Patents

Literature

38results about How to "Optimize cooling method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

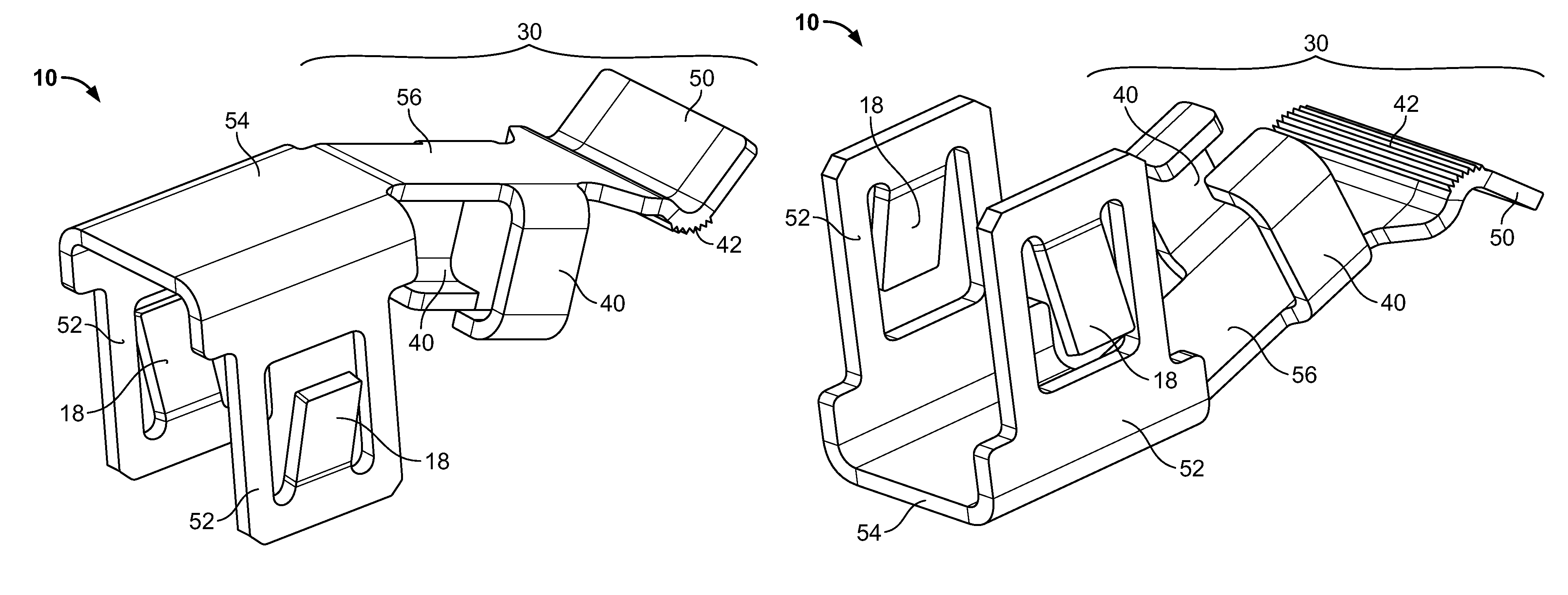

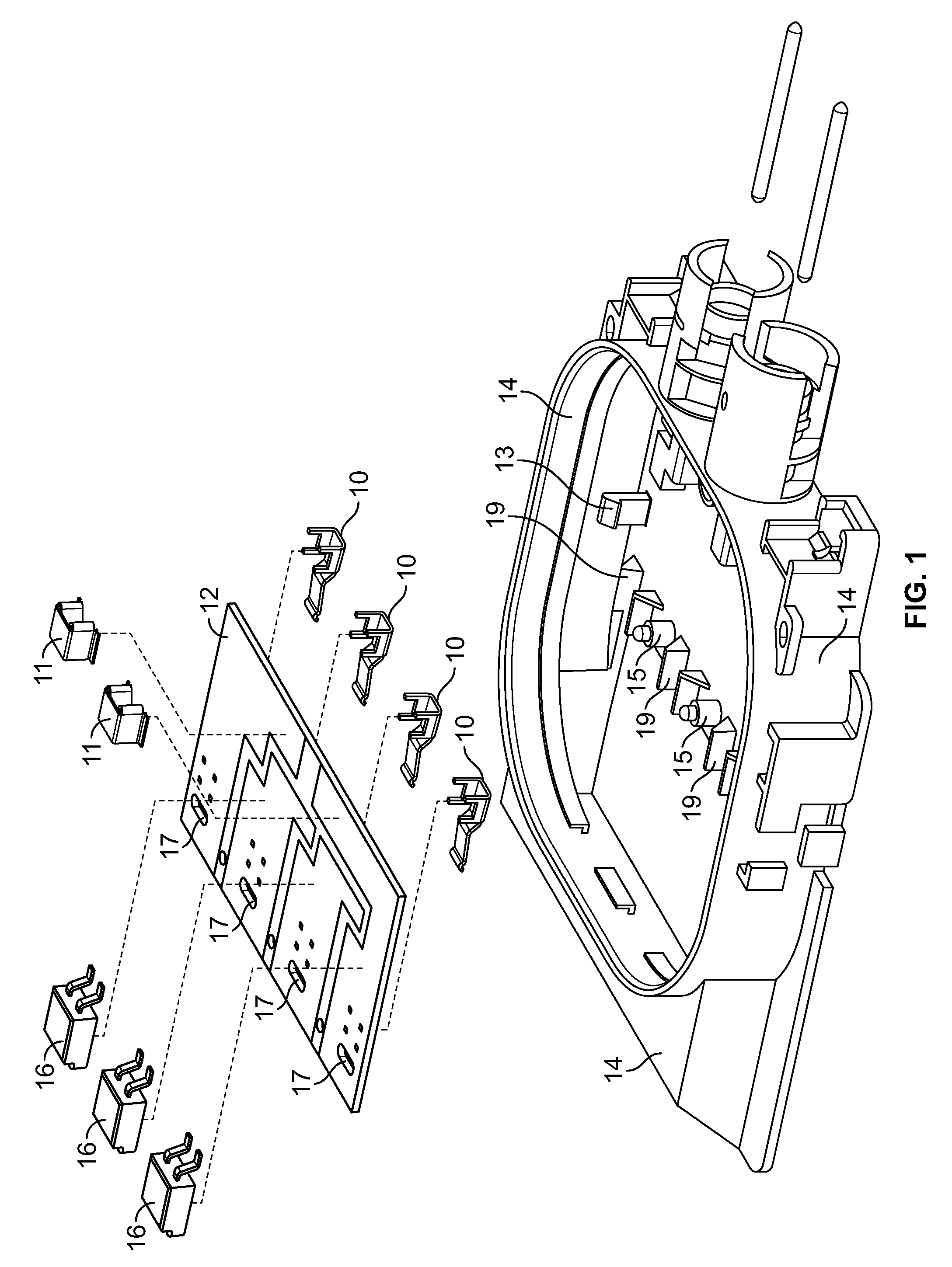

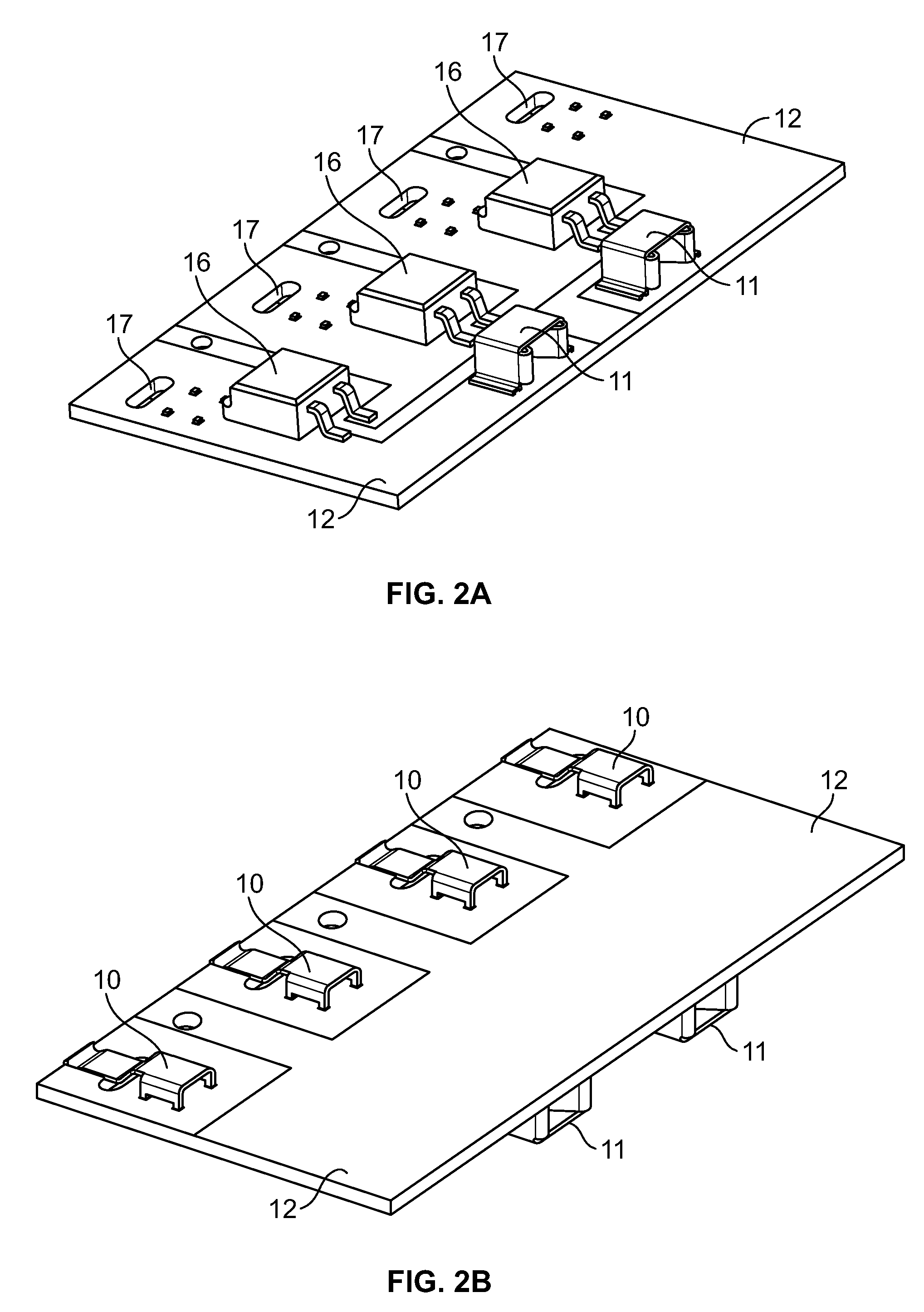

Spring-clamp style contact for PCB to terminate solar panel tabbing

ActiveUS7285006B1Low manufacturing costImprove performanceCoupling device detailsContact members penetrating/cutting insulation/cable strandsPrinted circuit boardEngineering

A spring clip modular assembly for a printed circuit board that has a solderless connection with a junction box. The assembly allows for easier and more efficient removal and replacement of the printed circuit board and electrical components while meeting the IEC 61215 second edition temperature standards. In addition, the spring clip is configured to reduce the amount of normal force applied to the printed circuit board when wire tabbing is inserted into the clips.

