Patents

Literature

45results about How to "Ensure site safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

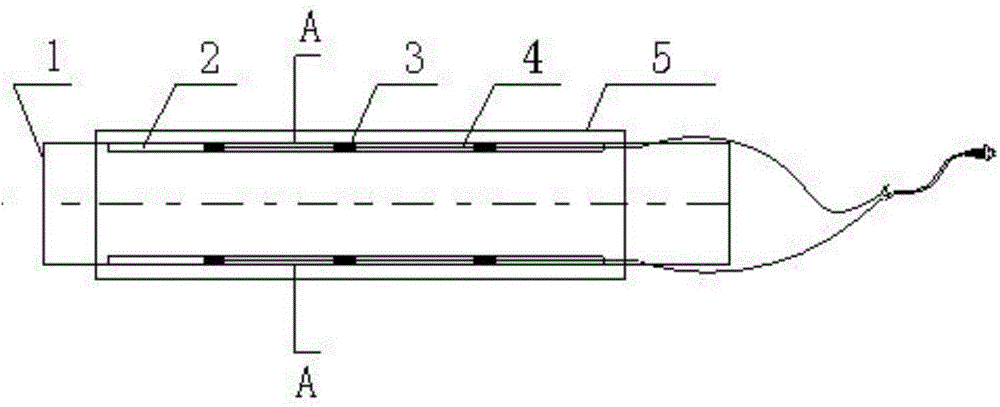

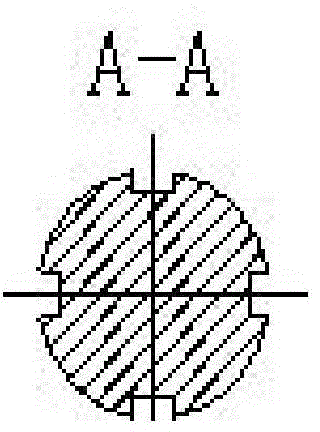

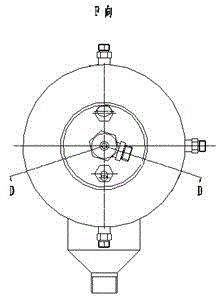

Roadway surrounding rock stress monitoring device based on fiber bragg grating sensing

ActiveCN103454021AUnderstanding Stress SituationsImprove stabilityForce measurement by measuring optical property variationUsing optical meansGratingFiber Bragg grating

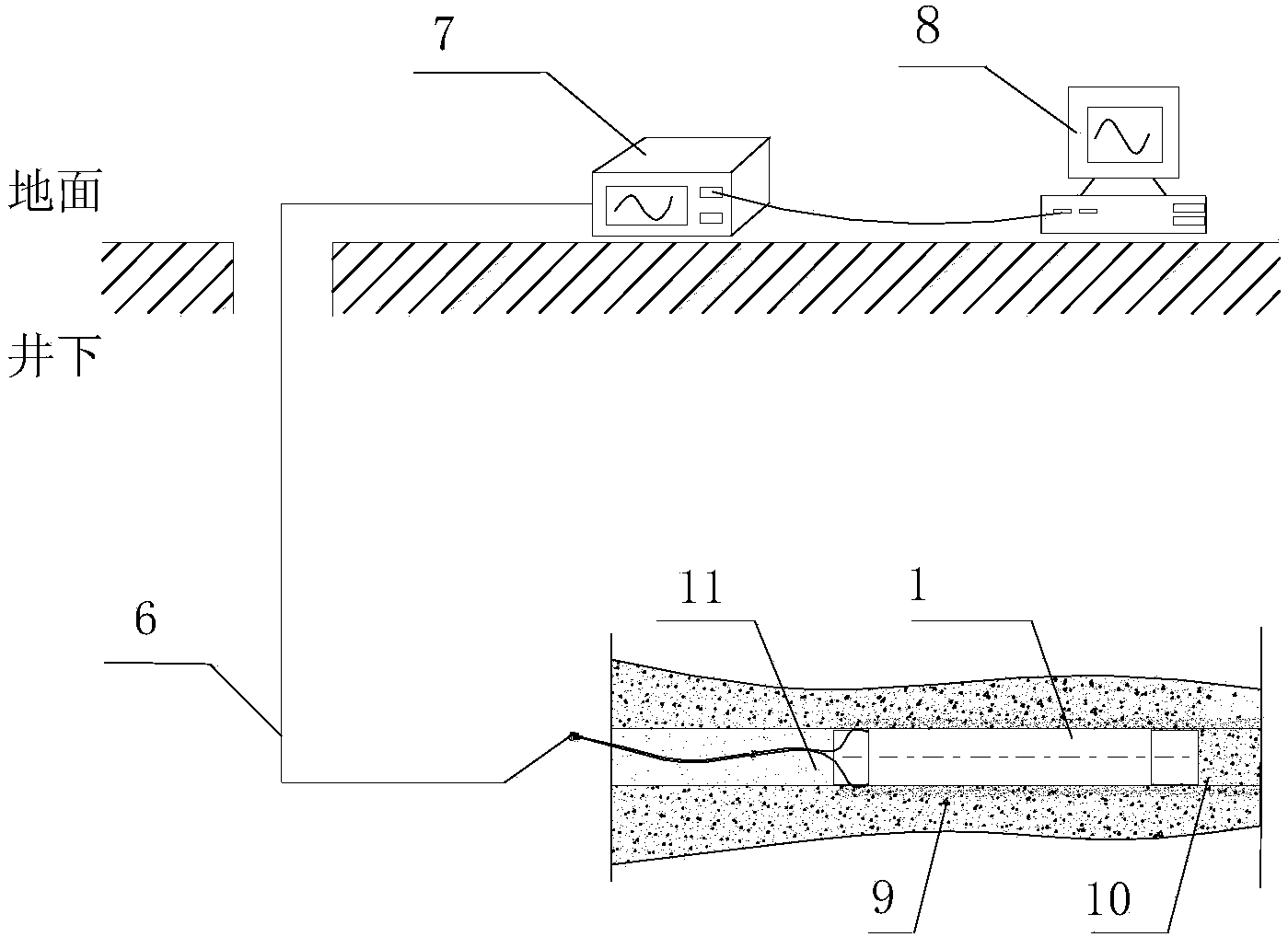

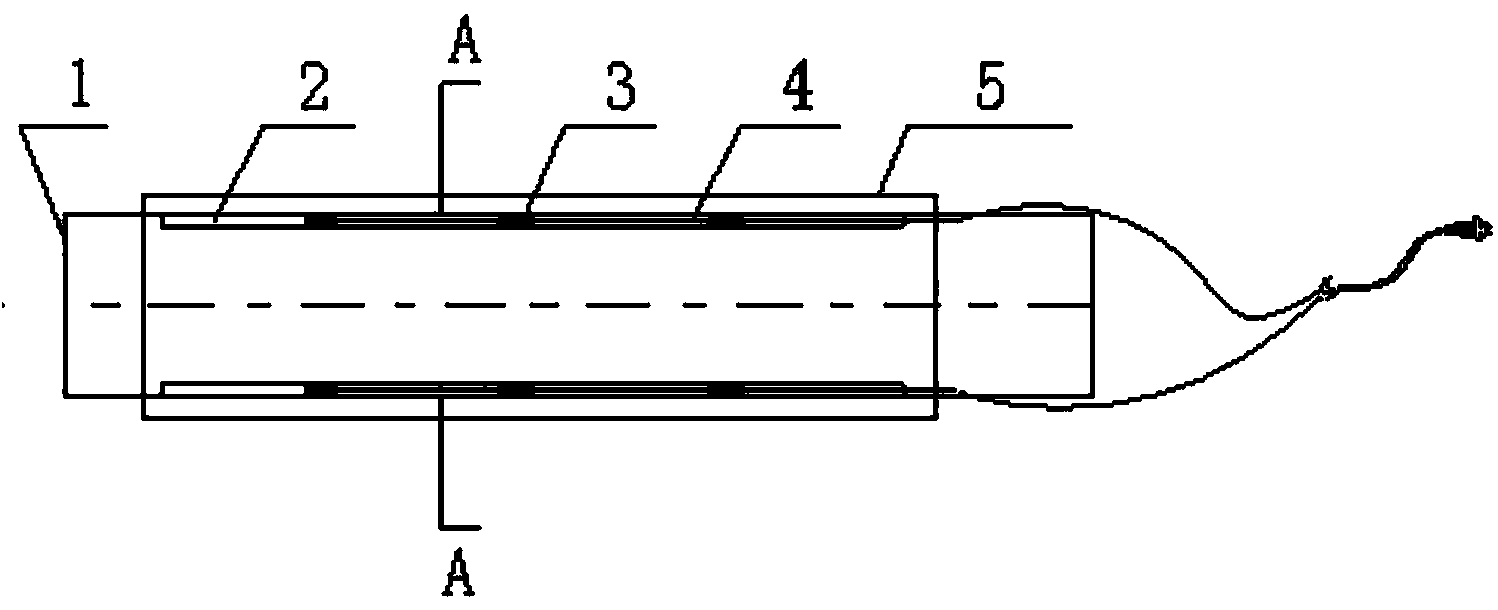

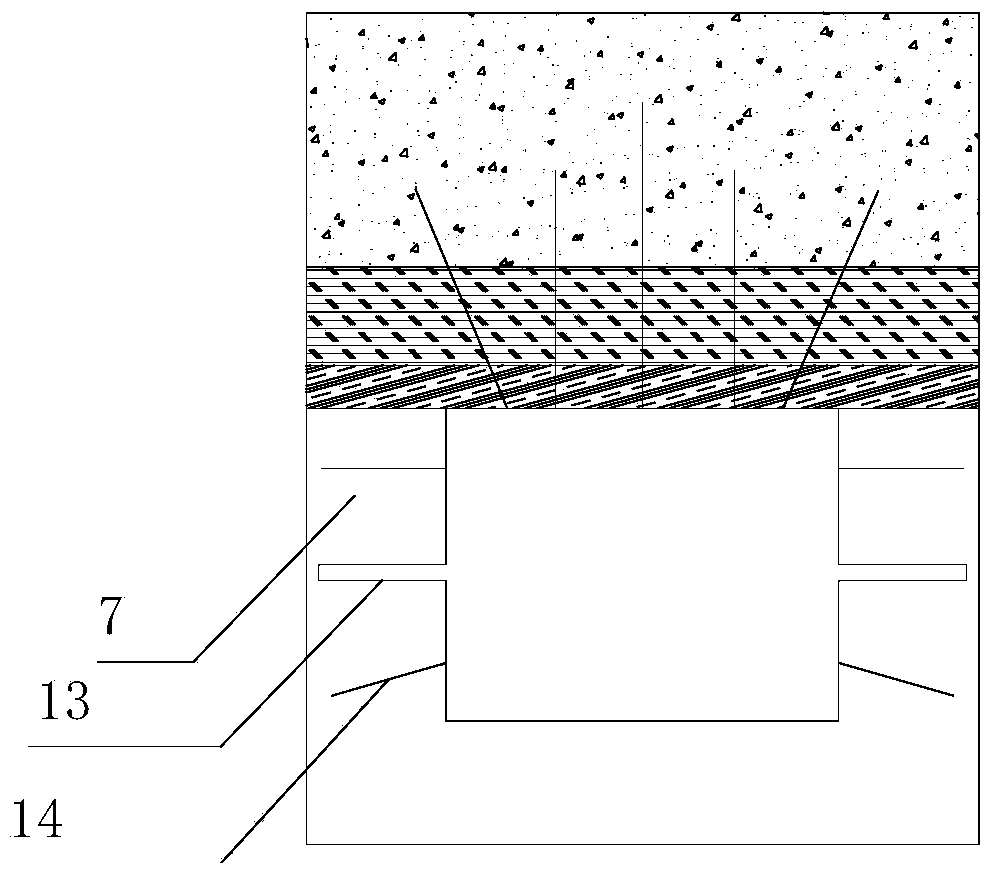

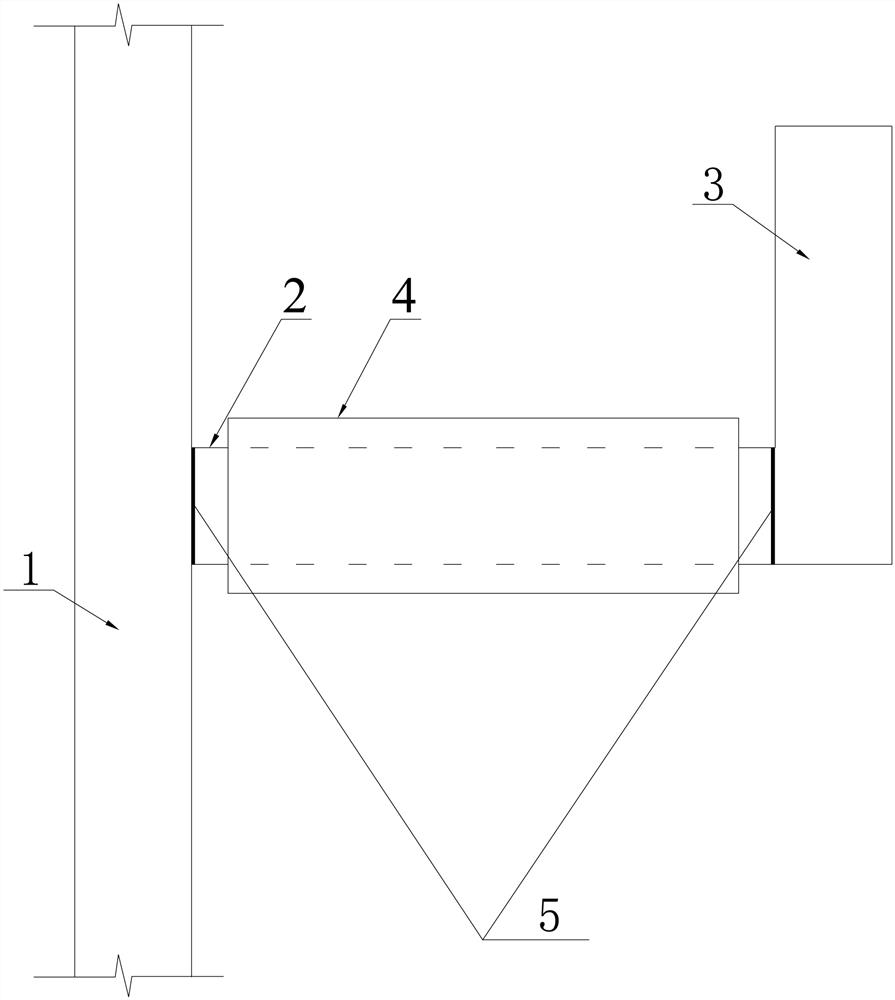

The invention discloses a roadway surrounding rock stress monitoring device based on fiber bragg grating sensing. Grooves are symmetrically carved in a metal rod along the axial center, an FBG set is fixedly installed inside each groove, FBGs serve as sensitive elements, when roadway surrounding rock is deformed, the stress of the surrounding rock will be changed, therefore, force is generated through the metal rod, surface micro-deformation is generated, the grating distances of the FBGs attached to the metal rod are changed along with the metal rod, the center reflection wavelength of the FBGs can be caused to generate drifting, wavelength signals are demodulated into electrical signals through an FBG interrogator, and the stress situations of different sites can be obtained. The roadway surrounding rock stress monitoring device has the advantages that installation is easily achieved, and the roadway surrounding rock stress monitoring device is suitable for wide popularization; power is not required to be supplied to the working face end, and site safety is guaranteed; all-optical measurement and fiber transmission are adopted, and influences of electromagnetic interference are effectively avoided; the temperature error is compensated, and the accuracy is improved; the surrounding rock stress monitoring results can be timely and accurately provided, and guidance on site production and scientific research is facilitated.

Owner:CHINA UNIV OF MINING & TECH

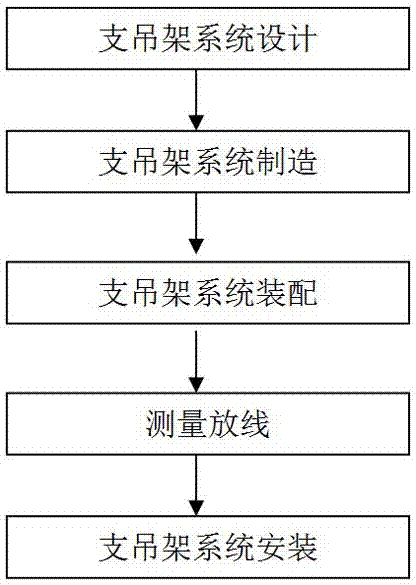

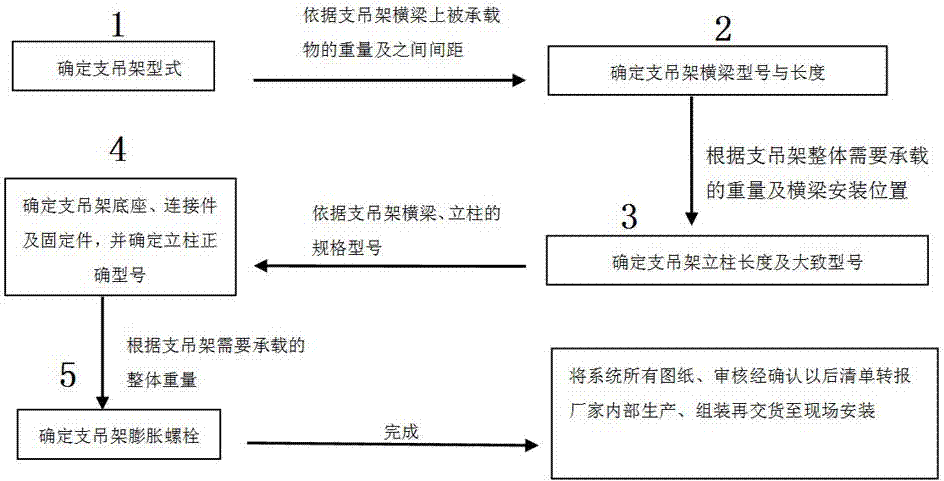

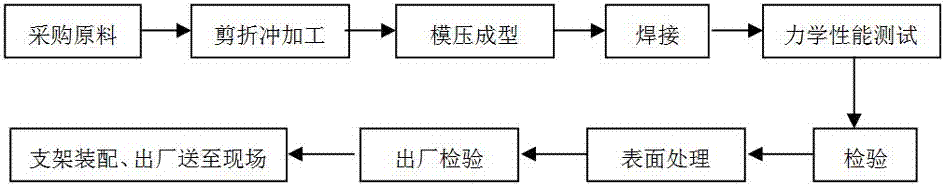

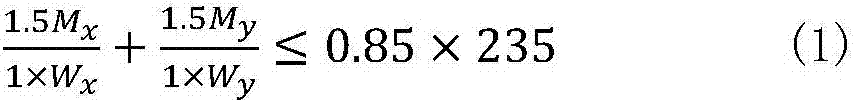

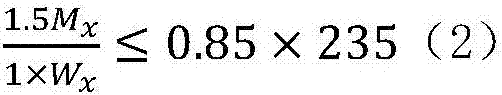

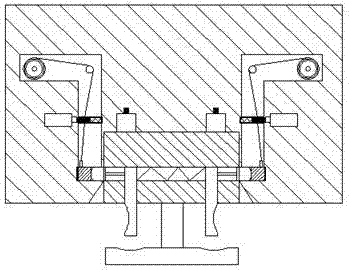

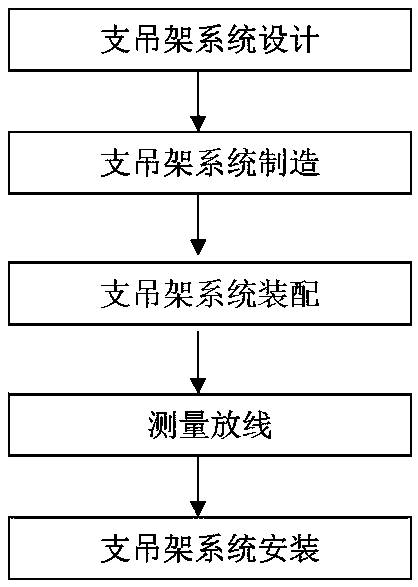

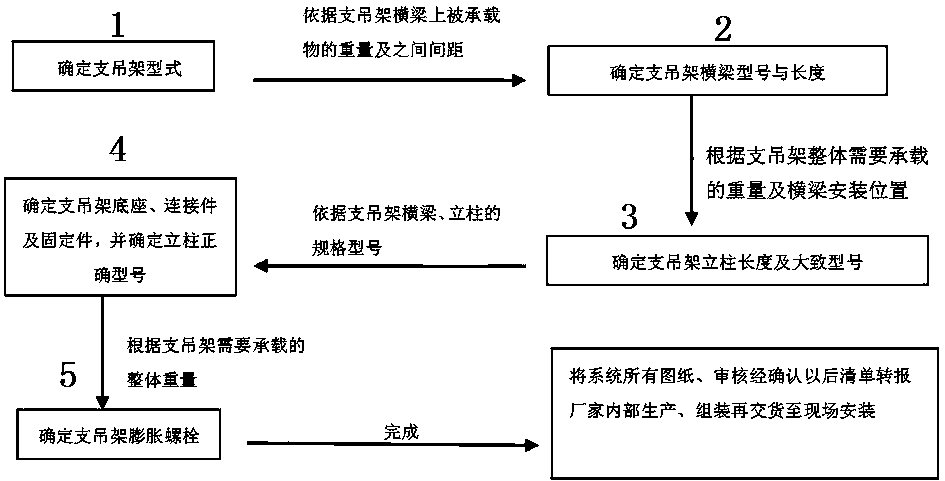

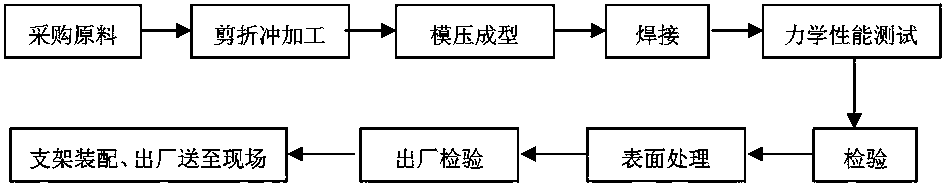

Assembly type building pipeline supporting and lifting frame system installation method based on BIM

ActiveCN106989211AReduce work intensityEnsure site safetyGeometric CADPipe supportsPunchingLight pollution

The invention discloses an assembly type building pipeline supporting and lifting frame system installation method based on a BIM. The installation method includes the steps that supporting and lifting frame design and stress analysis are conducted, the supporting and lifting frame connecting and fixing manner is determined, and a supporting and lifting frame design drawing is obtained; the drawing is guided into BIM software, and three-dimensional modeling is conducted; adjustment optimization is conducted on supporting and lifting frame arrangement, arrangement design, stress calculation and product model selecting of supporting and lifting frames are completed; part drawings and assembling drawings of all assemblies are generated, and factory production of the assemblies is achieved accordingly; measuring paying-off of the supporting and lifting frame system is conducted on the spot, and structure punching operation is conducted accordingly; and the supporting and lifting frames are formed through assembling, and installation is completed. By means of the assembly type building pipeline supporting and lifting frame system installation method based on the BIM, energy can be obviously saved, steel is saved, air pollution, noise pollution and light pollution brought by field feeding, cutting, welding, drilling and the like are avoided during installation, the manufacturing cost is reduced, meanwhile, the field safety of a constructor is ensured, and the work intensity of a laborer is effectively lowered.

