Flying-wing-type formwork space truss structure and construction method thereof

A space truss and truss structure technology, applied in special structures, building components, building structures, etc., can solve problems such as unsatisfactory engineering construction, achieve the effects of reducing construction costs, simple construction methods, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

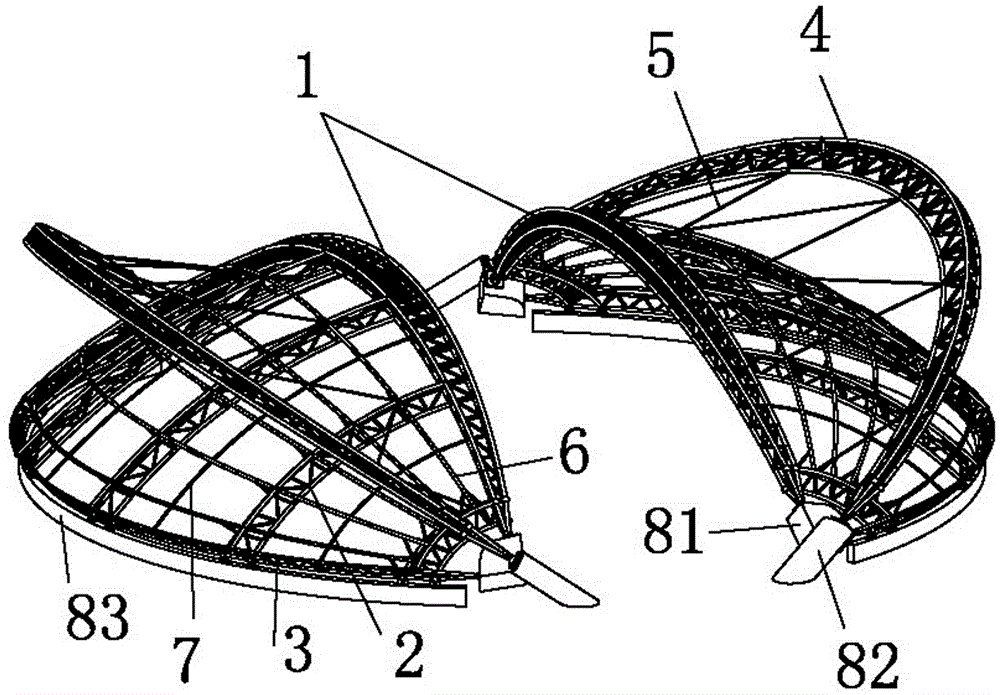

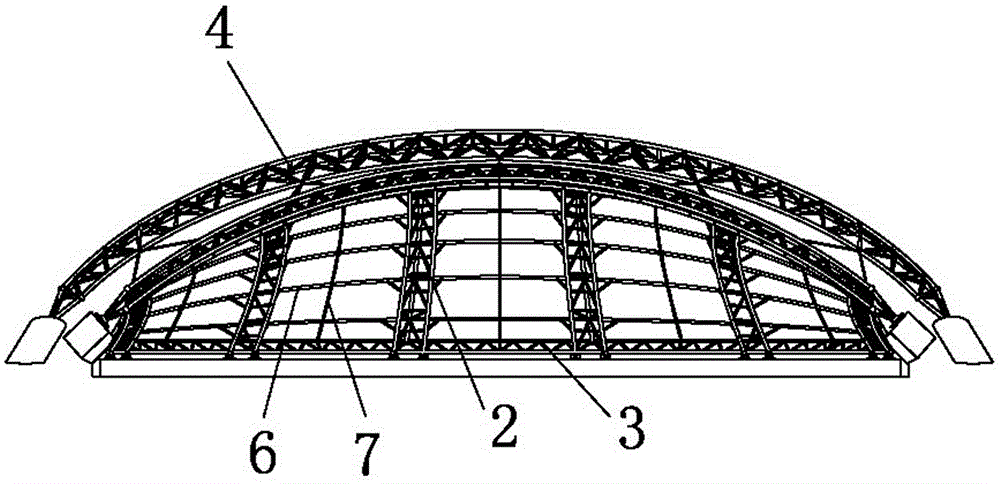

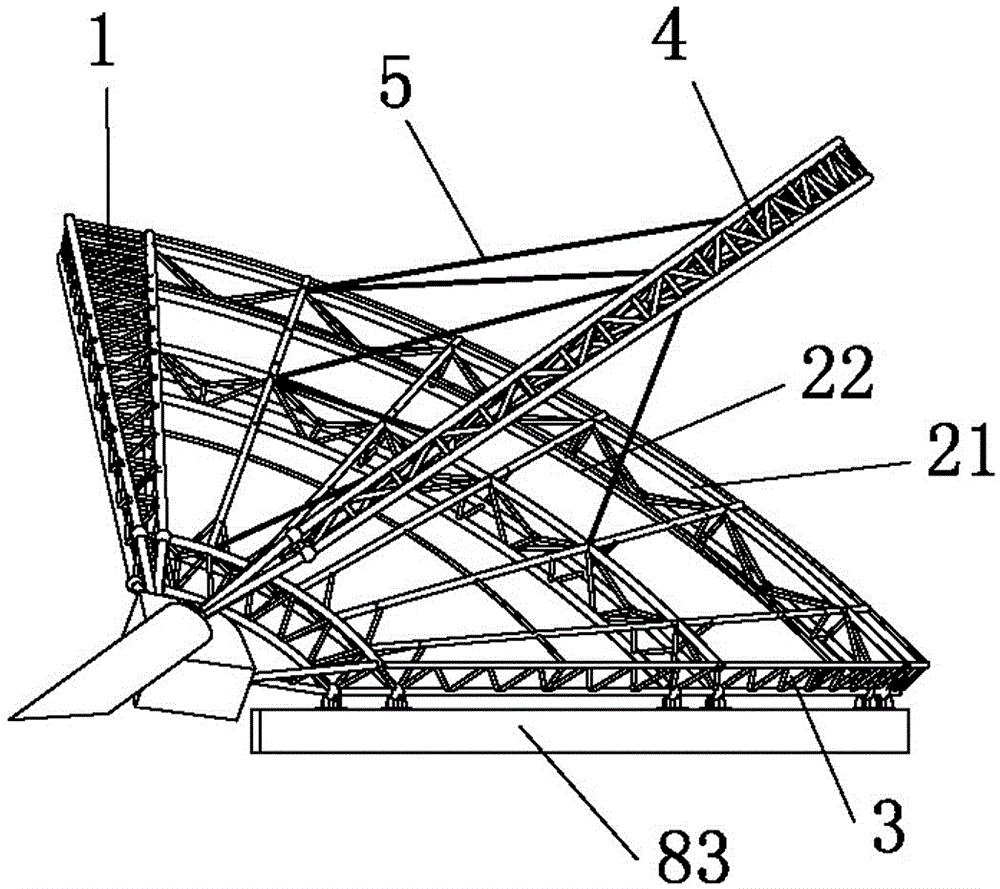

[0030] This project has one floor above the ground and one floor below the ground. The underground is an exhibition hall, and the ground is a commercial steel truss structure, mainly a space triangular tube truss structure project; including welding balls and space cables. Each part of the truss is connected by welding balls to form two hemispheres. In order to ensure the stability and stability of the two hemispheres, a flying wing-shaped truss is added to each hemisphere and connected to the hemisphere truss by cables. Make the whole structure more stable. The overall shape is a symmetrical two-lobed formwork shell with flying wings, which is novel in design, unique in shape, and evenly stressed. The horizontal projection size of the roof is about 38.2m×38.8m, and its coverage area is about 750 square meters. The top elevation of the steel truss is 9.746m. The primary and secondary trusses are mainly spatial triangular trusses with a span of 38.8m. The truss chord section i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com