Process for improving comprehensive mechanical performances of weld of high-frequency straight welded tube

A straight seam welded pipe and comprehensive mechanics technology, applied in the field of high frequency straight seam welded pipe heat treatment, can solve the problems of poor comprehensive mechanical properties, reduced impact toughness and high production cost, and achieve the effects of improving comprehensive mechanical properties, increasing strength and stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

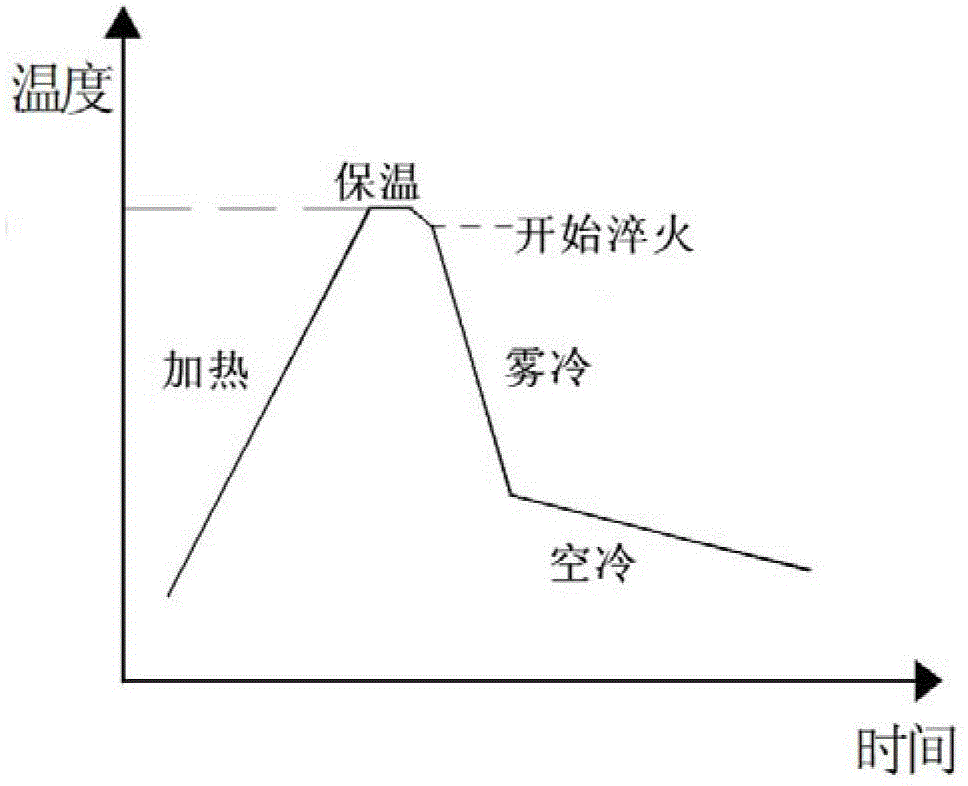

[0024] Heat treatment of high frequency longitudinal welded pipe welds:

[0025] (1) Intermediate frequency heating: In the heating room, intermediate frequency induction heating equipment is used to conduct on-line heat treatment on the weld seam, and the temperature of the weld seam is raised to 935°C and then kept for 2.5s.

[0026] (2) Water mist cooling: After the welded pipe leaves the heating room and runs along the roller table for 1~3 meters, water mist cooling is carried out. There are 3 sets of water mist cooling devices. The water pressure of water mist cooling is 0.5Mpa, and the cooling speed of the welded pipe is 80 °C / s, and the final cooling temperature is 550 °C. The water mist cooled by water mist is sprayed through the full cone water mist nozzle, the spray angle is 67°, and the distribution is 1-1-3. Such a water mist nozzle can make the water form natural particles of 0.01~0.15mm. After water mist cooling quickly cools the welded pipe from the austenitizi...

Embodiment 2

[0030] Heat treatment of high frequency longitudinal welded pipe welds:

[0031] (1) Intermediate frequency heating: In the heating room, intermediate frequency induction heating equipment is used to conduct on-line heat treatment on the weld seam, and the temperature of the weld seam is raised to 935°C and then kept for 2.5s.

[0032] (2) Water mist cooling: After the welded pipe leaves the heating room and runs along the roller table for 1~3 meters, water mist cooling is carried out. There are 3 sets of water mist cooling devices. The water pressure of water mist cooling is 0.6Mpa, and the cooling speed of the welded pipe is 90 °C / s, and the final cooling temperature is 500 °C. The water mist cooled by water mist is sprayed through the full cone water mist nozzle, the spray angle is 67°, and the distribution is 1-1-3. Such a water mist nozzle can make the water form natural particles of 0.01~0.15mm. After water mist cooling quickly cools the welded pipe from the austenitizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com