Owner:ZHONGYIFENG CONSTR GRP

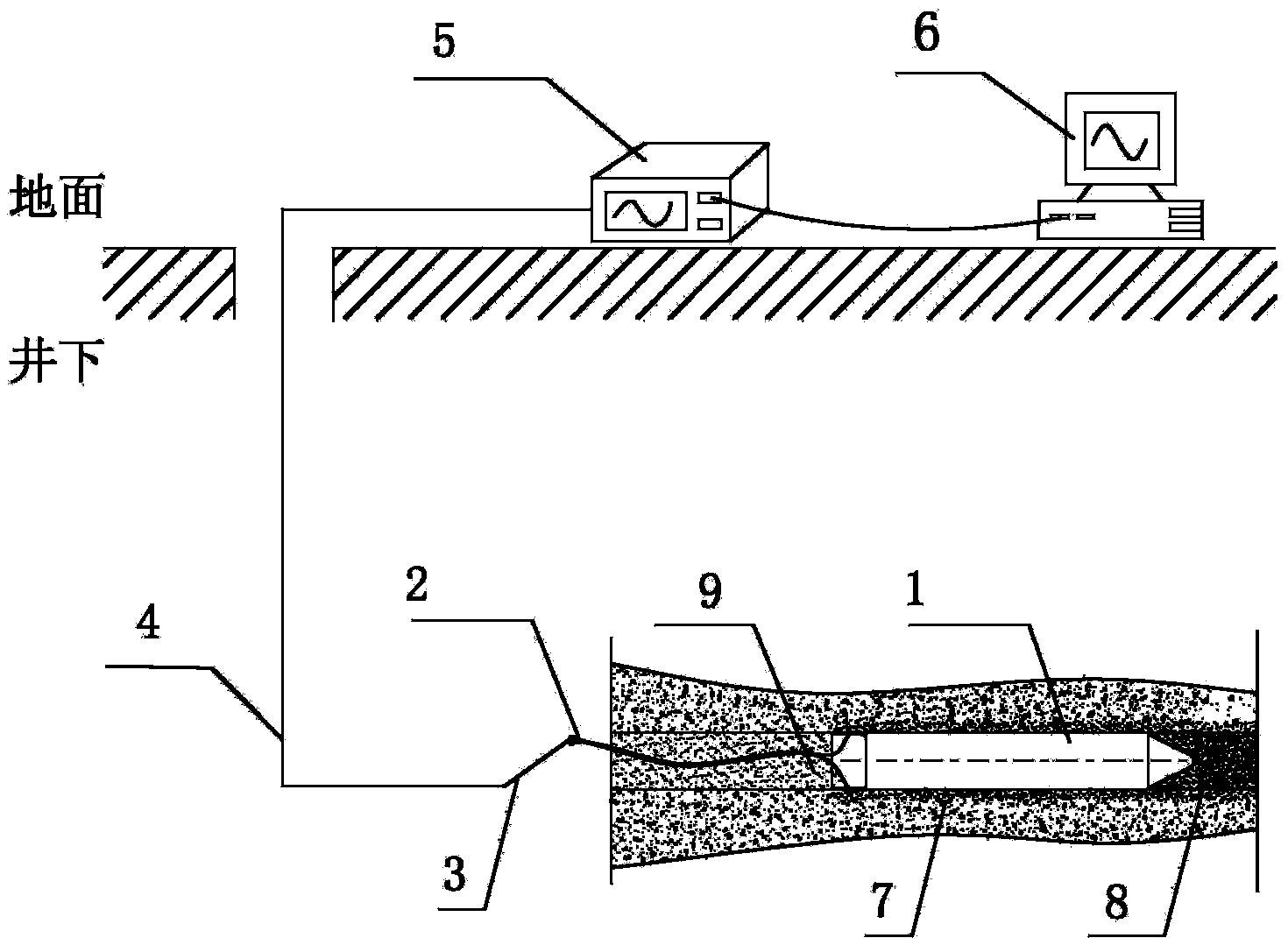

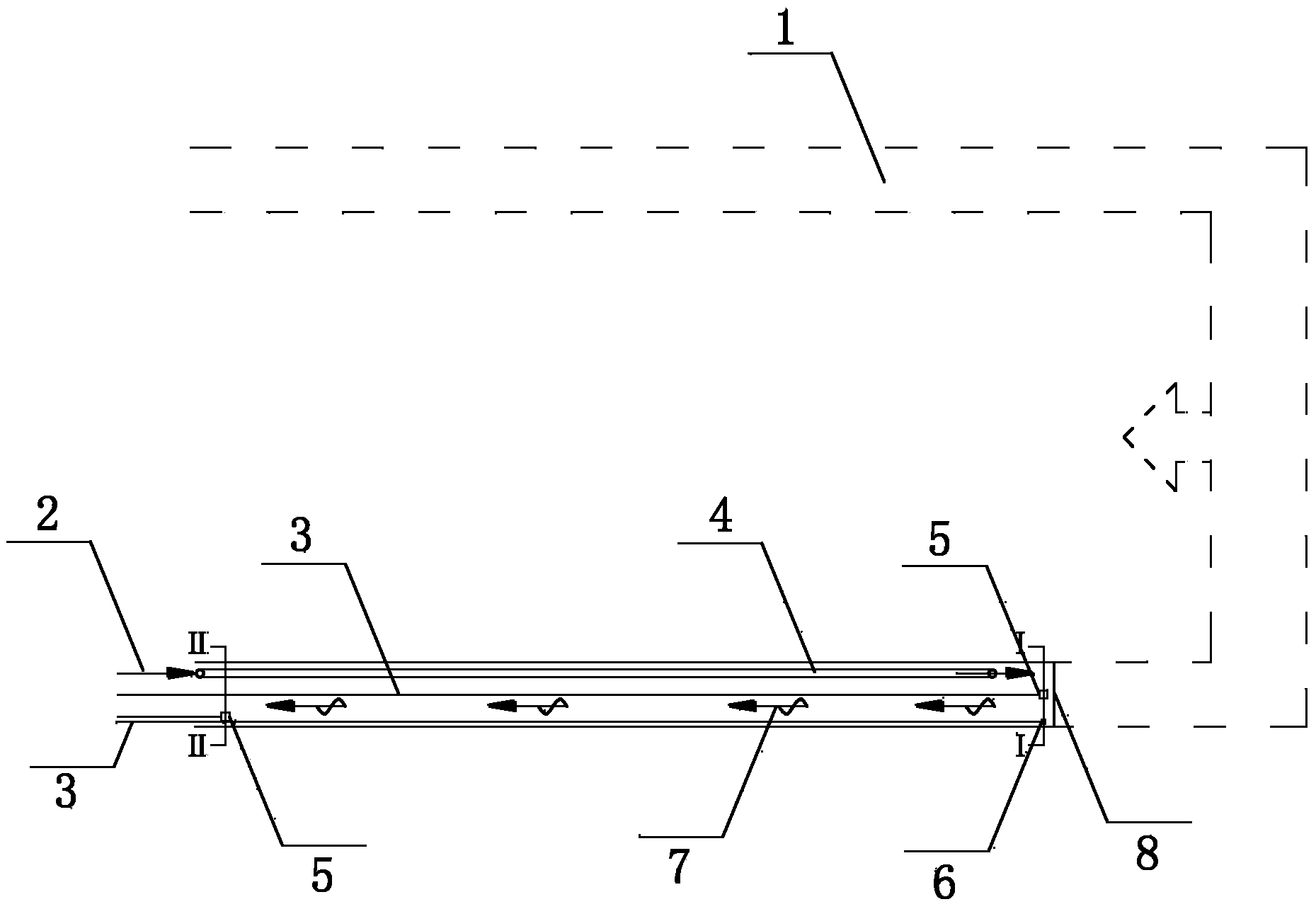

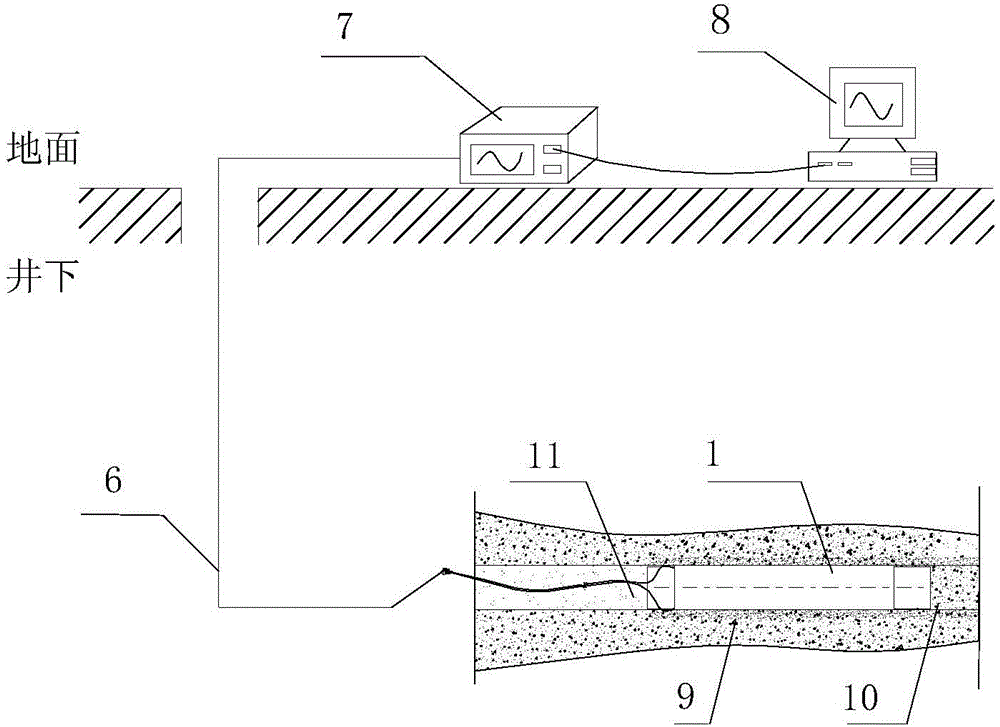

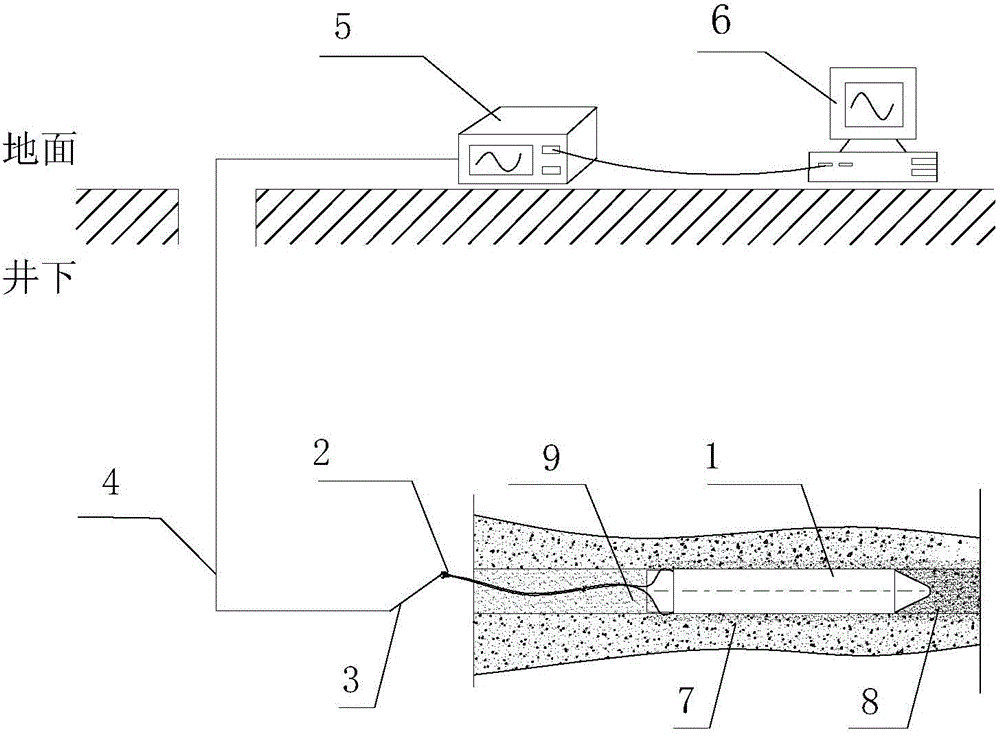

Surrounding rock stress on-line monitoring system and method based on fiber bragg grating borehole stress meter

ActiveCN103454020AShort lifeMonitoring accuracy is not goodForce measurement by measuring optical property variationFiberGrating

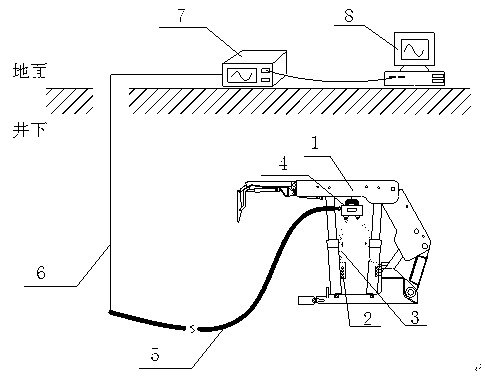

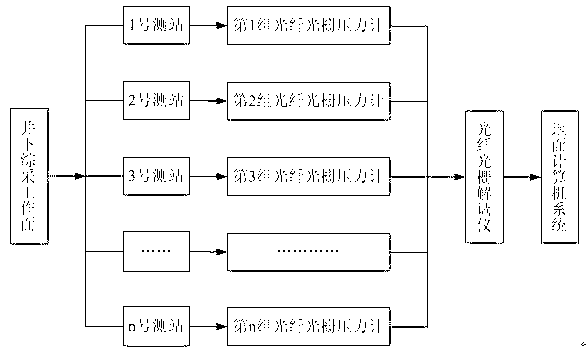

The invention relates to a surrounding rock stress on-line monitoring system and method based on a fiber bragg grating borehole stress meter. A plurality of measurement points are arranged on a surrounding rock, the fiber bragg grating borehole stress meter is installed in a surrounding rock wall drill hole, an optical fiber connector is connected with an optical fiber, and the optical fiber is connected to a mining optical cable, is then directly connected to the ground, and is connected with a fiber bragg grating modulator; an optical signal is modulated to a digital signal by the fiber bragg grating modulator, the digital signal is transmitted to a computer, is monitored in real time and is analyzed and processed, and a surrounding rock axial stress and transverse stress analyzing and processing method is provided under the temperature compensation condition according to grating stress characteristics. The surrounding rock stress on-line monitoring system and method have the advantages that equipment is easy to install, long in service life and suitable for popularization and use; power supply is not needed underground, electrical signals and electronic devices do not exist, and therefore the field is safe; because all-optical measurement and optical fiber transmission are adopted, monitoring precision is greatly improved, and effect of electromagnetic interference can be effectively avoided under complex and poor environment; surrounding rock stress monitoring results can be provided in time and guiding of field production and scientific research work is facilitated.

Owner:CHINA UNIV OF MINING & TECH

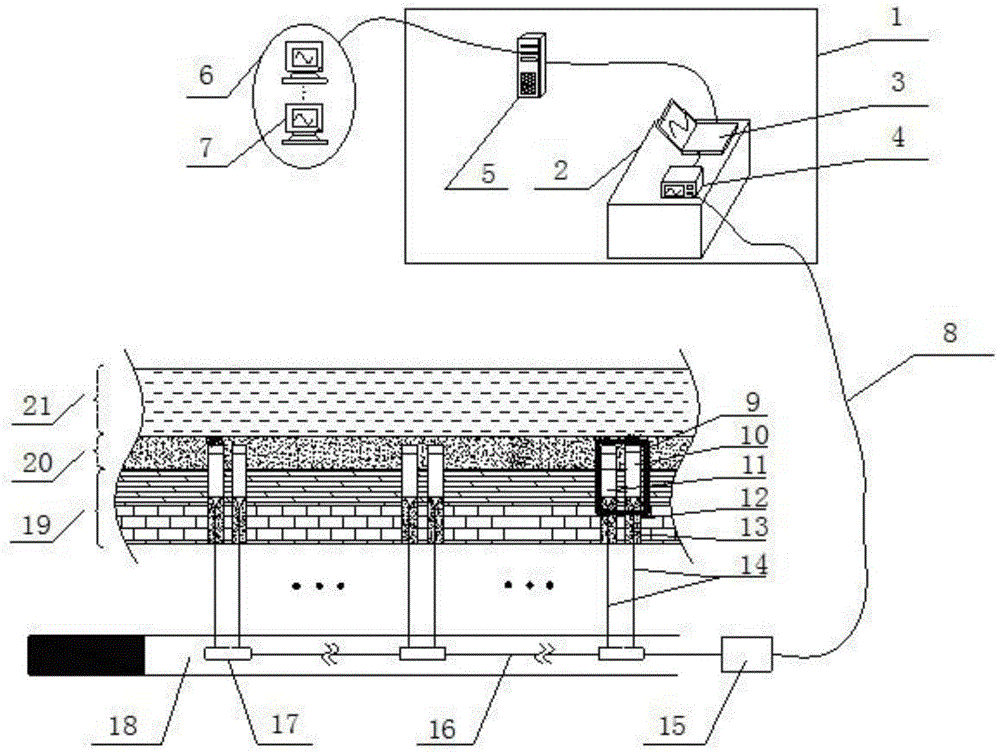

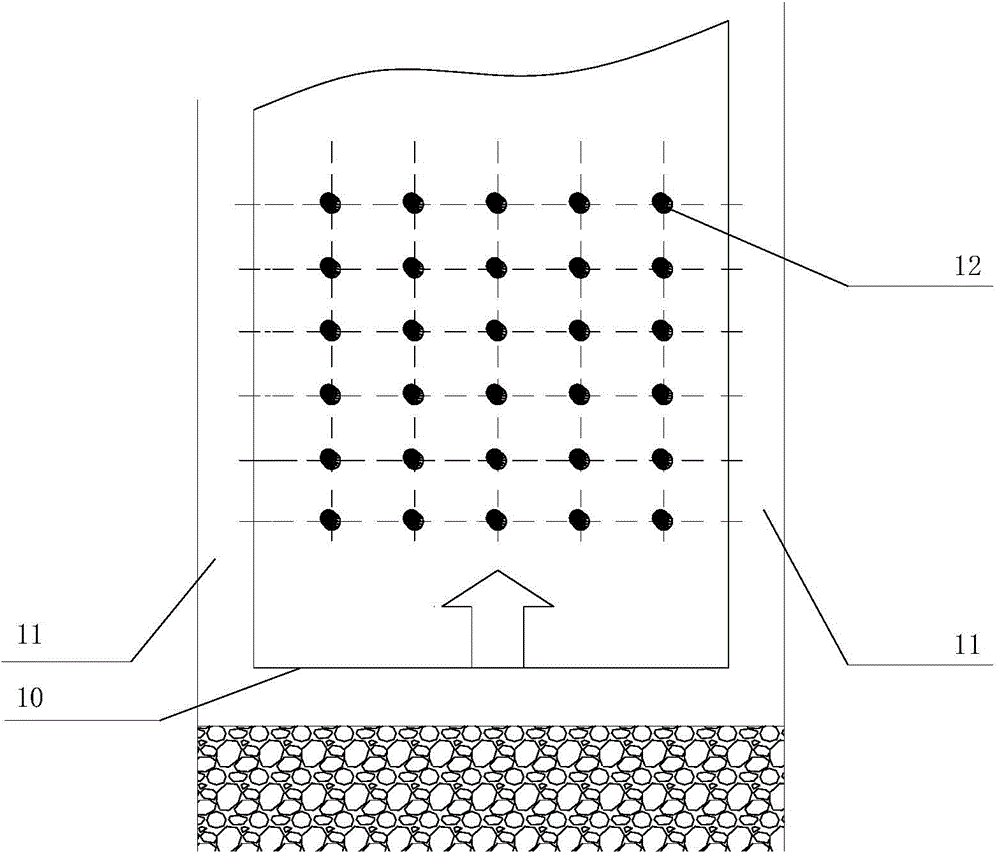

Working face mine pressure on-line monitoring system based on fiber grating sensing

InactiveCN103257009ARealize online monitoringRealize functionForce measurement by measuring optical property variationFiberGrating

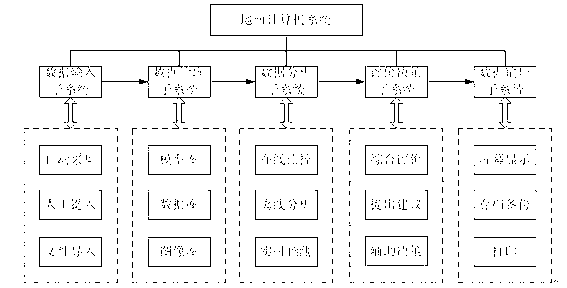

The invention belongs to mine pressure on-line monitoring systems, and discloses a working face mine pressure on-line monitoring system based on fiber grating sensing. According to the monitoring system, a plurality of measurement points are selected on a working face in a pit, one monitoring system is installed inside each measurement point, a hydraulic control valve of each monitoring system is installed in a hydraulic support and is connected with a pressure guide hole of an intrinsic safety type fiber grating pressure meter through an oil pipe, an optical signal of the intrinsic safety type fiber grating pressure meter is transmitted to a fiber grating demodulator on the ground through an optical fiber and a mining optical cable, the fiber grating demodulator is demodulated into a digital signal to be transmitted to a computer system, and the computer system carries out real-time monitoring and analysis processing. The working face mine pressure on-line monitoring system based on the fiber grating sensing has the advantages of being simple in installation, adopting full-optical measurement and optical fiber transmission, being capable of effectively avoiding influence of electromagnetic interference, greatly improving monitoring accuracy due to adoption of a temperature compensation grating for compensating a temperature error, and being capable of timely providing a working face mine pressure monitoring and predicting result so as to bring convenience to production and scientific researches of a guidance site.

