Multifunctional slab monitor and use method thereof

A monitor and multi-functional technology, applied in the field of optical range finder, can solve problems such as inability to apply detection methods, limit slab monitoring, etc., to achieve the effects of improving continuity and stability, avoiding cutting failures, and optimizing cooling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

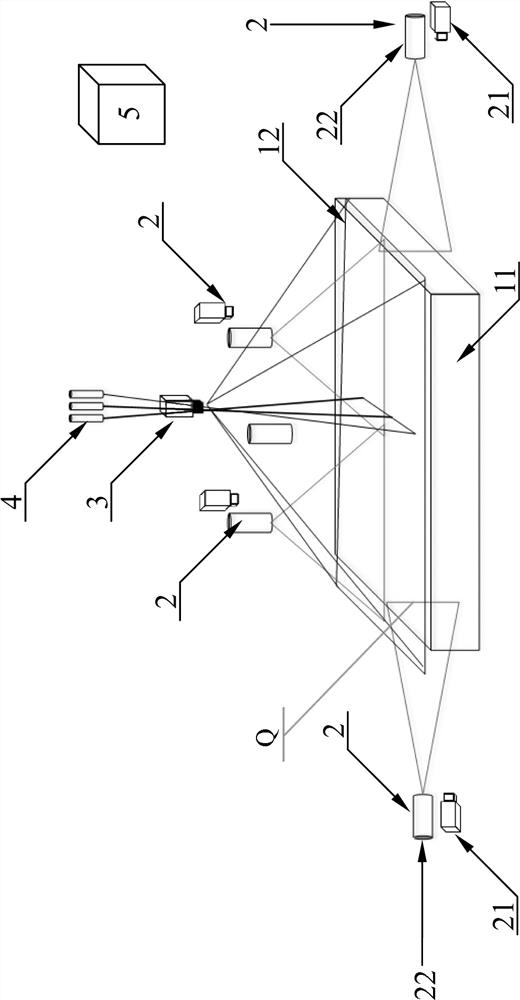

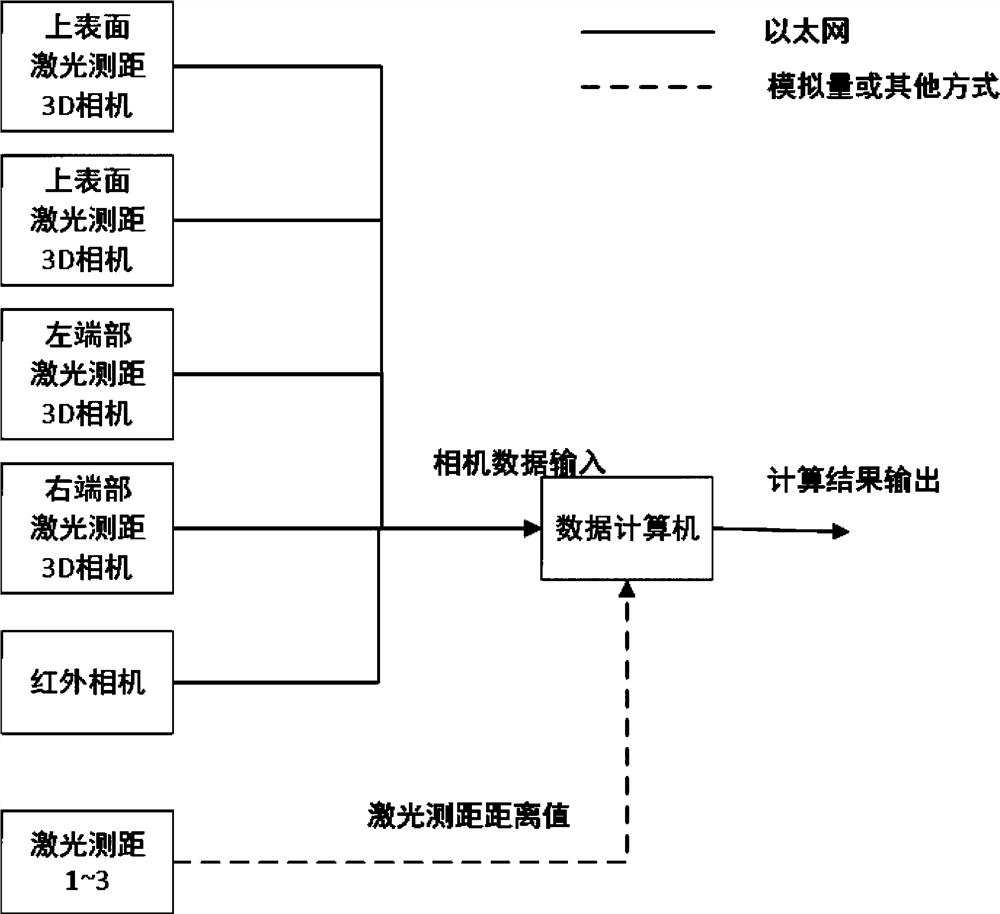

[0024] A kind of slab multifunctional monitoring instrument, is arranged around the slab 12 of the roller table 11 at the outlet of the sector, including at least 3 detection units 2, infrared camera 3, laser range finder 4 and controller 5, such as figure 1 As shown, the specific structure is:

[0025] Each detection unit 2 includes a laser 21 and a laser 3D camera 22. Taking the central axis of the slab 12 along the conveying direction of the roller table 11 as the reference line, at least two detection units 2 are arranged in turn directly above the reference line. And each laser emitting end of the detection unit 2 is facing the reference line, a detection unit 2 is respectively arranged at both ends of the reference line, and each laser emitting end of the detection unit 2 is facing the reference line respectively. both ends of the line;

[0026] The infrared camera 3 and the laser range finder 4 are successively arranged directly above the midpoint of the reference line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com