Owner:TE CONNECTIVITY CORP

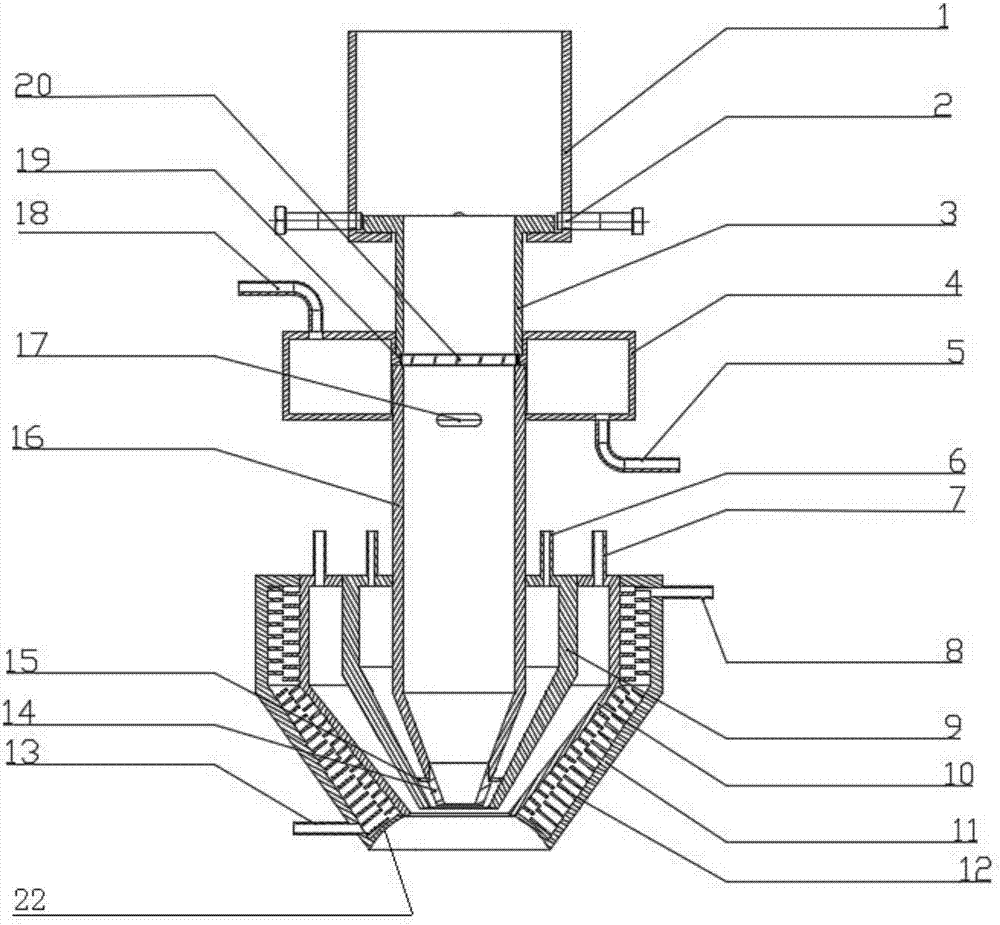

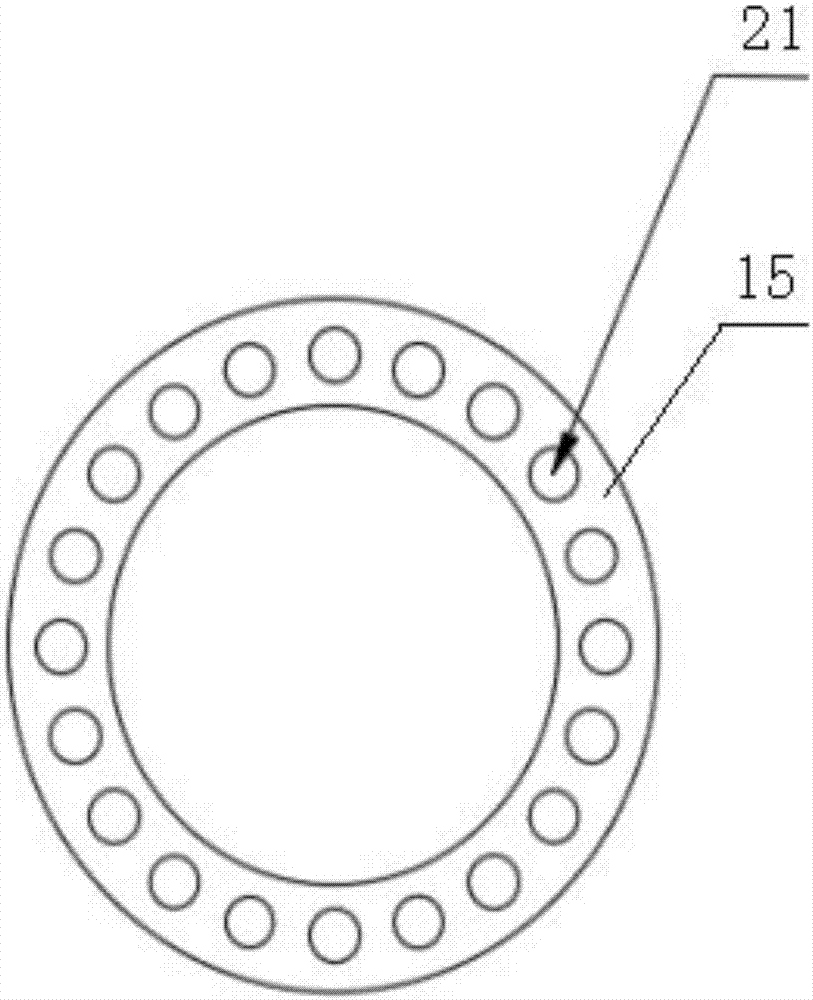

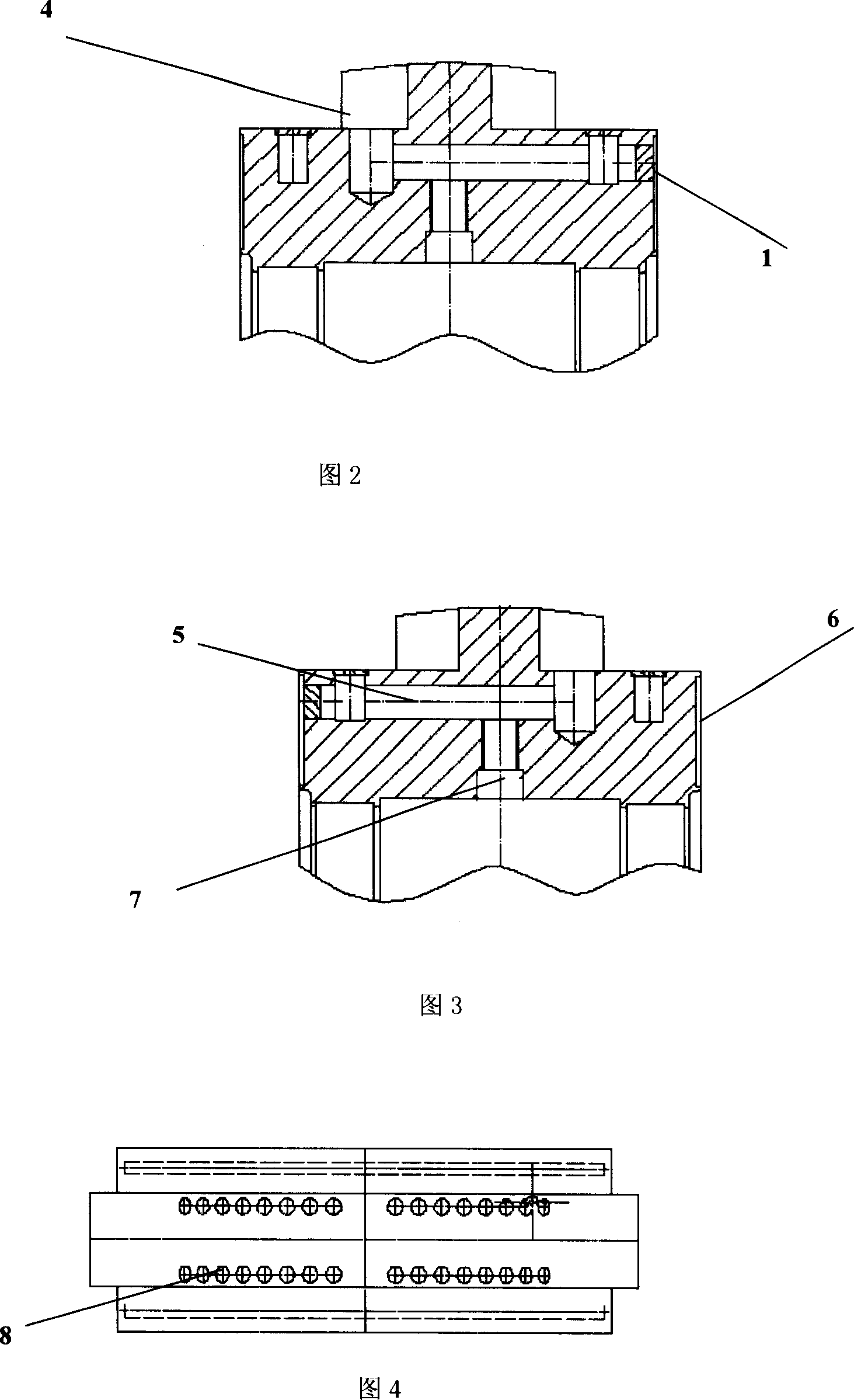

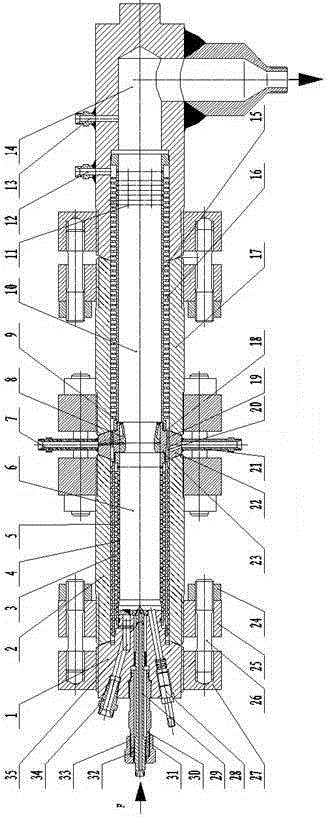

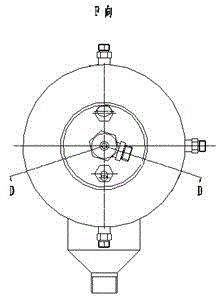

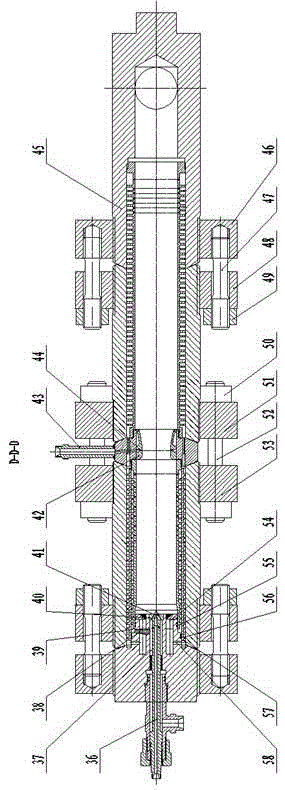

Sieve hole built-in type annular laser cladding nozzle

ActiveCN107245715AGood pink matchEasy to replaceMetallic material coating processesProtective glassesEngineering

The invention discloses a sieve hole built-in type annular laser cladding nozzle which comprises a laser head connection part, a middle part sleeve part and a nozzle part; the laser head connection part is composed of an upper connection sleeve which is connected with a laser head; the middle part sleeve part is composed of a sliding sleeve which is connected with the upper connection sleeve; protective glass is arranged between the lower end of the sliding sleeve and the upper end of a center sleeve; a protective glass water cooled jacket is in threaded connection with the sliding sleeve and the center sleeve; a protective gas hole is formed in the center sleeve; a nozzle part is composed of a conical nozzle core which is connected with the center sleeve; and the outer side of each of the conical nozzle core and the center sleeve is sequentially provided with a powder inlet sleeve, a gas inlet sleeve and a water cooled jacket. The sieve hole built-in type annular laser cladding nozzle overcomes the disadvantages that the service life is short, a powder convergence diameter cannot be regulated, and the existing laser cladding nozzle cannot be suitable for powder particles in different sizes.

Owner:CHINA UNIV OF MINING & TECH

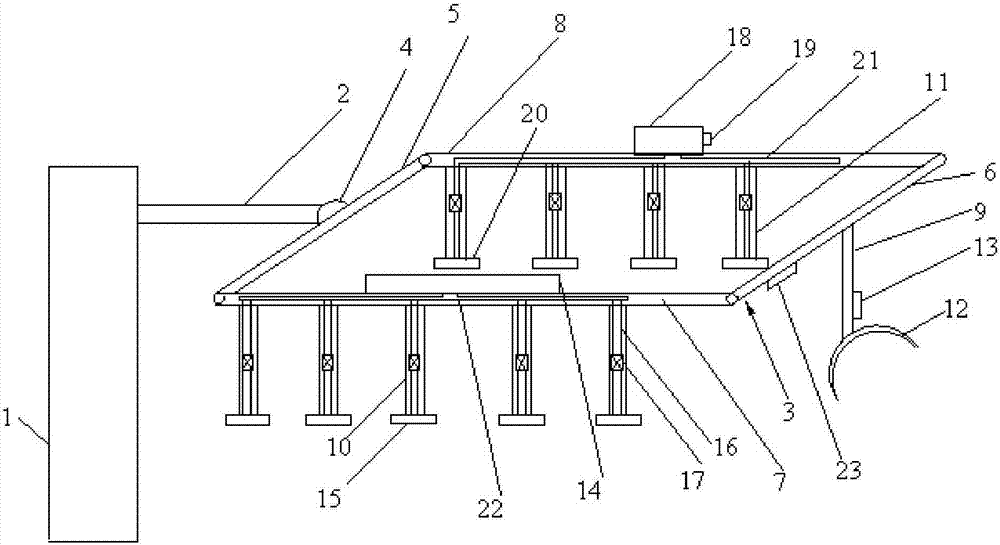

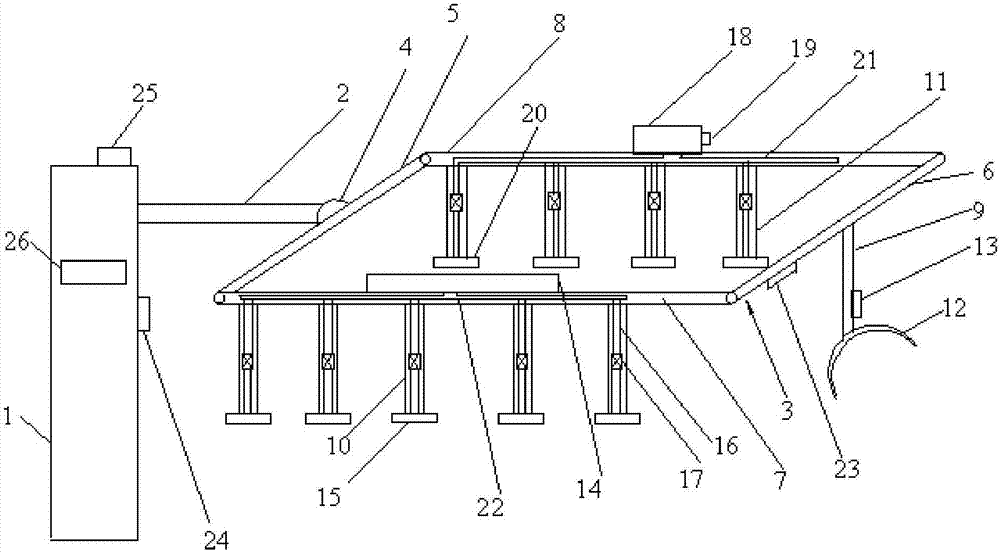

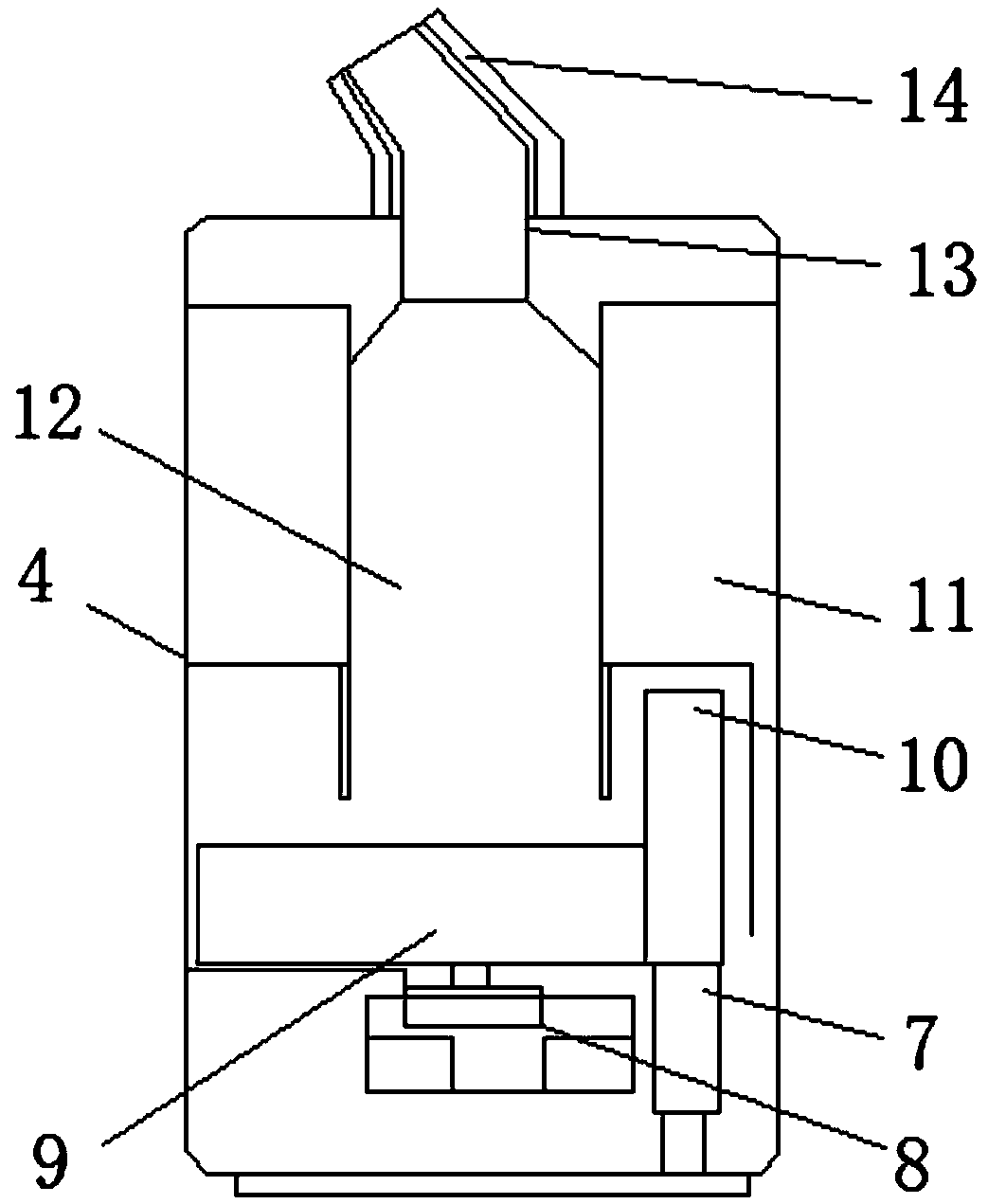

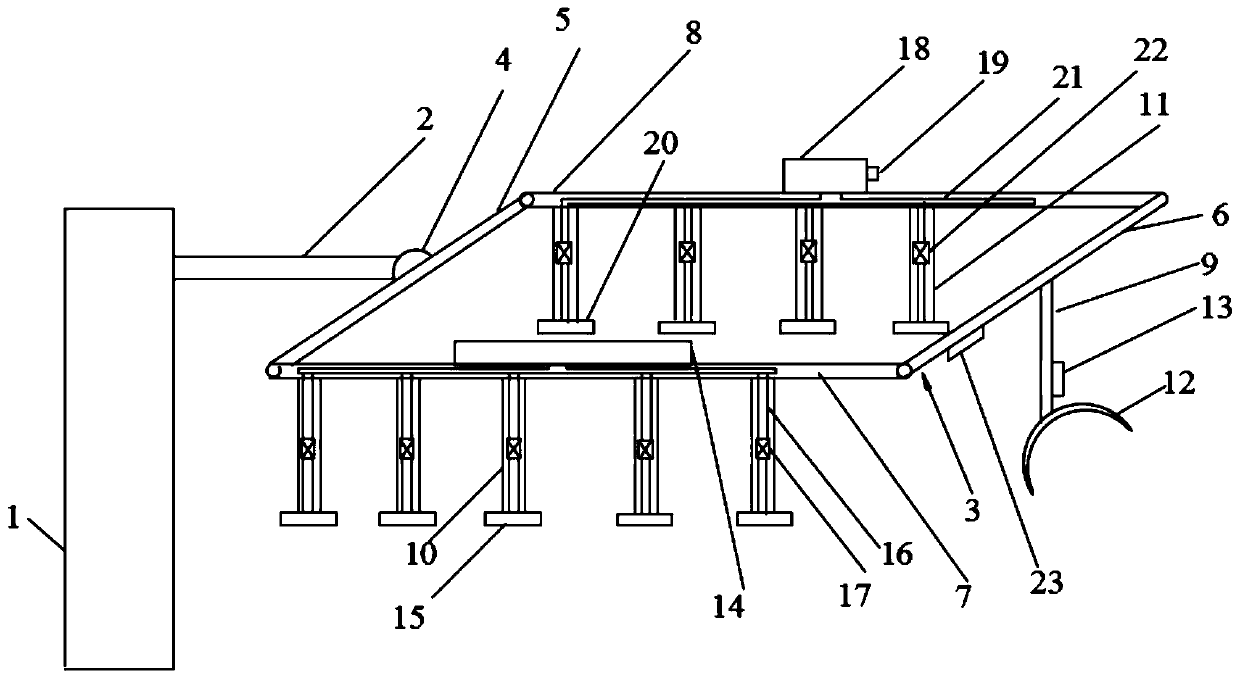

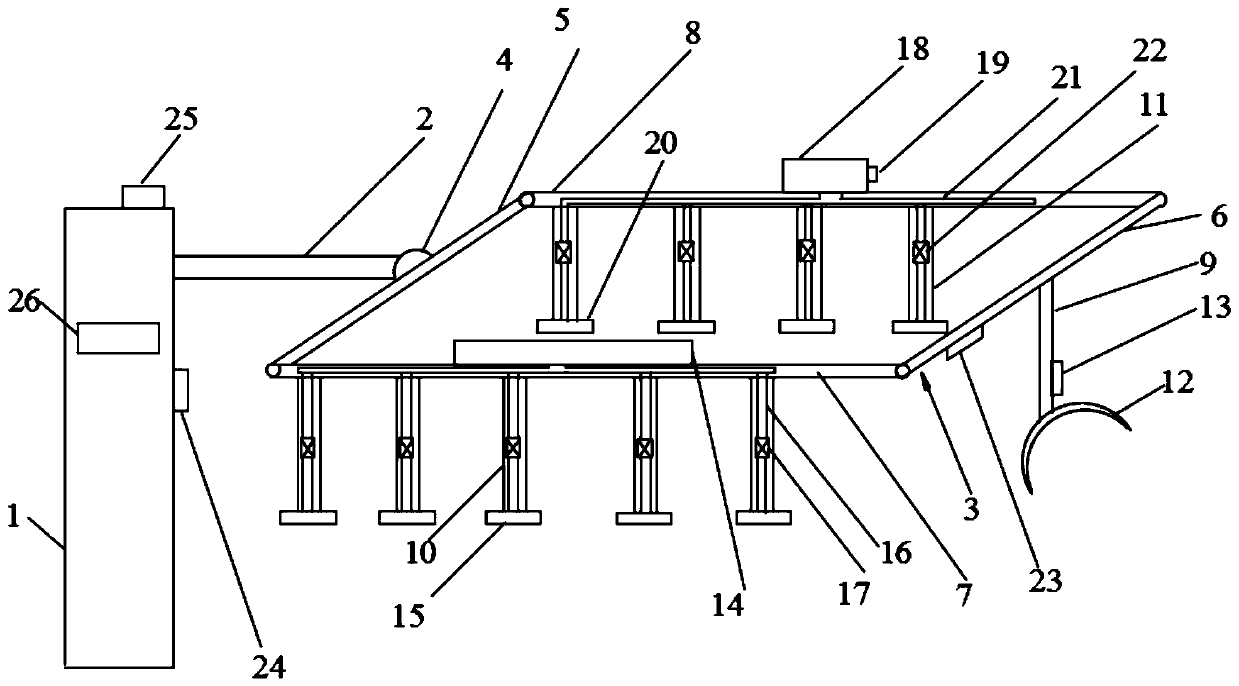

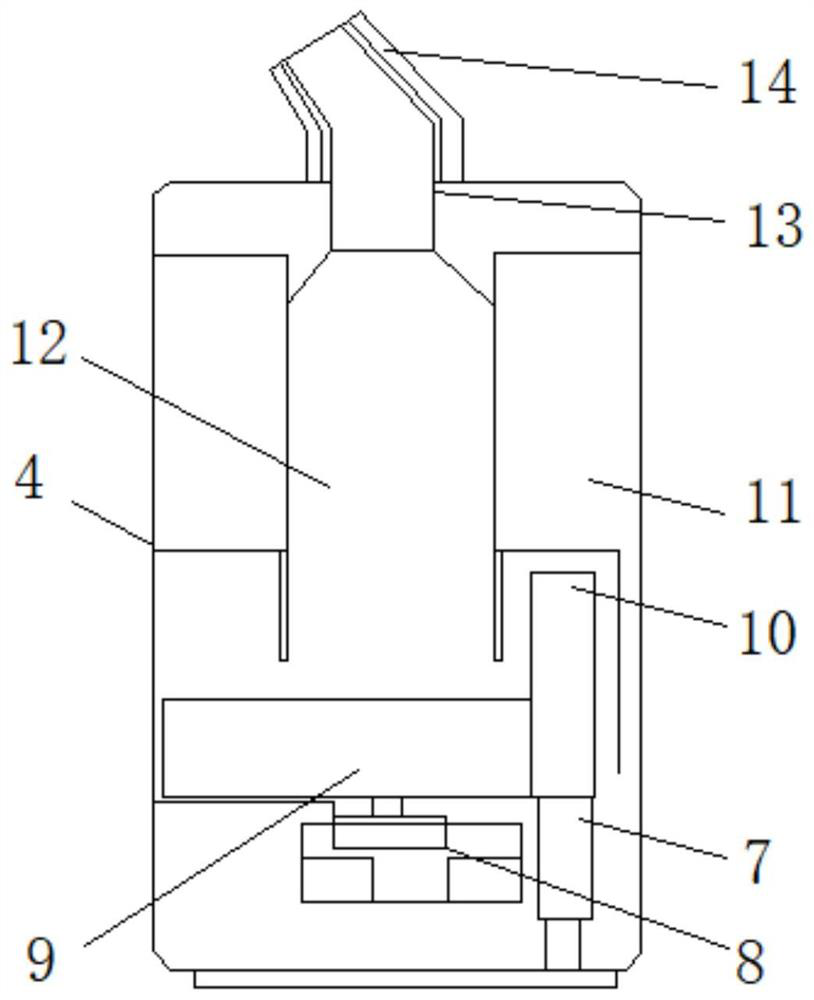

Emergency in-vitro cooling device

ActiveCN106859840AFast coolingGood cooling effectMedical applicatorsTherapeutic coolingSemiconductorIn vitro

The invention discloses an emergency in-vitro cooling device. The emergency in-vitro cooling device comprises a fixing base and a bracket, one side of the fixing base is connected with the bracket through a support rod, the bracket is rectangular, and cross rods and side rods of the bracket are provided with first branch rods, second branch rods and third branch rods respectively; each first branch rod is connected with an ice water bag, and each ice water bag is connected with a semiconductor refrigeration sheet; a first side rod is provided with a first container, each second branch rod is provided with a first wiping piece in a communicated mode, each first wiping piece is communicated with the first container through a first pipeline, and a first flow controller is arranged on each first pipeline; a second side rod is provided with a second container, the second container is connected with a thermostat, a second wiping piece is arranged on each third branch rod, each second wiping piece is communicated with the second container through a second pipeline, and a second flow controller is arranged on each second pipeline. According to the emergency in-vitro cooling device, a plurality of cooling modes and usage methods are integrated, and the device has the advantages of being convenient to use, good in cooling effect and suitable for different patients to use.

