Polyolefin microporous membrane as well as preparation method and application thereof

A polyolefin microporous film and polyolefin technology, applied in the field of polyolefin materials, can solve problems such as uneven cooling of the melt, affecting product uniformity, quality and application, and generation of waves, etc., to overcome uneven cooling of the melt , reduce the formation of spherulites and epiphytic crystals, and reduce the uneven effect of stretching into holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

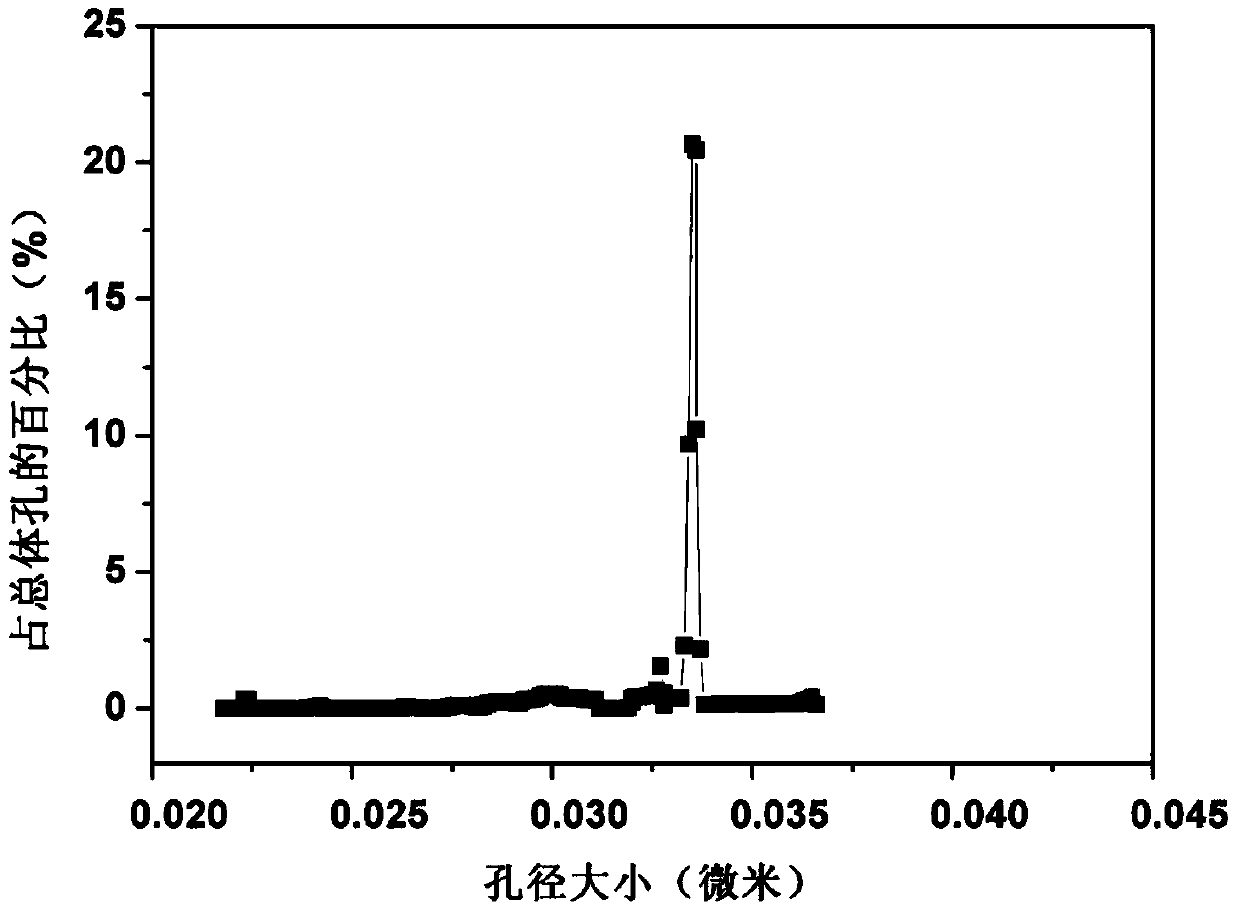

