A kind of preparation method of fuel cell CCM membrane electrode

A fuel cell, membrane electrode technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as affecting gas mass transfer process, and achieve the effect of improving battery performance, reducing adhesion, and improving water management problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

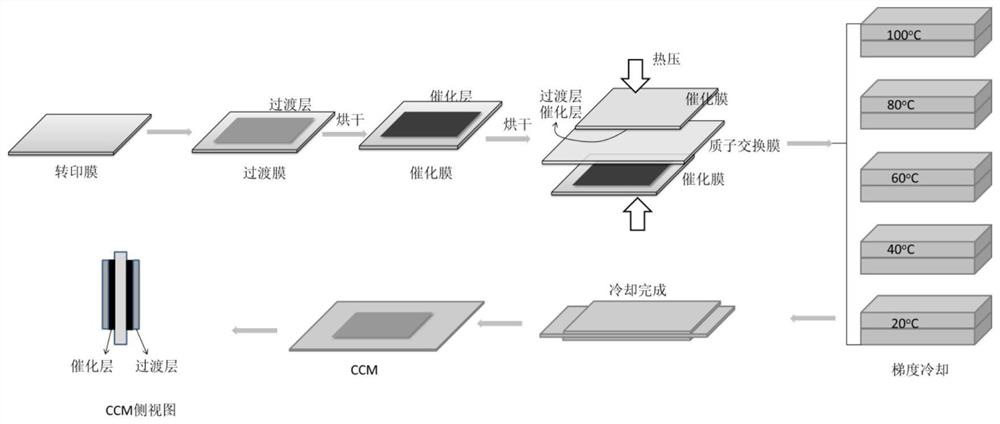

[0023] according to figure 1 In the process shown, a piece of aluminum foil with a thickness of about 20 microns is preferred, wipe it clean with alcohol cotton and lay it flat. The size of the aluminum foil is 5cm*5cm. Weigh 25mg of XC-72 carbon powder, add 1ml of water and 5ml of ethanol, mix well, spray it on the surface of aluminum foil, and dry it at 80°C to form a transition layer. Then weigh 20 mg of 50% Pt / C catalyst, disperse it with 10 ml of ethanol, add 160 mg of 5% Nafion solution, ultrasonically vibrate evenly, spray it on the surface of the transition layer, and dry it at 90° C. to form a catalytic layer.

[0024] Take a proton exchange membrane with a thickness of 50 microns, cut two small pieces with an area of 2cm*2.5cm from the above-mentioned sprayed sheet, clamp them on both sides of the proton exchange membrane oppositely, and clamp them with a thin metal plate Then put it in a hydraulic press at 140°C, and control the pressure on the surface of the mem...

Embodiment 2

[0028] according to figure 1 In the process shown, a tetrafluoromembrane with a thickness of about 50 microns is preferred, wiped clean with alcohol cotton and paved. The size of the tetrafluoromembrane is 5cm*5cm. Weigh 25mg of graphite powder with a particle size of about 50nm, add 1ml of water and 5ml of ethanol, mix well, spray it on the surface of the PTFE membrane, and dry it at 90°C to form a transition layer. Then weigh 20 mg of Pt black catalyst, disperse it with 10 ml of water, add 80 mg of 5% Nafion solution, ultrasonically vibrate evenly, spray it on the surface of the transition layer, and dry it at 90° C. to form a catalytic layer.

[0029] Take a proton exchange membrane with a thickness of 150 microns, cut two small pieces with an area of 2cm*2.5cm from the above-mentioned sprayed sheet, clamp them on both sides of the proton exchange membrane oppositely, and clamp them with a thin metal plate Then place it in a hydraulic press at 150°C, and control the pres...

Embodiment 3

[0032] according to figure 1 In the process shown, a tetrafluoromembrane with a thickness of about 50 microns is preferred, wiped clean with alcohol cotton and paved. The size of the tetrafluoromembrane is 5cm*5cm. Weigh 25 mg of carbon powder with a particle size of about 20 nm, add 1 ml of water and 5 ml of ethanol, mix well, spray it on the surface of the PTFE film, and dry it at 100 ° C to form a transition layer. Then weigh 40 mg of PtPd / C catalyst, disperse it with 10 ml of water, add 800 mg of 5% Nafion solution, ultrasonically vibrate evenly, spray it on the surface of the transition layer, and dry it at 100° C. to form a catalytic layer.

[0033] Take a proton exchange membrane with a thickness of 10 microns, cut two small pieces with an area of 2cm*2.5cm from the above-mentioned sprayed sheet, clamp them on both sides of the proton exchange membrane oppositely, and clamp them with a thin metal plate Then put it in a hydraulic press at 145°C, and control the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com