Recycling device for thermal power station tail water and utilizing method

A recovery device, thermal power station technology, applied in lighting and heating equipment, irreversible cycle compressors, fluid circulation arrangements, etc., can solve the problem of uneconomical investment and operation efficiency, reduce system heat exchange efficiency, and large heat exchange area of coolers and other problems, to achieve the effect of reducing cooling water volume and circulating pump power, broad application prospects and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the advantages of the present invention will become clearer and easier to understand.

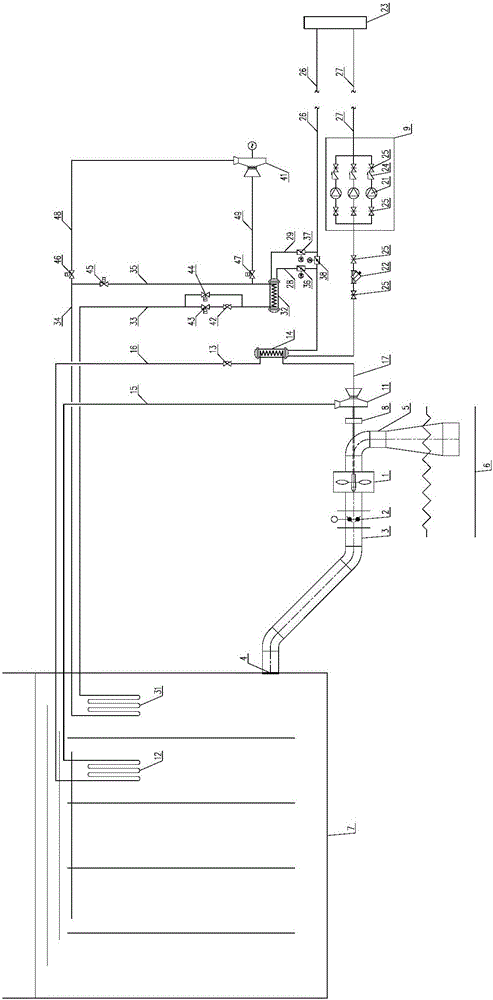

[0034] refer to figure 1 Shown: a thermal power station tail water recovery device, characterized in that: a water energy recovery culvert 3 is provided at the outlet of the pressure forebay 7, and a water energy recovery culvert 3 and a tail water culvert 5 are provided between the described water energy recovery culvert 3 and the tail water culvert 5 The water turbine 1 is equipped with a filter screen 4 at the water outlet of the pressure forebay 7, and communicates with the water energy recovery culvert 3, and a butterfly valve 2 is arranged on the water energy recovery culvert 3. The tail of the tail water culvert pipe 5 is inserted into the water source 6, a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com