Installing method for assembly type hanging bracket for pipelines

An installation method and assembly technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as complex support and hanger processes, achieve quality assurance, reduce manufacturing costs, and ensure site safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

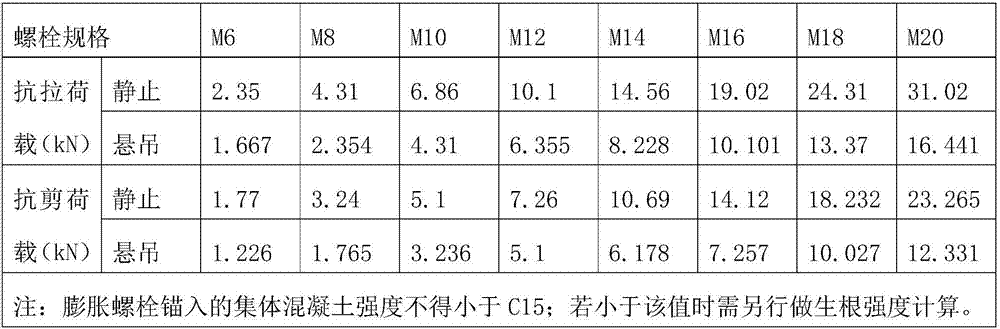

[0024] A pipeline assembly hanger installation method, using BIM technology to carry out three-dimensional deepening design of building pipelines, and then on the basis of this and the relevant support setting requirements put forward by the manufacturer, the design and arrangement of the support and hanger, force calculation, Product selection, processing and manufacturing. Among them, in the support and hanger design process, the manufacturer first provides the design of the support and hanger to the construction party for review. If there is no problem in the review, the manufacturer will proceed to the next step. If there is any problem, it will be modified and then submitted to the construction party. The construction party will The final bracket size positioning diagram is printed out for setting-out measurement.

[0025] Specifically include the following processes:

[0026] 1. Construction preparation

[0027] In the prefabricated building pipeline support and hanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com