Carburizing method suitable for instillation type gas carburizing furnace

A technology of gas carburizing and carburizing furnace, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of surface decarburization, easy oxidation, serious carbon black accumulation, etc., and achieve bright surface, The effect of inhibiting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

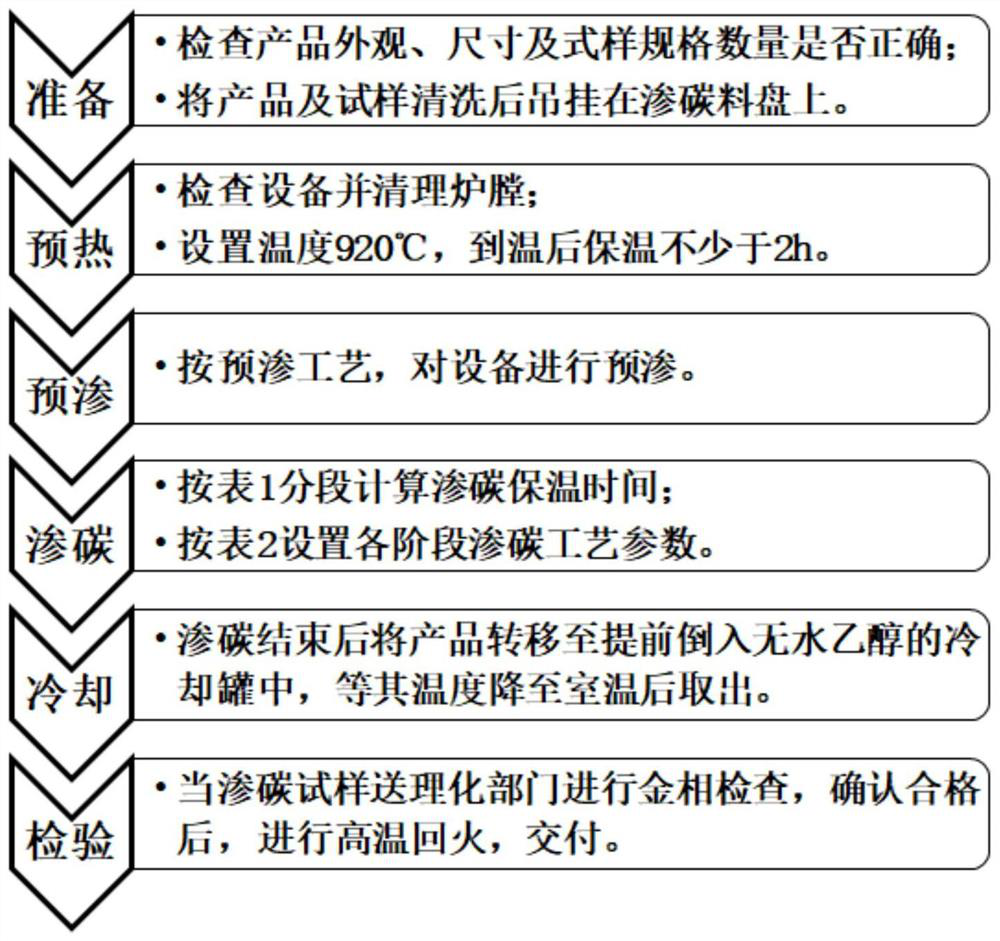

[0044] The specific implementation manners of the present invention are further explained below in conjunction with the examples and accompanying drawings, but are not intended to limit the present invention.

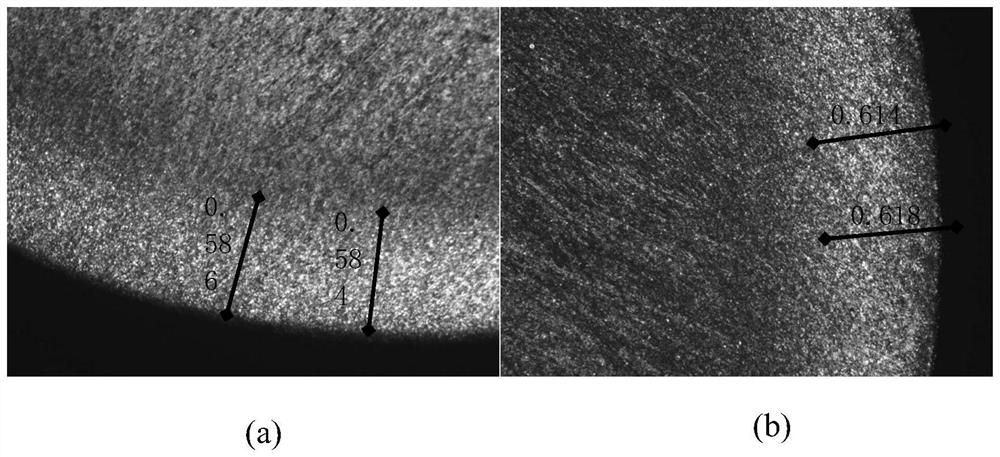

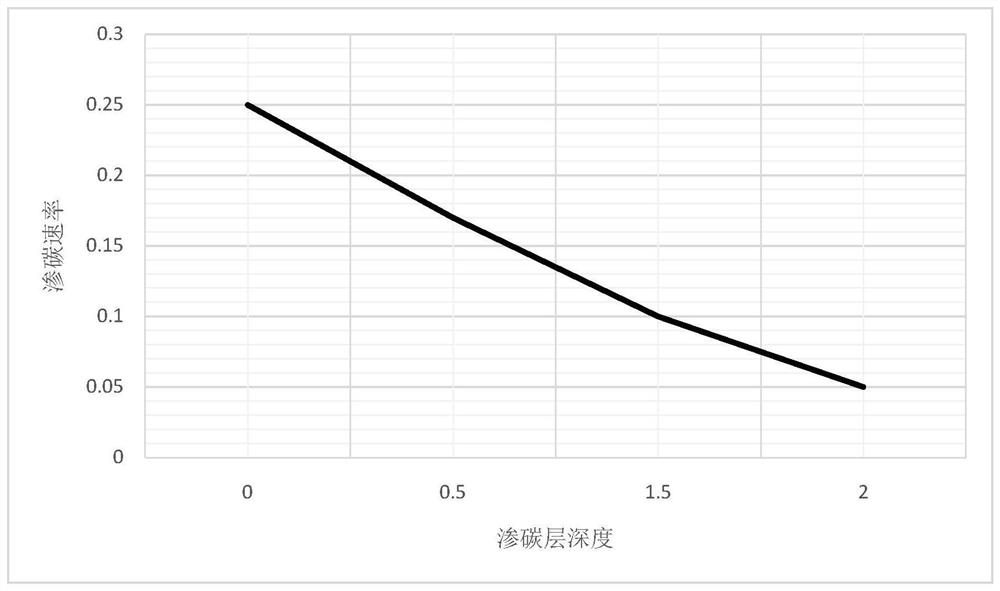

[0045] Such as figure 1 As shown, a carburizing method suitable for a drip-type gas carburizing furnace includes the following steps:

[0046] (1) Preparation of carburizing equipment before formal carburizing

[0047] If the carburizing equipment is continuously used for carburizing and maintains a stable carburizing temperature and atmosphere in the furnace, this preparation work is not required; if the carburizing equipment is used intermittently, it should be preheated and warmed up before use. Pre-infiltration, the specific process is as follows:

[0048] Equipment preheating process: set the temperature at 920°C, and conduct electric heating on the carburizing furnace. After the equipment reaches temperature, the carburizing furnace preheating and holding time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com