Owner:欧阳艳红

Colorful co-extruded plastic pipeline

InactiveCN104530600AImproved color durabilityOptimizing vacuum level and pulling speedSynthetic resin layered productsTubular articlesPolycarbonateCalcium carbonate

The invention discloses a colorful co-extruded plastic pipeline. The pipeline comprises a PVC base material and an ASA resin modified layer, wherein the ASA resin modified layer is prepared from the following components in percentage by mass: 5-45 percent of polycarbonate, 8-20 percent of PMMA, 0.1-0.4 percent of lubricant, 0.2-1.2 percent of dispersant, 0.4-0.8 percent of antioxidant, 0.25-0.7 percent of ultraviolet absorbent, 2-8 percent of pigment, 6-8 percent of calcium carbonate, 0.3-0.8 percent of silicon dioxide, 3-6 percent of stabilizer and the balance of ASA resin. The invention further discloses a particular method for compounding the PVC base material and the ASA resin modified layer by means of co-extrusion molding. The color durability of the colorful co-extruded plastic pipeline is greatly improved, and the prepared pipeline has uniform wall thickness and excellent surface performance.

Owner:LIAONING CHENGWEI PLASTIC PROFILE

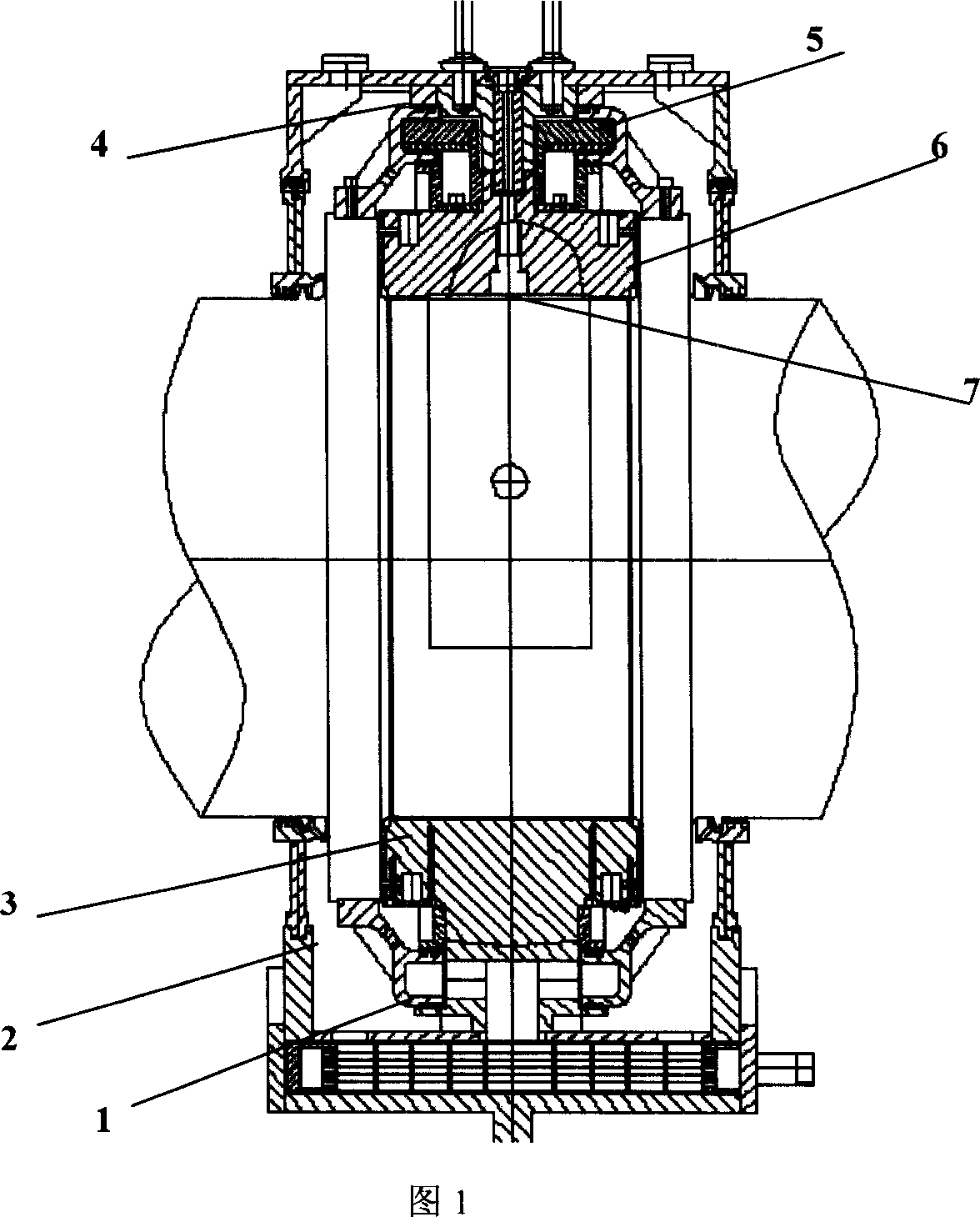

Large-sized sleeve bearing thrust-face reverse-lubricating and lubricating oil cooling method

The invention relates to a reverse lubrication for pushing face of huge journal bearing and the lubricating oil cooling method, belonging to the bearing technology area. In the invention, the lubricating oil carried by left impeller with oil thrower disc and oil scraping plate supplies to the right pushing face by left oil inlet channel, on the opposite hand, the lubricating oil carried by right impeller with oil thrower disc and oil scraping plate supplies to the left pushing face by right oil inlet channel. After bearing and pushing face are lubricated by the lubricating oil, the lubricating oil returns to the oil pool by oil return pipe and it is cooled by cooler effectively so as to ensure that the pushing face can obtain full lubrication and cooling to form continuous oil film under the condition that the bearing is inclined. The invention can ensure continuous stable lubrication with oil film is formed under the condition that the bearing is inclined so as to improve the stability of bearing and avoid the loss of huge equipments such as large ball mill, rotary kiln, ship propulsion motor and cooling machine so on, because of the bearing failure.

