Afterburning-type supercritical-pressure gas-liquid fuel-generator combustion-chamber redundancy-cooling device

A technology of fuel generator and cooling device, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of equipment heat transfer deterioration, damage to equipment, destruction, etc., and achieve the effect of avoiding heat transfer deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

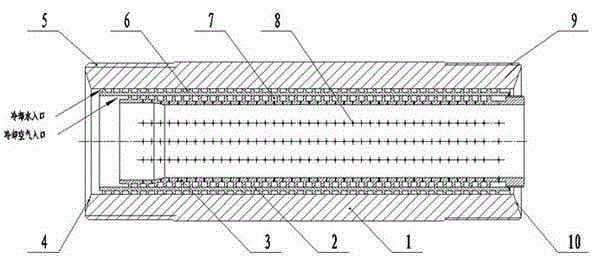

[0018] Refer below figure 1 The present invention will be described in detail.

[0019] The auxiliary combustion type supercritical pressure gas-liquid two-phase fuel steam injection generator combustion chamber redundant cooling device consists of a pre-combustion chamber shell 1, a pre-combustion chamber lining 2, and a pre-combustion chamber lining 3. Wherein, the front end surface 4 and the rear end surface 10 of the pre-chamber housing 1 are all conical, and the threaded flanges and studs on the flange thread 5 and the flange thread 9 connected on the pre-chamber housing 1 and nuts, which are respectively pressed and sealed with the spherical end faces of the pre-combustion chamber injector housing and the supplementary combustion injector housing located at the front and rear ends thereof. The outer edge of the lining 2 in the pre-combustion chamber is provided with multi-head spiral grooves. The outer edge of the pre-combustion inner lining 3 is also provided with mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com