High-temp. high-melting-point liquid medium cooling method

A technology of liquid medium and cooling method, which is applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of poor system safety, system operation failure, vaporization, etc., and achieve the effect of safe cooling method and wide application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

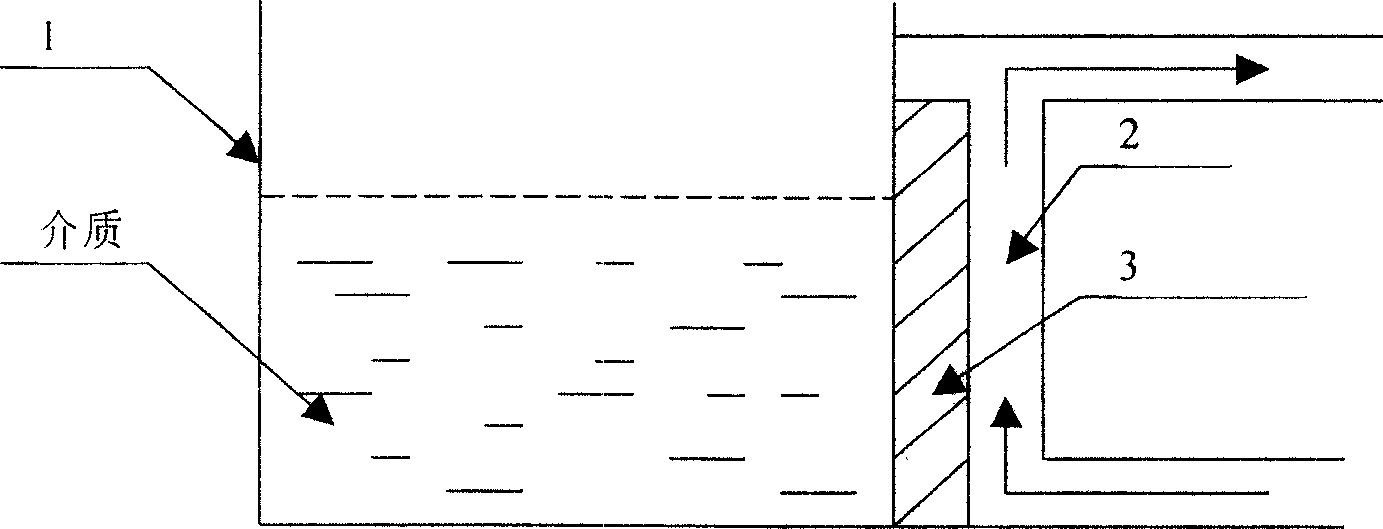

[0008] A heat dissipation air duct 2 is provided on the outer wall of the medium container 1 , and a heat dissipation fin 3 is also provided on the outer wall of the medium container 1 adjacent to the heat dissipation air duct 2 .

[0009] When in use, the surface area and air volume of the cooling fins can be calculated according to the amount of heat exchange. As shown in the attached figure, the cooling fins and air ducts are directly installed on the outer wall of the container, and the negative pressure ventilation device is used to realize the forced air in the air ducts. Convection to achieve the purpose of cooling the medium in the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com