Automatic brake control system

A technology of automatic braking and control system, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling and mining, etc., and can solve problems such as potential safety hazards, top-rushing, and ground-impacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

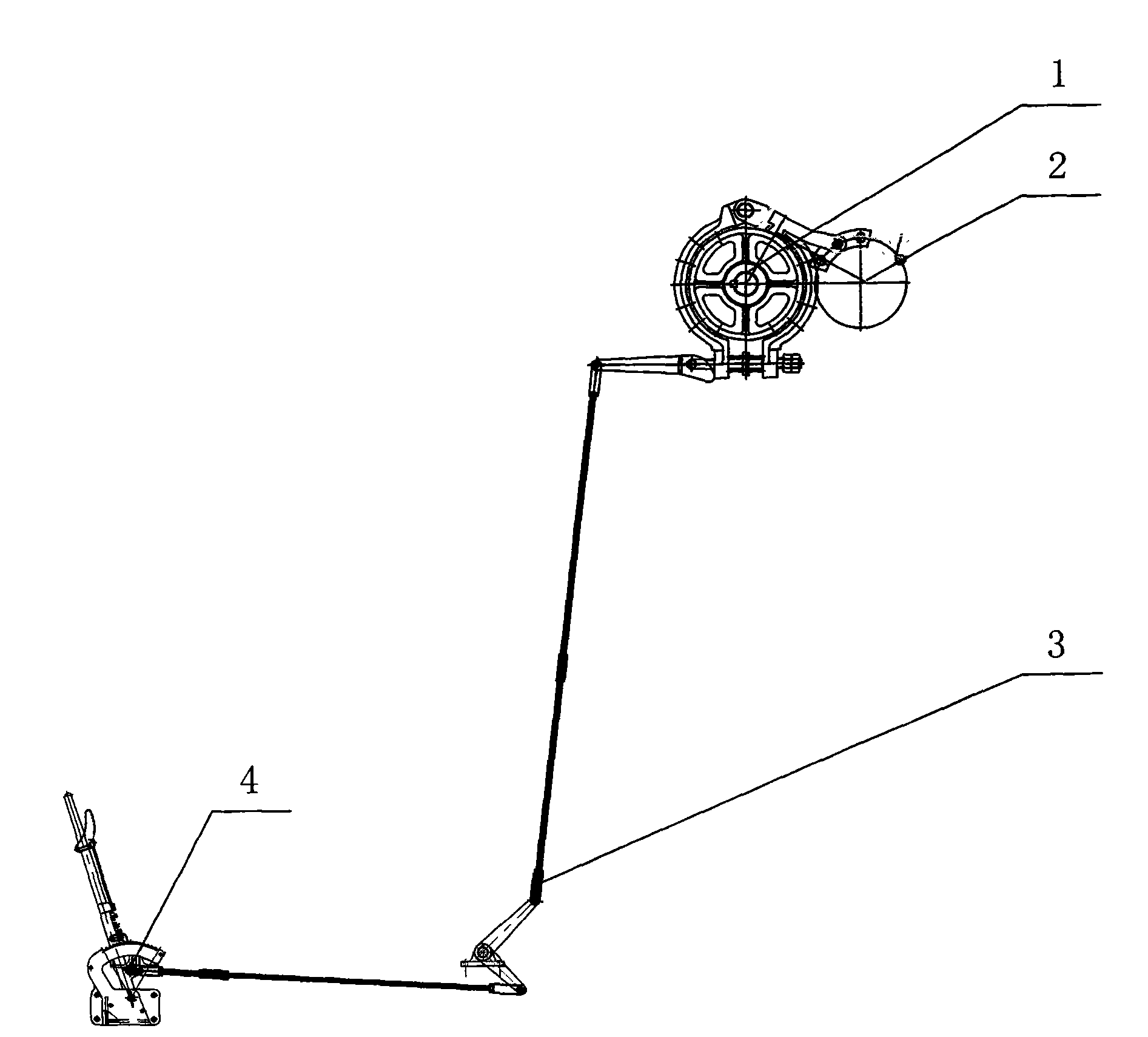

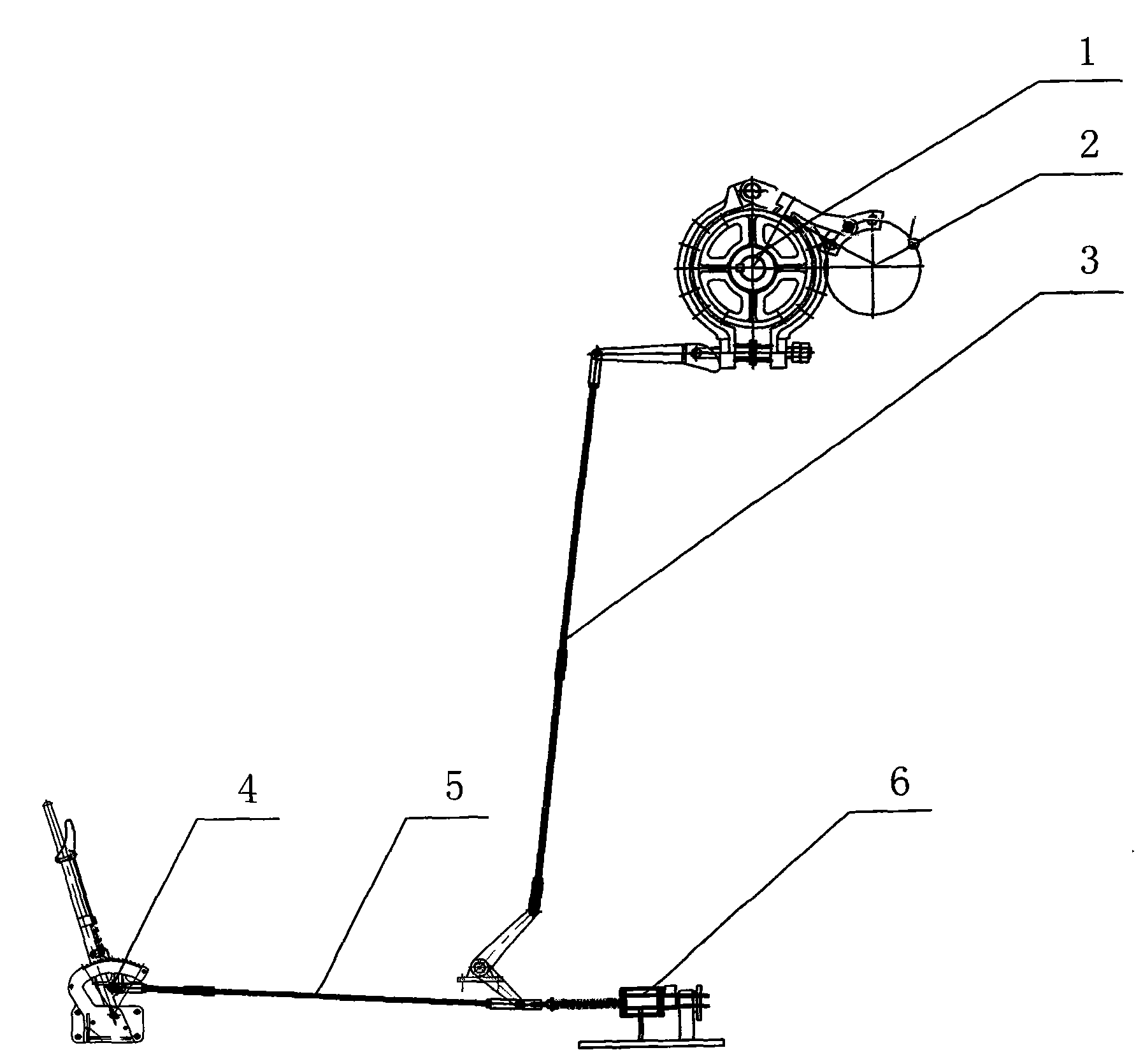

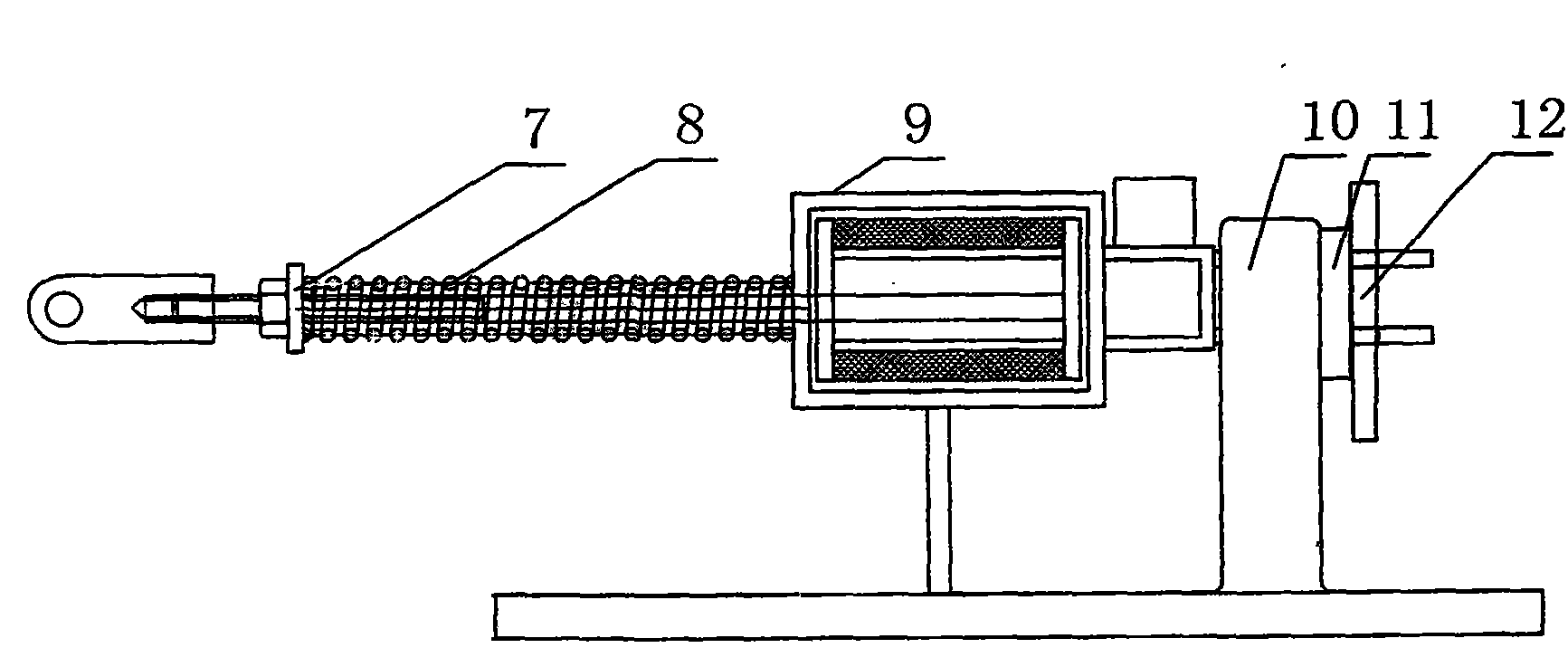

[0010] exist figure 2 In the embodiment, by improving the braking system of the original pumping unit, an automatic braking device is added on the basis of the original pumping unit. The device consists of a pressure spring 8, an electromagnetic coil 9, a base 10, an adjusting gasket 11, Cylindrical pin 12 etc. are formed. When the pumping unit stops: the electromagnetic coil 9 is powered off, and the suction disappears, and the push rod 7 is promoted under the action of the spring 8, so that the connecting rod device 3 moves downward, the brake is applied, and the pumping unit stops working. When the pumping unit starts: first release the handbrake device, the electromagnetic coil 9 is energized, generates magnetic force, pulls the push rod 7, makes the connecting rod device 3 move upwards, releases the brake device 1, and the pumping unit operates normally. If the machine is maintained and needs to stop working for a long time, pull on the manual brake device 4, stop the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com