Owner:CHINA UNIV OF MINING & TECH

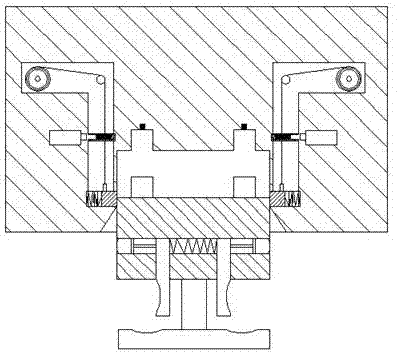

Installing method for assembly type hanging bracket for pipelines

InactiveCN107990052AQuality assuranceReduce work intensityPipe supportsStress conditionsModel refinement

The invention discloses an installing method for an assembly type hanging bracket for pipelines, and belongs to the field of building construction. The installing method comprises the following stepsthat A, construction preparation is carried out; B, position design is carried out, wherein three-dimensional modeling is carried out through BIM on a construction site, and model refinement and supporting hanging bracket distribution point optimization design are carried out through REVIT software in a model according to section drawings of the pipelines and the stress conditions; C, the supporting hanging bracket is manufactured; D, the supporting hanging bracket is assembled; E, measuring and setting out are carried out, wherein measuring and setting out are carried out on the constructionsite according to a building structure diagram through infrared level gauges, and lines are marked on the designed positions of distribution points of the supporting hanging bracket; and F, a supporting hanging bracket system is installed, and the assembled complete set of supporting hanging bracket is assembled and installed on the construction site. By adopting the installing method, the problems of complex processes, a long construction period and serious environmental pollution existing in site production are solved.

Owner:CHONGQING CONSTR ENG SECOND CONSTR CO LTD

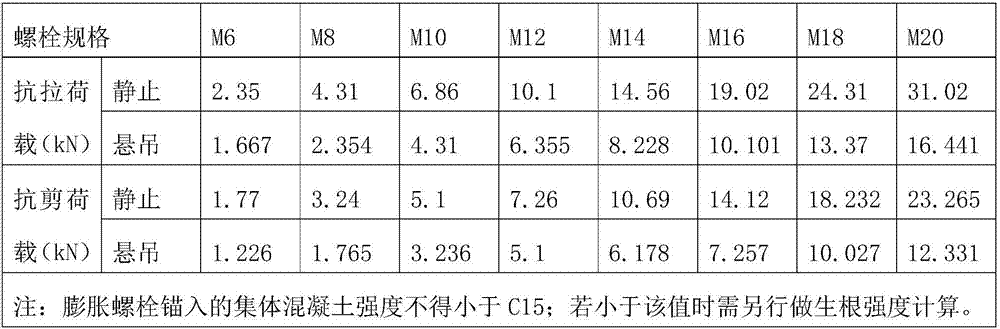

Train reminding and pre-warning system

ActiveCN105416340AReduce accidentsEnsure site safetySignalling indicators on vehiclePhase splittingMobile device

The invention discloses a train reminding and pre-warning system which comprises a master server, wireless service hosts and trainman handheld mobile devices. A reminding and pre-warning database is updated by the master server in real time, and newest reminding and pre-warning data is acquired in real time according to duty lines and automatically pushed to the mobile devices. The wireless service hosts are responsible for the large file storage service and communication between the mobile devices and the master server. The mobile devices carry out reminding and pre-warning on trainmen dynamically in the forms of images, characters and sounds in the running process according to the public service line where a train is located at present and kilometer posts. Reminding and pre-warning comprises reminding of various safety places, reminding before arrival, stop reminding, departure reminding, phase splitting reminding, route indicator reminding, construction running reminding, brake force testing and train tail relevant reminding, and running accounts are recorded automatically. By means of application of the train reminding and pre-warning system, the operation level of the trainmen can be effectively increased, and forceful guarantees are provided for running safety.

Owner:HENAN THINKER INFORMATION TECH CO LTD

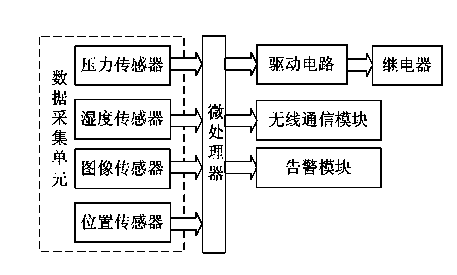

Integrated real-time monitoring system of excavating equipment

InactiveCN103742142AEnsure site safetyMining devicesSlitting machinesStress sensorsReliability engineering

An integrated real-time monitoring system of excavating equipment is disclosed. The excavating cutting equipment is provided with a pressure sensor, a temperature sensor, an imaging sensor and a position sensor which form a data collecting unit. The output data of the data collecting unit is outputted to a microprocessor. The microprocessor is connected through a driving circuit to a relay and the relay controls a motor to be started and closed. The microprocessor is connected to a wireless communication module to achieve communication with a remote machine, and is connected to a warning module to achieve warning for persons on site. The system can acquire pressure, rock types and temperature nearby a cutting head the first time and can acquire the specific position of the cutting equipment, and send the information to the processor to be processed. The information is then sent to the remote machine through a wireless way and monitored by the remote machine in real time, and therefore the cutting device is effectively protected and the on-site safety is guaranteed.

Owner:SHAANXI JOIN CREATE SCI & TECH

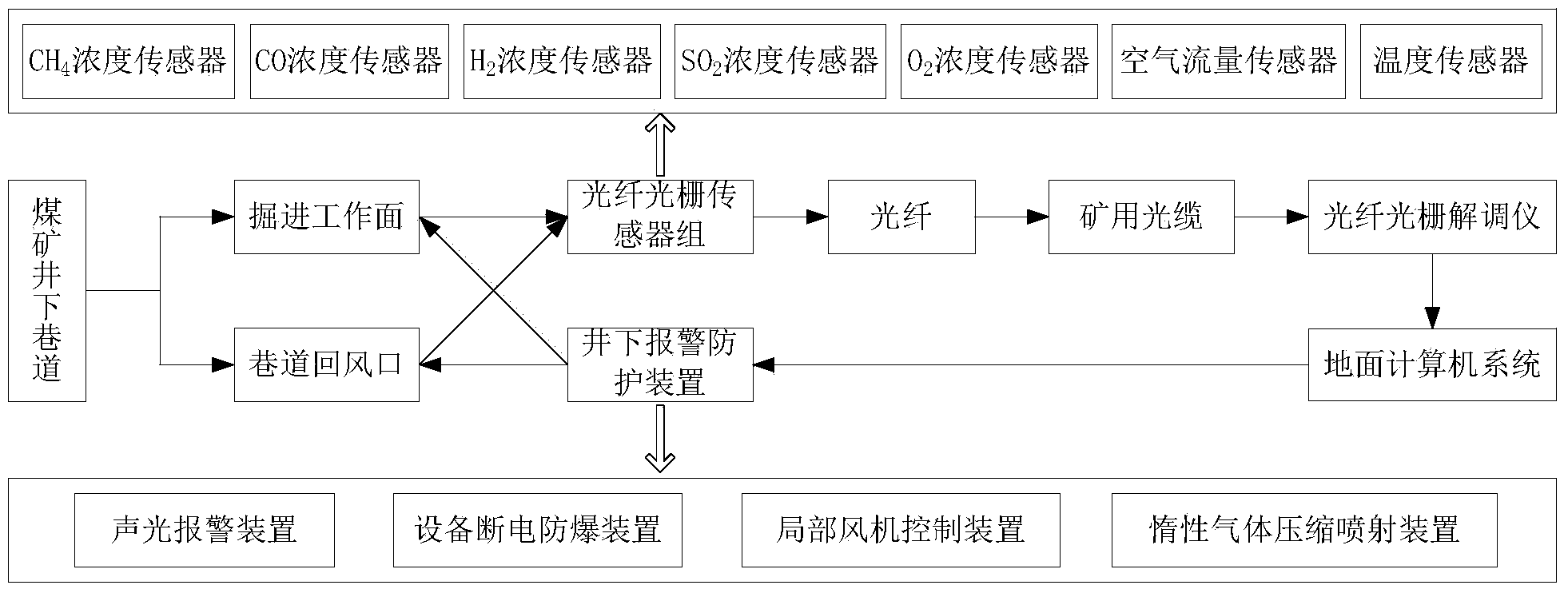

Roadway gas monitoring system based on optical fiber grating sensing technology

InactiveCN103528951AImprove test accuracyHigh test sensitivityMaterial analysis by optical meansGratingMonitoring system

The invention discloses a roadway gas monitoring system based on an optical fiber grating sensing technology, belonging to the roadway gas monitoring system. The monitoring system comprises a grating optical fiber sensor set, an underground alarm protective device, an optical fiber, a mining optical cable, an optical fiber grating demodulator and a computer system, wherein the grating optical fiber sensor set is arranged on a roadway tunneling working surface and a roadway air return port; the grating optical fiber sensor set is connected to the mining optical cable by the optical fiber; the mining optical cable is connected with a ground optical fiber grating demodulator; the ground optical fiber grating demodulator is connected with the computer system; and an output end of the computer system is connected with the underground alarm protective device. The roadway gas monitoring system based on the optical fiber grating sensing technology disclosed by the invention has the advantages as follows: monitored result is more accurate; signal transmission distance is far, capacity of resisting disturbance is strong; the grating optical fiber sensors work inactively and do not need to be supplied with power underground, and do not have an electric signal and an electronic apparatus, so that field security is ensured; a monitored picture is directly displayed in figure, writing, report form, and the like, so that results can be timely monitored, and warning and forecasting of the roadway gas concentration can be realized, and therefore, the roadway gas monitoring system is beneficial to guiding field security production work.

Owner:CHINA UNIV OF MINING & TECH

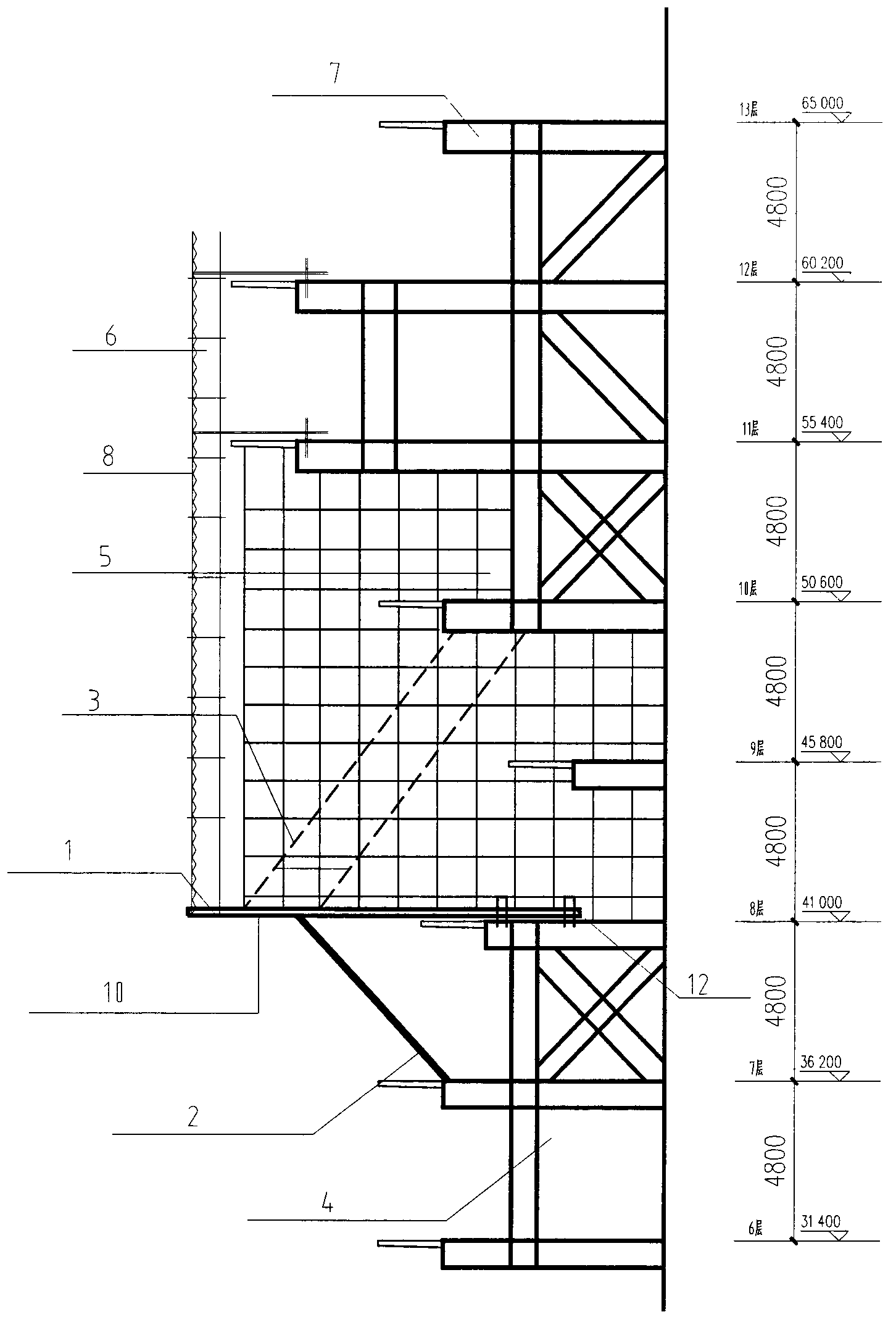

Long-length overhang trusswork high form hanger system

InactiveCN103306479AImprove construction efficiencyReduce investmentForms/shuttering/falseworksWire ropeCantilever

The invention discloses a long-length overhang trusswork high form hanger system comprising an upper truss body and a lower truss body. The lower truss body comprises an upper-supported steel cantilever beam, a lower-supported steel bracket, a pull-up steel wire rope and a lower frame concrete truss. The long-length overhang trusswork high form hanger system has the advantages that construction efficiency is greatly improved, input of revolving materials is reduced, production cost is saved, building time is reduced, and unit time availability of machinery and staff is increased.

Owner:中铁北京工程局集团北京有限公司

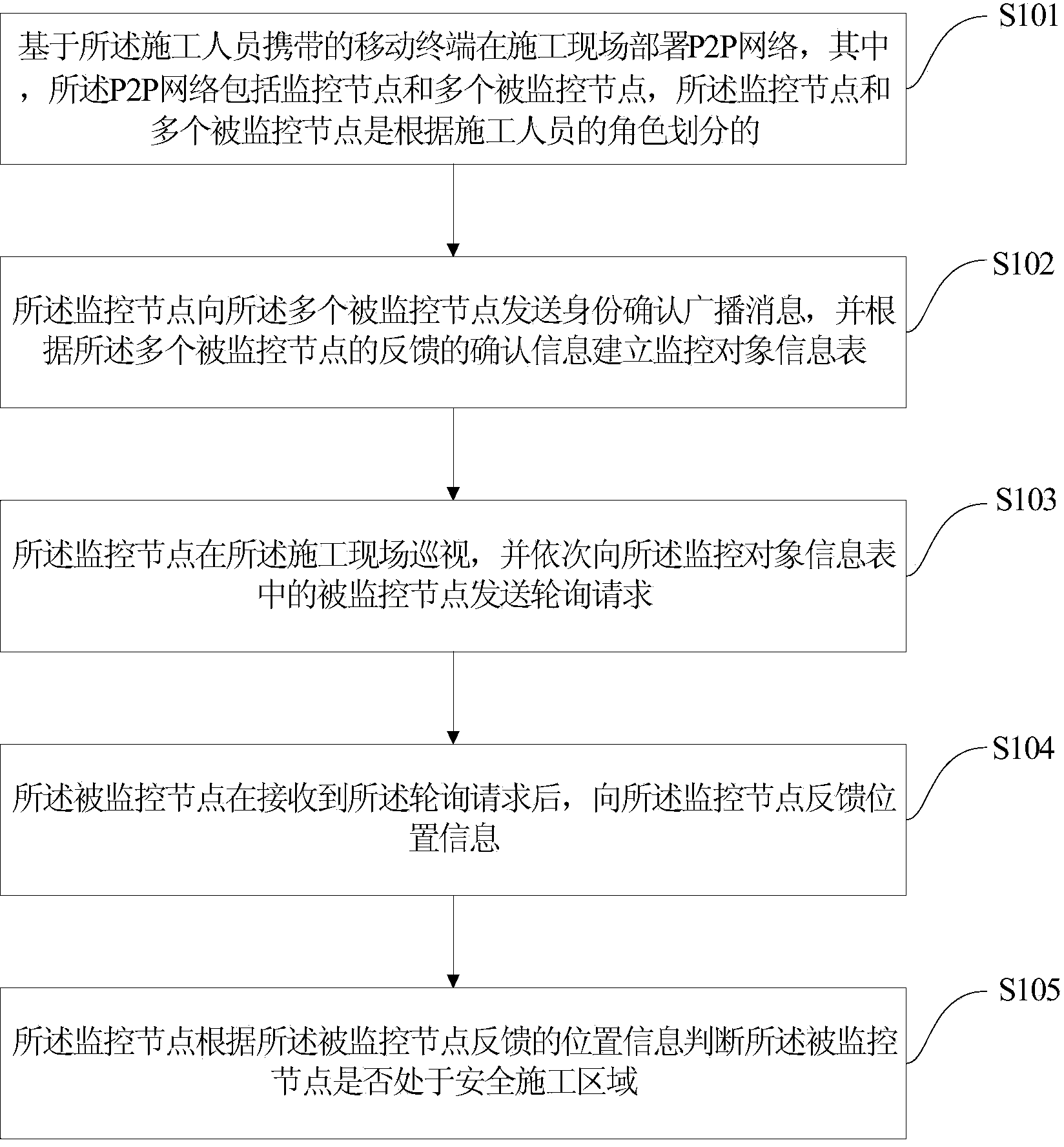

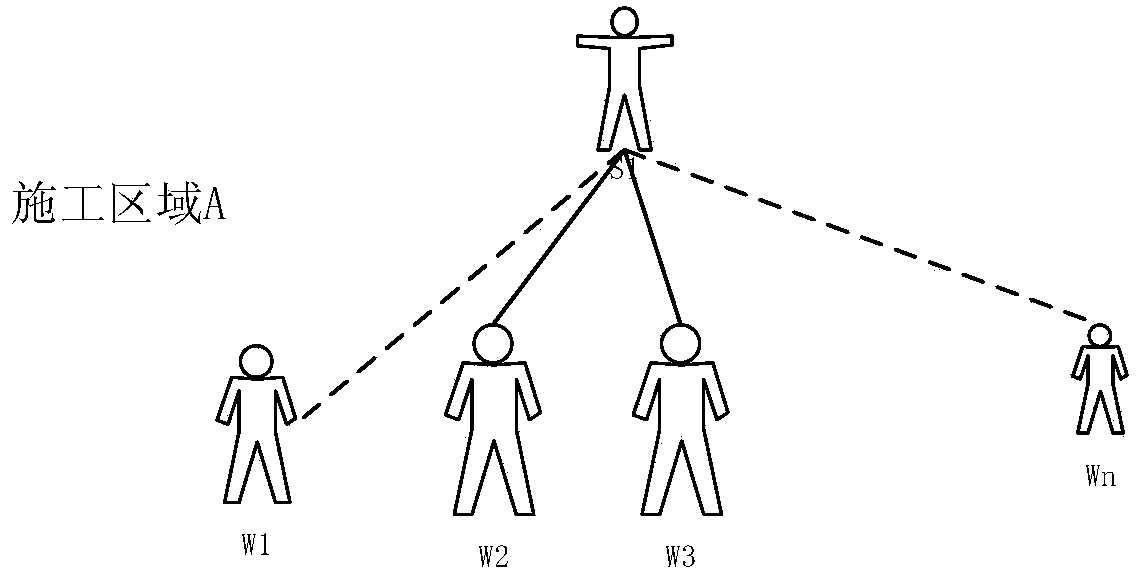

P2P (peer-to-peer) network based construction personnel safety monitoring method and system

ActiveCN104360645AEnsure site safetyTotal factory controlProgramme total factory controlComputer terminalPeer-to-peer

The invention provides a P2P (peer-to-peer) network based construction personnel safety monitoring method and system. The method includes: deploying a P2P network, which comprises a monitoring node and a plurality of monitored nodes, on a construction site on basis of mobile terminals carried by construction personnel; allowing the monitoring node to transmit, in sequence, a poll request to the monitored nodes in a monitoring object information table; after receiving the poll request, allowing the monitored nodes to feed position information back to the monitoring node; allowing the monitoring node to judge whether or not the monitored nodes are in the safety construction area according to the position information fed back by the monitored nodes. The monitoring node and the monitored nodes are divided according to roles of the construction personnel. The method and the system according to the embodiment have the advantage that site safety is provided with certain guarantee.