Owner:SHANGHAI JIAO TONG UNIV

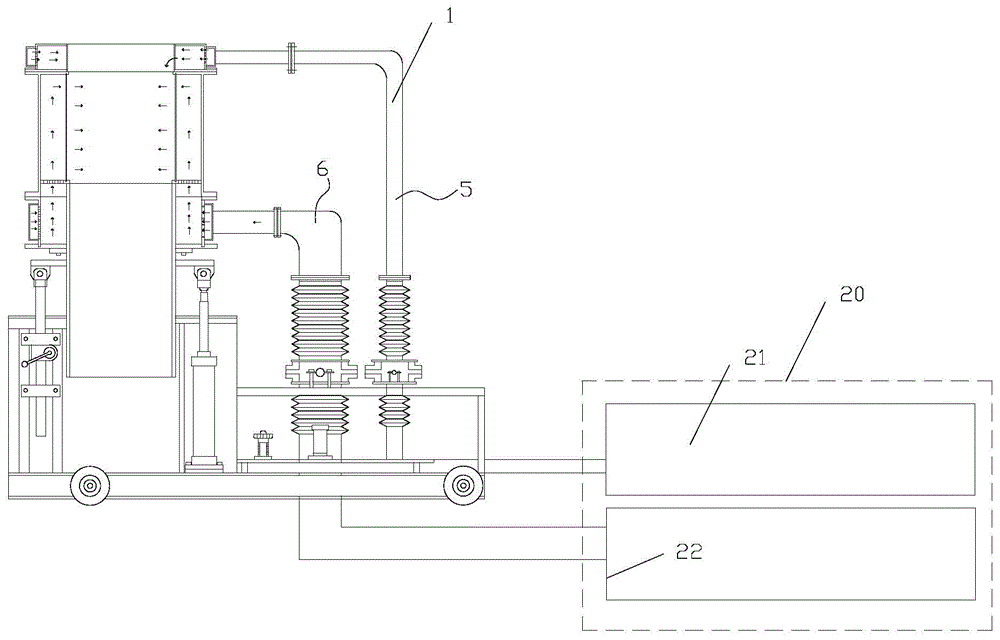

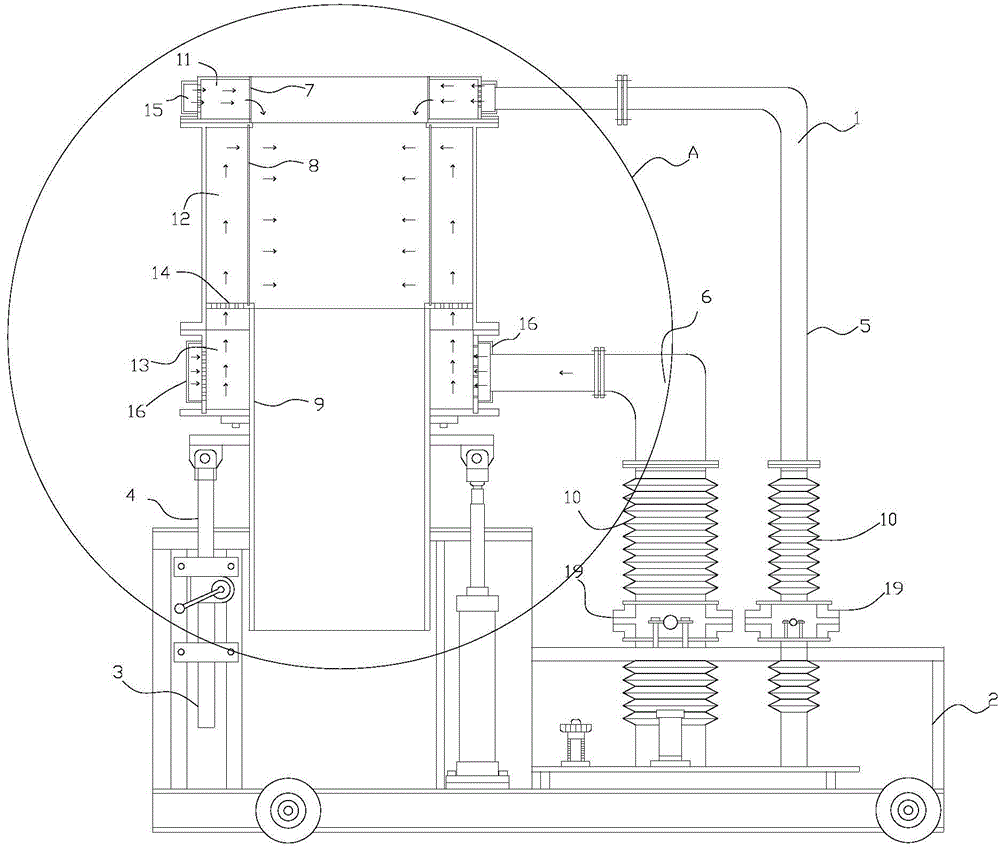

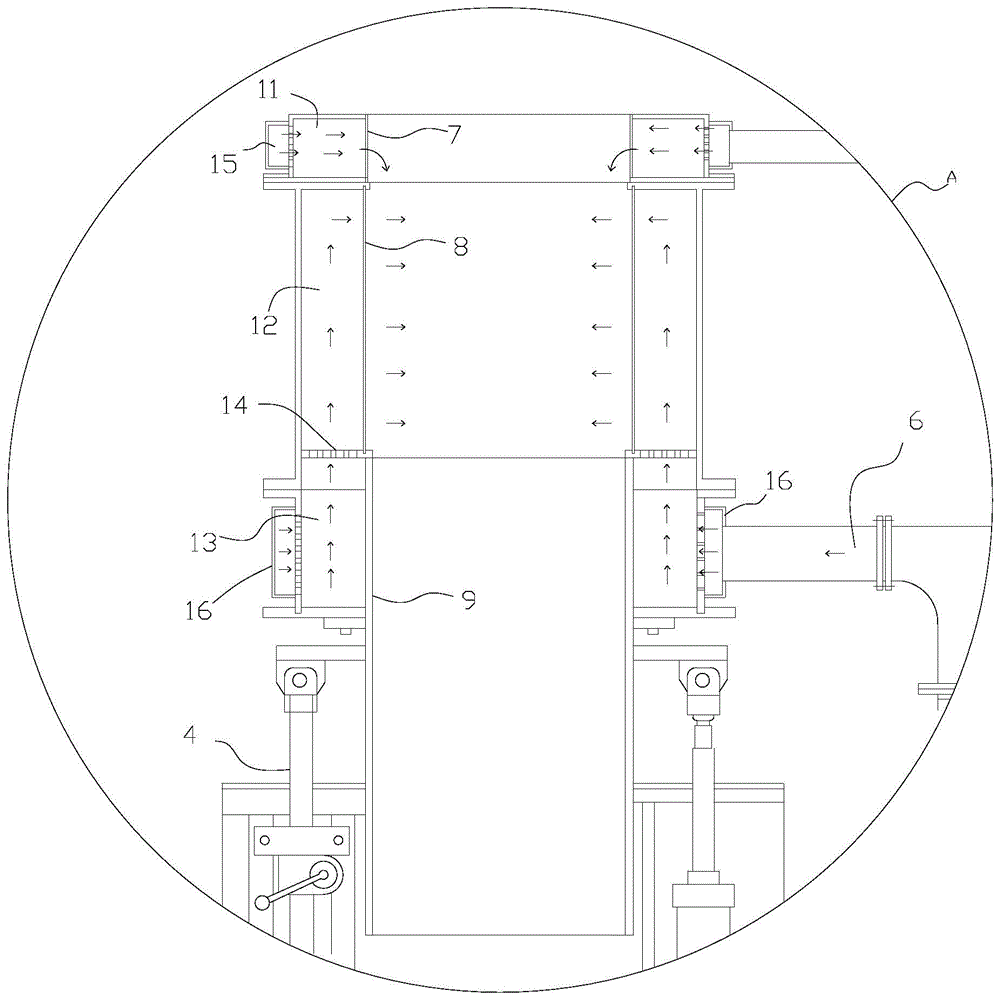

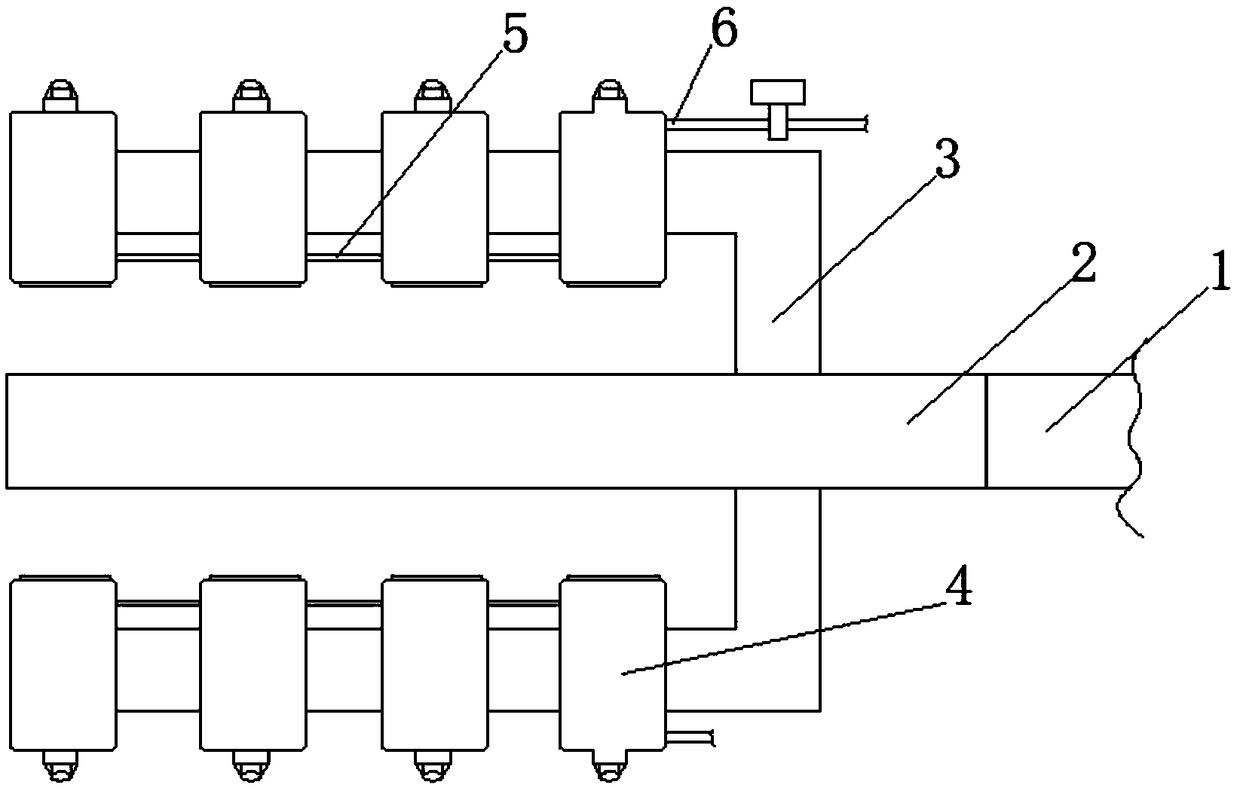

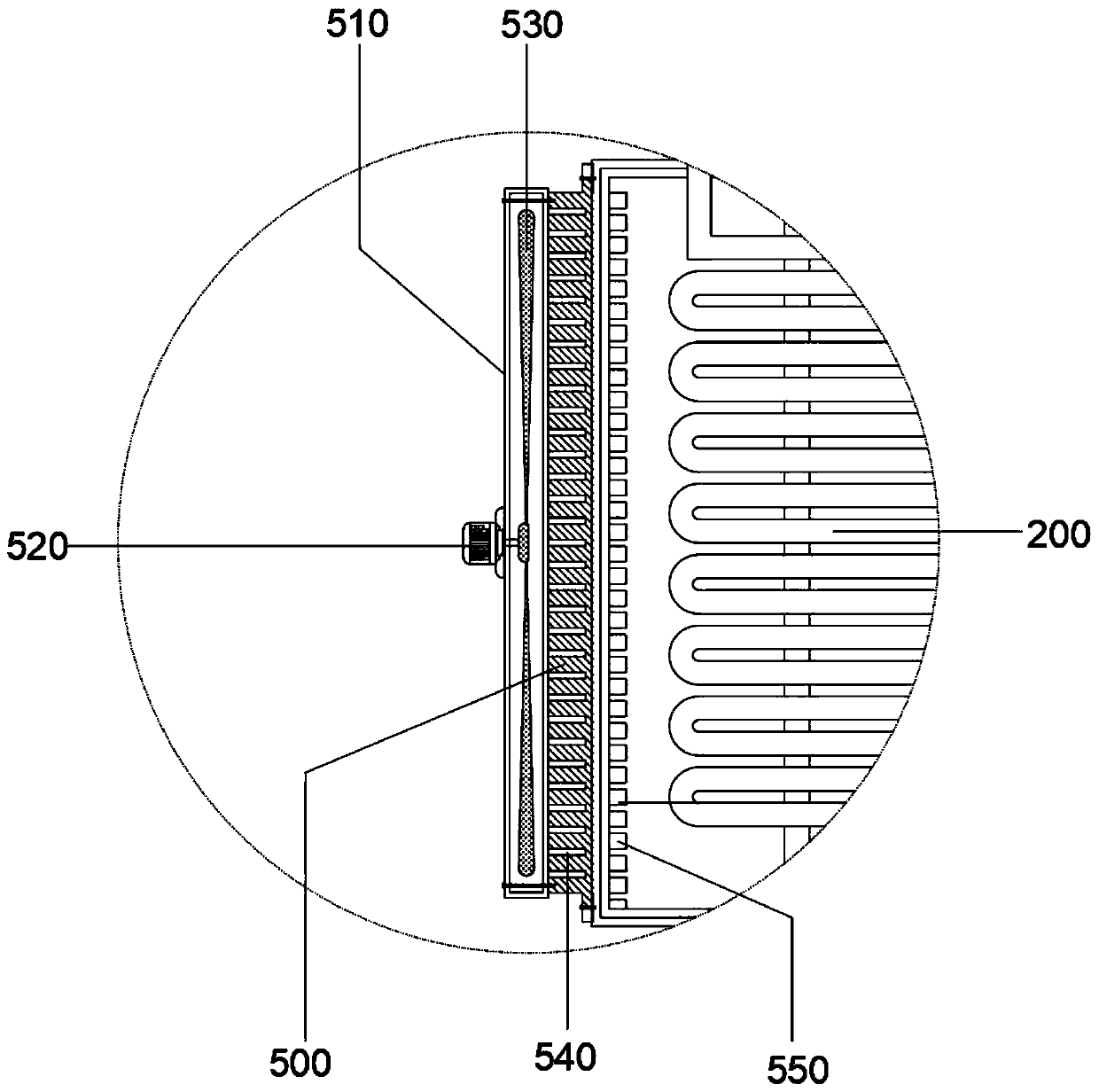

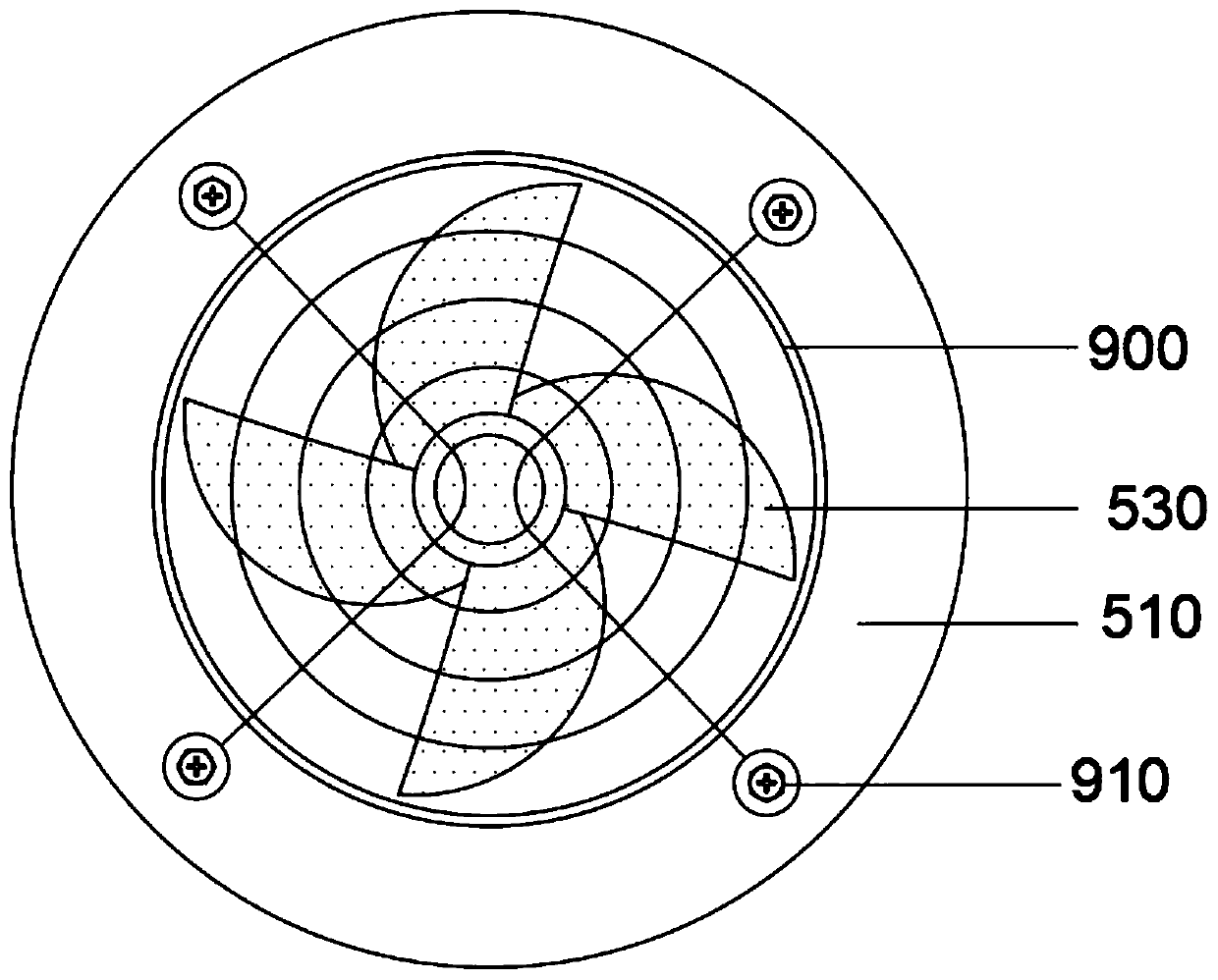

Circular blowing polyester spinning cooling device and method

The invention discloses a circular blowing polyester spinning cooling device. The device is composed of two parts, namely a blowing device and air-conditioning systems; the blowing device comprises a frame, a lifting cylinder, a lifting rod, a first air inlet pipe, a second air inlet pipe, a first air duct, a second air duct and a guide duct; a first annular cavity is arranged outside the first air duct, while a second annular cavity is arranged outside the second air duct and a third annular cavity is arranged outside the third guide duct; a first annular air equalizing cover is arranged outside the first annular cavity, while a second annular air equalizing cover is arranged outside the third annular cavity; the inlet pipeline of the first annular air equalizing cover is communicated with the first air inlet pipe; the inlet pipeline of the second annular air equalizing cover is communicated with the second air inlet pipe; the first air-conditioning system provides the first air inlet pipe with cooling air, while the second air-conditioning system provides the second air inlet pipe with cooling air. According to the circular blowing polyester spinning cooling device, a circular blowing cooling manner is adopted, air can be fed in each direction so that nascent fibers can be evenly cooled in each direction, and meanwhile, the upper and lower layers of circular blowing are evener, and the fiber cooling effect is good.

Owner:扬州天富龙集团股份有限公司

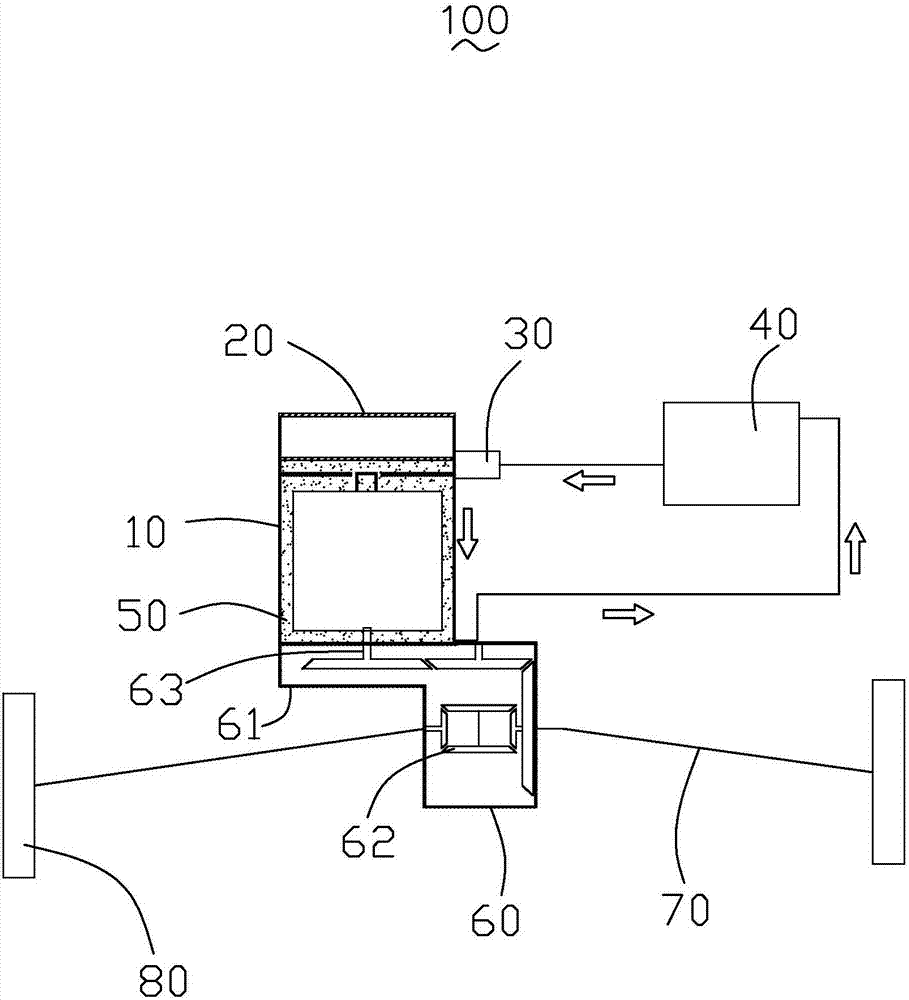

Power system cooling structure

PendingCN107284210AOptimize volumeOptimize cooling methodElectric propulsion mountingDrive motorCooling methods

A power system cooling structure comprises a driving motor, a motor controller, a pump, a radiator and cooling liquid. The driving motor comprises a motor inner shell and a motor outer shell, and the motor outer shell sleeves the motor inner shell and forms a first liquid cooling cavity for circulating the cooling liquid. The motor controller comprises a motor controller shell and a partition plate held in the motor controller shell. The motor controller shell is divided into a controller holding cavity and a second liquid cooling cavity by the partition plate, and the first liquid cooling cavity is communicated with the second liquid cooling cavity. The cooling liquid flows into the second liquid cooling cavity of the motor controller from the pump, flows into the first liquid cooling cavity of the driving motor, flows out to the radiator and then flows back to the pump. The power system cooling structure optimizes the size and the cooling mode of a power system, so that the system is light in weight, and the cooling capacity of the system is improved.

Owner:JIANGSU ENE CARBON ENERGY TECH CO LTD

High-carbon and high-boron wear resistant steel for impeller

The invention discloses high-carbon and high-boron wear resistant steel for an impeller. The wear resistant steel comprises the following components in percentage by mass: 0.65-1.0% of C, 0 / 3-0.8% of Si, 1.0-1.5% of Mn, 1.0-2.0% of Cr, 0.4-0.8% of B, 0-0.04% of P, 0-0.04% of S, 0.05-0.2% of Ti, and the balance of Fe. The wear resistant steel is prepared by the following steps: (S1) all raw materials are weighed by the mass percentages, and are cast to form after being smelted to obtain a semi-finished wear resistant steel; (S2) the semi-finished wear resistant steel obtained in the step (S1) is put in a furnace to heat up to the temperature of 270-290 DEG C; after the temperature of 270-290 DEG C is kept for 115-125 min, the temperature is increased to the temperature of 640-670 DEG C; after the temperature of 640-670 DEG C is kept for 230-250 min, the temperature is increased to the temperature of 1000-1100 DEG C; after the temperature of 1000-1100 DEG C is kept for 200-220 min, the oil quenching is performed in quenching oil with the oil temperature of 110-130 DEG C; the quenching time is 12-15 min; the temperature from the room temperature to 100 DEG C is increased to the temperature of 375-385 DEG C by the heating speed of 20-100 DEG C / h in a heat insulating furnace after the oil quenching; after the temperature of 375-385 DEG C is kept for 470-490 min, the temperature is slowly decreased to the room temperature by 470-490 min; and then, the wear resistant steel is obtained. The wear resistant steel has good comprehensive performance.

Owner:宁国东方碾磨材料股份有限公司

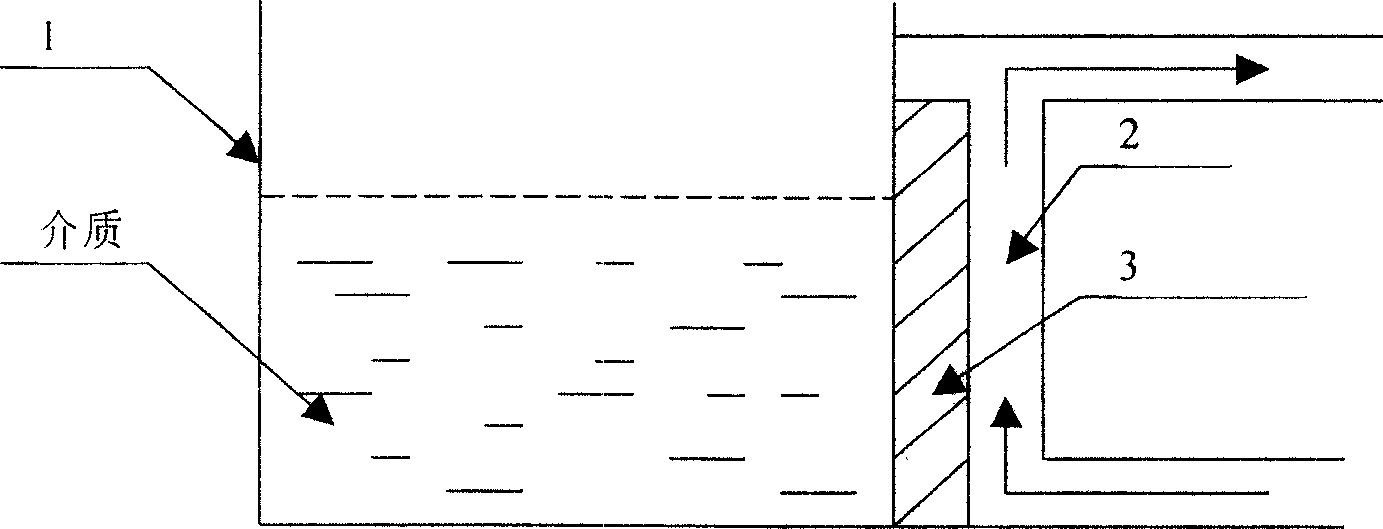

High-temp. high-melting-point liquid medium cooling method

InactiveCN1710361ATo achieve the purpose of cooling mediumOptimize cooling methodDomestic cooling apparatusLighting and heating apparatusLiquid mediumNuclear engineering

A cooling method of liquid media with high temperature and high melting point includes integrating heat exchanging device at outer wall of media container intensively and applying forced cooling air to achieve purpose of cooling the media. It is a safe and high efficient cooling method as neither media is circulated nor water cooling is applied.

Owner:JIANGSU WANLI MACHINERY

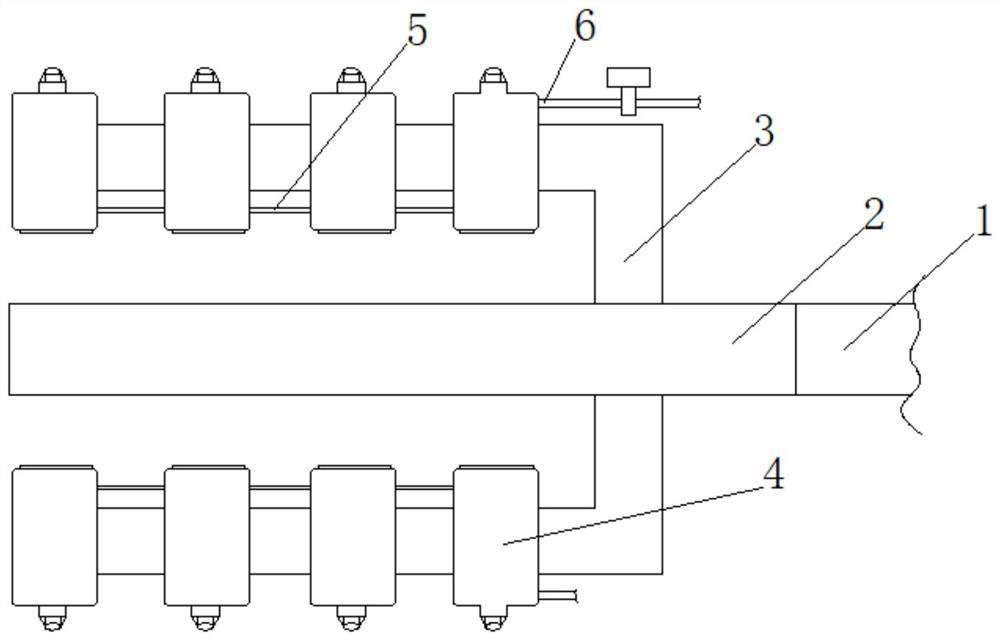

Liquid atomizing micro-dust introducing device for cooling and cleaning fan

ActiveCN109297118AChange the cooling methodOptimize cooling methodPump componentsLighting and heating apparatusTemperature controlEngineering

The invention discloses a liquid atomizing micro-dust introducing device for cooling and cleaning a fan, and belongs to the technical field of fans for workshop cooling. The liquid atomizing micro-dust introducing device for cooling and cleaning of the fan comprises a fan rotating shaft rod, a heat island control temperature and humidity heat conduction rod is fixedly connected to the left end ofthe fan rotating shaft rod, the rear end of the heat island control temperature and humidity heat conduction rod is fixedly connected with an auxiliary epitaxial temperature control heat transfer pipe, and the auxiliary epitaxial temperature control heat transfer pipe is connected with a plurality of heat island cooling liquid transferring devices in a sleeved mode; and the heat island cooling liquid transferring devices are fixedly connected with the auxiliary epitaxial temperature control heat transfer pipe, a liquid guide circulating water pipe is fixedly connected to the right end of the heat island cooling liquid transferring device at the rightmost side, the liquid guide circulating water pipe is fixedly connected with an external water pipe, and a circulating liquid conveying waterpipe is fixedly connected among the different heat island cooling liquid transferring devices. Changing of a cooling mode of the fan while the fan is cooled can be realized, air cooling inside a workshop and outside the workshop is completed, and the ventilation and cooling mode of the fan are greatly improved.

