Large-sized sleeve bearing thrust-face reverse-lubricating and lubricating oil cooling method

A sliding bearing and lubricating oil technology, applied in the directions of bearing cooling, bearing components, shafts and bearings, etc., can solve problems such as no public reports, no lubrication and oil cooling methods, etc., to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

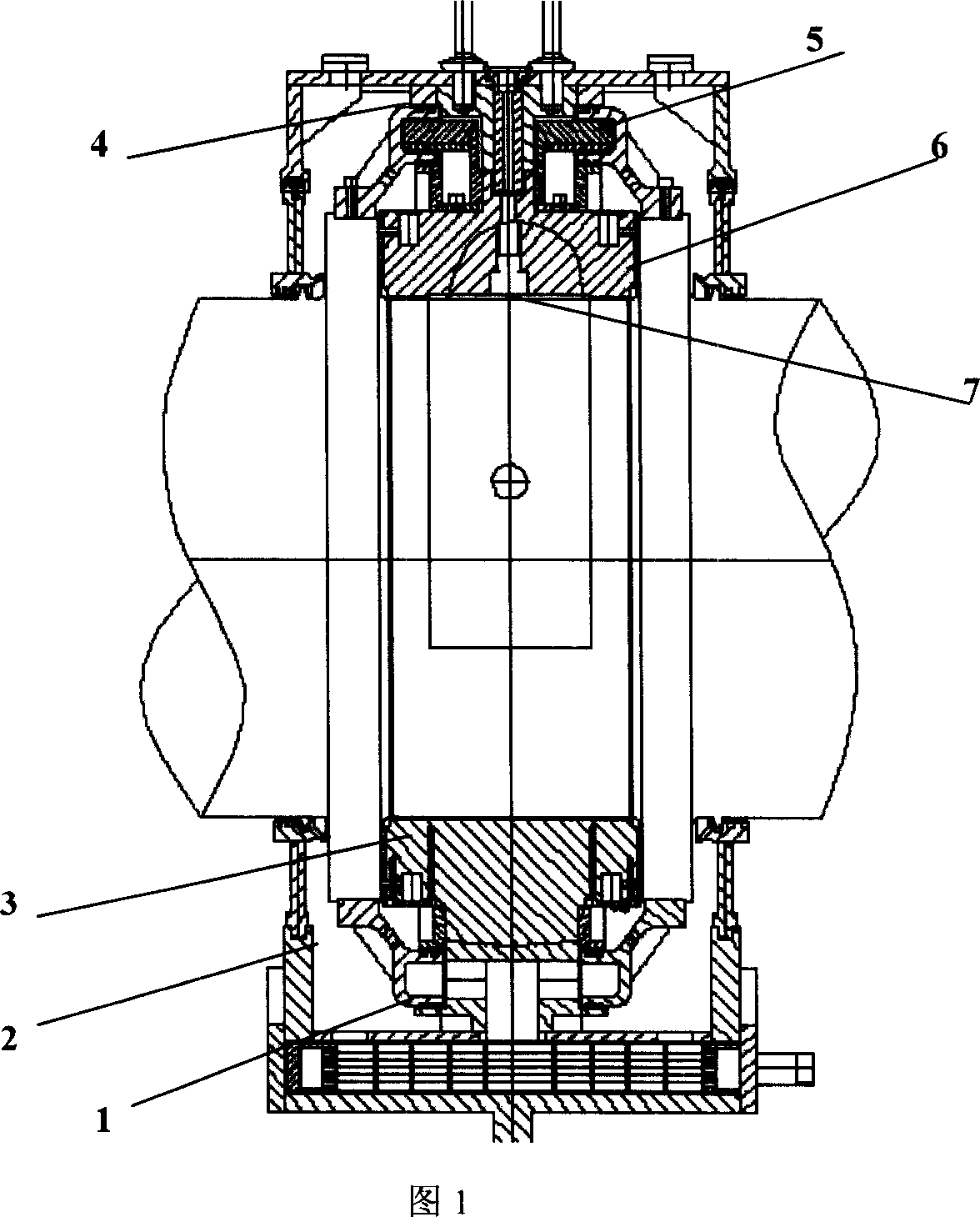

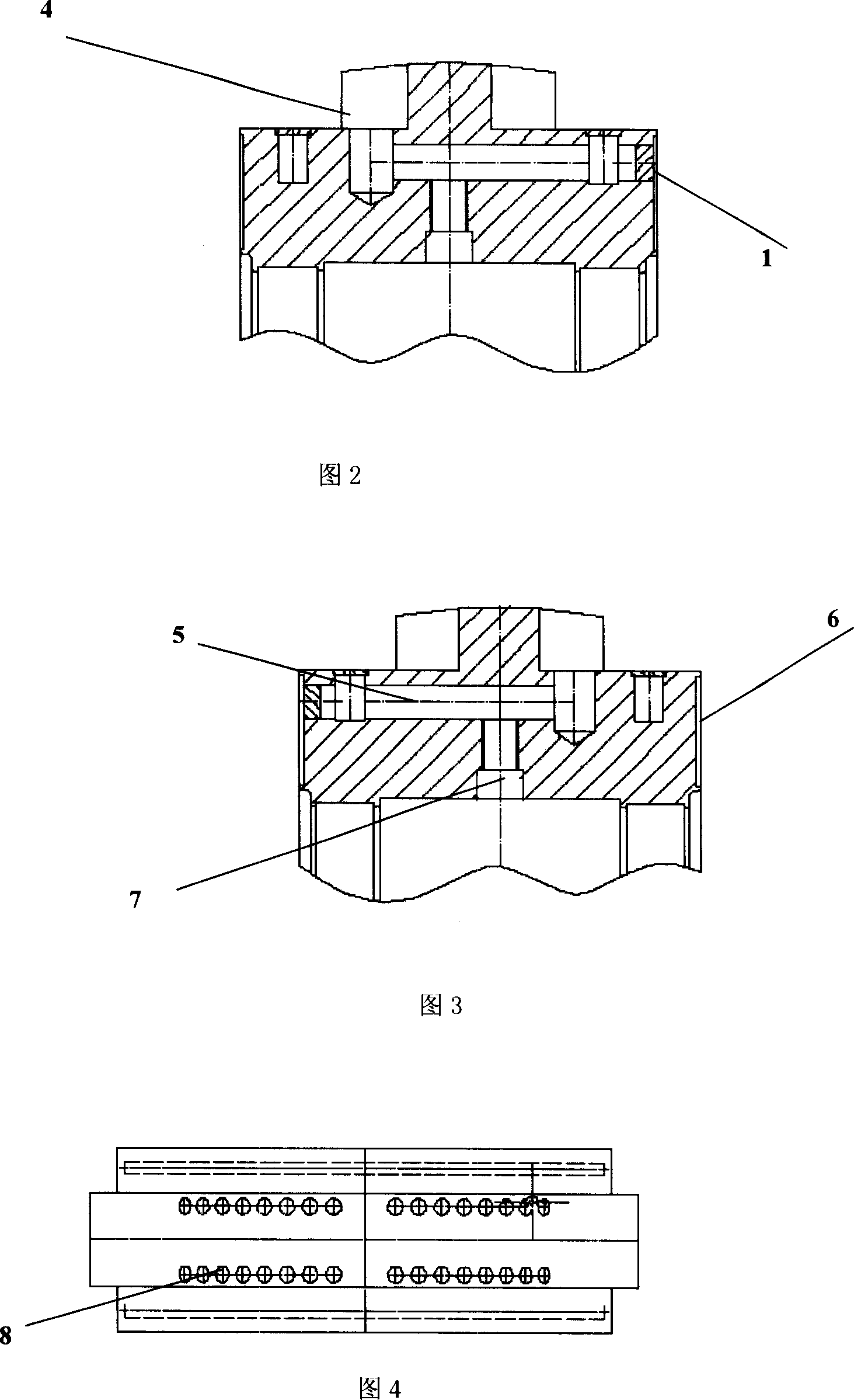

[0020] As shown in Figure 1, in the method of lubricating and lubricating oil cooling in non-horizontal working conditions involved in this embodiment, the left and right symmetrical oil thrower impeller 1 installed on the main shaft rotates with the shaft, and the lubricating oil is drawn from the bearing oil pool 2 After being brought into the top of the bearing bush 3, the oil scraper 4 is respectively introduced into the left and right oil inlet pipes 5, and the thrust surface 6 of the bearing bush and the inner diameter of the bearing bush 3 are lubricated by gravity and centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com