Owner:TSINGHUA UNIV +1

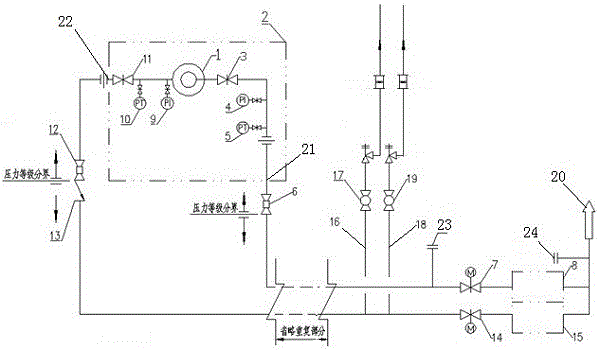

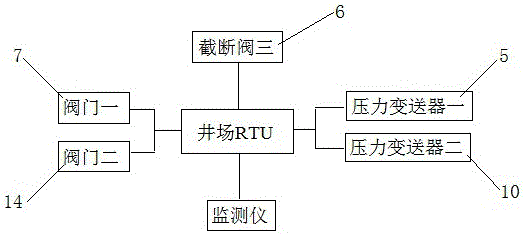

Air foam flooding oil-extraction well site device and air foam flooding oil-extraction well site technology

ActiveCN106761622ARealize safe venting and pressure reliefProtection processSurveyConstructionsElectricityGeneration process

The invention provides an air foam flooding oil-extraction well site device and an air foam flooding oil-extraction well site technology. A first pressure transmitter is arranged between an oil extraction wellhead and an oil tubing outlet, a second pressure transmitter is arranged between an oil extraction wellhead and a casing gas outlet, a third intercepting valve and a first valve are sequentially arranged on a pipeline between the oil tubing outlet and a well site pitching device, a fourth intercepting valve, a check valve and a second valve are sequentially arranged on a pipeline between the casing gas outlet and a casing gas constant-pressure gas release area, and the first pressure transmitter, the third intercepting valve, the first valve, the second pressure transmitter and the second valve are electrically connected to a well site RTU. The air foam flooding oil-extraction well site device and the air foam flooding oil-extraction well site technology have the advantages that through a normal production process, a gas channeling generation process, a safety emptying process and an oxygen content monitoring process, production safety is ensured, safety, high automation degree and environment protection are achieved, the technical problems that air foam flooding personnel is high in operation labor intensity and potential safety hazard are solved, and accordingly the device and the technology are promising in application prospect for test or oil fields employing enhanced oil recovery.

Owner:XIAN CHANGQING TECH ENG

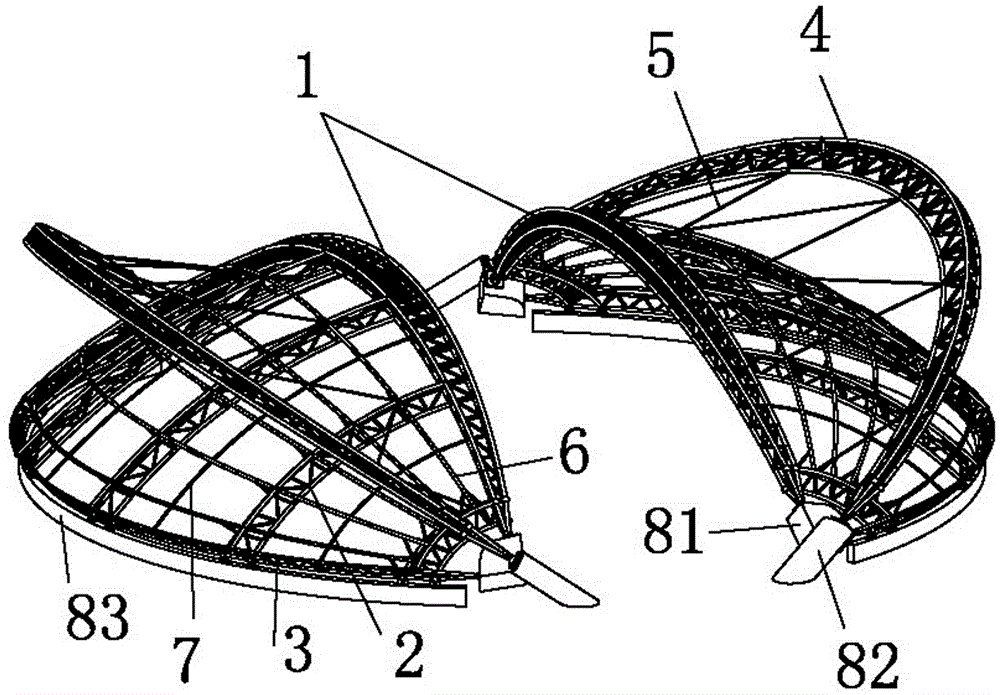

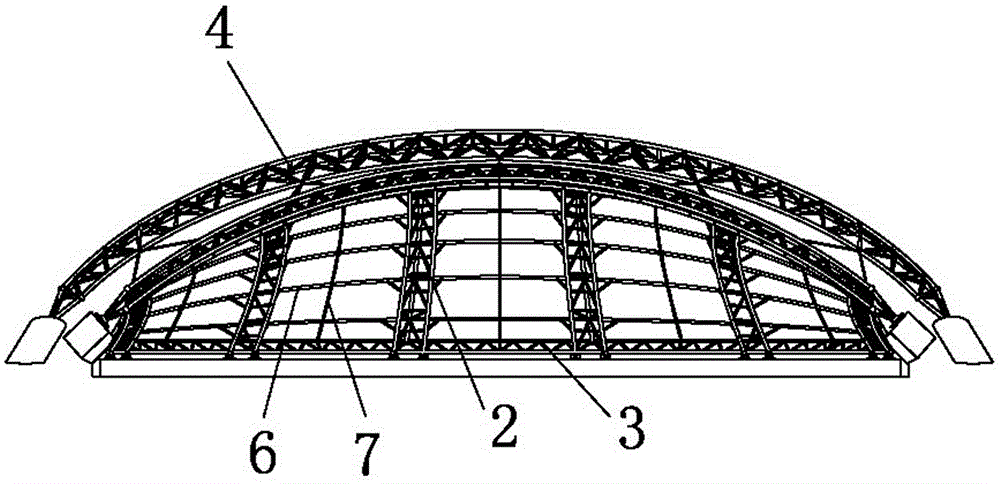

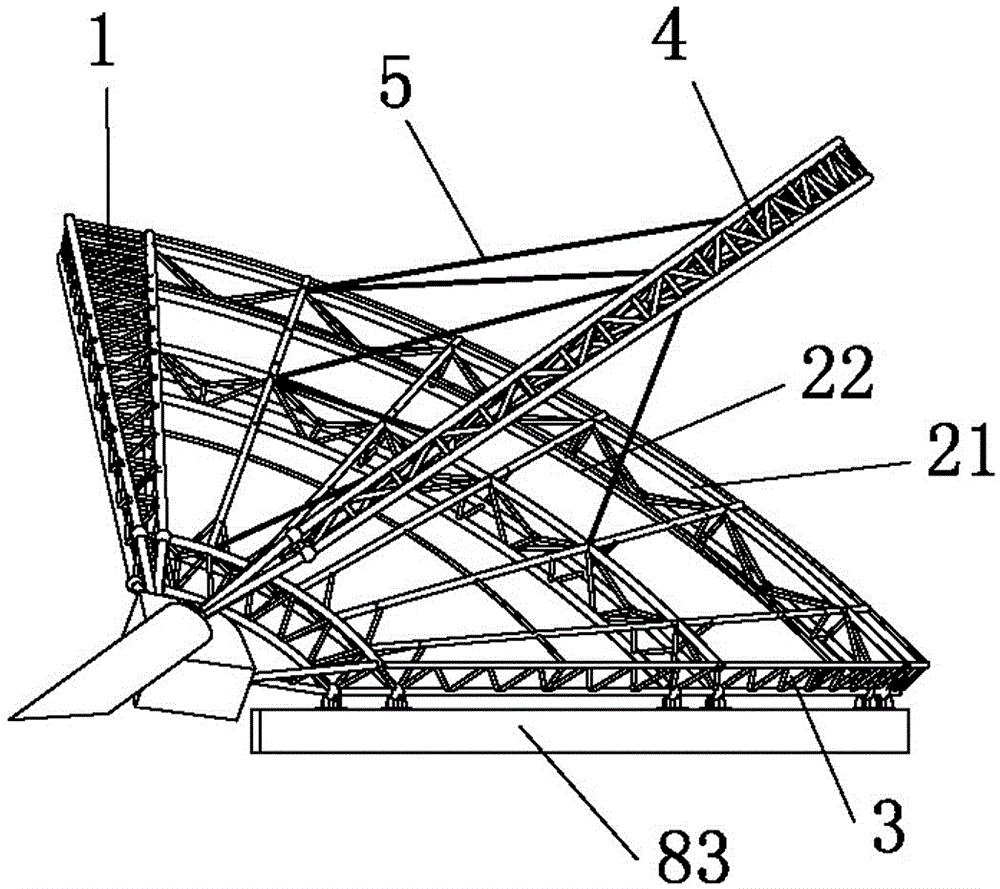

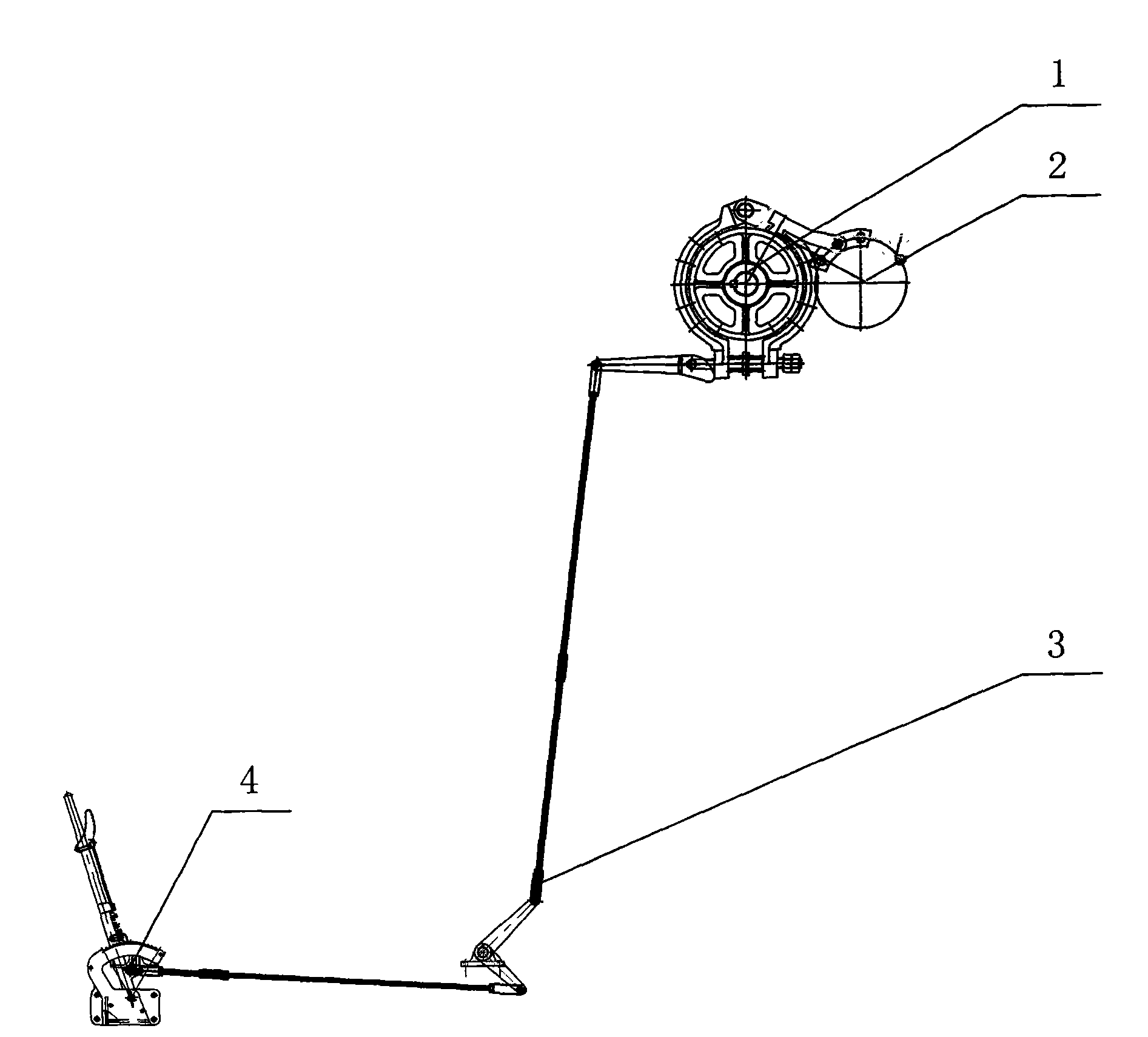

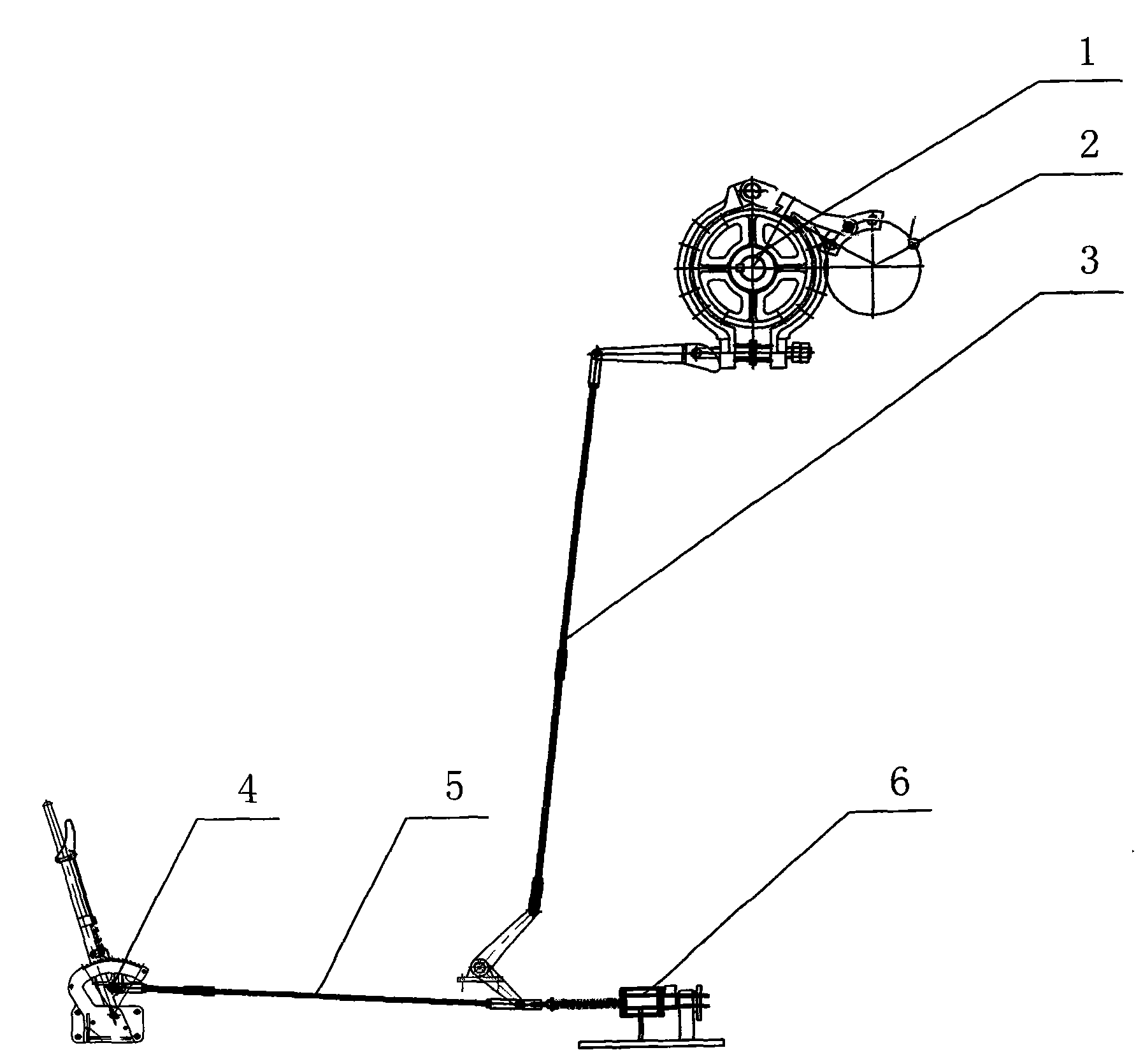

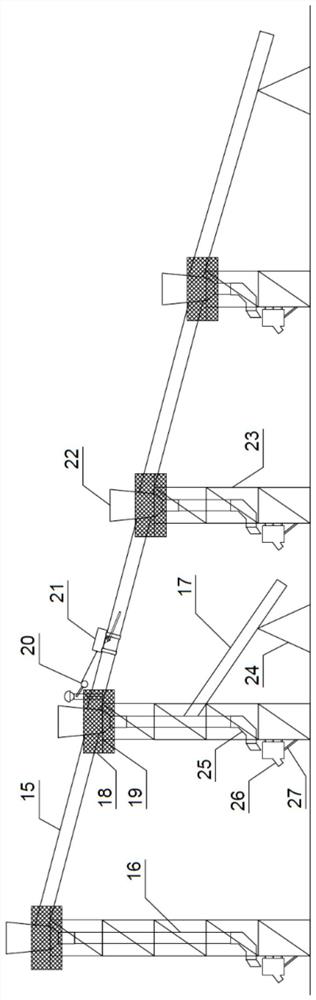

Flying-wing-type formwork space truss structure and construction method thereof

ActiveCN105019557AEnsure site safetyEnsure site safety and construction qualityExtraordinary structuresBuilding material handlingEngineeringPulley

The invention belongs to the field of steel structure construction, and particularly discloses a flying-wing-type formwork space truss structure and a construction method thereof. The flying-wing-type formwork space truss structure comprises main trusses, auxiliary trusses and parallel chord member trusses. The main trusses, the auxiliary trusses and the parallel chord member trusses are welded and fixedly connected to form a formwork space truss structure body. The flying-wing-type formwork space truss structure further comprises flying-wing-type trusses located above the formwork space truss structure body. The flying-wing-type trusses are connected with the auxiliary trusses of the formwork space truss structure body through draglines. The invention further discloses the construction method of the flying-wing-type formwork space truss structure. The construction method includes the construction steps of support installing, main truss installing, hemisphere auxiliary truss installing, steel dragline constructing and the like. By means of the flying-wing-type formwork space truss structure, a whole structure is more stable, a chain block and a wall pulley are matched to carry out steel structure installing and steel dragline tensioning, the construction method is simple, the number of adopted machines is small, the site safety is guaranteed, the construction quality is also guaranteed, and the construction cost is greatly reduced.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