Owner:池州海琳服装有限公司

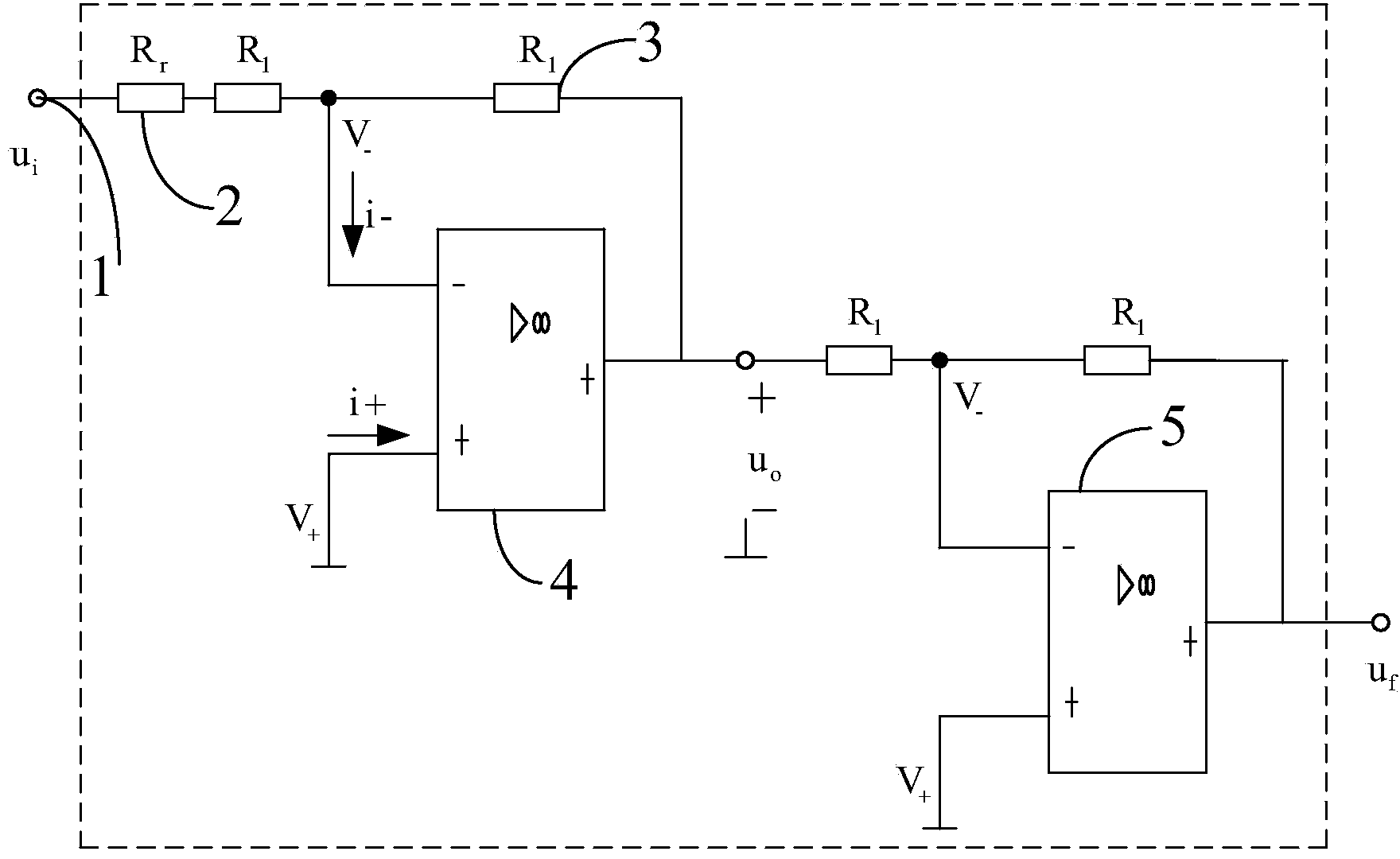

Self-adapting air cooling controller of transformer

InactiveCN104235046AOptimize cooling methodShort lifeTransformers/inductances coolingPump controlNegative temperatureAudio power amplifier

The invention discloses a self-adapting air cooling controller of a transformer. An external power supply of the controller is connected with a negative temperature coefficient thermistor; the negative temperature coefficient thermistor is connected with a first operational amplifier; the first operational amplifier is connected with a second operational amplifier. The negative temperature coefficient thermistor and the operational amplifiers are utilized to constitute a self-adapting controller, so that the rotation speed of a transformer fan is controlled, and when the temperature raises, the rotation speed is increased, so that heat dissipation is quickened; when the temperature decreases, the rotation speed is correspondingly reduced, so that the cooling mode of the transformer is optimized; and furthermore, resources are saved, the service lives of the transformer and the fan are prolonged. The self-adapting air cooling controller is only applicable to an air-cooled transformer and can be used for controlling the heat dissipation speed of the air-cooled transformer.

Owner:STATE GRID CORP OF CHINA +1

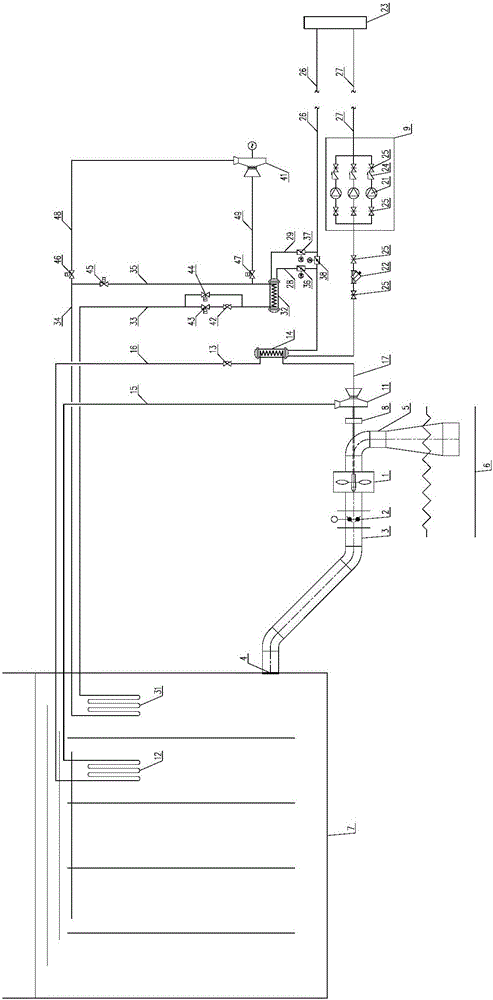

Recycling device for thermal power station tail water and utilizing method

ActiveCN106052174AImprove water managementImprove water qualityCompression machines with non-reversible cycleMachines/enginesRefrigeration compressorWater use

The invention discloses a recycling device for thermal power station tail water and a utilizing method. The recycling device for the thermal power station tail water is characterized in that a refrigerating compressor (11) is directly driven through a water turbine (1); a first condenser (12) and a second condenser (13) in a refrigerating cycle system are arranged in a pressure forebay (7) and are cooled by water; a natural refrigerating manner is adopted for a second evaporator (32) in winter, and a mechanical refrigerating manner is adopted for the second evaporator (32) in summer and transition seasons; the first refrigerating compressor (11), a second air pipe (17), a first evaporator (14), a first expansion valve (13), a first liquid pipe (16), the first condenser (12) and a first air pipe (15) are sequentially connected in series; and the first evaporator (14), a chilled water returning pipe (26), an auxiliary machine equipment cooling water system (23), a chilled water supplying pipe (27), a pump set (9) and a water filter (22) are sequentially connected in series. Compared with the prior art, the recycling device has the beneficial effects of cyclic water use, cascading water use and multiple purposes of one kind of water are achieved.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

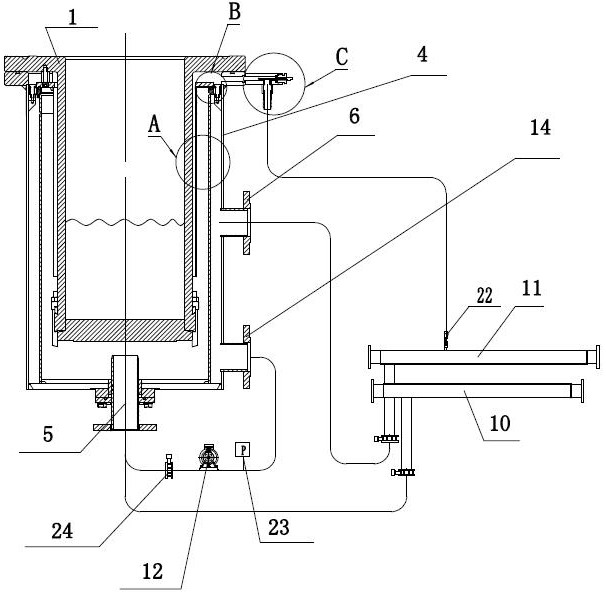

Supplementary combustion chamber of supercritical pressure gas-liquid fuel generator

The invention provides a supplementary combustion chamber of a supercritical pressure gas-liquid fuel generator, and relates to oil extraction equipment in an oil field. The supplementary combustion chamber is characterized by comprising a pre-combustion chamber (6), a secondary combustion chamber (10) and a vaporizing chamber (14). A spouting mode of fuel of the supplementary combustion chamber is as follows: the pre-combustion chamber (6) only sprays part of the fuel and full air for oxygen-enriched combustion; the remaining fuel is sprayed into the secondary combustion chamber (10) from a supplementary combustion inspirator and completely combusted with oxygen-enriched gas from the pre-combustion chamber in the secondary combustion chamber (10). By the combustion chamber, simultaneous combustion of gas fuel and liquid fuel is realized, and heat transfer deterioration is prevented due to various cooling modes.

Owner:刘殿玺 +2

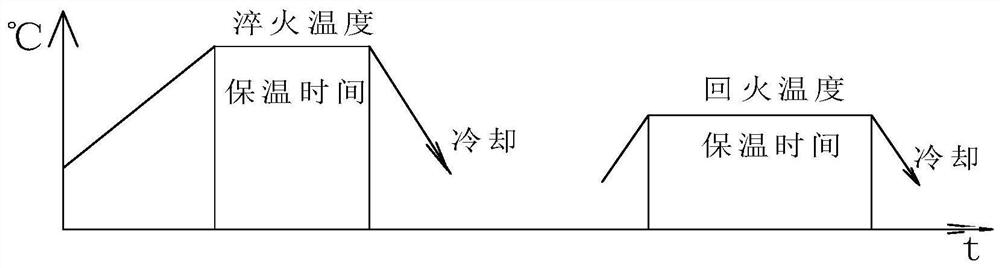

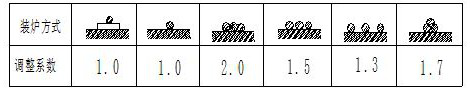

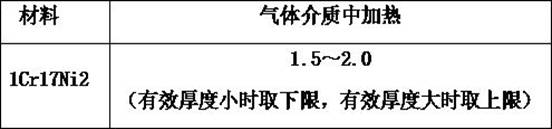

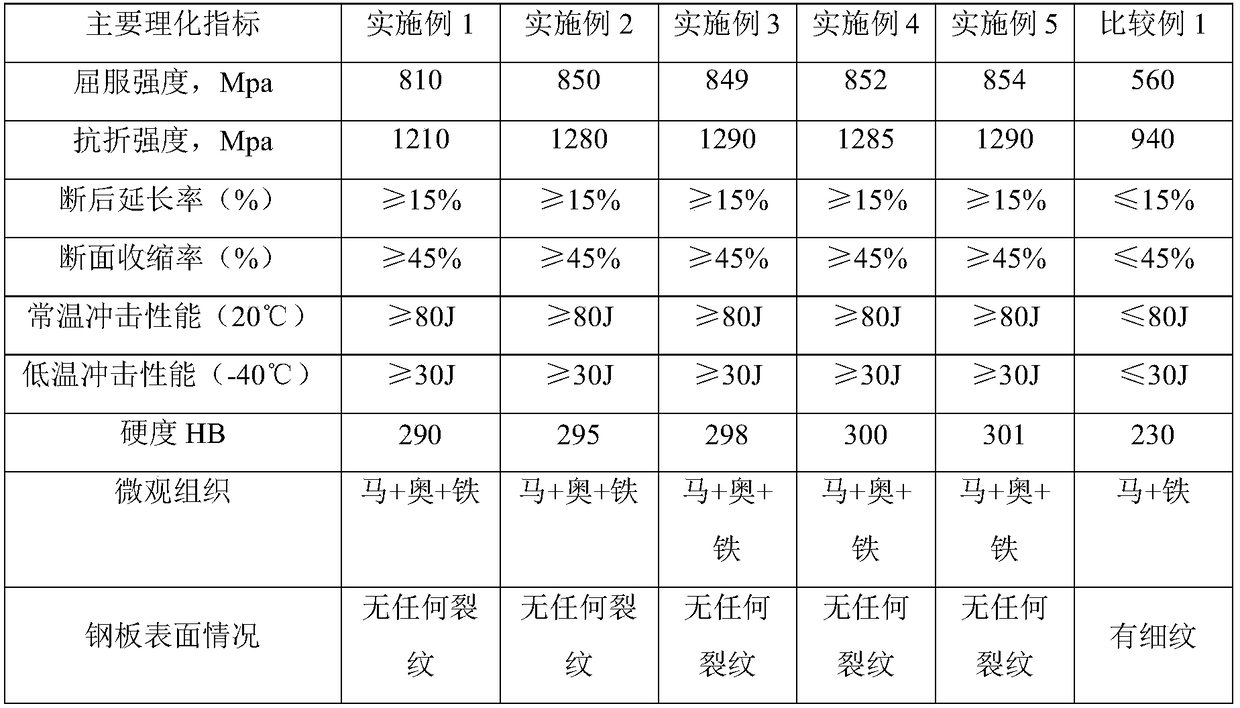

1Cr17Ni2 stainless steel screw and heat treatment process thereof

InactiveCN112609124AImprove mechanical propertiesAvoid pollutionFurnace typesQuenching agentsMartensite transformationWater use

The invention relates to a heat treatment process development and improvement method of a martensitic stainless steel 1Cr17Ni2 screw. The process comprises a charging procedure, a quenching procedure, a quenching cooling procedure and a tempering and tempering cooling procedure. According to the heat treatment process method, by improving heat treatment process parameters such as the quenching temperature, the tempering temperature and the quenching medium, the quenching temperature and the tempering temperature are greatly reduced, original oil medium quenching is changed into F2000 water-based liquid quenching, the using temperature of water-based liquid is strictly controlled, an austenitized workpiece is rapidly immersed into the water-based liquid to be cooled, and accordingly, martensite transformation is achieved. According to the process, the mechanical property index of 1Cr17Ni2 material products is improved, the one-time qualification rate is greatly increased and reaches 98% or above, due to the fact that the quenching temperature and the tempering temperature are greatly reduced, the electricity consumption cost is greatly reduced, the problem that original heat treatment parts are directly scrapped and cannot be produced due to cracks generated on the surfaces is solved, and performance indexes meet the requirements of design drawings after the process is improved. The water-based liquid is used for cooling, so that environmental pollution is avoided, and the medium consumption cost is reduced.

Owner:CSSC NANJING LUZHOU MACHINE

Heat treatment method for 35CrMo steel

The invention provides a heat treatment method for 35CrMo steel. The method comprises steps as follows: (A) an alloy is subjected to heat treatment between 800 DEG C and 850 DEG C for 2-5 h, is subjected to water cooling for 40-60 s and is immersed in oil for cooling; (B) the alloy is subjected to heat treatment between 600 DEG C and 650 DEG C for 4-30 h and is subjected to natural air cooling, and then heat treatment is completed. By the aid of the heat treatment method for the 35CrMo steel, the traditional heat treatment technology is optimized, the quenching temperature is adjusted, the cooling manner after normalization and quenching is optimized, the stress inside a workpiece is eliminated with the heat treatment method, the crystal structure inside the workpiece is stable, the hardness is moderate, the problem that the steel is prone to cracking is solved thoroughly, the method is easy to operate, the operation process is environment-friendly, the two steps are closely connected,the referable specific method is provided for subsequent operation, and the heat treatment method is relatively excellent.

