Supplementary combustion chamber of supercritical pressure gas-liquid fuel generator

A fuel generator and supplementary combustion chamber technology, applied in steam generation, steam boilers, components of steam boilers, etc., can solve the problems of heat transfer influence, change, heat transfer deterioration of the inner wall of the regenerative cooling jacket, etc., and improve the cooling effect , improve the life, improve the effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below with reference to the accompanying drawings.

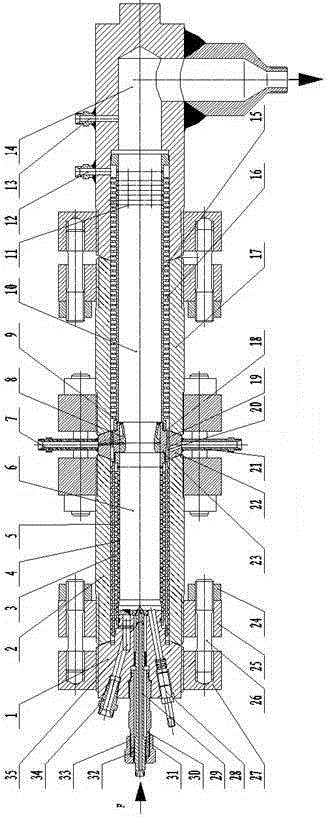

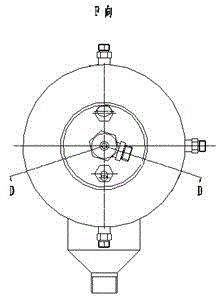

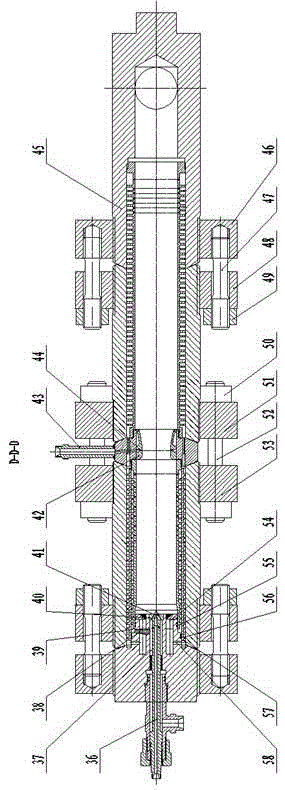

[0041] Supercritical pressure natural gas supplementary combustion type combustor of the present invention such as figure 1 , figure 2 , image 3 As shown, the combustion chamber is composed of pre-combustion chamber 6, after-combustion chamber 10, vaporization chamber 14 three parts.

[0042] The pre-combustion chamber 6 is composed of a pre-combustion injector, a pre-combustion chamber housing 2, a pre-combustion chamber water cooling jacket 57, a pre-combustion chamber lining 3, a pre-combustion chamber lining 4, a supplementary combustion injector, a supplementary combustion injection Front end metal "O" ring 23, air cooling jacket sealing ring 55, water cooling jacket sealing ring 56, pre-combustion injector housing 1 and pre-chamber housing 2 front-end flange fastening nut 24, pre-chamber Front end threaded flange 25 of shell 2, pre-combustion injecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com