Shear wall horizontal rib installation positioning rod and construction method

A construction method and technology of horizontal ribs, which are applied in the direction of construction, building structure, and building materials processing, etc., can solve the problems of uneven installation of horizontal rib spacing, prolong installation time, and increase connection difficulty, so as to save manpower and speed up on-site The effect of progress and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060] see Figure 5-9 , the construction method for installing the positioning rod for the installation of the horizontal reinforcement of the shear wall to carry out the installation of the horizontal reinforcement of the shear wall, it includes the following steps:

[0061] Step 1: According to the design requirements of the shear wall, make the positioning bar for installing the horizontal reinforcement of the shear wall;

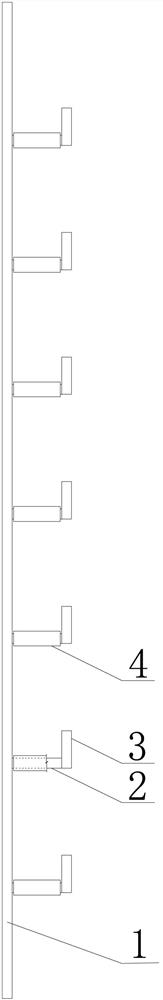

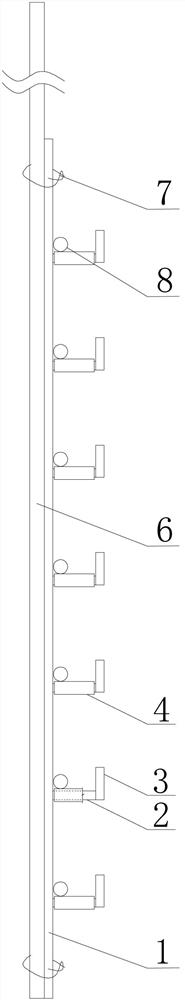

[0062]Step 2: Fix and connect the finished shear wall horizontal tendon installation positioning bar with the vertical rib 6 through the connecting tie wire 7, and set multiple sets of shear wall horizontal tendon installation positioning bars at intervals according to the length of the shear wall;

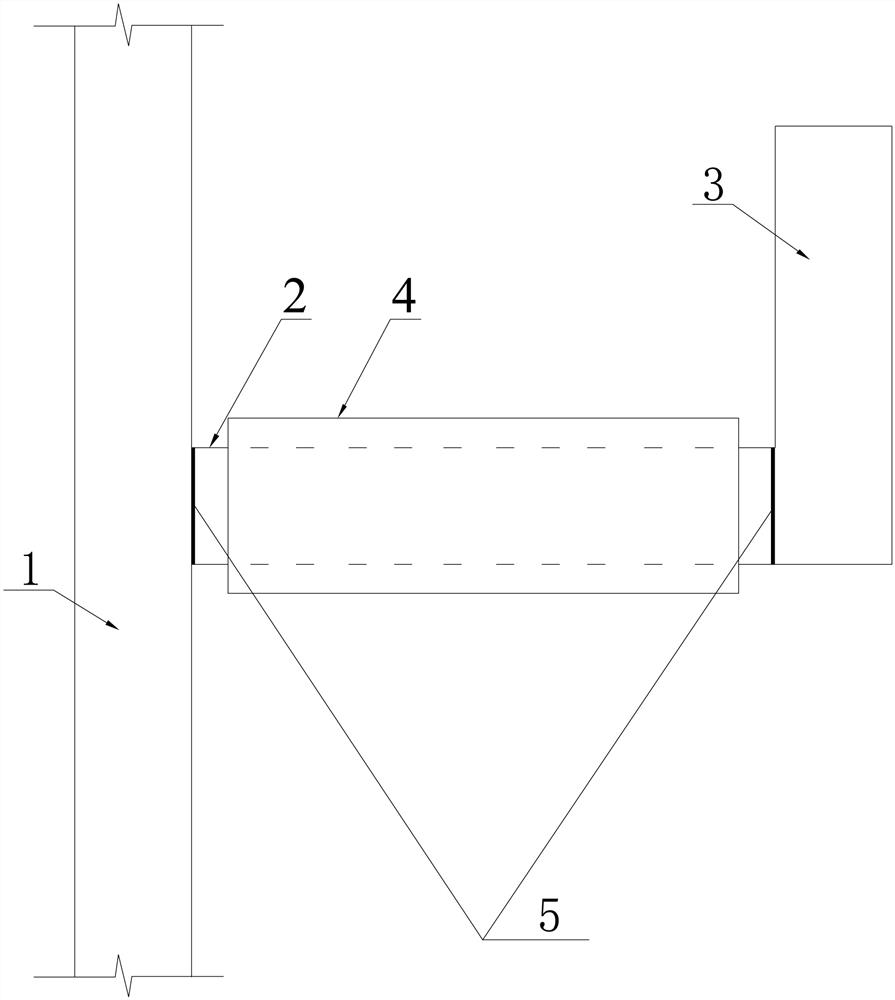

[0063] Step 3: Arranging the horizontal ribs 8 in sequence along the positioning cross bar 2 on the main bar 1, and supporting them on the rotating sleeve 4 to realize the preliminary positioning of the horizontal ribs 8;

[0064] Step 4: Connect the horiz...

Embodiment 3

[0069] The specific steps for installing the positioning bar in the horizontal reinforcement of the shear wall in the step 1 are:

[0070] Step 1.1: Select the waste steel pipe material from the construction site, and cut it into the main rod 1, the positioning cross bar 2, the limit vertical rod 3 and the rotating sleeve 4 according to the design size;

[0071] Step 1.2: Fix the positioning bar 2 on the side wall of the main bar 1 by spot welding at equal intervals according to the spacing requirements of the horizontal ribs 8;

[0072] Step 1.3: Install rotating sleeves 4 on each positioning crossbar 2;

[0073] Step 1.4: Vertical spot welding at the end of the positioning cross bar 2 to fix the limit vertical bar 3;

[0074] Step 1.5: Spray red and white paint on the main pole 1 as a marking section;

[0075] Step 1.6: Use the full welding method to weld firmly the main rod 1 and the positioning cross bar 2, as well as between the positioning cross bar 2 and the limit ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com