1Cr17Ni2 stainless steel screw and heat treatment process thereof

A stainless steel and screw technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of impact energy not reaching the design index, poor mechanical properties, and large amount of scrap, so as to reduce the risk of quenching deformation and cracking, Reduce the stress of martensitic transformed tissue and ensure the safety of personnel and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]A stainless steel screw is 1 CR17NI2 material containing the following mass percent components: C 0.11 to 0.17%, Si ≤ 0.80%, Mn ≤ 0.80%, CR 16.00 ~ 18.00%, Ni1.50 ~ 2.50%, P ≤ 0.035%, S ≤ 0.030%, the rest is Fe and inevitable impurity elements.

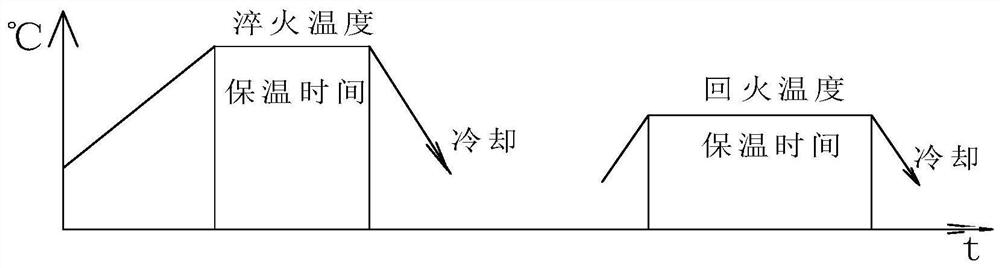

[0028]A heat treatment process for stainless steel screws, which uses a tuning process, including the following steps:

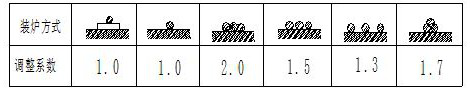

[0029]The first step, the furnace process: placed the parts that need to be processed in the quenching tool (quenching equipment is a hanging frame), and then the quenching machine is hanged, and the quenching tool is automatically transported to the box resistance furnace. In an effective heating zone, the implementation standard of the effective heating zone measurement method is: GB / T9452, automatically operate the program after setting the parameters after the front desk, automatically opens.

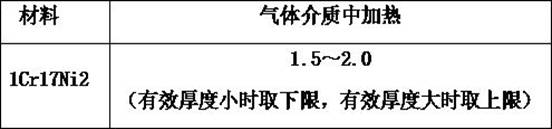

[0030]In the second step, the quenching process begins to be quenched. In the quenching operation, the quenching temperature i...

Embodiment 2

[0045]In this example, the F2000 water-based liquid is carried out by the F2000 water-based liquid as an example of φ38 × 200 mm, φ55 × 200 mm, φ85 mm × 200 mm, respectively, and the F2000 water-based liquid is carried out by the cooling medium in the cooling medium.

[0046]In this embodiment, a connecting box (nitrogen protection) resistor furnace is also employed, the device level is V, and the temperature control accuracy is ± 1 ° C. And use the same manner as the foregoing.

[0047]The heat treatment quenching heating temperature is: 900 ± 10 ° C, and the hi-furnace warming method is from 75 minutes, 100 points, 150 points, and the heat treatment quenching cooling medium is a F2000 water-based liquid, and the quenching water is 30 ° C. The concentration was measured to be 11% and the pH was 7.8. To prevent cracking, control the liquid temperature, i.e., the workpiece is empty after 2 to 3 points.

[0048]Temperature and time: The temper temperature is 650 ± 10 ° C, the holding time is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com