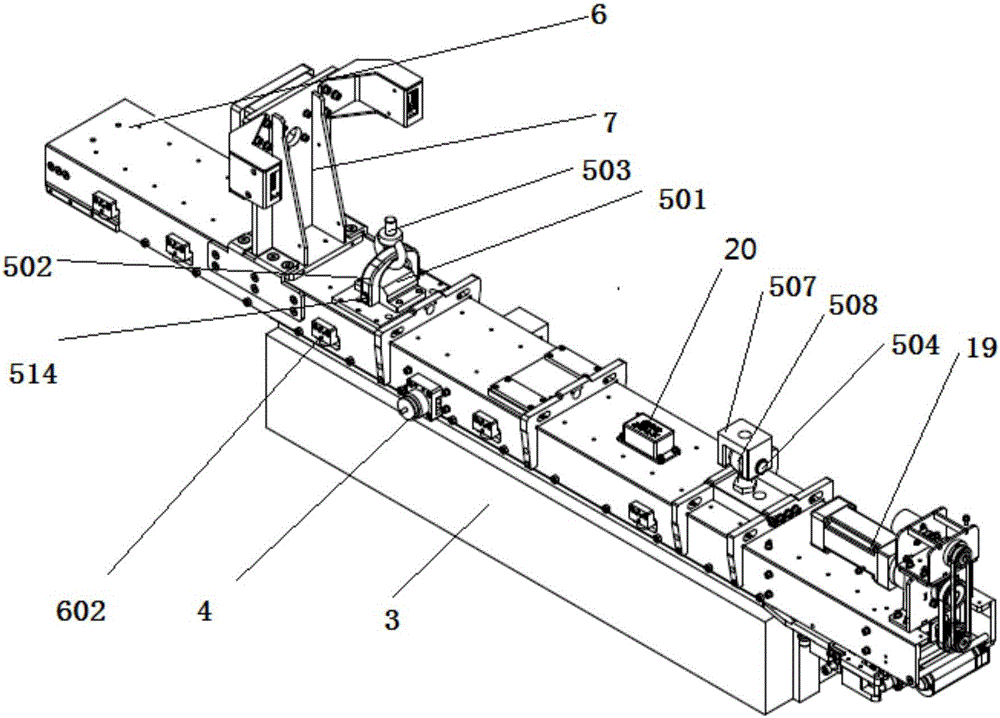

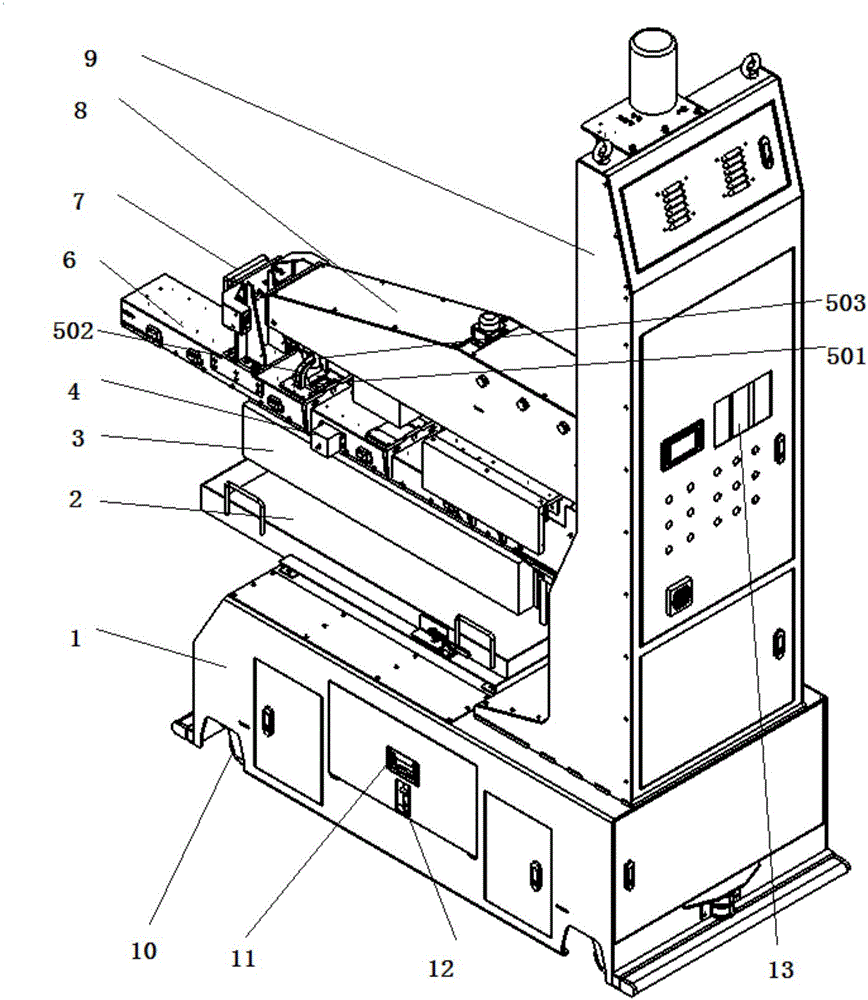

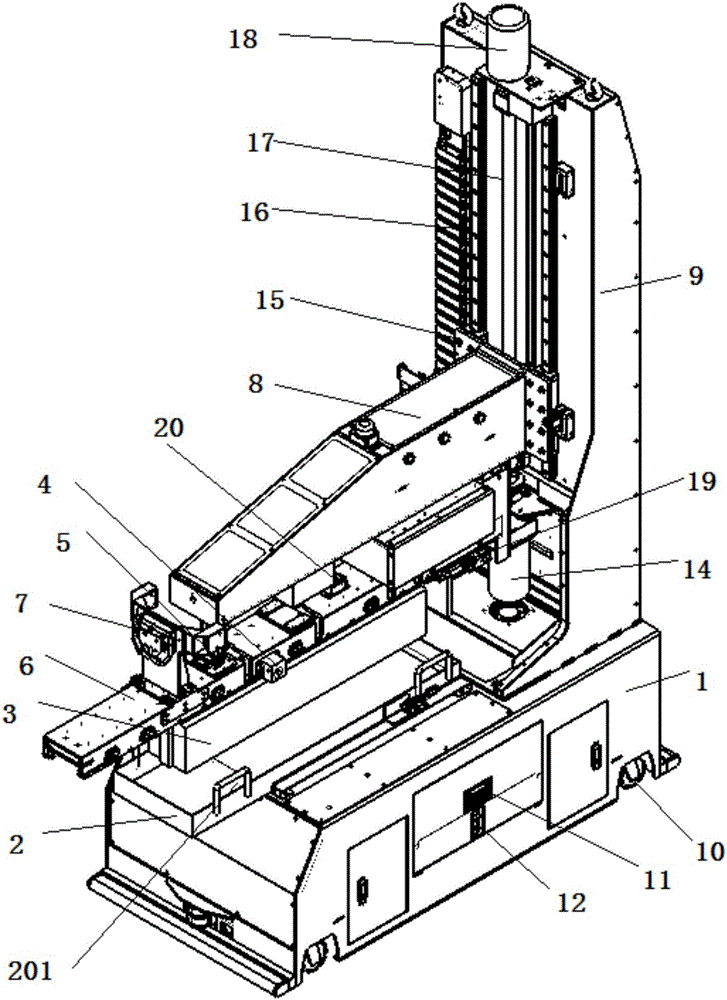

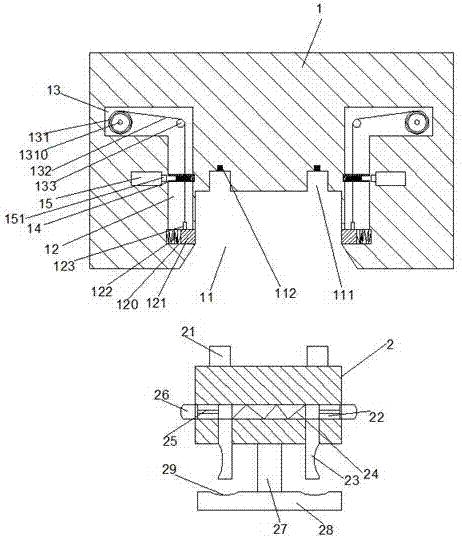

Clamping mechanism for loading and unloading silicon rods

ActiveCN106743634AAchieve clamping and fixingImprove securityAfter-treatment apparatusNuclear energy generationEngineeringCopper

The invention provides a clamping mechanism for loading and unloading silicon rods. The clamping mechanism comprises a magnet fixing seat. A stepped through hole is formed in the center of the magnet fixing seat. A copper column is elastically connected in the through hole through a spring. An electromagnet is fixed to the magnet fixing seat. A sliding column penetrates through the electromagnet and is in clearance fit with the electromagnet. An iron block is fixed to the end, close to the electromagnet, of the sliding column. According to the clamping mechanism for loading and unloading the silicon rods, the clamping mode is firm and reliable, the silicon rods are further clamped, the effect is good, the silicon rods are further clamped and fixed by applying the clamping mechanism, the safety coefficient in the silicon rod transfer process is increased, operation is achieved through power on and power off, the mechanical maintenance frequency is reduced, and the service life is prolonged.

Owner:TIANJIN LONYU SCI & TECH PROGRESS

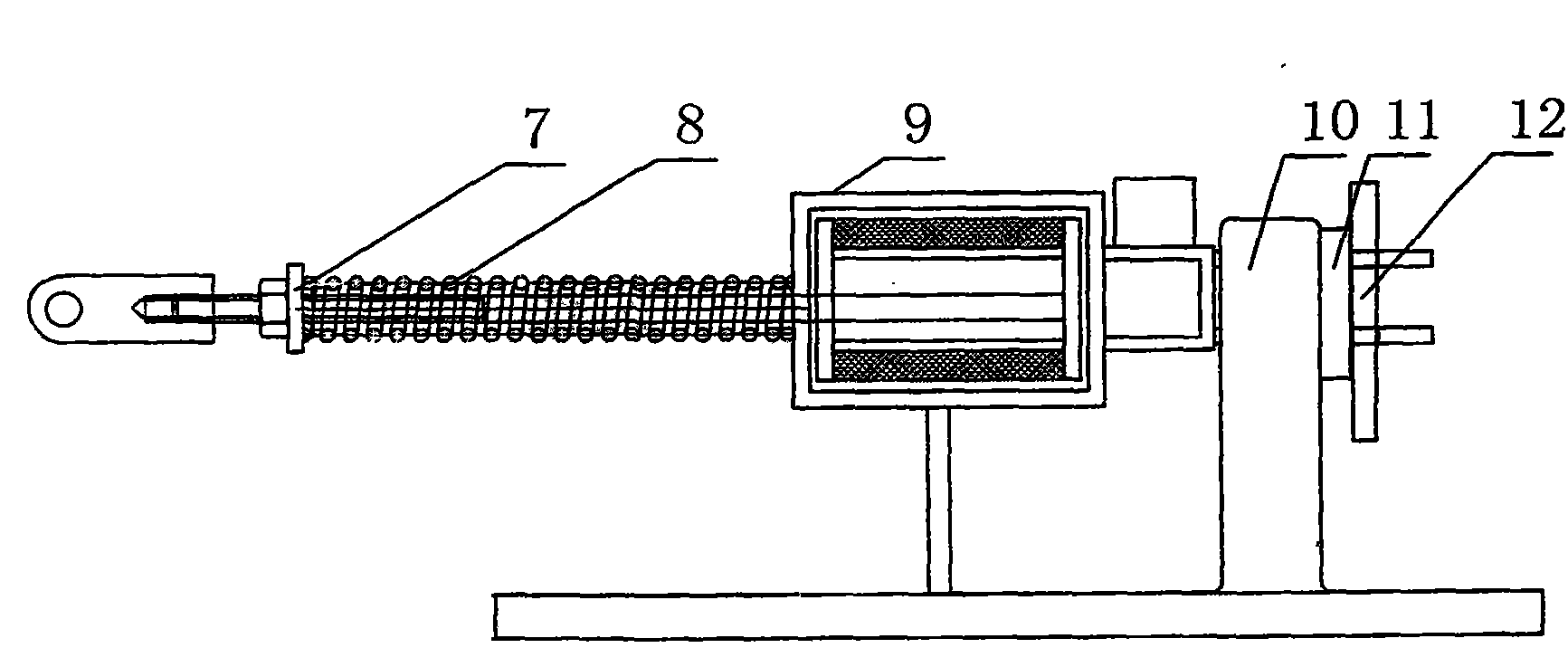

Automatic brake control system

InactiveCN103967452AImprove securityEnsure site safetyFluid removalAutomatic train controlAutomatic control

An automatic brake control system comprises a brake device, a parking insurance device, a connection rod device, an automatic control device, a connection steel wire rope, a hand brake device and the like. The automatic control device is composed of a push rod, a compression spring, an electromagnetic coil, a machine base, an adjusting gasket and a cylinder pin. The base is a carrier and is arranged on a pumping unit machine base, one end of the push rod is connected with a steel wire rope connector, the other end of the push rod is arranged on the compression spring in a sleeved mode and inserted into a center hole of the electromagnetic coil, and the cylinder pin is inserted into the right side of the machine base after a gasket gap is adjusted properly. The hand brake device is connected with the automatic control device through the flexible steel wire rope. According to the system, a motor can be braked in time during artificial parking, and a brake function can be achieved during a power grid failure without human intervention. Safety accidents caused by brake do not exist, the safety hidden hazard caused due to the fact that people forget to pull a hand brake is not caused, and the automatic brake control system is safe and reliable.

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

Safety control device for construction site

InactiveCN107978895AAchieve lockingReliable lockingLive contact access preventionSafety controlEngineering

The invention discloses a safety control device for the construction site, which comprises an electrification guide base and an electrification sliding head, wherein the bottom inside the electrification guide base is designed with a guide socket, the top of the guide socket is provided with guide socket slots communicated with the guide socket, the top of each guide socket slot is fixedly provided with a supply contact, both the left side and the right side of the electrification guide base are internally provided the same electrification cavities, the electrification cavity comprises a lowercavity arranged in a mode of extending along the vertical direction and an upper cavity arranged in a mode of extending along the transverse direction, the lower cavity and the upper cavity are connected, the bottom of the lower cavity is provided with a sliding cavity hole, an opening of the sliding cavity hole faces towards the guide socket, each sliding cavity hole is connected with the guidesocket, the inner layer of each lower cavity at the outer side of the sliding cavity hole is fixedly provided with a jacking loop spring. The safety control device is simple in structure and convenient to operate, the whole internal part adopts simple transmission, and the cost is low. Meanwhile, the safety of power utilization on the construction site is ensured, and unnecessary waste of resources is saved.

Owner:GUILIN XINGMEI INTELLIGENT TECH CO LTD

Installation method of prefabricated building pipeline support and hanger system based on bim

ActiveCN106989211BReduce work intensityEnsure site safetyGeometric CADPipe supportsEngineeringProduct model

