Long-length overhang trusswork high form hanger system

A technology of truss structure and formwork support, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of high cost and low safety factor, and achieve the reduction of erection time Improve construction efficiency and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below according to the drawings and embodiments.

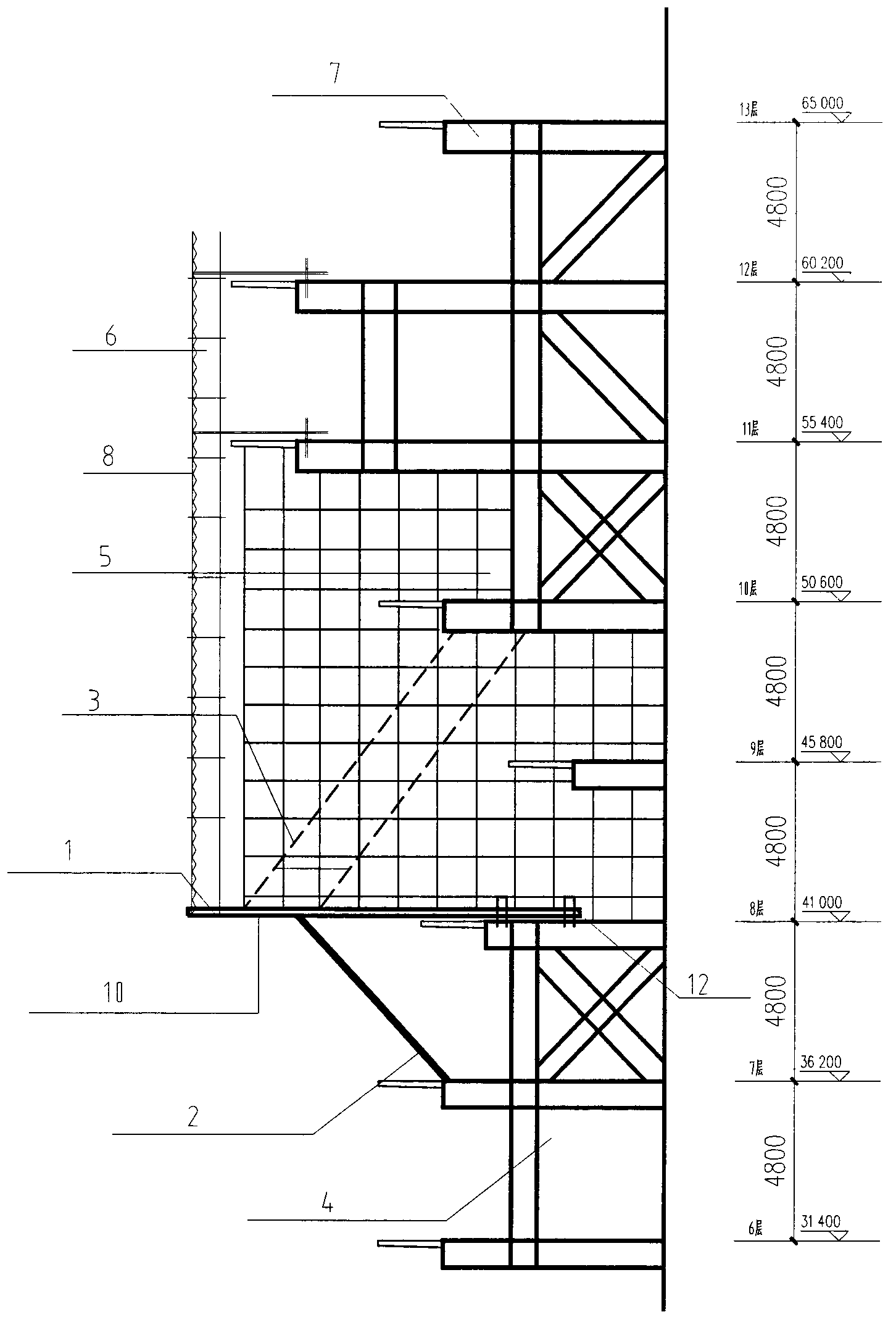

[0013] figure 1 It is a structural schematic diagram of the high-altitude formwork support system of the super-long cantilever truss structure of the present invention, referring to figure 1 , the present invention selects the canopy-shaped building of a certain hotel as an implementation case. The high-altitude formwork support system of the ultra-long cantilever truss structure includes an upper frame body and a lower frame body. The frame body includes a load-bearing formwork frame 5, an outer protective frame 6, and an upper concrete truss 7. One end of the steel cantilever beam 1 is fixed on the top of the lower concrete truss 4 through the cantilever beam anchor ring 12 and extends out from the top of the lower concrete truss 4. The upper surface of the cantilever beam 1 is paved with multi-layer protective plates 10, the bottom of the lower braced steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com