Heat treatment method for 35CrMo steel

A heat treatment method and water cooling technology, applied in the field of alloy steel processing, can solve the problems of uneven internal structure, poor weldability, high hardenability, etc., and achieve the effect of avoiding sudden cooling of the workpiece surface, green and environmental protection during the operation process, and stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

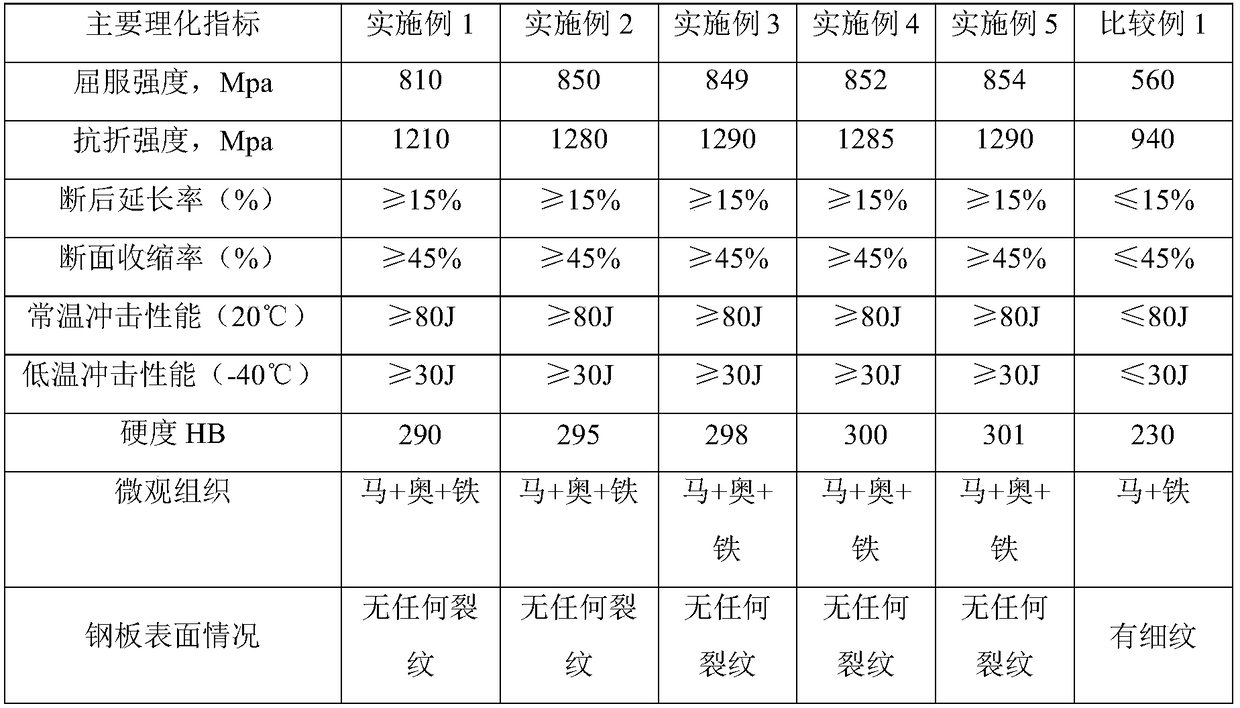

Examples

Embodiment 1

[0033] The heat treatment method of 35CrMo steel is carried out according to the following process steps:

[0034] (1) Put the 35CrMo steel piece into the heating furnace first, raise the temperature of the heating furnace, heat it to 800-850 ° C, and pass a certain amount of protective gas for 2 hours, then cool it with water for 40 seconds and put it in the oil cool down;

[0035] (2) Put the steel piece into the box-type heating furnace, raise the temperature of the heating furnace, control the furnace temperature at 600°C for 30h, heat preservation and tempering after quenching;

[0036] (3) After tempering is completed, let it cool at natural temperature, and it will be ready.

Embodiment 2

[0038] The heat treatment method of 35CrMo steel is carried out according to the following process steps:

[0039] (1) Put the 35CrMo steel piece into the heating furnace first, raise the temperature of the heating furnace, heat it to 800-850 ° C, and pass a certain amount of protective gas for 5 hours, then cool it with water for 60 seconds and put it in the oil Cool for 30s, add polyethylene glycol, polyacrylamide and sodium chloride to the water, the amount of the above three substances added is 6wt% of the water amount;

[0040] (2) Put the steel piece into a box-type heating furnace, raise the temperature of the heating furnace, control the furnace temperature at 650°C for 4 hours, keep warm and temper after quenching, and protect it with inert gas;

[0041] (3) After the tempering is completed, cool at natural temperature. When the temperature drops below 100°C, put the steel plate into water for further cooling. Add 3wt% sodium hydroxide to the water and cool it to room t...

Embodiment 3

[0043] The heat treatment method of 35CrMo steel is carried out according to the following process steps:

[0044] (1) Put the 35CrMo steel piece into the heating furnace first, raise the temperature of the heating furnace, heat it to 800-850 ° C, and pass a certain amount of protective gas for 4 hours, then cool it with water for 50 seconds and put it in the oil Cool for 20s, add polyethylene glycol, polyacrylamide, sodium chloride and a random copolymer of ethylene oxide and propylene oxide with a number average molecular weight of 30,000 in the water, and the amount of the above four substances added is 5wt% of the water amount ;

[0045] Polyethylene glycol, polyacrylamide, sodium chloride, ethylene oxide and propylene oxide random copolymer are measured in parts by mass, 4 parts of polyethylene glycol, 3 parts of polyacrylamide, chlorinated 2 parts of sodium, 4 parts of random copolymer of ethylene oxide and propylene oxide;

[0046] (2) Put the steel piece into a box-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com