Owner:SICHUAN YIHENG MACHINERY MFG CO LTD

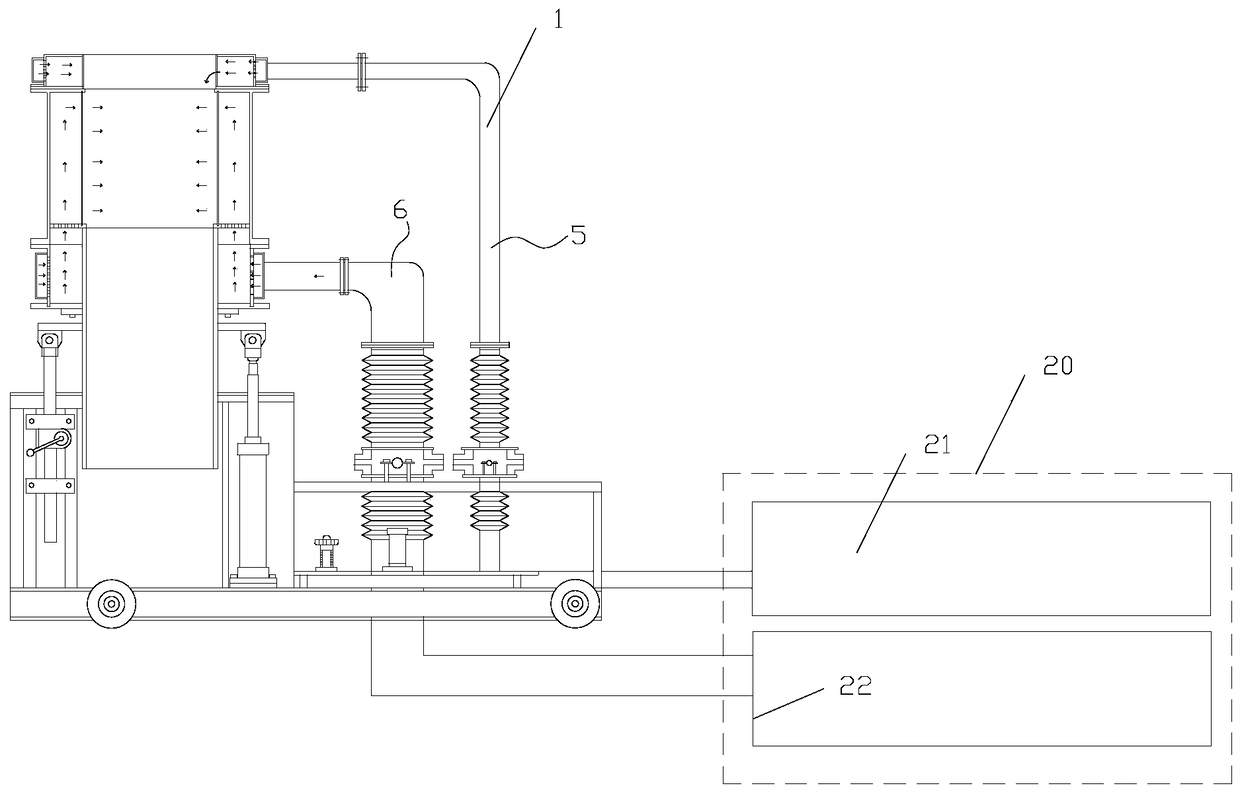

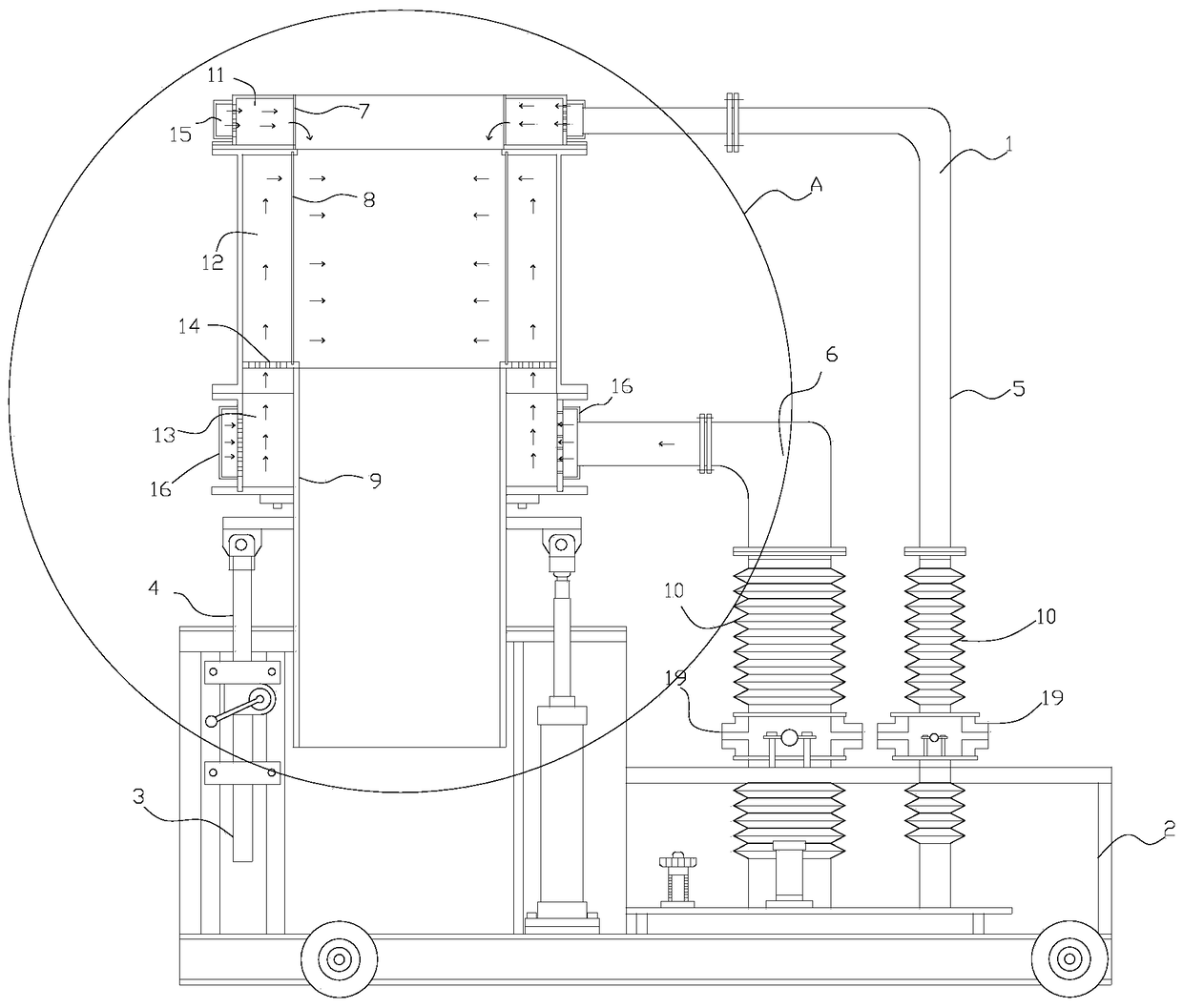

A cooling device and method for spinning polyester with ring blowing

The invention discloses a circular blowing polyester spinning cooling device. The device is composed of two parts, namely a blowing device and air-conditioning systems; the blowing device comprises a frame, a lifting cylinder, a lifting rod, a first air inlet pipe, a second air inlet pipe, a first air duct, a second air duct and a guide duct; a first annular cavity is arranged outside the first air duct, while a second annular cavity is arranged outside the second air duct and a third annular cavity is arranged outside the third guide duct; a first annular air equalizing cover is arranged outside the first annular cavity, while a second annular air equalizing cover is arranged outside the third annular cavity; the inlet pipeline of the first annular air equalizing cover is communicated with the first air inlet pipe; the inlet pipeline of the second annular air equalizing cover is communicated with the second air inlet pipe; the first air-conditioning system provides the first air inlet pipe with cooling air, while the second air-conditioning system provides the second air inlet pipe with cooling air. According to the circular blowing polyester spinning cooling device, a circular blowing cooling manner is adopted, air can be fed in each direction so that nascent fibers can be evenly cooled in each direction, and meanwhile, the upper and lower layers of circular blowing are evener, and the fiber cooling effect is good.

Owner:扬州天富龙集团股份有限公司

Process method for eliminating aluminum skimmings on surface of continuously extruded aluminum alloy flat tube

PendingCN113290068AGood casting performanceFavorable extrusion fluidityExtrusion control devicesExtrusion cleaning devicesMaterials scienceMetal

The invention relates to a process method for eliminating aluminum skimmings on the surface of a continuously extruded aluminum alloy flat tube. The process method comprises the following steps that aluminum alloy components are optimized, so that aluminum alloy components comprise 0.09-0.12% of Cu, 0.03-0.05% of Si, 0.12-0.17% of Fe, the ratio of Fe to Si is greater than or equal to 3, 0.006-0.0075% of Ti, 0.045-0.055% of Ce and La mixed rare earth and the balance A so as to improve the casting performance and the structure uniformity of an aluminum rod; and meanwhile, a refining process of adding rare earth in a furnace and adding aluminum-titanium-boron wires on line is combined, so that the looseness of the aluminum rod is ensured to reach grade 1. Ultrahigh-speed online homogenizing heat treatment is adopted, so that chemical components of the aluminum rod are homogenized within an extremely short time, and intragranular segregation is eliminated. While the fluidity of metal is improved, extrusion process parameters are optimized, a mold cooling process is changed, it is guaranteed that the extrusion temperature fluctuation is within the minimum range, and constant-temperature extrusion is achieved; and after a product is formed, the surface of the flat tube is subjected to online treatment, and finally the technical purposes of eliminating aluminum skimmings on the surface of the aluminum flat tube, reducing indentation defects and the like are achieved.

Owner:湖南恒佳新材料科技有限公司

An emergency external cooling device

ActiveCN106859840BFlexible usageSave spaceMedical applicatorsTherapeutic coolingIce waterCooling effect

Owner:欧阳艳红

High-toughness high-abrasion resistance metallic material for sports equipment and preparation method thereof

The invention discloses a high-toughness high-abrasion resistance metallic material for sports equipment. The high-toughness high-abrasion resistance metallic material comprises the following raw materials by weight percent: 0.5 to 2.3% of C, 0.1 to 0.7% of Si, 0.2 to 2.6% of Mn, 17 to 23% of Cr, 0.15 to 0.25% of N, 0 to 0.05% of P, 0 to 0.05% of S, 0.13 to 0.16% of Al, 0.18 to 0.25% of Mo, 0.2 to 1.0% of Y and 0.02 to 0.12% of Nb, and the balance being Fe. The invention further discloses a preparation method of the high-toughness high-abrasion resistance metallic material for sports equipment. The high-toughness high-abrasion resistance metallic material for sports equipment is obtained through adopting a three-step temperature increasing method and quenching and controlling the temperature increasing and temperature decreasing speeds, a product is good in abrasion resistance, high in rigidity and excellent in comprehensive performance, and the operation is easy and feasible.

Owner:芜湖地心引力运动科技有限公司

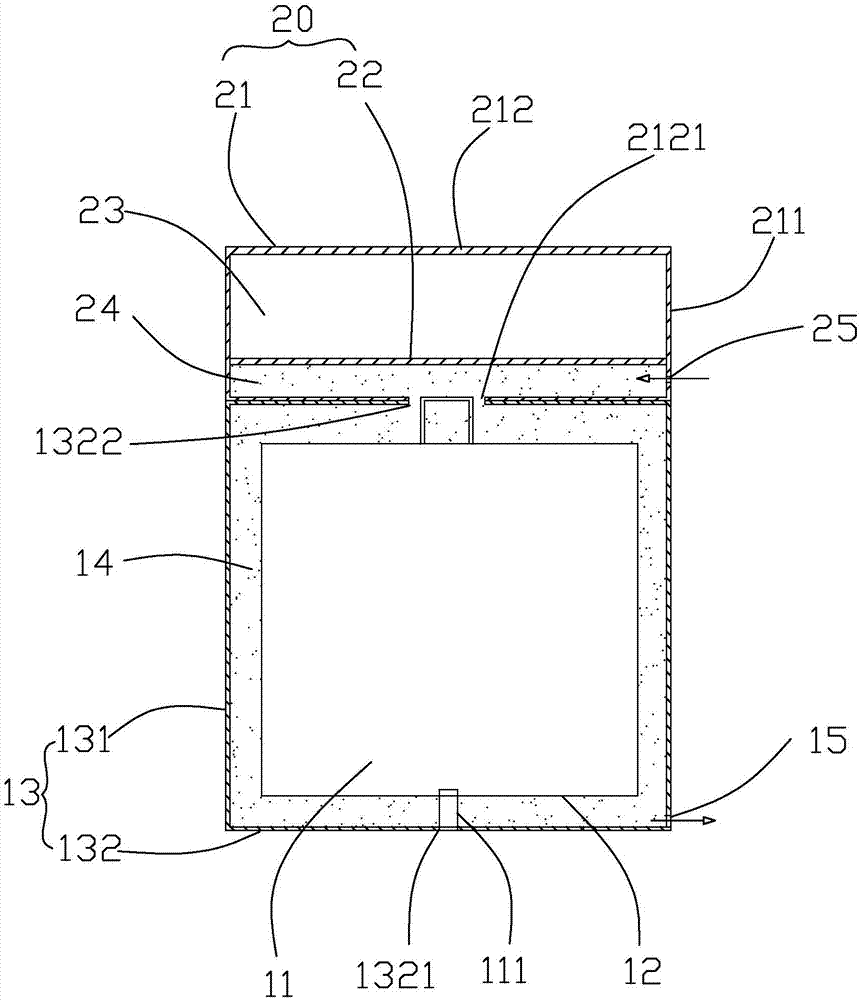

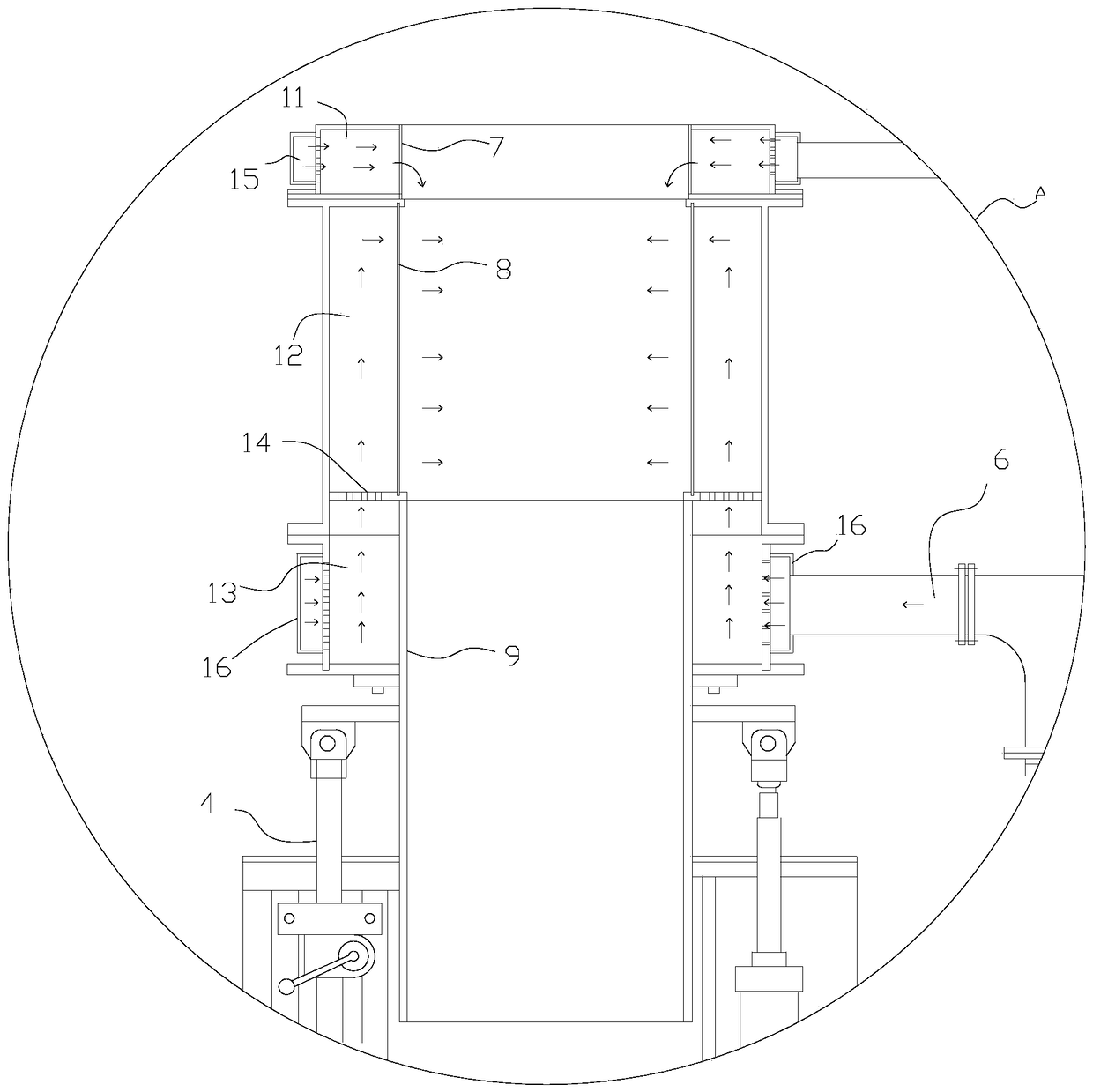

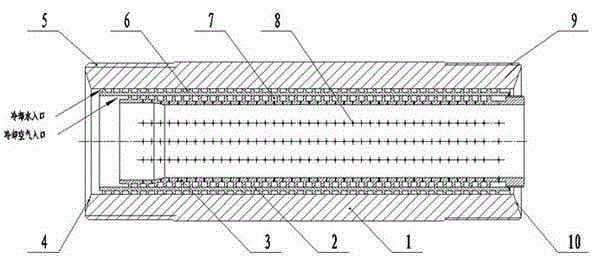

Vacuum consumable electrode furnace crystallizer cooling device and cooling method thereof

ActiveCN114705041AOptimize structureOptimize cooling methodIncreasing energy efficiencyCrucible furnacesCrystalliteEngineering

The invention relates to the technical field of metallurgical equipment, in particular to a vacuum consumable electrode furnace crystallizer cooling device and a cooling method thereof. The crystallizer comprises a crucible, a waterproof sleeve, a water distribution sleeve and a crystallizer shell are sequentially arranged on the outer wall of the crucible from inside to outside, a water inlet layer is arranged between the outer wall of the crucible and the waterproof sleeve, a water storage layer is arranged between the waterproof sleeve and the water distribution sleeve, and a water return layer is arranged between the water distribution sleeve and the crystallizer shell; a water inlet is formed in the lower part of the crucible and is connected with a water inlet and outlet; and one end of a water return port of the water return layer is arranged on the crystallizer shell, and the other end of the water return port is connected with a water return inlet. According to the vacuum self-consuming furnace crystallizer cooling device and the cooling method thereof, when molten metal in the crucible is crystallized, crystal grains are finer, arrangement is more regular, and the metallographic structure of a metal ingot is more uniform.

Owner:SHENYANG VACUUM TECH INST

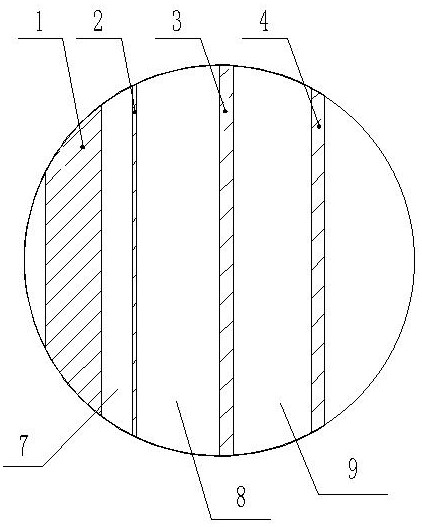

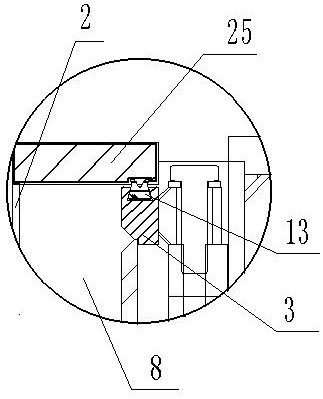

Afterburning-type supercritical-pressure gas-liquid fuel-generator combustion-chamber redundancy-cooling device

ActiveCN102287854BAvoid Heat Transfer DeteriorationSolve the problem of inner lining burningContinuous combustion chamberCombustion chamberSpray nozzle

The invention relates to an afterburning-type supercritical-pressure gas-liquid fuel-generator combustion-chamber redundancy-cooling device, which relates to oilfield oil-production equipment and comprises a precombustion-chamber shell (1), a precombustion-chamber middle lining (2) and a precombustion-chamber inside lining (3). A water-cooling sleeve (6) is formed between the precombustion-chamber shell (1) and the middle lining (2), an air-cooling sleeve (7) is formed between the precombustion-chamber middle lining (2) and the inside lining (3), the inner wall of the air-cooling sleeve is provided with a plurality of tangential air nozzles (8), and air is sprayed out from the nozzles (8) and contacted with the surface of fuel gas on the inside lining to form a continuous air film to coola precombustion chamber. Cooling water is forced to flow through the water-cooling sleeve (6) to carry out regenerative cooling for the heated air in the air-cooling sleeve and implement redundancy cooling for the high-temperature fuel gas. In the invention, the burning-loss and damage problems of the inside lining of a steam-injecting generator are solved by a method of improving an equipment structure and a cooling mode.

