Working face mine pressure on-line monitoring system based on fiber grating sensing

A fiber grating and monitoring system technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems of susceptibility to electromagnetic interference and external environment interference, inability to meet long-term monitoring, and high cost of the monitoring system , to achieve the effect of strong anti-electromagnetic interference ability, good monitoring effect and improved monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

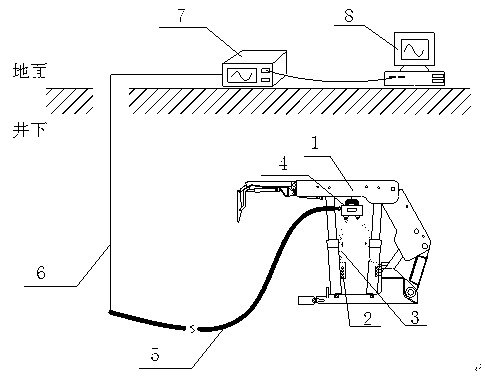

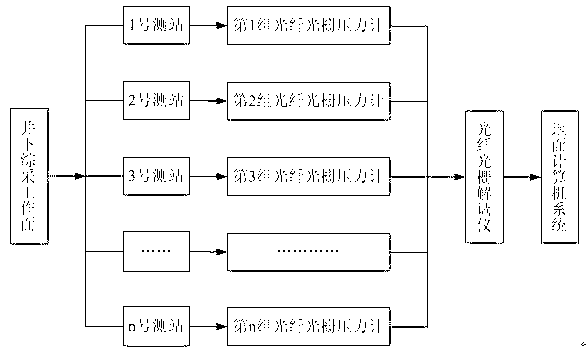

[0020] Embodiment 1: Select several measuring points in the underground working face, and an online monitoring system will be installed in the measuring points; the online monitoring system includes: hydraulic support 1, hydraulic control valve 2, oil pipe 3, intrinsically safe fiber grating pressure gauge 4 , optical fiber 5, mine optical cable 6, optical fiber grating demodulator 7 and computer system 8; hydraulic control valve 2 is installed in hydraulic support 1, and hydraulic control valve 2 is guided through oil pipe 3 and intrinsically safe optical fiber grating pressure gauge 4 The holes are connected, and the optical signal of the intrinsically safe fiber grating pressure gauge 4 is transmitted to the fiber grating demodulator 7 on the ground through the optical fiber 5 and the mine optical cable 6, and the fiber grating demodulator 7 is demodulated into a digital signal and then transmitted to the computer system 8. The computer system 8 performs real-time monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com