Owner:ZHONGYIFENG CONSTR GRP

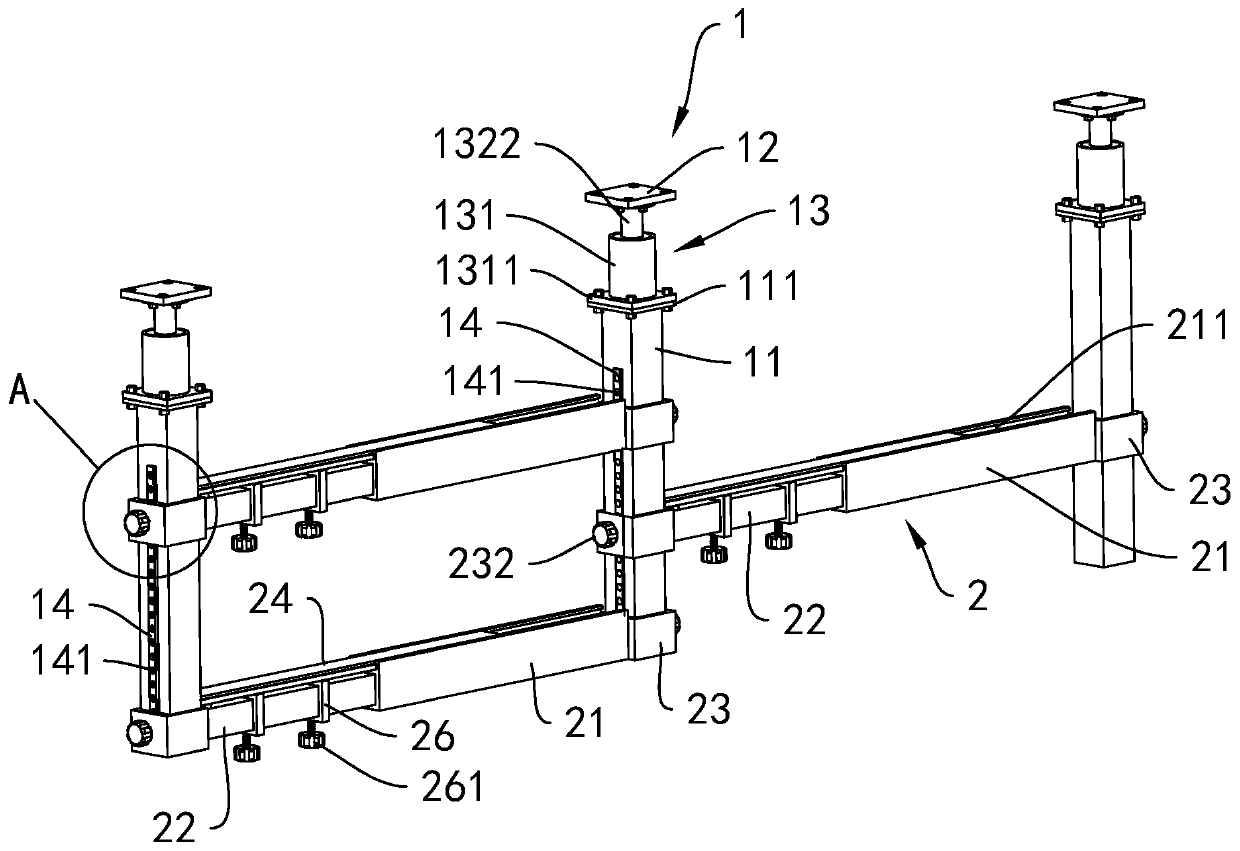

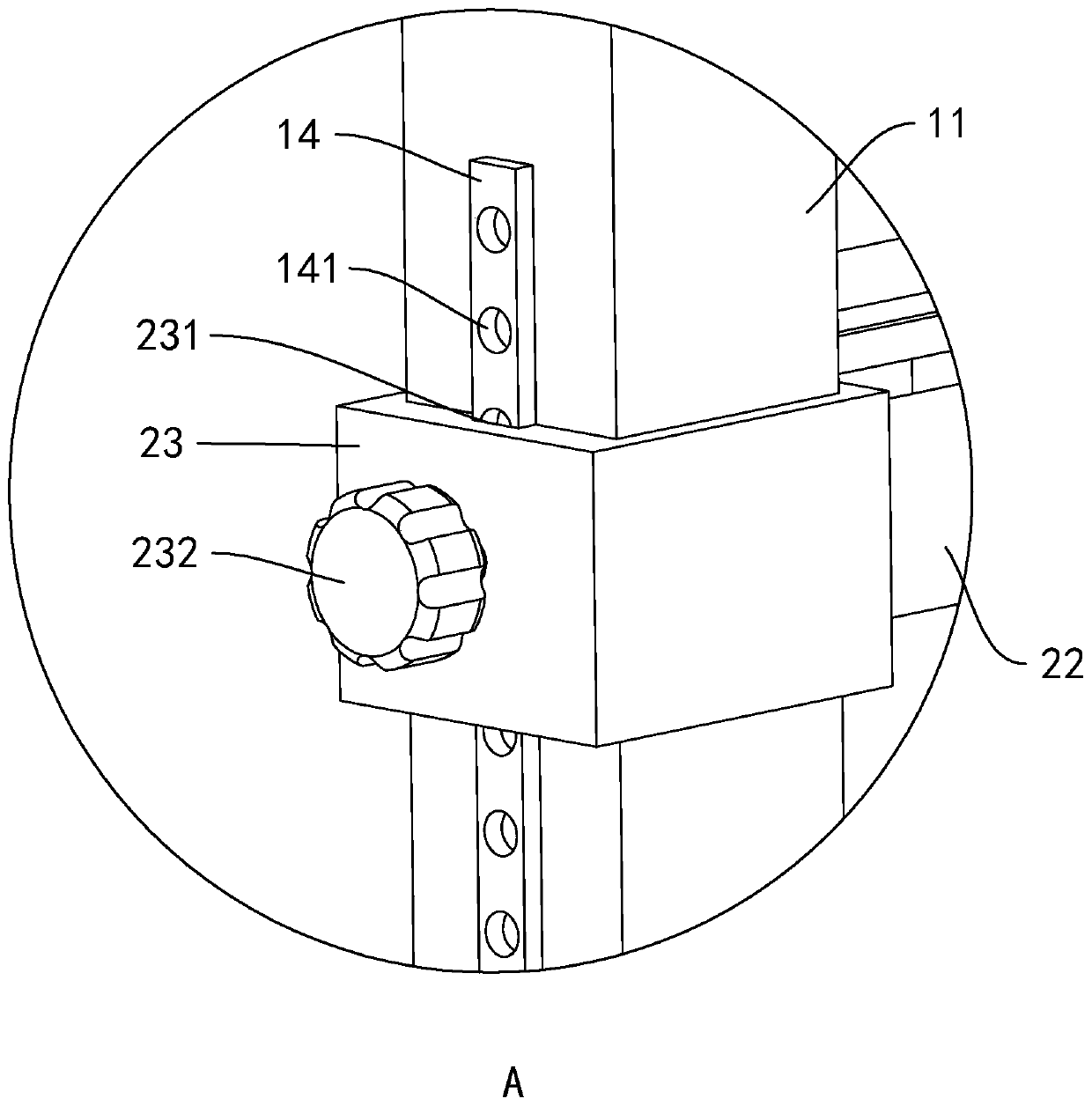

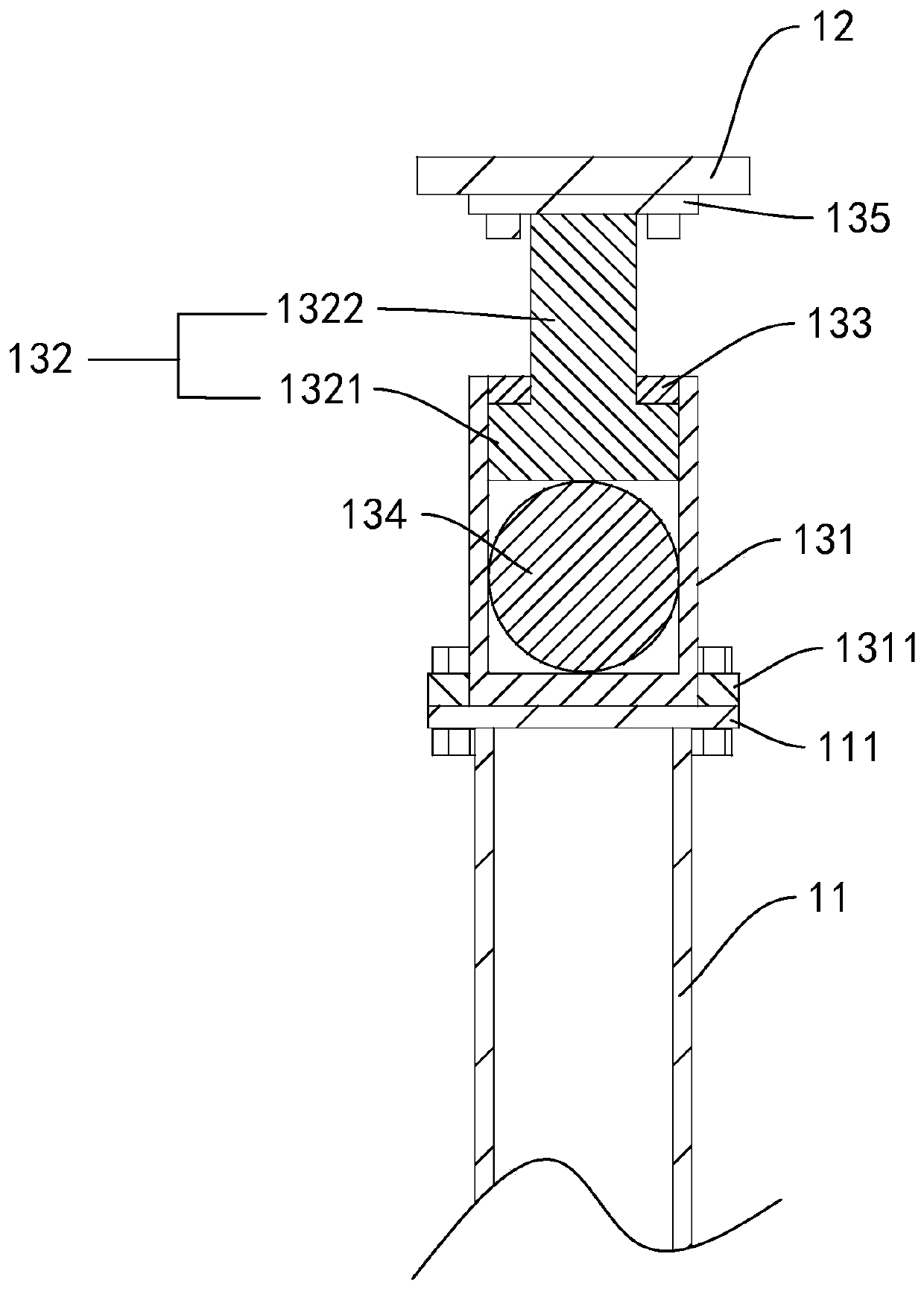

Electromechanical comprehensive support hanger and installation method thereof

PendingCN111271514APrevent looseningEnsure site safetyPipe supportsPipe elementsStructural engineeringLine tubing

The invention relates to an electromechanical comprehensive support hanger. The electromechanical comprehensive support hanger comprises at least two vertically-arranged stand columns, a connecting disc is arranged at the top ends of the stand columns, a length-adjustable bearing cross beam is arranged between every two adjacent stand columns, the bearing cross beams are horizontally arranged, sliding sleeves which are arranged on the adjacent stand columns in a sleeving mode and are connected with the stand columns in a sliding mode are arranged at the two ends of the bearing cross beam correspondingly, and fixing structures used for fixing the positions where the sliding sleeves are located are arranged between the sliding sleeves and the stand columns. The electromechanical comprehensive support hanger can be adjusted according to different sizes of ring corridors and mounting positions of pipelines in the ring corridors, so that large-scale production of the electromechanical comprehensive support hanger is realized; the invention further discloses an installation method of the electromechanical comprehensive support hanger, industrial production can be carried out, only assembly, positioning and punching of assemblies need to be carried out on an installation site, the site safety of operators is guaranteed, and the working intensity of workers is effectively reduced.

Owner:北京住总第一开发建设有限公司

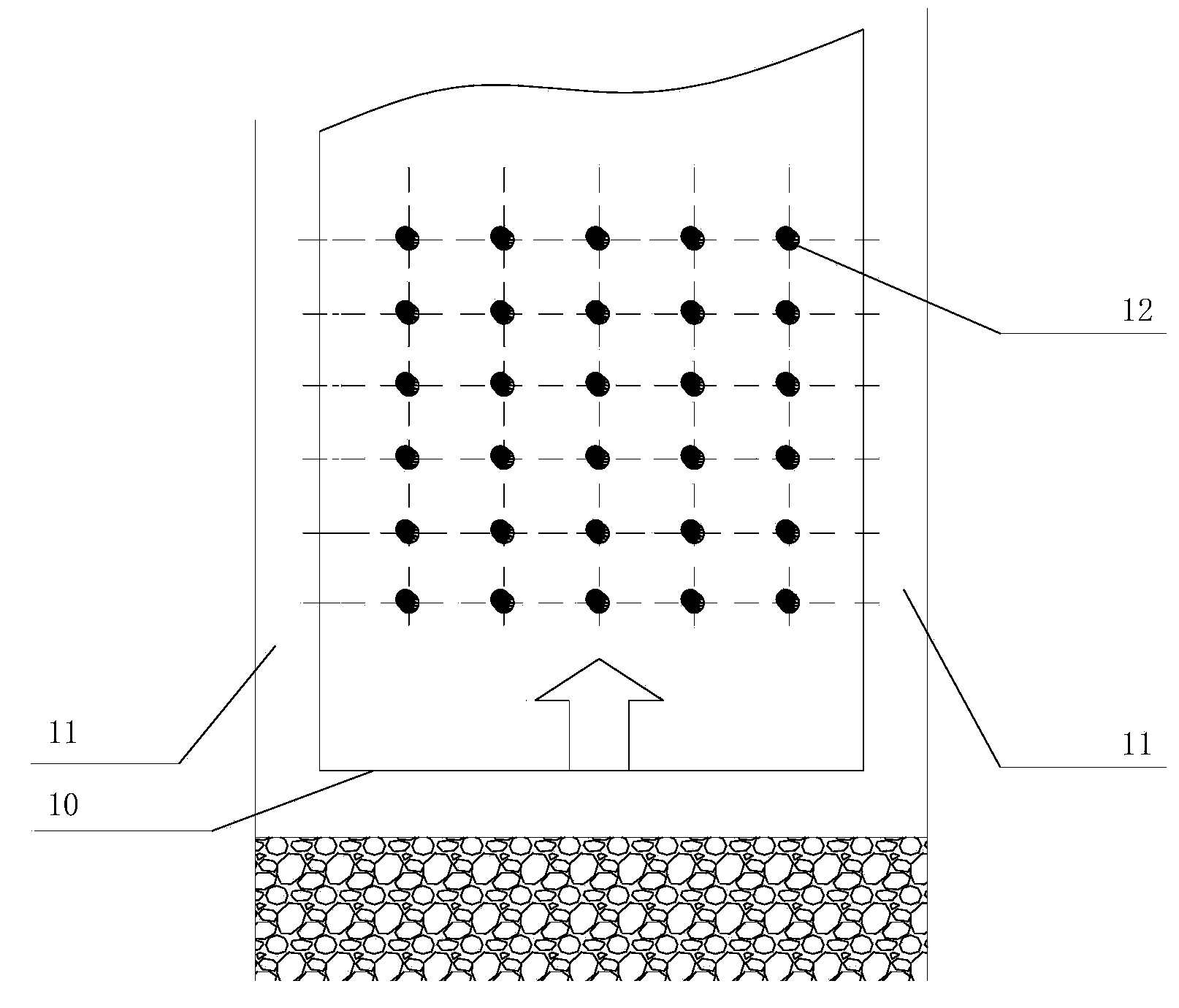

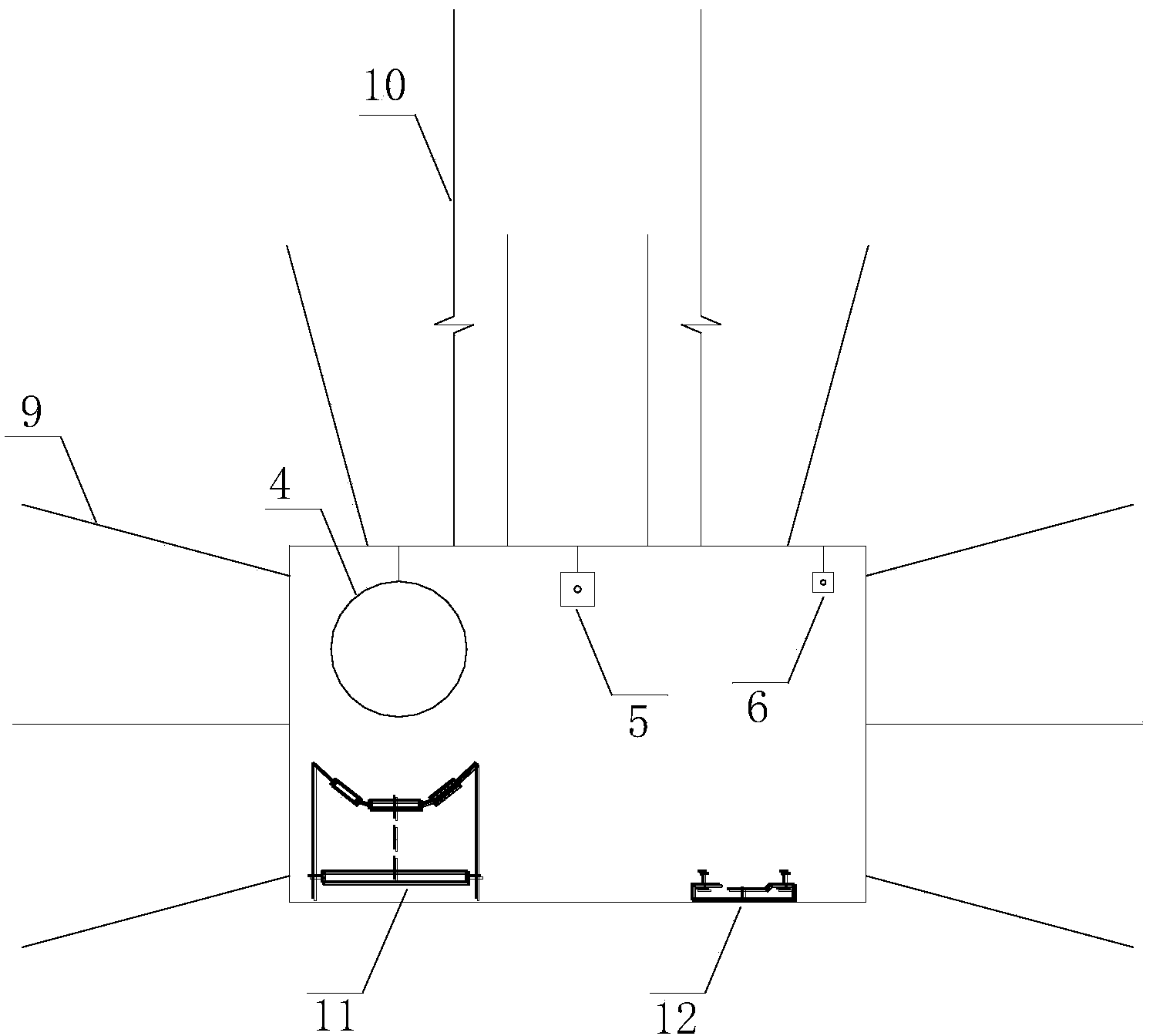

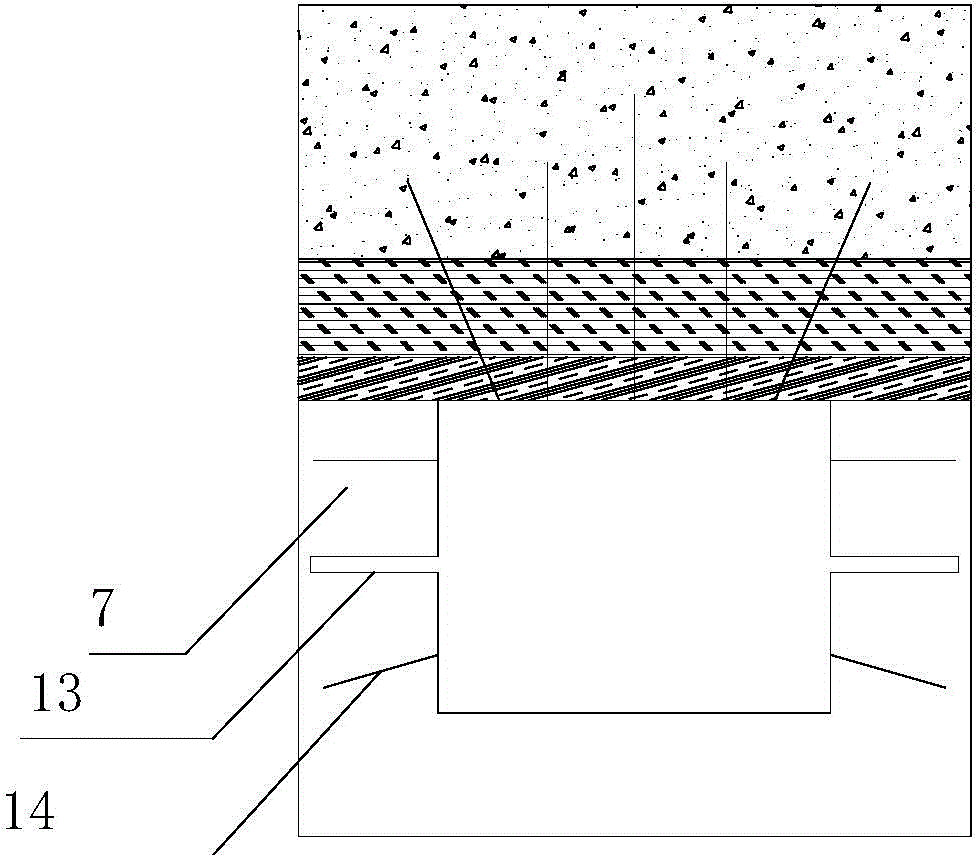

The stability monitoring system and method of coal mine roof aquifer based on fiber grating

Disclosed is a coal mine top plate aquiclude stability monitoring system based on a fiber Bragg grating. A measurement station is arranged on a work surface mining roadway, a vertical top plate drilling hole is drilled in a top plate of the work surface mining roadway to an aquiclude, a fiber Bragg grating pressure sensor is arranged at the top end of the drilling hole, a fiber Bragg grating top plate bed separation instrument is installed at the height position of the drilling hole between the aquiclude and a rock stratum below, and an optical fiber connector is led out of the drilling hole and connected with an optical fiber tail fiber, thereby being connected with an optical fiber splitter. The optical fiber connector is connected with an optical fiber terminal box through a communication optical fiber and connected to an optical fiber interrogator of a ground control chamber through a mining optical cable, signals are transmitted to a monitoring server after demodulation and are processed through the monitoring server, and the data processing result is shared with a client side through a mine local area network. The stability conditions of the aquiclude are monitored in real time through a computer display, and an alarm is given timely when the stress is near the bearing upper limit of the aquiclude and separation occurs between the aquiclude and the overlying strata blow.

Owner:CHINA UNIV OF MINING & TECH

Roadway surrounding rock stress monitoring device based on fiber bragg grating sensing

ActiveCN103454021BEasy to implementEasy to installForce measurement by measuring optical property variationUsing optical meansGratingFiber Bragg grating

The invention discloses a roadway surrounding rock stress monitoring device based on fiber bragg grating sensing. Grooves are symmetrically carved in a metal rod along the axial center, an FBG set is fixedly installed inside each groove, FBGs serve as sensitive elements, when roadway surrounding rock is deformed, the stress of the surrounding rock will be changed, therefore, force is generated through the metal rod, surface micro-deformation is generated, the grating distances of the FBGs attached to the metal rod are changed along with the metal rod, the center reflection wavelength of the FBGs can be caused to generate drifting, wavelength signals are demodulated into electrical signals through an FBG interrogator, and the stress situations of different sites can be obtained. The roadway surrounding rock stress monitoring device has the advantages that installation is easily achieved, and the roadway surrounding rock stress monitoring device is suitable for wide popularization; power is not required to be supplied to the working face end, and site safety is guaranteed; all-optical measurement and fiber transmission are adopted, and influences of electromagnetic interference are effectively avoided; the temperature error is compensated, and the accuracy is improved; the surrounding rock stress monitoring results can be timely and accurately provided, and guidance on site production and scientific research is facilitated.

Owner:CHINA UNIV OF MINING & TECH

Surrounding rock stress on-line monitoring system and method based on fiber bragg grating borehole stress meter

ActiveCN103454020BShort lifeMonitoring accuracy is not goodForce measurement by measuring optical property variationFiberGrating

The invention relates to a surrounding rock stress on-line monitoring system and method based on a fiber bragg grating borehole stress meter. A plurality of measurement points are arranged on a surrounding rock, the fiber bragg grating borehole stress meter is installed in a surrounding rock wall drill hole, an optical fiber connector is connected with an optical fiber, and the optical fiber is connected to a mining optical cable, is then directly connected to the ground, and is connected with a fiber bragg grating modulator; an optical signal is modulated to a digital signal by the fiber bragg grating modulator, the digital signal is transmitted to a computer, is monitored in real time and is analyzed and processed, and a surrounding rock axial stress and transverse stress analyzing and processing method is provided under the temperature compensation condition according to grating stress characteristics. The surrounding rock stress on-line monitoring system and method have the advantages that equipment is easy to install, long in service life and suitable for popularization and use; power supply is not needed underground, electrical signals and electronic devices do not exist, and therefore the field is safe; because all-optical measurement and optical fiber transmission are adopted, monitoring precision is greatly improved, and effect of electromagnetic interference can be effectively avoided under complex and poor environment; surrounding rock stress monitoring results can be provided in time and guiding of field production and scientific research work is facilitated.

