Roadway surrounding rock stress monitoring device based on fiber bragg grating sensing

A technology of surrounding rock stress and optical fiber grating, which is applied in the direction of measuring devices, optical devices, and measurement of the change force of optical properties of materials when they are stressed, can solve the problems of low reliability, strong dependence, and large data errors To improve stability and safety, avoid the influence of electromagnetic interference, and simplify equipment installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

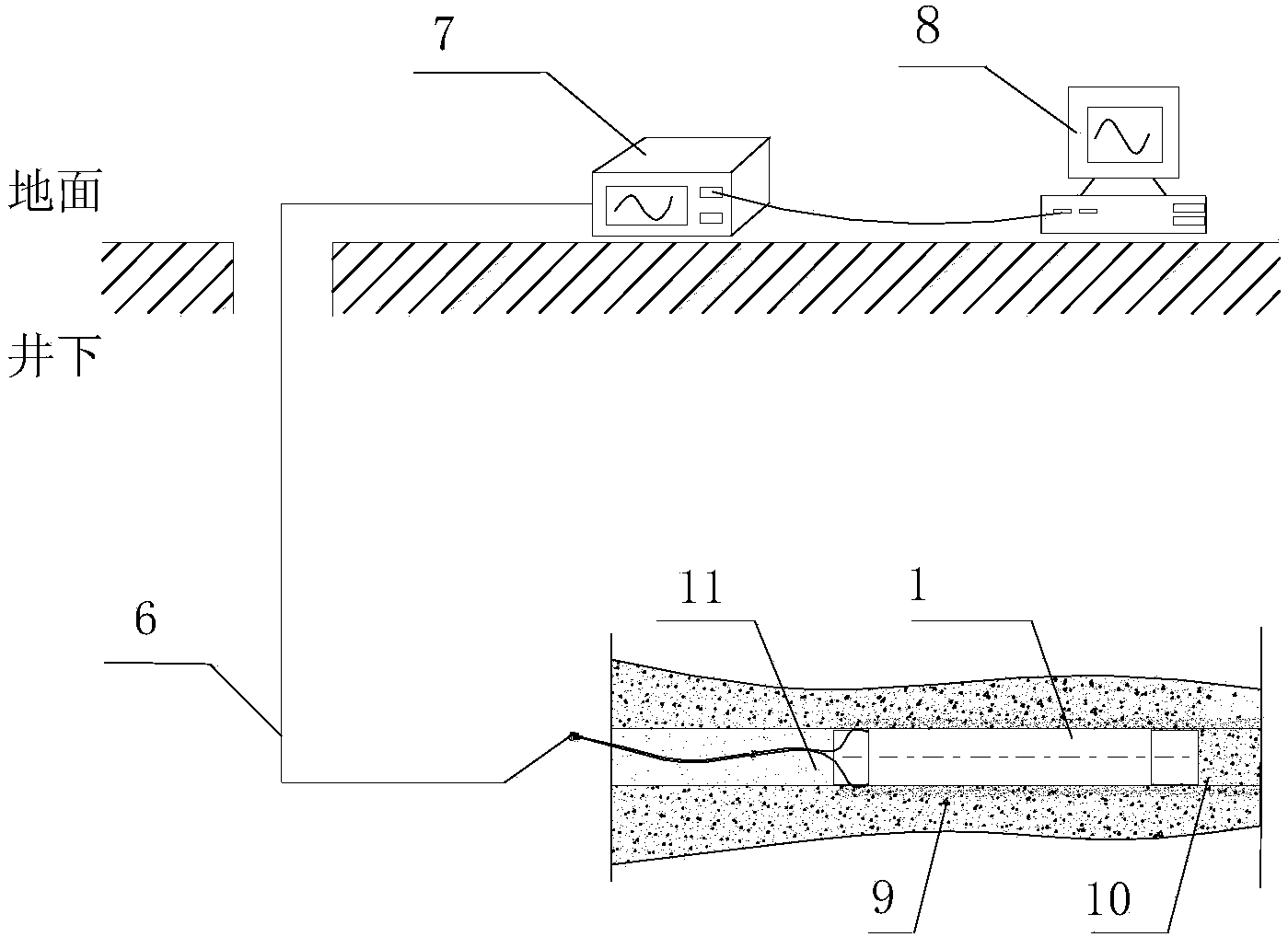

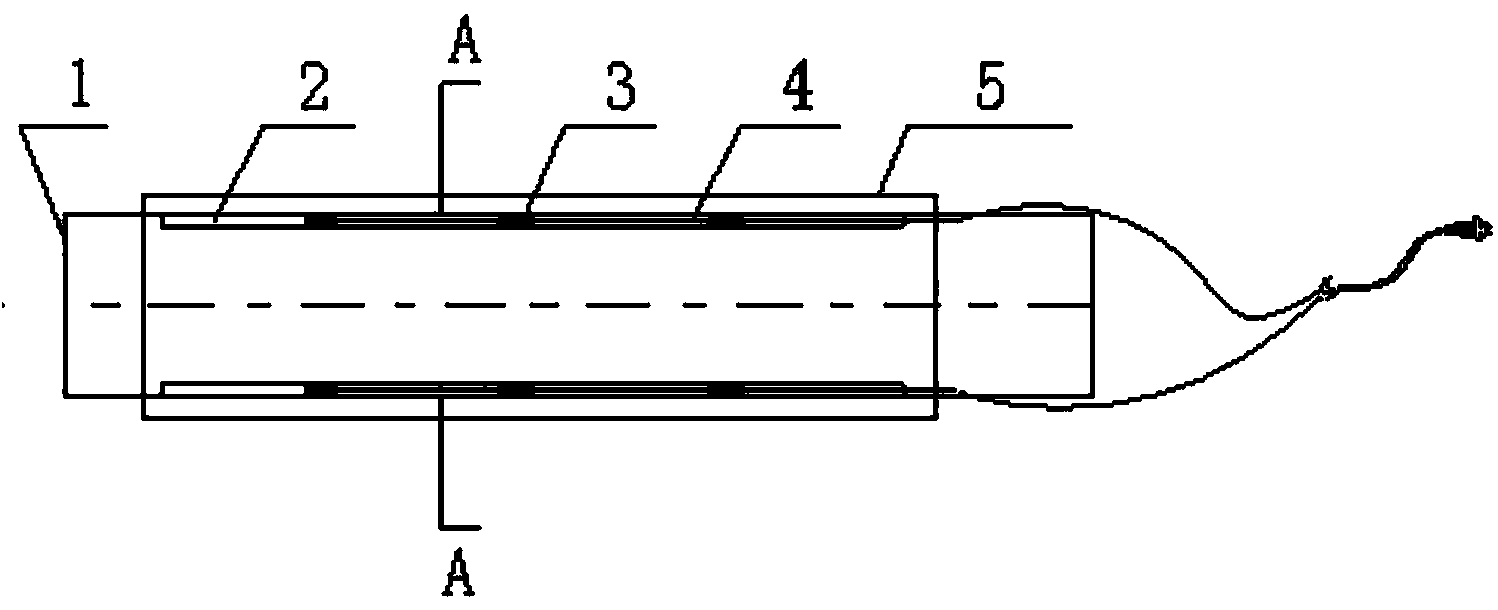

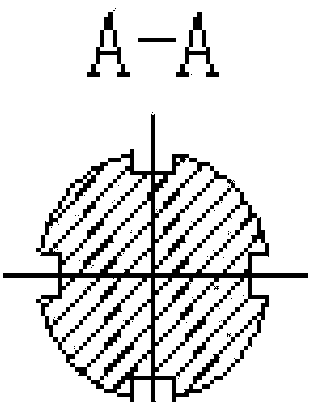

[0019] Embodiment 1: The roadway surrounding rock stress monitoring device includes: metal rod 1, groove 2, FBG grating group 3, optical fiber 4, fiber grating protection tube 5, mine optical cable 6, fiber grating demodulator 7 and computer system 8 There is a groove 2 on the body of the metal rod 1, and there is a FBG grating group 3 in the groove 2, the FBG grating group 3 is connected with the optical fiber 4, the fiber grating protection tube 5 is installed on the surface of the metal rod 1 shaft, and the optical fiber 4 It is connected with the mine optical cable 6 and leads directly to the ground, and the optical fiber 4, the fiber grating demodulator 7 and the computer system 8 are sequentially connected.

[0020] The device is assembled and connected through the following steps: the metal rod 1 is symmetrically engraved with four groups of grooves 2 along the axial center, and the position of the grooves 2 is determined according to the depth of the surrounding rock to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com