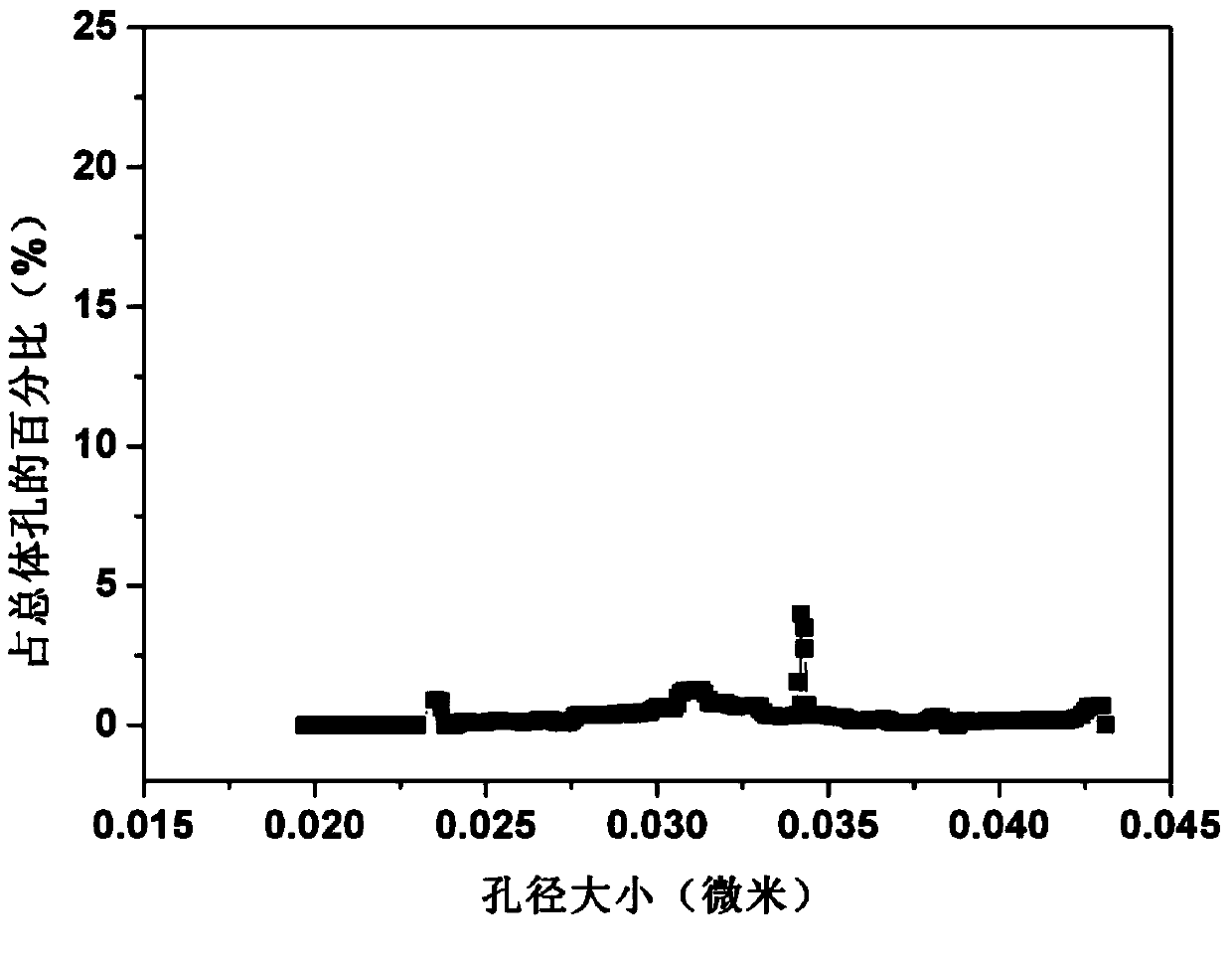

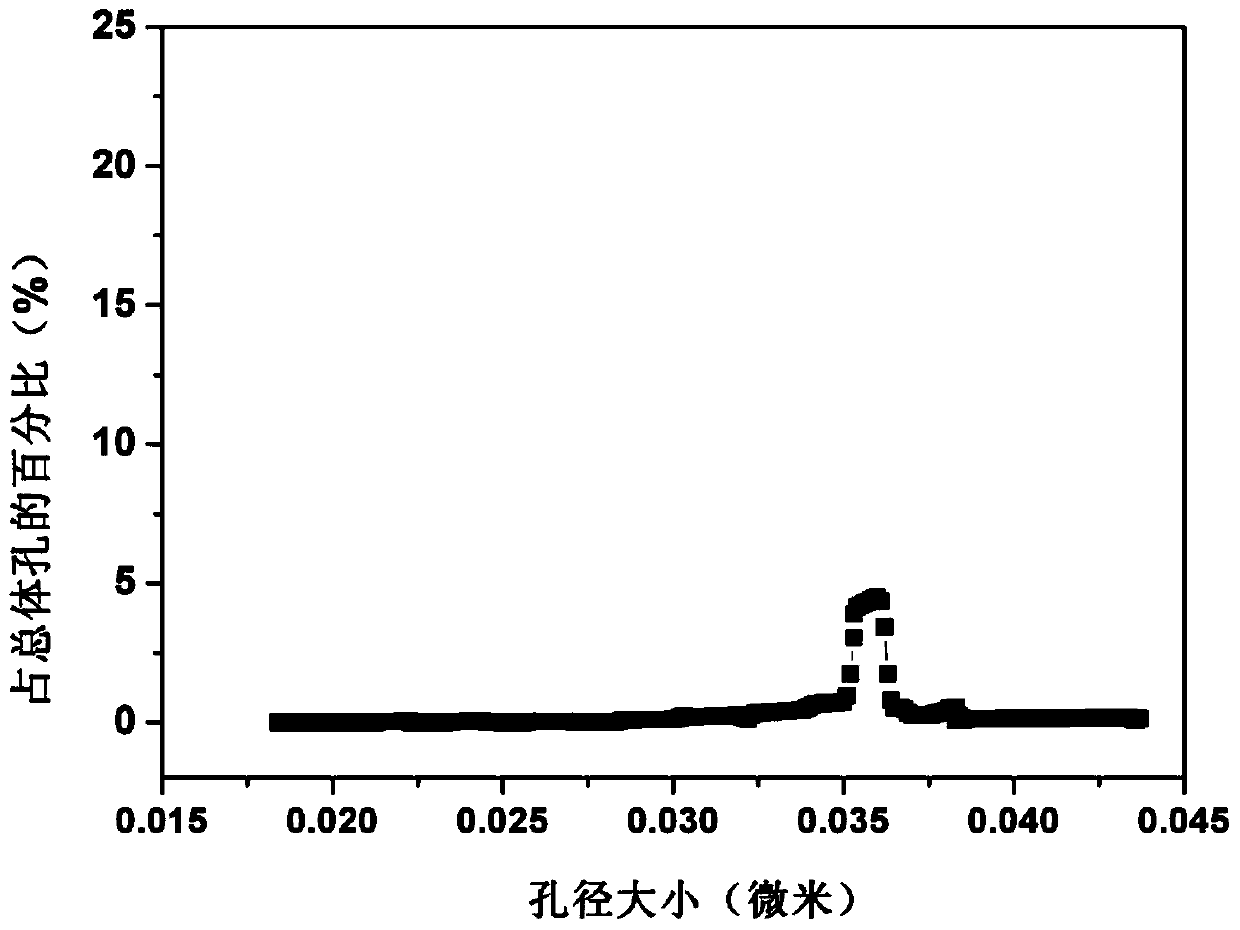

[0029] In this application, the casting method is used to prepare polyolefin microporous membranes. In view of the problem of uneven cooling of the melt caused by air fluctuations in the casting cooling process in the prior art, this application adopts fog surface quenching during the preparation process. The rolls draw and cool the polyolefin melt into a polyolefin base film. The use of matte chilled rollers in the casting cooling process of polyolefin melts can make the air layer between the melt and the rollers formed due to the high-speed movement of the rollers during the cooling process of the polyolefin melt close to the matted chilled rollers The air brought in enters the grooves on the surface of the matte chilled roller, thereby reducing air fluctuations and effectively reducing the generation of waves. The matte chill roll suitable for this application needs to satisfy: its Ra value is 0.04-2 μm, and the diameter of the matte chill roll is 200-2000 mm. Wherein, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com