Owner:CHINA UNIV OF MINING & TECH

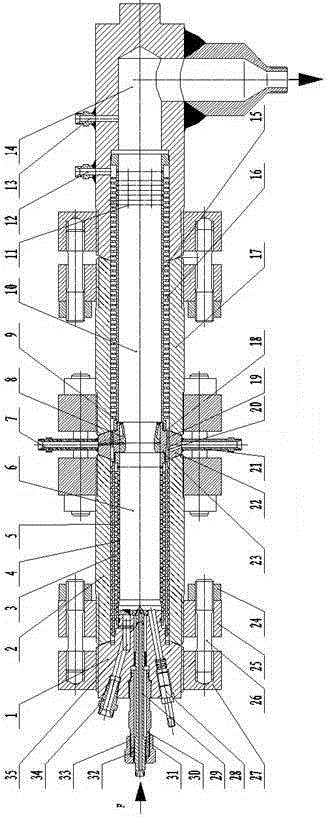

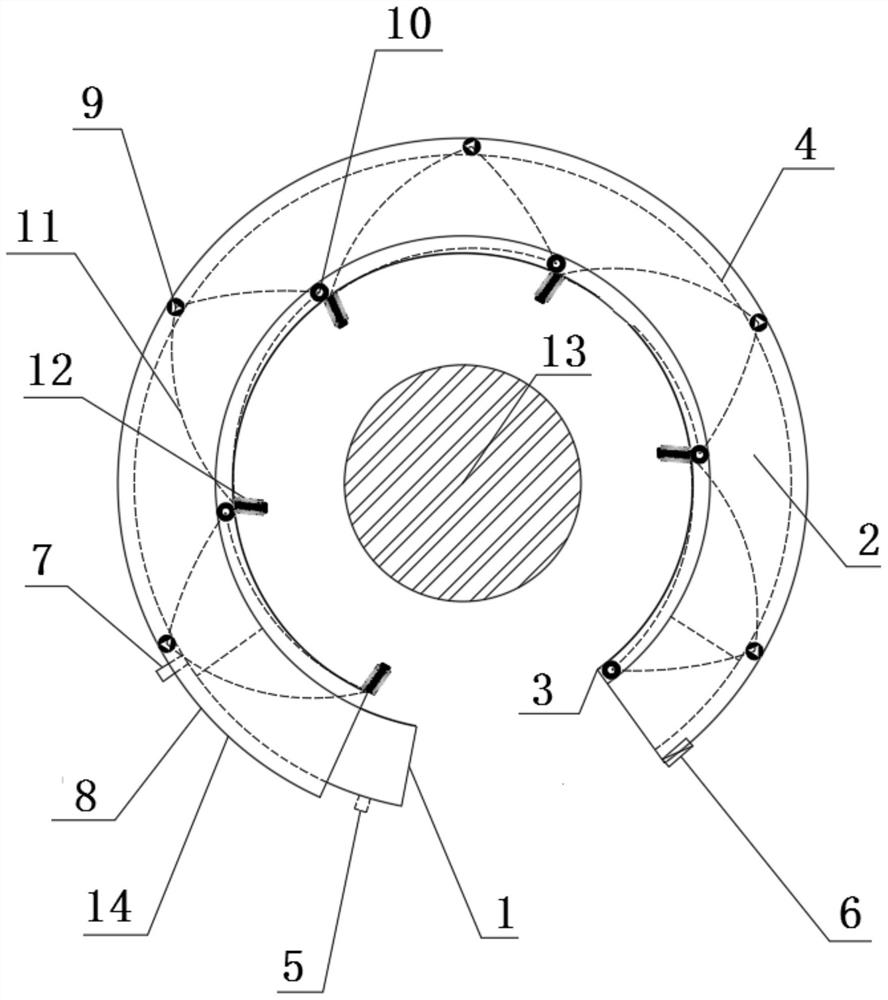

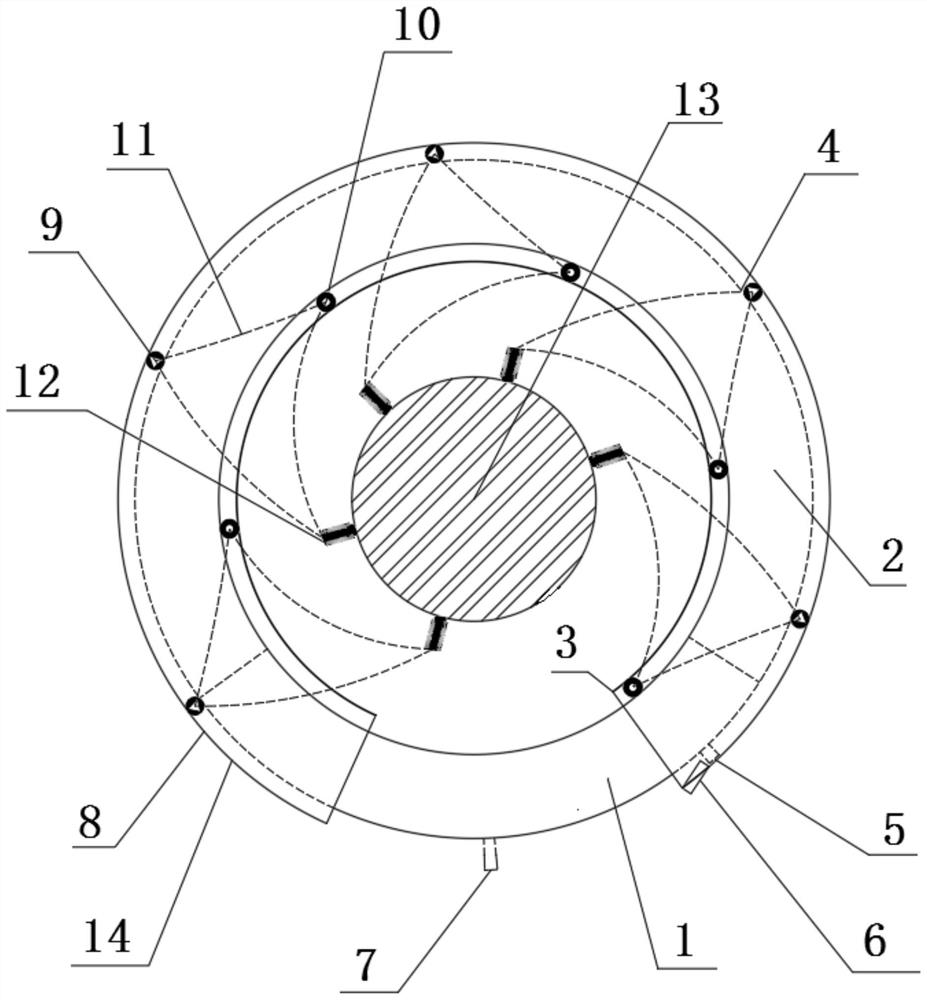

Supplementary combustion chamber of supercritical pressure gas-liquid fuel generator

The invention provides a supplementary combustion chamber of a supercritical pressure gas-liquid fuel generator, and relates to oil extraction equipment in an oil field. The supplementary combustion chamber is characterized by comprising a pre-combustion chamber (6), a secondary combustion chamber (10) and a vaporizing chamber (14). A spouting mode of fuel of the supplementary combustion chamber is as follows: the pre-combustion chamber (6) only sprays part of the fuel and full air for oxygen-enriched combustion; the remaining fuel is sprayed into the secondary combustion chamber (10) from a supplementary combustion inspirator and completely combusted with oxygen-enriched gas from the pre-combustion chamber in the secondary combustion chamber (10). By the combustion chamber, simultaneous combustion of gas fuel and liquid fuel is realized, and heat transfer deterioration is prevented due to various cooling modes.

Owner:刘殿玺 +2

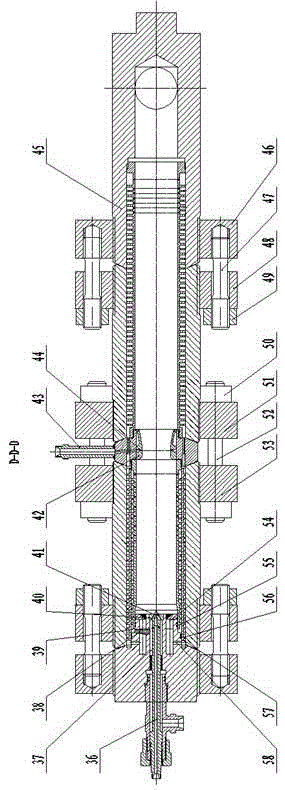

Intelligent reminding high voltage presence display device

InactiveCN106249033AGuarantee personal safetyGood warningCurrent/voltage measurementLED displaySignal processing circuits

The invention discloses an intelligent reminder high-voltage electrified display device, which comprises a high-voltage electrified sensor installed at a high-voltage pile head and collecting three-phase voltage, and a compensation circuit, an input protection circuit, a current / voltage conversion circuit, and a signal The processing circuit, the signal processing circuit is connected with the programmable control circuit through the wave detection circuit; the infrared sensor for sensing personnel activities is connected with the programmable control circuit; the programmable control circuit is connected with the alarm circuit, and the programmable control circuit is connected with the three-phase charging circuit LED display device connection. The invention collects the three-phase voltage through the high-voltage charging sensor installed at the high-voltage pile head, displays the three-phase charging situation through the LED, and automatically senses whether someone is moving in front of the high-voltage charging display device through the infrared sensor. Voice reminder "high voltage live, please do not approach".

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH +1

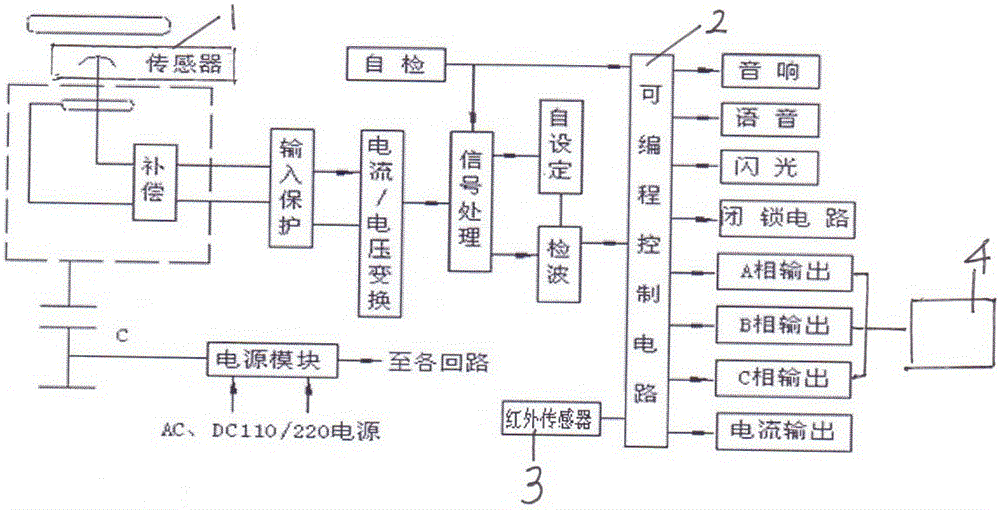

A substation intelligent inspection system and method

ActiveCN104362739BImprove inspection qualityRealize standardized customizationCircuit arrangementsInformation technology support systemMaster stationEmbedded system

The present invention relates to a substation intelligent inspection system and method. The system includes: a master station server and a plurality of inspection clients; wherein, the master station server is used to provide inspection task information for the plurality of inspection clients; The plurality of inspection clients are used to obtain the inspection task information from the master station server in a wireless manner, and execute inspection tasks for power transformation equipment according to the inspection task information. The invention can realize standardized customization of substation inspection tasks, visualized execution of inspection content, trace query of inspection results, further improves the inspection quality of substations, ensures on-site safety, improves work efficiency and reduces labor intensity at the same time.

Owner:国网河南省电力公司超高压公司 +2

GIS-based fire-fighting operational plan real-time realization method

InactiveCN105184447AEnsure site safetyThe display effect is intuitiveResourcesTransport engineeringEmergency situations

The invention relates to a GIS-based fire-fighting operational plan real-time realization method, mainly for solving the problems of few considered influence factors and quite poor safety in the prior art. By use of the GIS-based fire-fighting plan real-time realization method, through a geological information engine, major danger sources, resource resources, emergency resources and a fire-fighting operational plan map are visually displayed, onsite fire-fighting commanders calculate an accident spreading scope by use of value simulation through a mobile command platform according to factors including accident substances and accident onsite weather conditions, and finally, the fire-fighting operational plan map is generated on the basis of a GIS-based fire-fighting operational plan real-time realization system. The technical scheme of arrangement and disposition according to the real-time operational scheme map well solves the above problems and can be applied to formulation of a fire-fighting operational plan.

Owner:CHINA PETROLEUM & CHEM CORP +1

Elephant trunk method-based anti-blocking dredging system and construction method thereof

PendingCN114029288AEase congestionAvoid high requirements for open framesHollow article cleaningPipe elementsRemote controlControl theory

The invention discloses an elephant trunk method-based anti-blocking dredging system and a construction method thereof. The system comprises a probing and dredging device; the probing and dredging device comprises a case, a hoop type ring and a handheld end control device; the case is provided with a detector, and the bottom of the case is provided with an electric vibrating rod; one end, far away from a sleeve opening, of the hoop type ring is connected to the bottom of the case, a mounting hole for an elephant trunk to penetrate through is formed in the inner side of the ring, and a plurality of electric rollers are movably mounted in the mounting hole; and the handheld end control device is electrically connected to the electric vibrating rod, the electric rollers and the detector. The matched probing and dredging device is installed on the elephant trunk and moves along the elephant trunk through manual rope traction operation or complete remote control operation, a specific pipe blocking position is probed through an elephant trunk opening and a camera, and the vibrating rod is remotely operated to rotate to a proper position for vibrating and dredging; and pipe disassembly dredging and high-altitude operation are avoided, safety is guaranteed, meanwhile, construction is convenient, cost is saved, and the construction period is shortened. The dredging system is easy and convenient to operate, high in applicability, facilitates the application and popularization of the elephant trunk, and greatly improves the construction efficiency of deep foundation pits and mass concrete.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

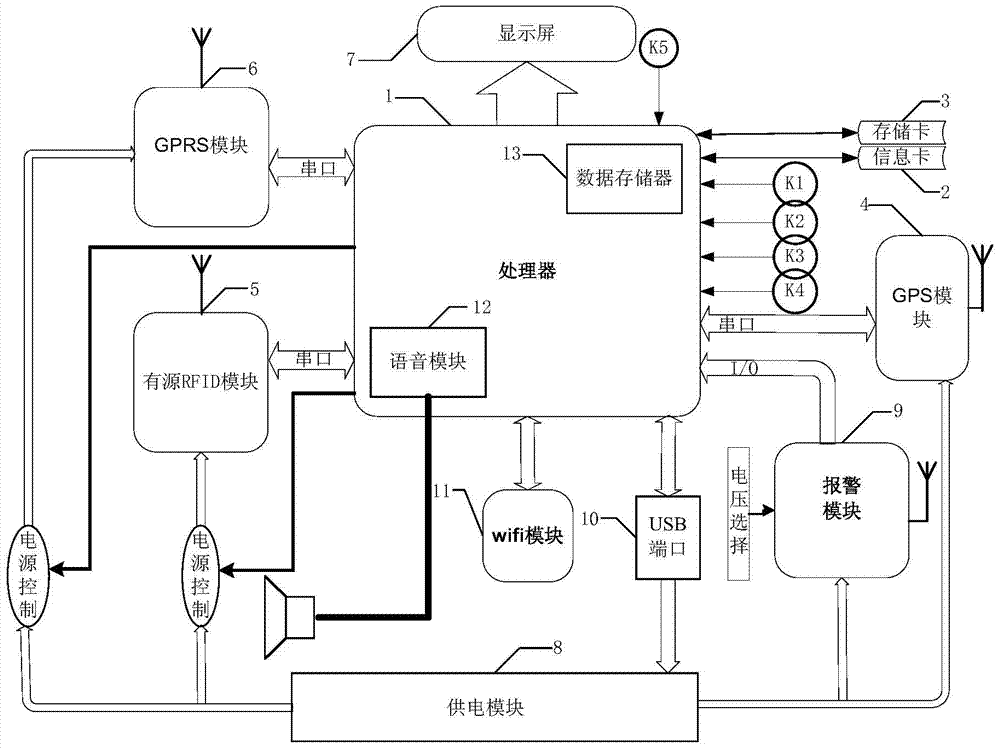

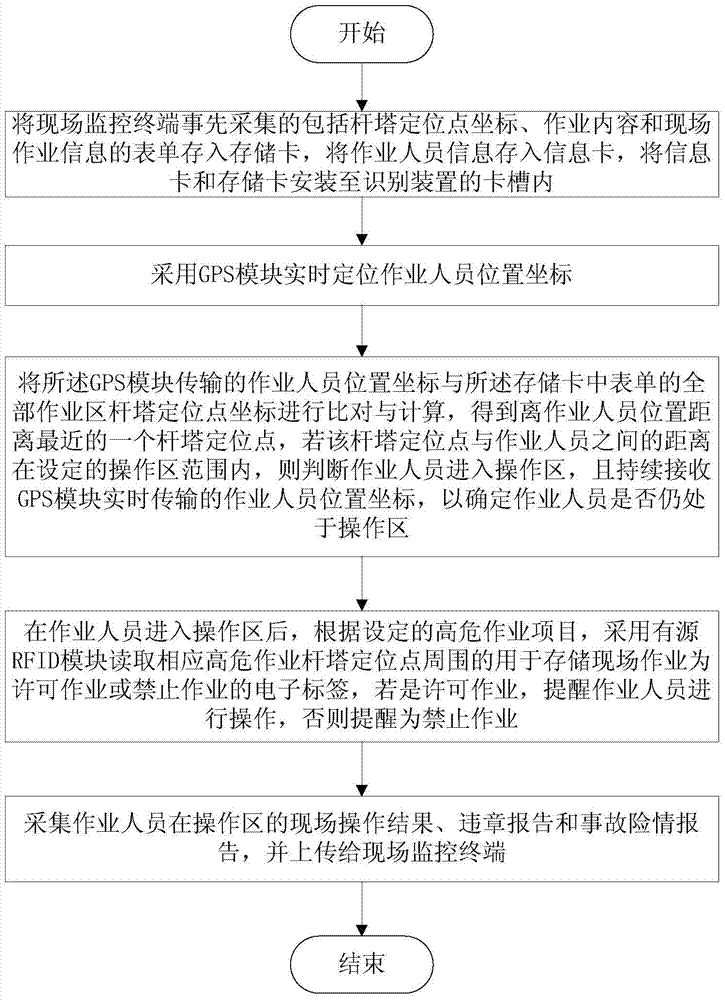

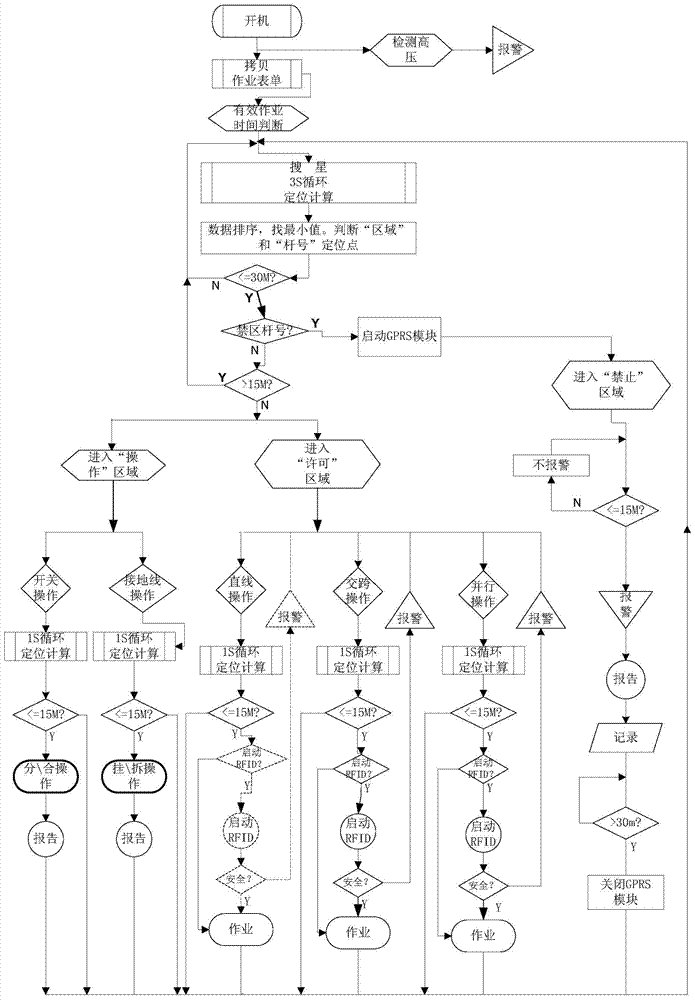

An identification device and identification method for electric power safety supervision

ActiveCN103854233BGuarantee the safety of lifeGuarantee property securitySpecial data processing applicationsInformation CardElectric power

The invention relates to an electric power security control recognition device and method. The device comprises an information card, a storage card, a GPS module, a processor, an active RFID module and a GPRS module, wherein the information card is used for storing worker information; the storage card is used for storing forms related to field security control; the GPS module is used for positioning position coordinates of workers in real time; the processor is used for comparing the collected position coordinates of the workers with positioning point coordinates of all working-region poles and towers and calculating the collected position coordinates of the workers and the positioning point coordinates of all the working-region poles and towers to obtain a pole and tower positioning point closest to the workers and judging whether the workers are located in an operation region or not according to the range of the preset operation region; the source RFID module is used for reading electronic tags, and the electronic tags are located around the corresponding pole and tower positioning points and used for storing information about whether field work is allowed or not; the GPRS module is used for uploading results of field operation carried out by the workers in the operation region, violation reports and accident and dangerous case reports to a field monitoring terminal. By means of the electric power security control recognition device and method, electric power circuit engineering construction control is facilitated, and safety of field staff is guaranteed.

