Liquid atomizing micro-dust introducing device for cooling and cleaning fan

A technology of liquid atomization and cleaning liquid, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, applications, etc., and can solve problems such as reducing the service life of equipment, production accidents, and abnormal temperature rises around the factory building. Achieve the effects of prolonging the service life, facilitating cleaning, and improving ventilation and cooling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

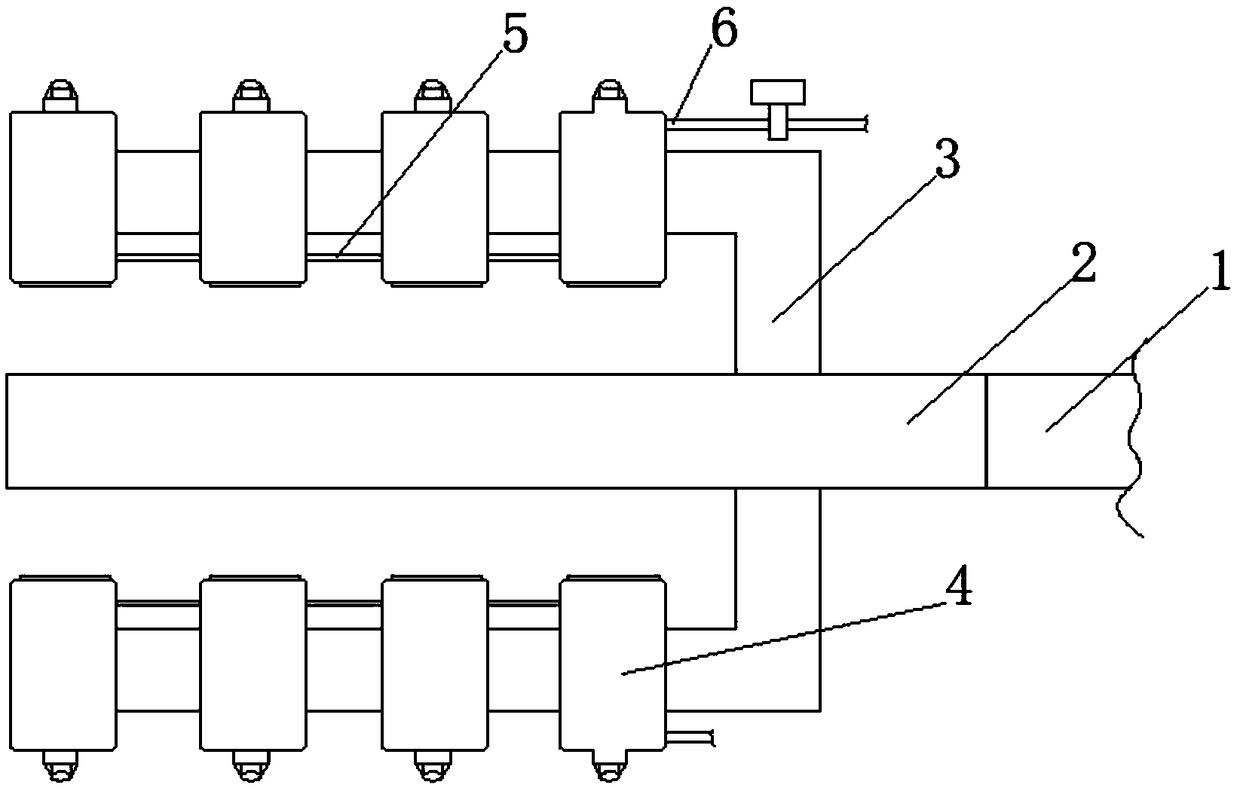

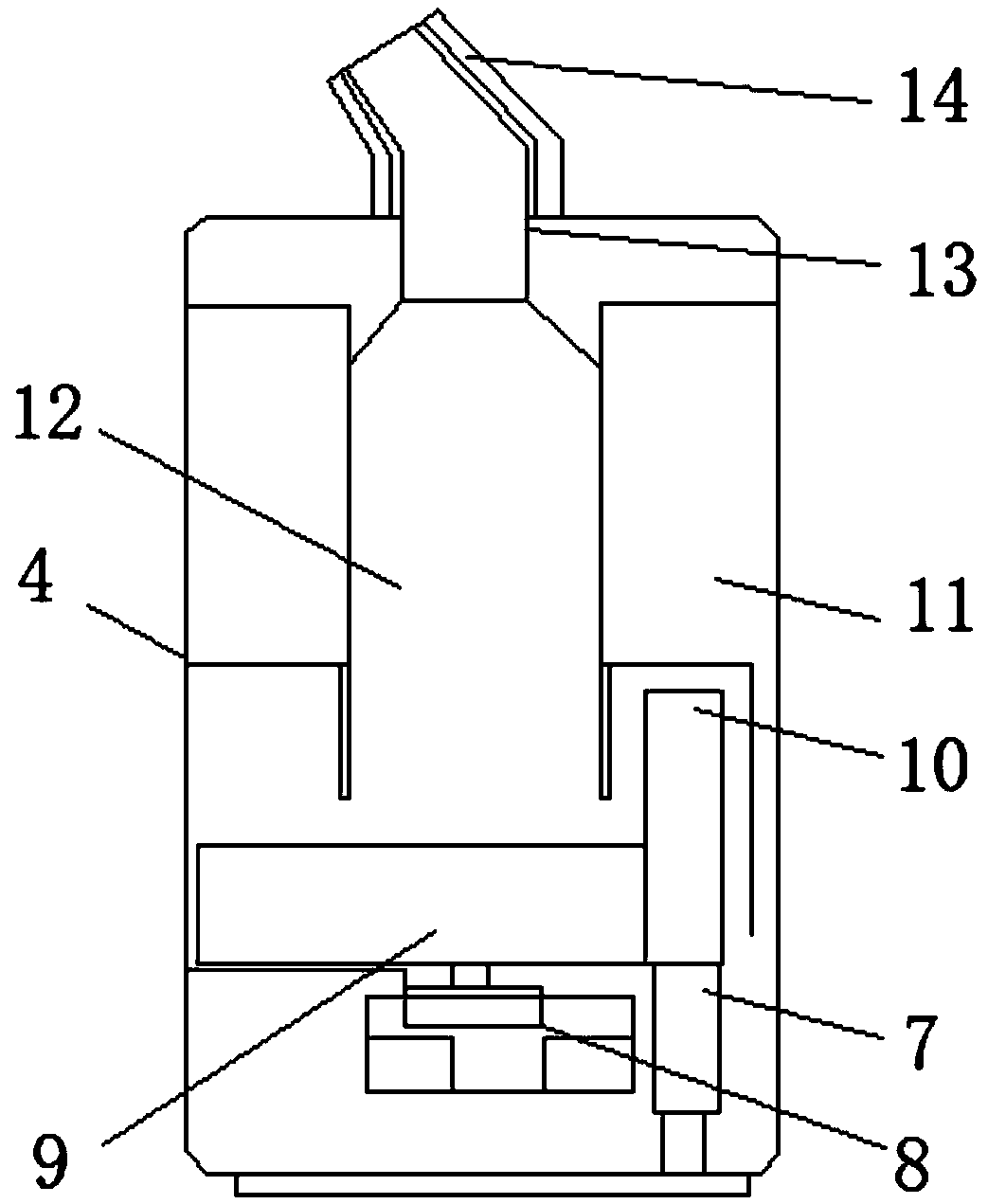

[0039] see Figure 1-2 , a liquid atomized dust inlet device for fan cooling and cleaning, including a fan shaft rod 1, the left end of the fan shaft rod 1 is fixedly connected with a heat island temperature control moisture heat conduction rod 2, behind the heat island temperature control moisture heat conduction rod 2 The end is fixedly connected with the attached extensional temperature control heat transfer tube 3, and the auxiliary extensional temperature control heat transfer tube 3 is sleeved with a plurality of heat island cooling liquid transfer devices 4, and the heat island cooling liquid transfer device 4 is fixed with the auxiliary extensional temperature control heat transfer tube 3 Connection, the right end of the heat island cooling liquid transfer device 4 on the far right is fixedly connected with a liquid diversion flow pipe 6, the liquid diversion flow pipe 6 is fixedly connected with an external water pipe, and the circulating fluid transfer pipes are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com