Owner:关兵 +2

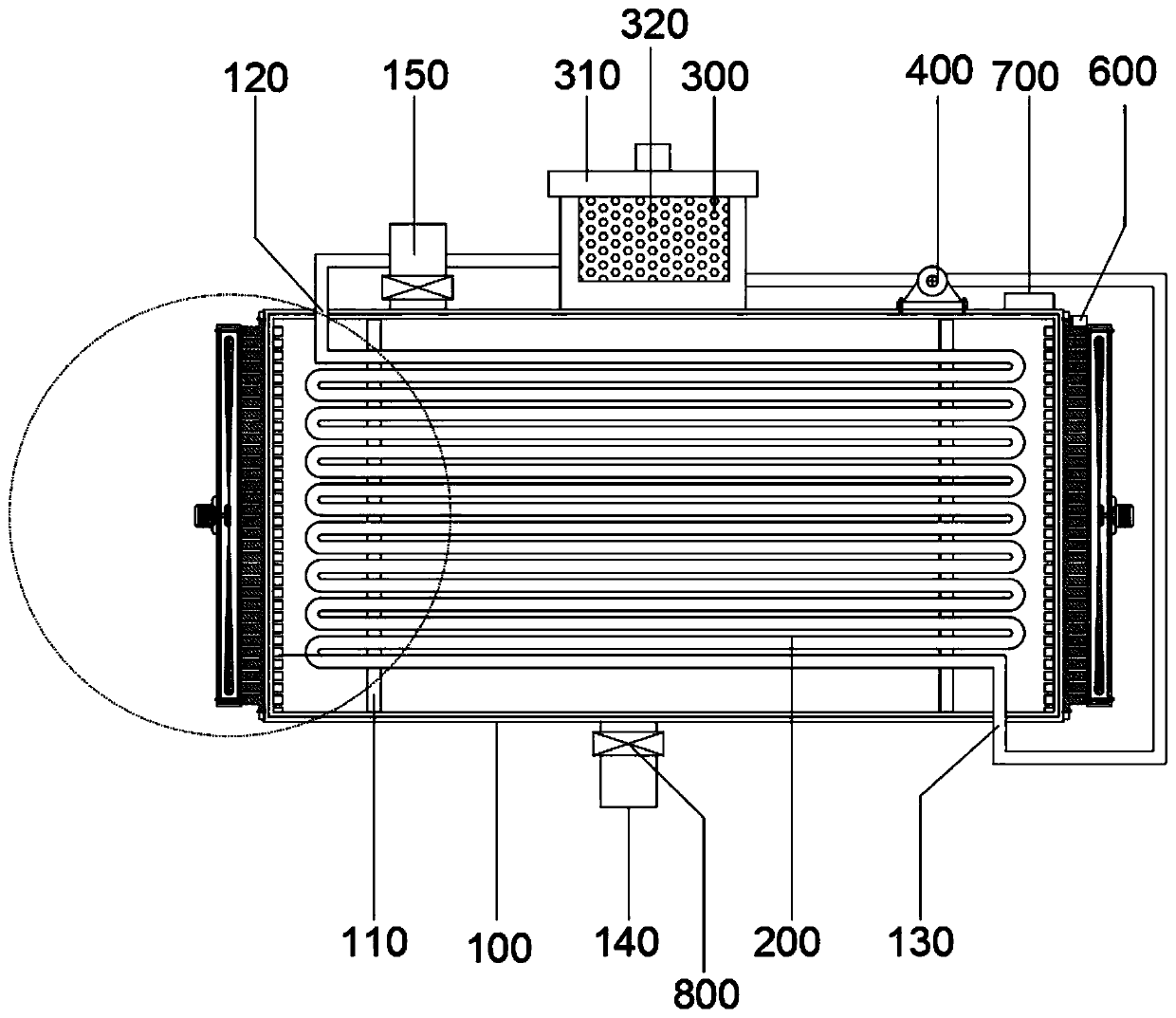

Hybrid internal combustion engine cooler

PendingCN110173334AControl accurate timeEffective diffusionLiquid coolingMachines/enginesCombustionExternal combustion engine

The invention belongs to the technical field of internal combustion engines and particularly relates to a hybrid internal combustion engine cooler. The hybrid internal combustion engine cooler comprises a casing, a U-shaped pipe, a coolant filling tank, a circulation pump, a heat dissipation plate, a temperature sensor, a controller and control valves. Mounting brackets are symmetrically mounted on the left and right sides of the inner wall of the casing, and a liquid inlet pipe is inserted into the top left side of the casing. A liquid outlet pipe is inserted into the right side of the bottomof the casing. The U-shaped pipe is fixedly mounted on the two mounting brackets. The mounting brackets are welded to the top end of the U-shaped pipe. The liquid inlet pipe is welded to the bottom end of the U-shaped pipe. A water inlet pipe is arranged on the left side of the top of the casing. A drainage pipe is arranged at the center of the bottom of the casing. The control valves are correspondingly screwed to the drainage pipe and the water inlet pipe. By the adoption of the hybrid internal combustion engine cooler, the comprehensive effects of improving the cooling efficiency and precisely controlling the cooling time are achieved.

Owner:JILIN UNIV

A liquid atomized fine dust feeding device for fan cooling and cleaning

ActiveCN109297118BChange the cooling methodOptimize cooling methodPump componentsLighting and heating apparatusTemperature controlEngineering

The invention discloses a liquid atomizing micro-dust introducing device for cooling and cleaning a fan, and belongs to the technical field of fans for workshop cooling. The liquid atomizing micro-dust introducing device for cooling and cleaning of the fan comprises a fan rotating shaft rod, a heat island control temperature and humidity heat conduction rod is fixedly connected to the left end ofthe fan rotating shaft rod, the rear end of the heat island control temperature and humidity heat conduction rod is fixedly connected with an auxiliary epitaxial temperature control heat transfer pipe, and the auxiliary epitaxial temperature control heat transfer pipe is connected with a plurality of heat island cooling liquid transferring devices in a sleeved mode; and the heat island cooling liquid transferring devices are fixedly connected with the auxiliary epitaxial temperature control heat transfer pipe, a liquid guide circulating water pipe is fixedly connected to the right end of the heat island cooling liquid transferring device at the rightmost side, the liquid guide circulating water pipe is fixedly connected with an external water pipe, and a circulating liquid conveying waterpipe is fixedly connected among the different heat island cooling liquid transferring devices. Changing of a cooling mode of the fan while the fan is cooled can be realized, air cooling inside a workshop and outside the workshop is completed, and the ventilation and cooling mode of the fan are greatly improved.

Owner:池州海琳服装有限公司

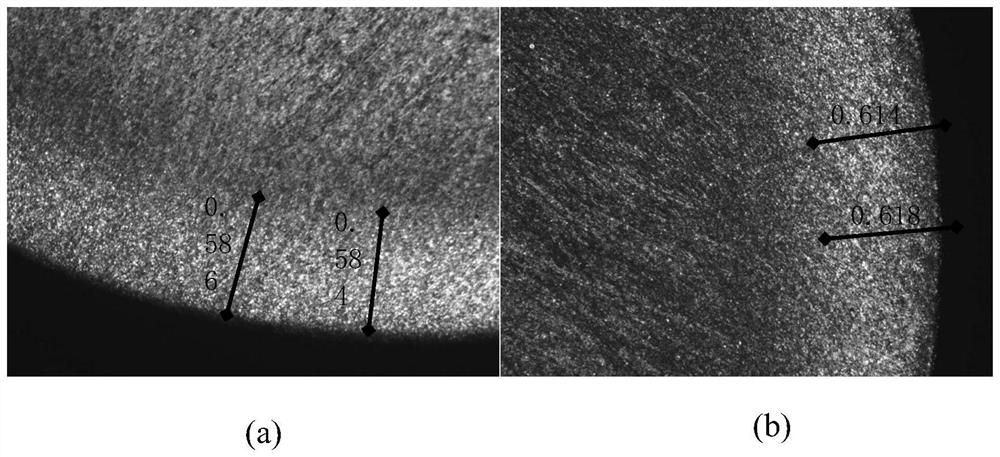

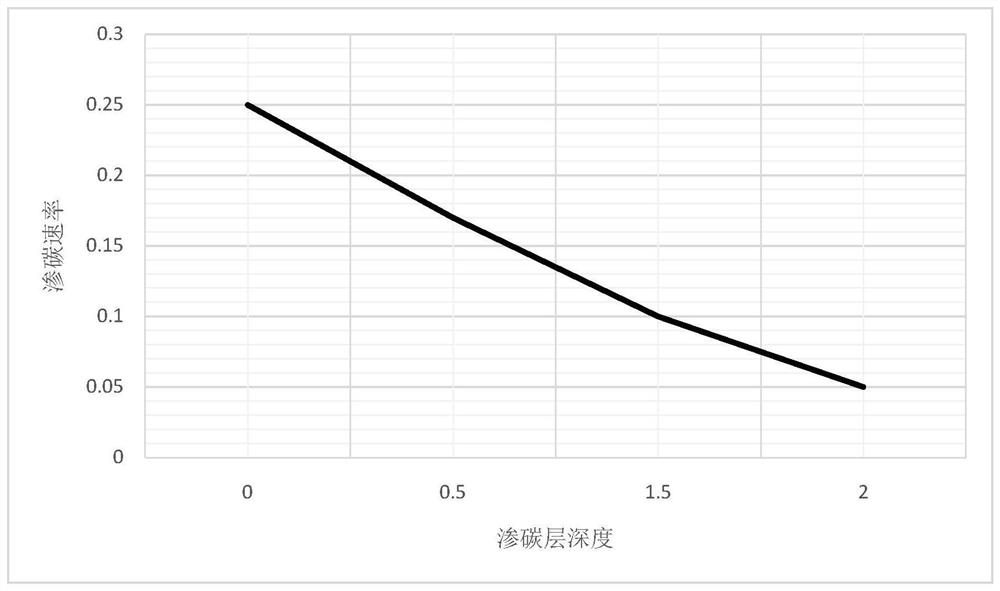

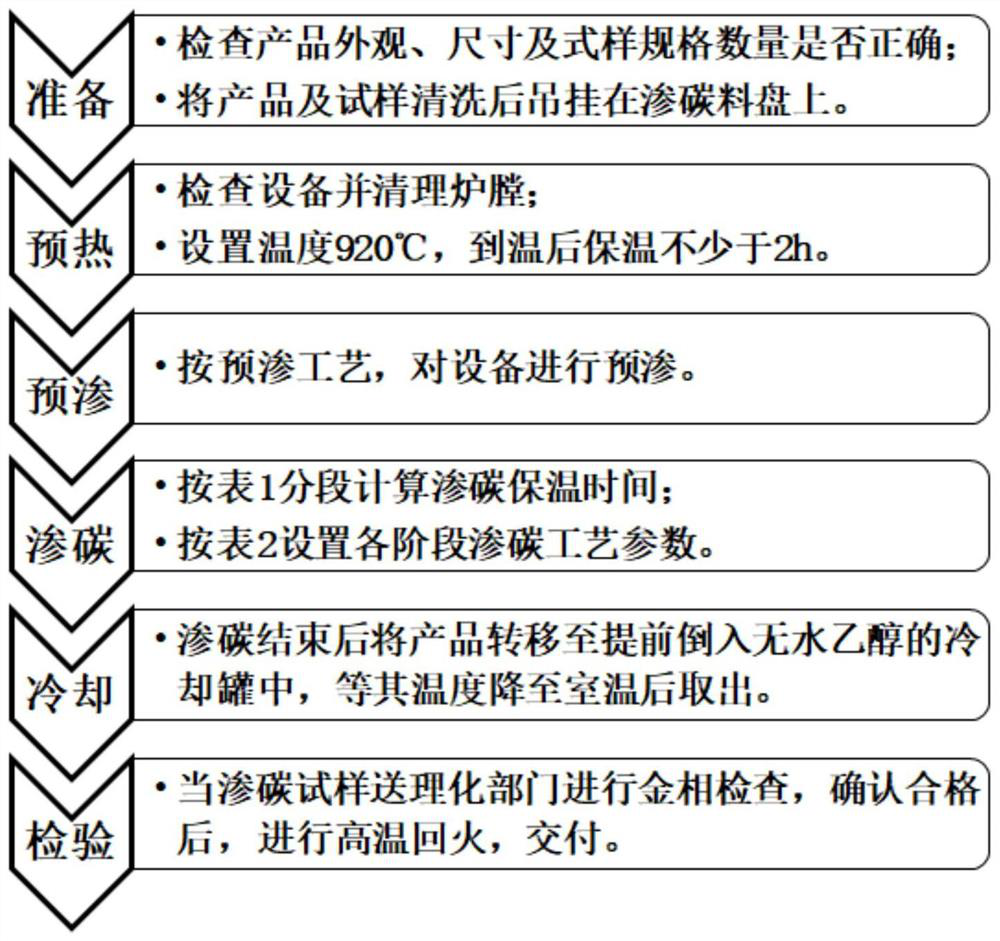

Carburizing method suitable for instillation type gas carburizing furnace

PendingCN114214589AKeep it brightPrevent oxidationSolid state diffusion coatingMetallic materialsHeat conservation

The invention discloses a carburizing method suitable for an instillation type gas carburizing furnace, and belongs to the technical field of metal material heat treatment. According to the stage type carburizing method, the carburizing layer depth is divided, the heat preservation time is calculated section by section, and the total carburizing heat preservation time is obtained through accumulation, so that the carburizing depth accuracy can be achieved, and the carburizing layer depth uniformity is ensured; and meanwhile, carbon black accumulation and decarburization phenomena on the surface of the carburized product are avoided.

Owner:大连长丰实业总公司

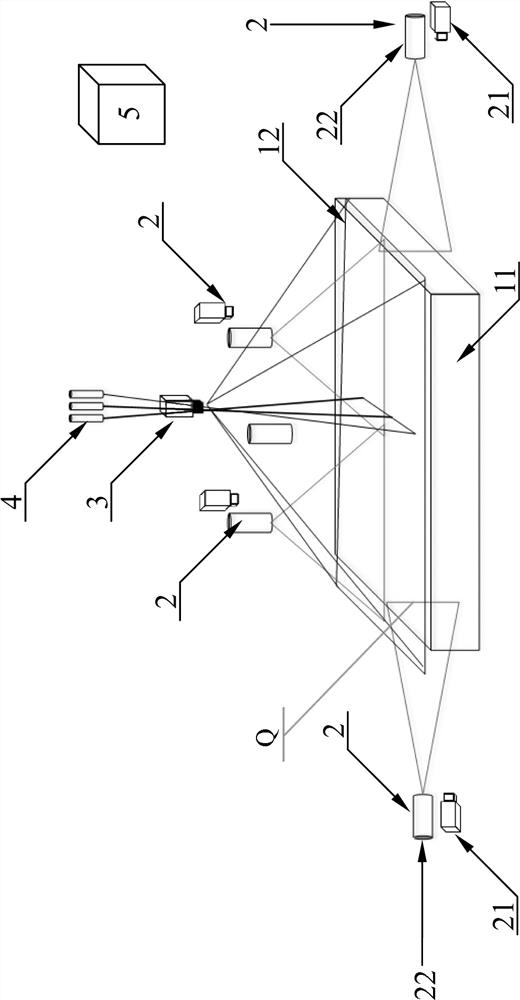

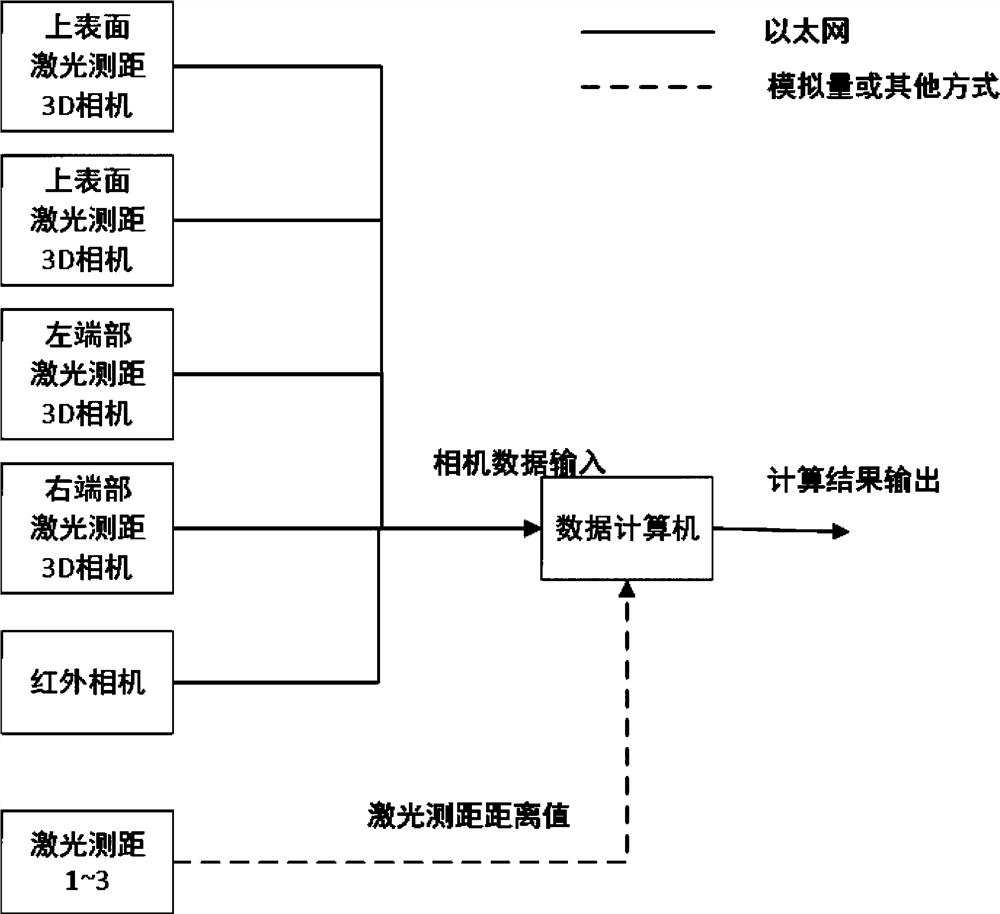

Multifunctional slab monitor and use method thereof

InactiveCN112880742AOptimize cooling methodImprove continuityMeasurement devicesCasting parameters measurement/indication devicesLaser rangingEngineering

The invention relates to the field of optical range finders, and concretely relates to a multifunctional slab monitor and a using method thereof. The multifunctional slab monitor is arranged around a slab (12) of a fan-shaped section outlet roller way (11), and is characterized by comprising at least three detection units (2), an infrared camera (3), three laser range finders (4) and a controller (5), and each detection unit (2) comprises a laser (21) and a laser 3D camera (22) which are sequentially arranged right above the midpoint of a datum line from bottom to top, or are respectively arranged on two sides of the midpoint of the datum line. The using method of the multifunctional slab monitor is characterized by comprising the following steps of: (1) restoring the profile; (2) measuring the warping degree; (3) measuring the temperature distribution; and (4) displaying. The monitor is accurate in measurement and comprehensive in information.

