake, of course, the first air inlet 17 is also inclined inwardly and upwardly, so that before entering the first air cylinder 7, the cooling air experiences an oblique upward direction, and blows obliquely upward The effect is better. The surrounding air blown out by the first air duct 7 is blown upward obliquely. When the primary fiber is ejected, it goes down at a high speed. In the prior art, the cooling ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com