Installation method of prefabricated building pipeline support and hanger system based on bim

A system installation, support and hanger technology, applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, instruments, etc., can solve the problems of limited application occasions, light pollution, high technical requirements, reduce production costs, reduce work intensity, The effect of ensuring on-site safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

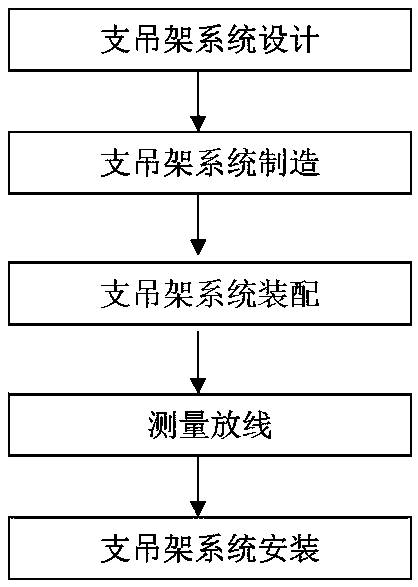

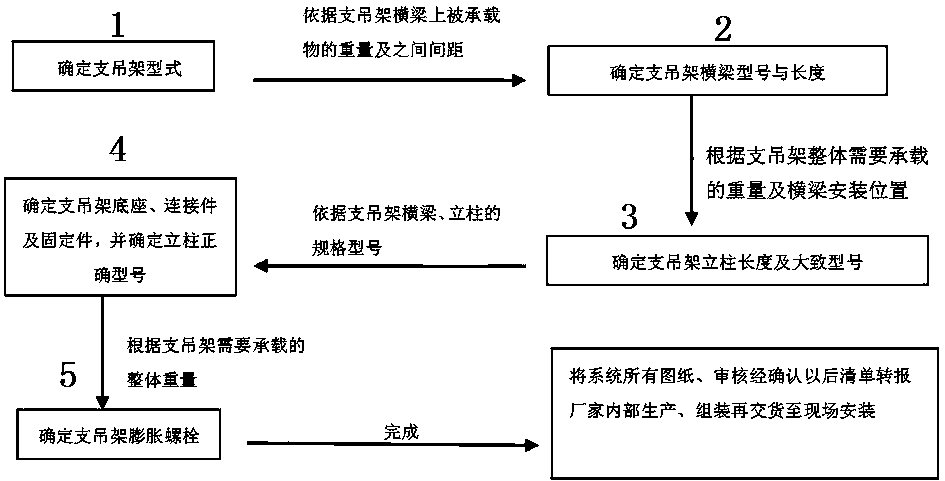

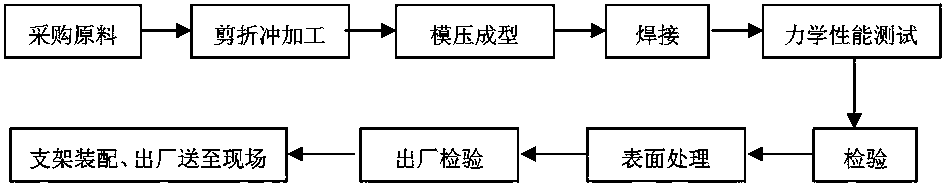

[0027] Example 1: see figure 1 As shown, a prefabricated construction pipeline support and hanger system installation method uses BIM technology to carry out a three-dimensional deepening design of the construction pipeline, and then the manufacturer and the construction party put forward the relevant support setting requirements for the design of the support and hanger. Fabric, force calculation, product selection, processing and manufacturing. In the support and hanger design link, the manufacturer first provides the support to the construction party for review after the support and hanger design is completed. If there is no problem in the review, the manufacturer will proceed to the next step. If there is a problem, it will be modified and submitted to the construction party after completion. The final stent size positioning map is printed out and used for pay-off measurement.

[0028] It includes the following processes:

[0029] 1. Construction preparation

[0030] In the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com