Owner:BEIJING YOUFUTE TECH

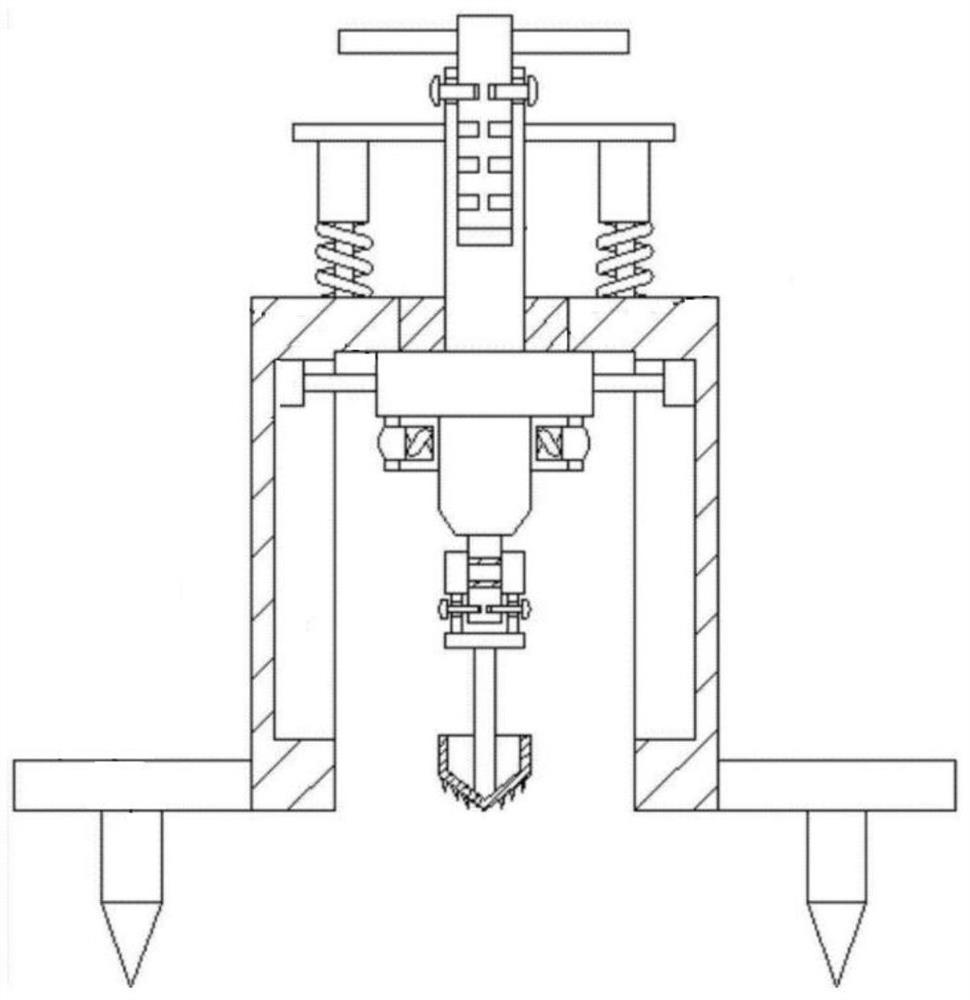

Rotary control platform based on satellite positioning

The invention relates to a rotation control platform based on satellite positioning. The platform comprises a mapping storage mechanism which is used for storing set soil colors and set soil types corresponding to different satellite positioning data and a targeted pit digging main body, wherein the targeted pit digging main body comprises a left side fixing framework, a right side fixing framework, a splicing plate body, a rotating head part, a rotating control motor, a left side supporting foot stool and a right side supporting foot stool, and the rotating control motor is used for unlocking a rotating control operation on the rotating head part when receiving a first control signal; and controlling the rotating head part to execute a rotating action at a rotating speed matched with the set soil type corresponding to the current satellite positioning data. According to the control platform, on the basis of the matching relationship between the satellite positioning data and the soil type as well as the soil color imaging characteristics, confirmation of the soil and the confirmation of the soil type based on visual detection can be completed, so safety and the reliability of a pit digging machine are improved.

Owner:孙满昌

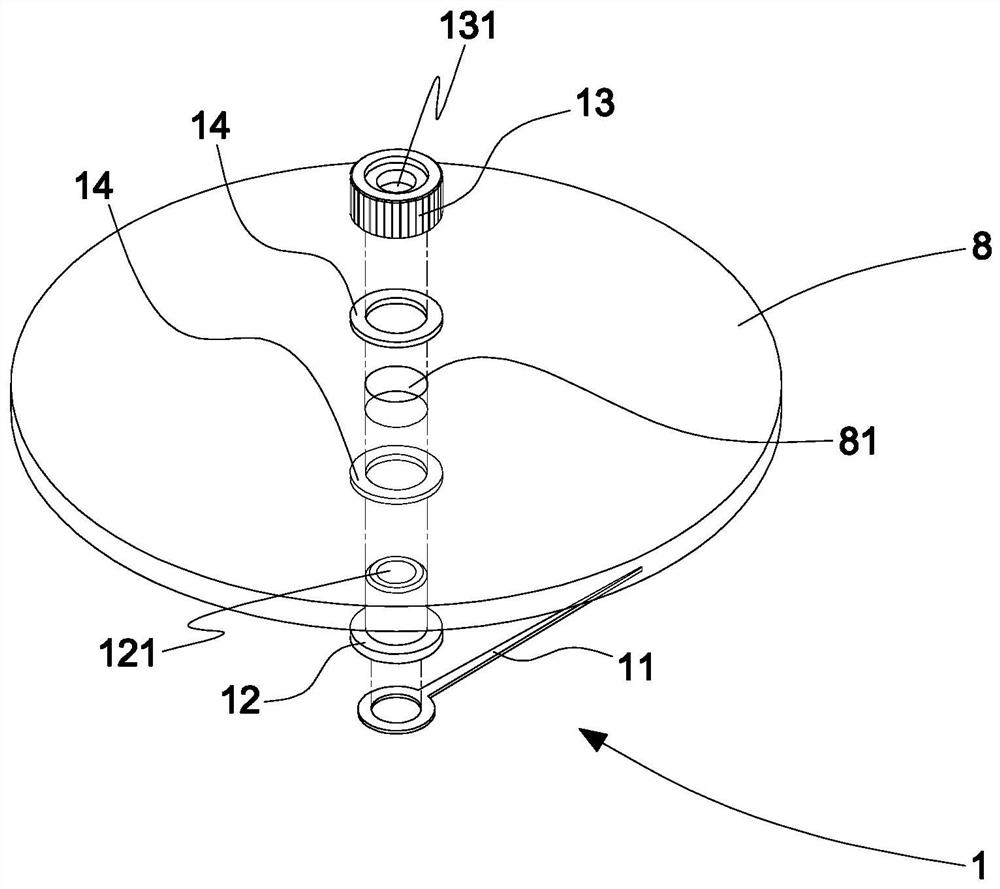

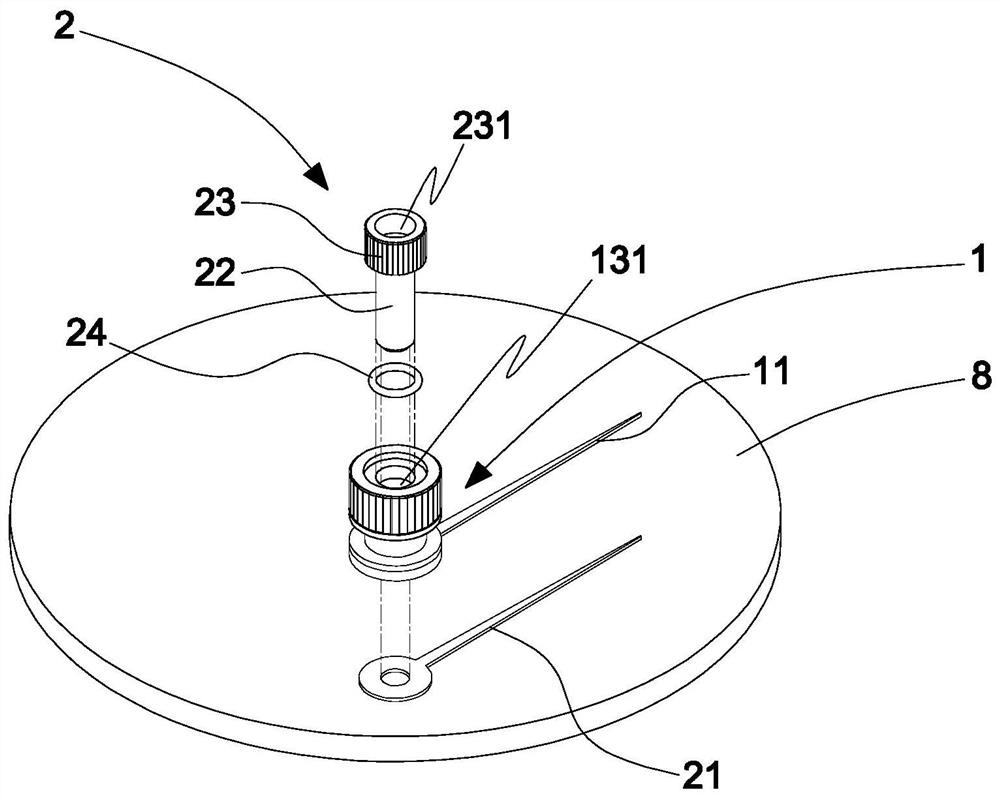

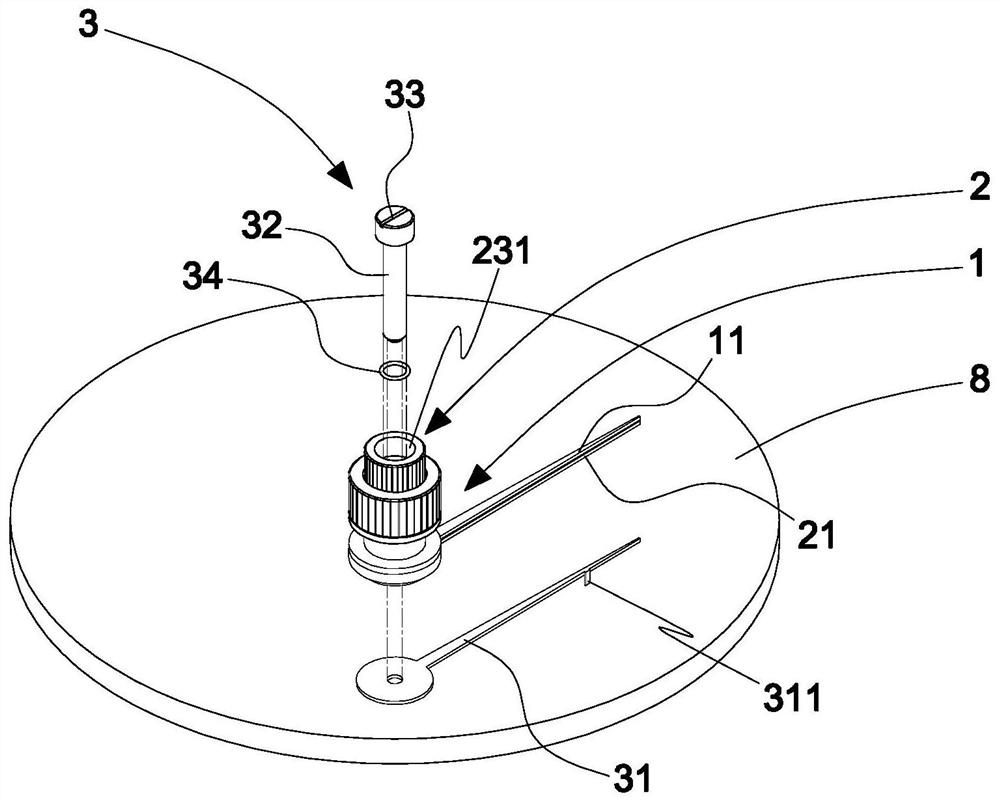

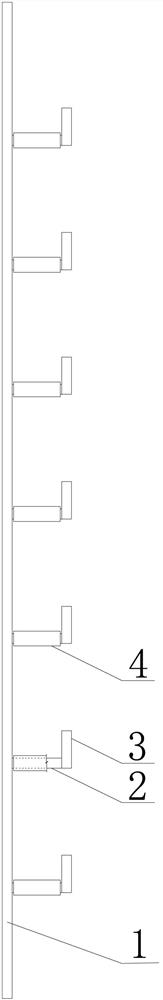

Pressure abnormity and interval display structure of pressure gauge

The invention provides a pressure abnormity and interval display structure of a pressure gauge. A first index unit, a second index unit and a third index unit are arranged on a transparent panel of the pressure gauge, and the index units are used for adjusting positions; two of the index units are used for setting the positions of a low pressure scale and a high pressure scale respectively, and the other index unit is driven by the pressure pointer to change the position if an overpressure condition exists after setting, so that field staff can know the overpressure condition conveniently. Practical pressure abnormity and interval display is provided, and actual requirements are met.

Owner:HWA CHIH TECH CO LTD

Shear wall horizontal rib installation positioning rod and construction method

PendingCN111636692AEasy to makeCost controlBuilding material handlingArchitectural engineeringShear wall

The invention provides a shear wall horizontal rib installation positioning rod and a construction method. The shear wall horizontal rib installation positioning rod comprises a main rod, wherein a plurality of positioning cross rods are welded and fixed to the side wall of the main rod at equal intervals in the height direction of the main rod, and a limiting vertical rod is vertically welded andfixed to the top of the tail end of each positioning cross rod; and the positioning cross rods are sleeved with rotating sleeves. The positioning rod can be used for auxiliary installation of a shearwall horizontal rib, the position precision and levelness of horizontal rib installation are guaranteed, meanwhile, the installation difficulty is effectively reduced, the installation of the horizontal rib can be completed by a single person, and the labor cost of operation is reduced.

Owner:CHINA NUCLEAR IND 22ND CONSTR

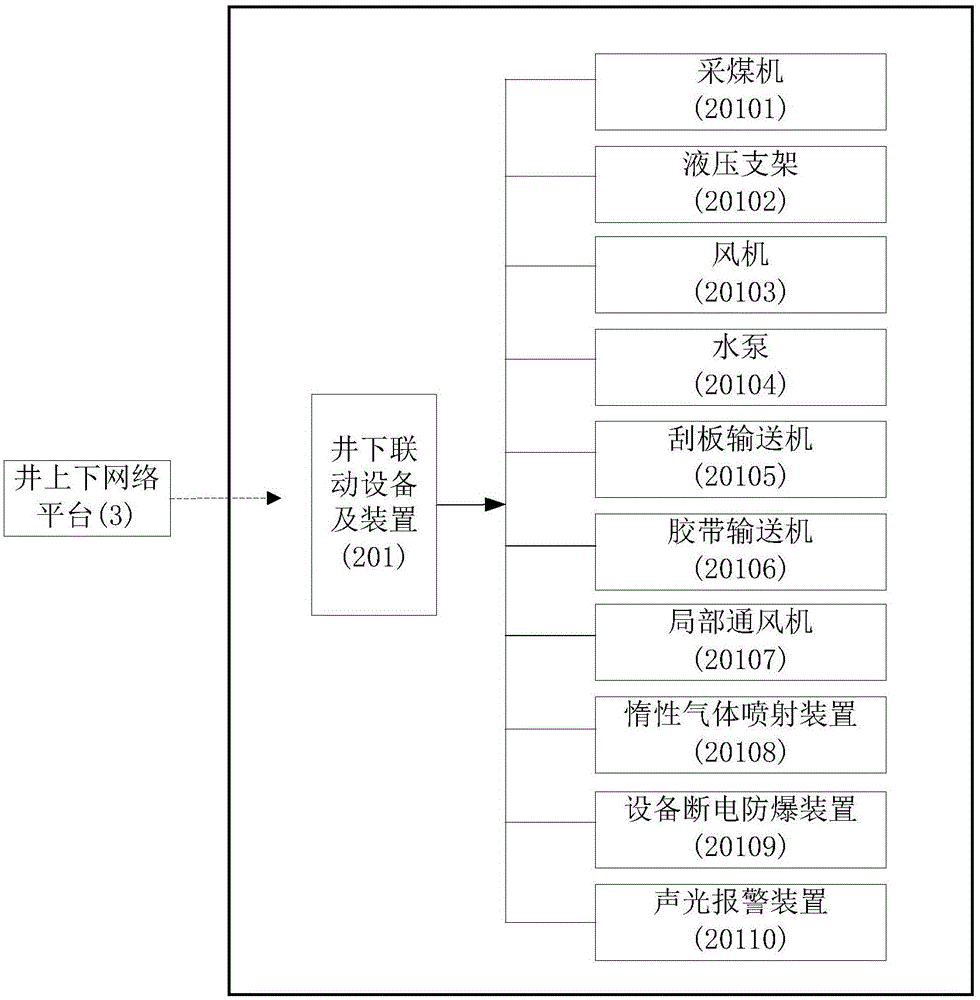

Internet of things dynamic monitoring and early warning method for major hazards in coal mines

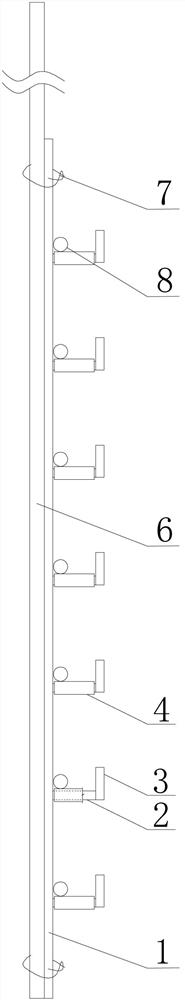

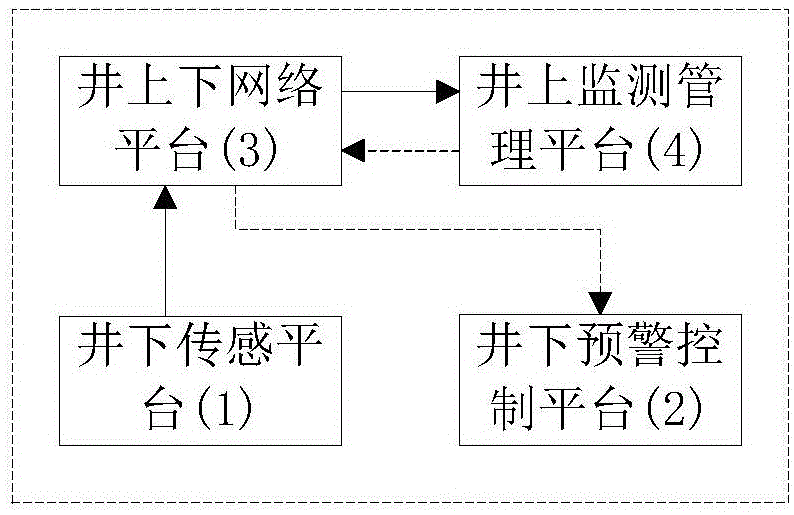

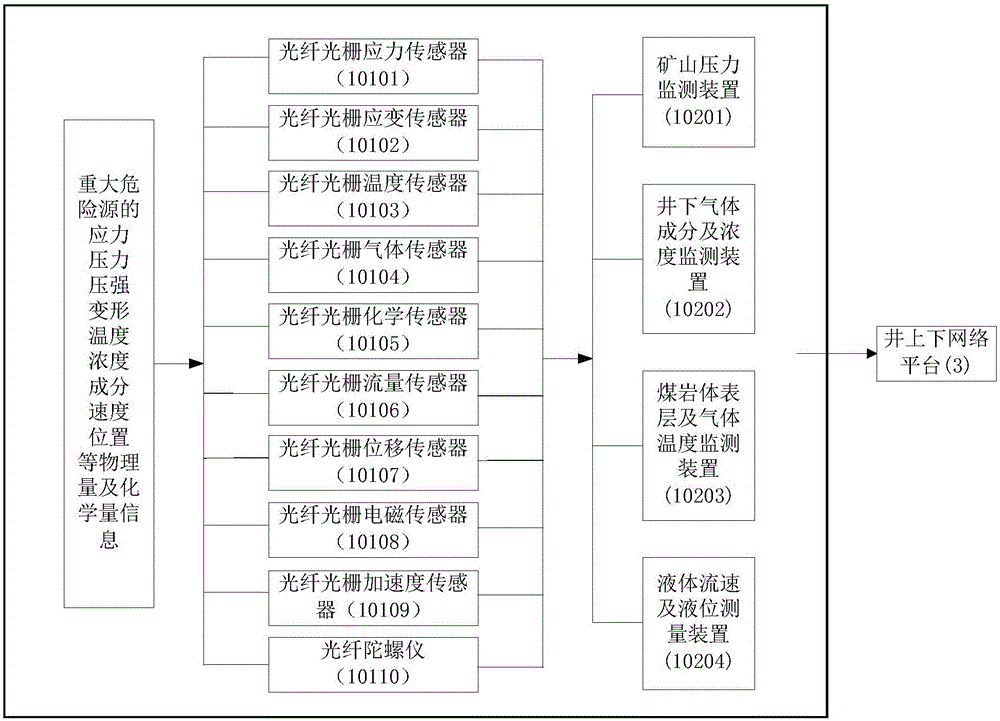

ActiveCN103528613BMeet dynamic management requirementsThe monitoring results are accurateSurveyTransmissionEarly warning systemInterference resistance

The invention relates to an Internet of Things dynamic monitoring and early warning method of a major hazard source under a coal mine and belongs to a dynamic monitoring and early warning method under a coal mine. A monitoring and early warning system comprises an underground sensing platform, an underground early warning control platform, an overground and underground network platform and an overground monitoring management platform; the underground sensing platform acquires major hazard source information through a monitoring device consisting of an optical fiber grating sensor; the overground and underground network platform transmits data; the overground monitoring management platform provides an application for analysis processing and provides a result to all parties for use after receiving the data; and the underground early warning control platform controls underground linkage equipment and a device according to a received instruction. The method is constructed based on Internet of Things; dynamic monitoring and early warning of the major hazard source under the coal mine are realized by adopting an optical fiber grating sensing technology; the monitoring result is more accurate; the interference resistance is high; a site is safe; a signal transmission distance is extended greatly; the signal transmission speed is increased greatly; a platform and a foundation are provided for cross-discipline analysis of the major hazard source; and requirements of different aspects on dynamic management can be met.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com