Owner:BAOSTEEL ENG & TECH GRP

High-hardness highly-wear-resistant metal material used for sports equipment and preparation method thereof

The invention discloses a high-hardness highly-wear-resistant metal material used for sports equipment. The high-hardness highly-wear-resistant metal material comprises the following raw materials in percentage by weight: 0.42-2.78% of C, 0.1-0.7% of Si, 0.10-0.35% of N, 0.1-0.3% of Mn, 15-25% of Cr, 0-0.05% of P, 0-0.05% of S, 0.10-0.20% of Al, 0.10-0.26% of B, 0.32-0.48% of V, 0.18-0.25% of Mo, 0.2-1.0% of Y, 0.02-0.12% of Nb and the balance Fe. The invention further discloses a preparation method for the high-hardness highly-wear-resistant metal material used for sports equipment. A product is obtained by adopting a four-stage heating method and a nitrate bath quenching method. The product is good in wear resistance, is high in hardness, is excellent in comprehensive performance and is long in service life; and process steps are simple and easy to implement.

Owner:芜湖地心引力运动科技有限公司

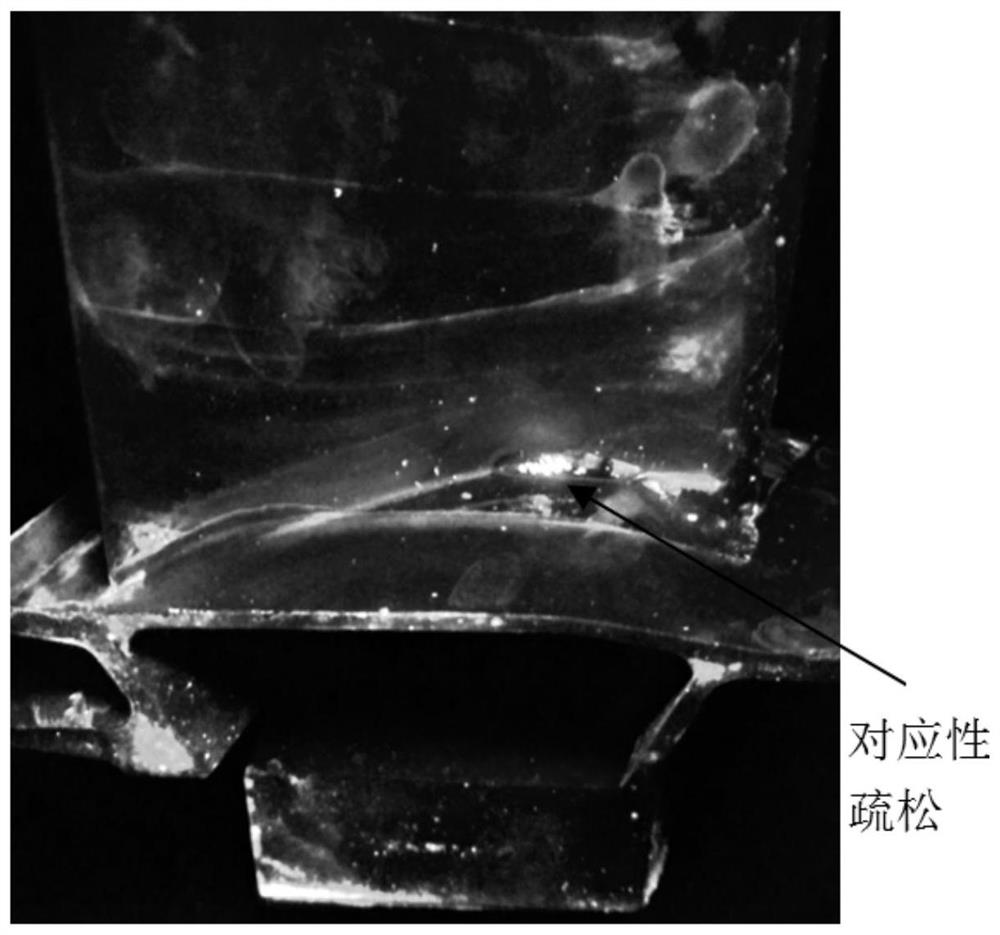

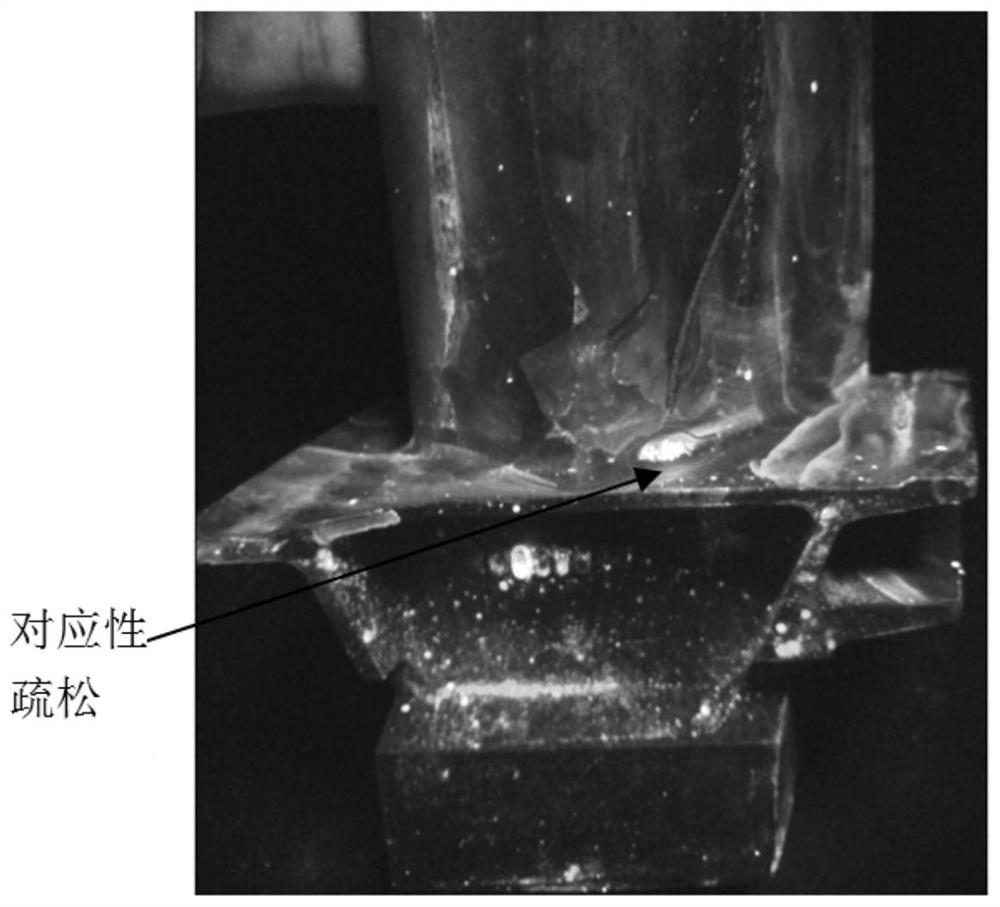

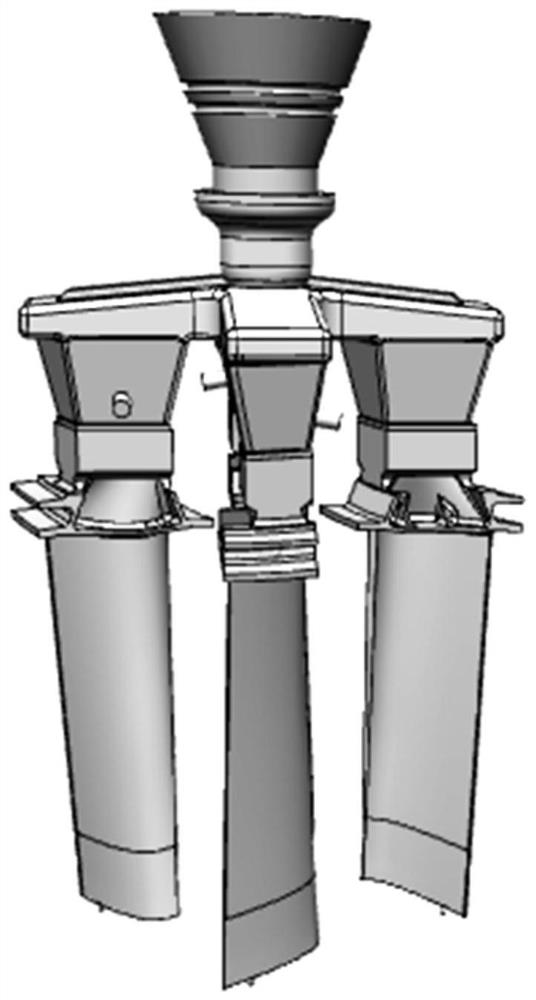

A Method for Reducing Turbine Blade Looseness of Gas Turbine

ActiveCN108941459BEliminate microporosityOptimize cooling methodFoundry mouldsFoundry coresTurbine bladeMolten steel

The invention discloses a method for reducing loosening of a gas turbine blade. The method for reducing loosening of the gas turbine blade comprises the following steps that (1) a gas turbine blade wax pattern is prepared, wherein the riser height of the gas turbine blade wax pattern is 1 / 5-1 / 6 of the total length of a gas turbine blade, and then a turbine blade die shell is prepared through the gas turbine blade wax pattern; (2) the turbine blade die shell is wrapped with three layers of ceramic wool in a surrounded mode, the first layer of ceramic wool is located between the lower end of a ceramic sprue cup and a riser, the second layer of ceramic wool is located between the lower end of the ceramic sprue cup and 1 / 3 of a blade body, and the third layer of ceramic wool is located betweenthe lower end of the ceramic sprue cup and 2 / 3 of the blade body; (3) the turbine blade die shell after being treated through the step 2 is roasted; and (4) molten steel is prepared, then the moltensteel is filtered through a filter screen and poured into the turbine blade die shell, the turbine blade die shell is then removed, cutting is carried out, and the gas turbine blade is obtained. The method for reducing loosening of the gas turbine blade can avoid loosening at the joint R between the blade body and an edge plate.

Owner:AECC AVIATION POWER CO LTD

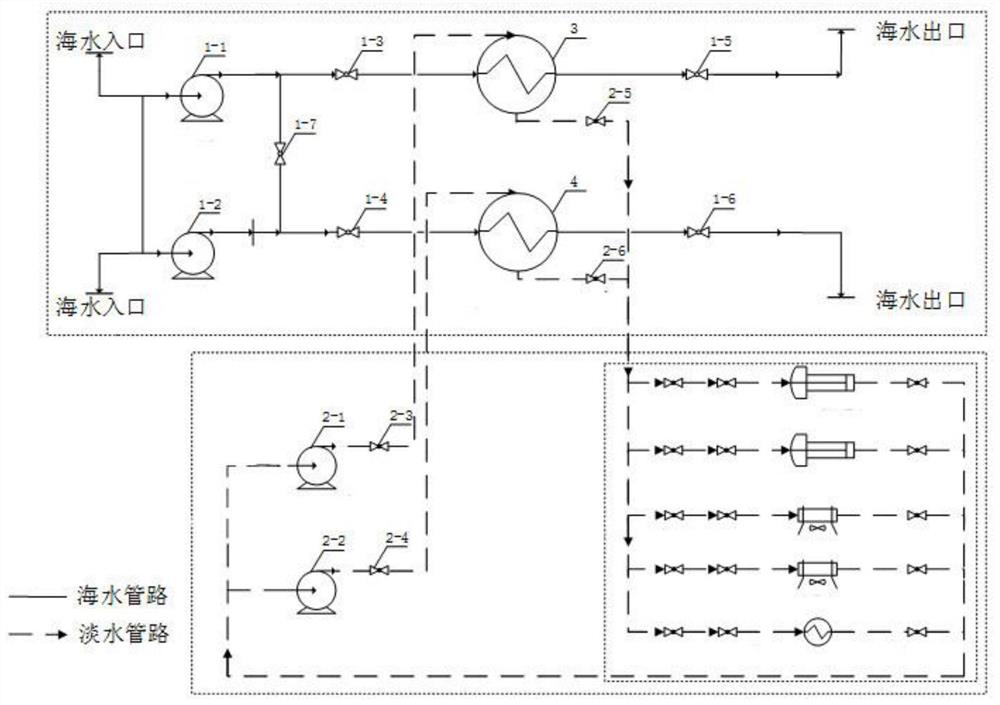

A method for adjusting the variable operating conditions of the secondary circuit cooling water system

ActiveCN111483583BReduce vibration and noise levelsFulfilling Fresh Water Cooling NeedsPropulsion power plantsPropulsive elementsNoise controlEngineering

The present invention proposes a system and method for adjusting working conditions of a secondary-circuit cooling water system, including a seawater circuit and a freshwater circuit, which are respectively composed of two seawater pipelines and freshwater heat exchange pipelines connected in parallel, and seawater pumps, The seawater ball valve, the seawater desalination heat exchanger unit and the seawater flow regulating valve, the freshwater heat exchange pipeline and the cooling water user pipeline form an internal circulation. The present invention utilizes the design method of the split heat exchanger, by switching the opening and closing states of the heat exchanger, and matching the different heat transfer requirements of the cooling water system when the working conditions change, it can reduce the adjustment demand of the cooling user branch flow regulating valve, which is beneficial Flow adjustment distribution and flow-induced noise control of cooling water system.

Owner:CHINA SHIP DEV & DESIGN CENT

A kind of high-carbon high-boron wear-resistant steel for impeller

The invention discloses high-carbon and high-boron wear resistant steel for an impeller. The wear resistant steel comprises the following components in percentage by mass: 0.65-1.0% of C, 0 / 3-0.8% of Si, 1.0-1.5% of Mn, 1.0-2.0% of Cr, 0.4-0.8% of B, 0-0.04% of P, 0-0.04% of S, 0.05-0.2% of Ti, and the balance of Fe. The wear resistant steel is prepared by the following steps: (S1) all raw materials are weighed by the mass percentages, and are cast to form after being smelted to obtain a semi-finished wear resistant steel; (S2) the semi-finished wear resistant steel obtained in the step (S1) is put in a furnace to heat up to the temperature of 270-290 DEG C; after the temperature of 270-290 DEG C is kept for 115-125 min, the temperature is increased to the temperature of 640-670 DEG C; after the temperature of 640-670 DEG C is kept for 230-250 min, the temperature is increased to the temperature of 1000-1100 DEG C; after the temperature of 1000-1100 DEG C is kept for 200-220 min, the oil quenching is performed in quenching oil with the oil temperature of 110-130 DEG C; the quenching time is 12-15 min; the temperature from the room temperature to 100 DEG C is increased to the temperature of 375-385 DEG C by the heating speed of 20-100 DEG C / h in a heat insulating furnace after the oil quenching; after the temperature of 375-385 DEG C is kept for 470-490 min, the temperature is slowly decreased to the room temperature by 470-490 min; and then, the wear resistant steel is obtained. The wear resistant steel has good comprehensive performance.

Owner:宁国东方碾磨材料股份有限公司

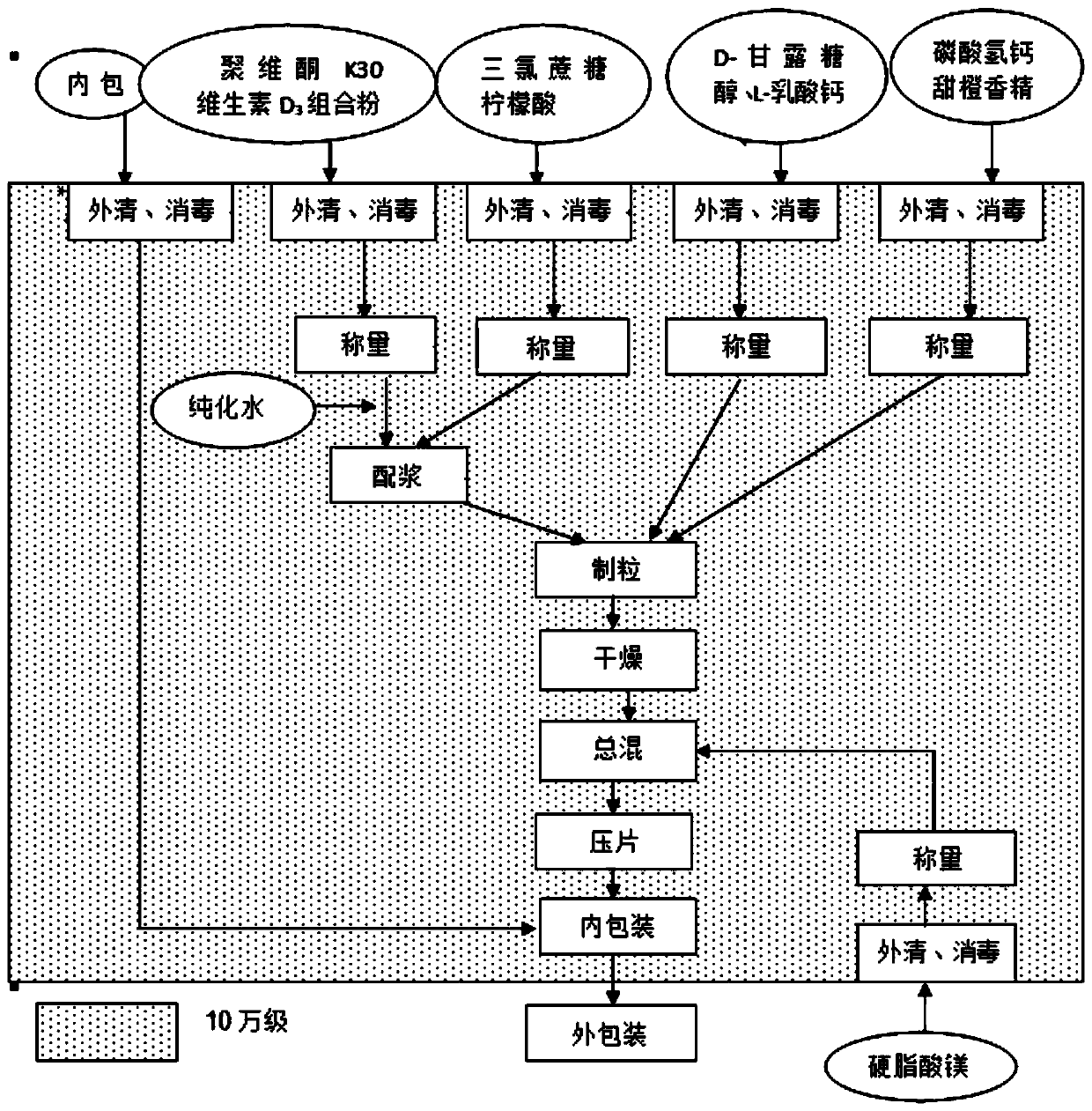

Calcium and vitamin-D chewable tablet and preparation method

InactiveCN110693901AHas left-handed propertiesImprove solubilityMetabolism disorderPharmaceutical non-active ingredientsSucroseCALCIUM LACTOBIONATE

The invention provides a calcium and vitamin-D chewable tablet and a preparation method. The calcium and vitamin-D chewable tablet is prepared from, by weight, 211.28 parts + / -1% of calcium hydrophosphate, 207.22 parts + / -1% of L-calcium lactate pentahydrate, 0.63 parts + / -1% of vitamin D3, 730.35 parts + / -1% of D-mannitol, 20.00 parts + / -1% of citric acid, 14.40 parts + / -1% of magnesium stearate,3.32 parts + / -1% of povidone, 0.80 part + / -1% of sucralose, and 12.00 parts + / -1% of sweet orange essence. The chewable tablet has flavor suitable for most of people; sticking in tableting is avoidedduring preparation, so that the tablet prepared is smooth and not easy to crack.

Owner:上海儿童营养中心(海南)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com