Air distributor system used in gas-solid heat exchange process and gas-solid heat exchange method

A technology of air distributor and thermal process, which is applied in the direction of heat exchanger type, direct contact heat exchanger, and treatment of discharged materials, which can solve the problem of uneven heat exchange between wind and high-temperature materials, and uneven air distribution of air distribution devices , low heat recovery efficiency and other issues, to achieve uniform cooling, avoid uneven cooling, and prolong the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

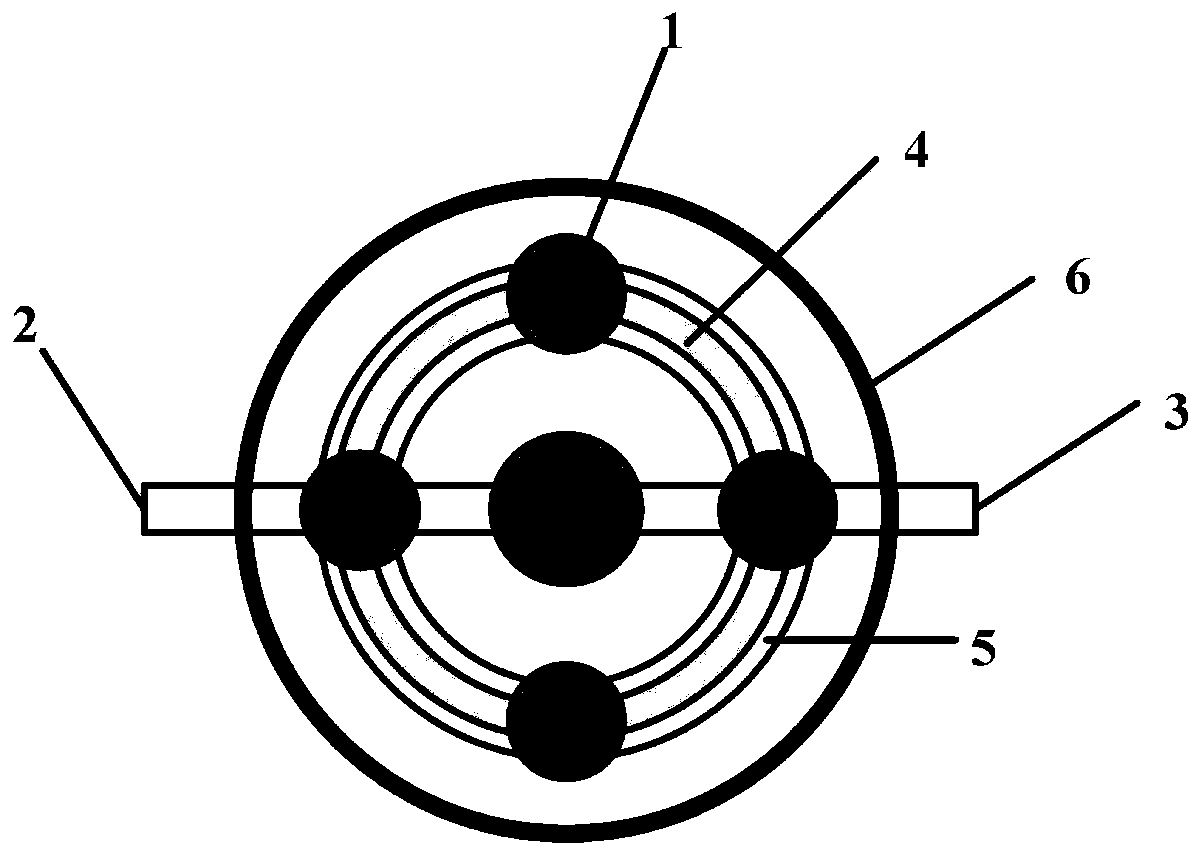

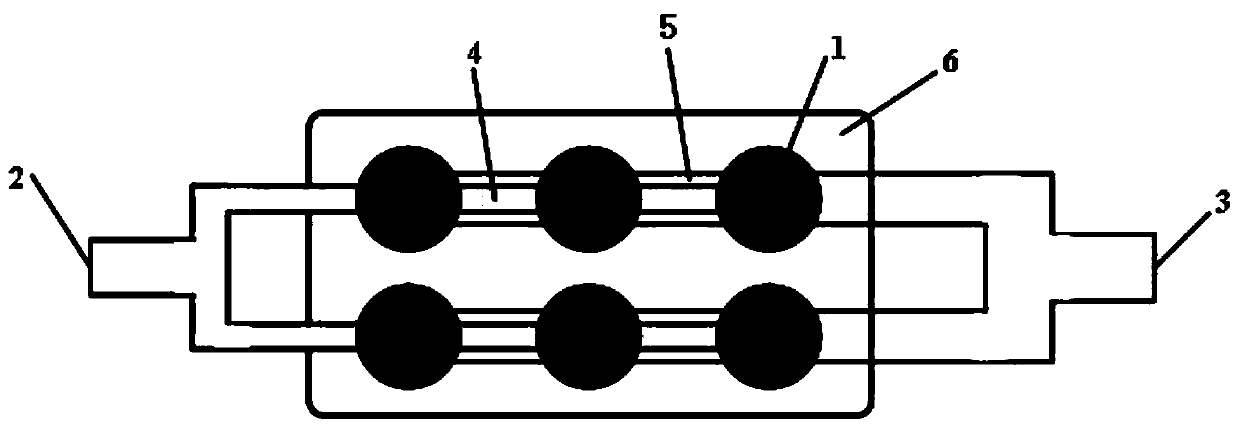

[0040] A specific embodiment of the present invention discloses an air distributor system used in the gas-solid heat exchange process, which includes a wind cap 1, a circulating hot air inlet 2, a circulating hot air pipe 4, an air inlet 3, Air duct 5, gas-solid heat exchange device 6.

[0041] Specifically, the horizontal section of the gas-solid heat exchange device 6 can be in different shapes such as circular, square, trapezoidal, etc. The height of the gas-solid heat exchange device 6 can be determined according to the amount of high-temperature solid materials fed in during actual implementation, and the gas-solid heat exchange The inside of the thermal device 6 is provided with an insulating layer.

[0042] Specifically, the circulating hot air pipe 4 includes an annular part and a straight part.

[0043] Among them, the shape of the circulating hot air pipe 4 in the annular part is the same as that of the gas-solid heat exchange device 6, and is evenly arranged inside...

Embodiment 2

[0075] This embodiment provides a gas-solid heat exchange method for cooling high-temperature solid materials using the air distributor system in Embodiment 1 of the present invention, including the following steps:

[0076] Step 1, transporting the high-temperature solid material to the gas-solid heat exchange device 6 of the air distributor system;

[0077] Step 2, passing air from the air inlet 3 into the air duct 5;

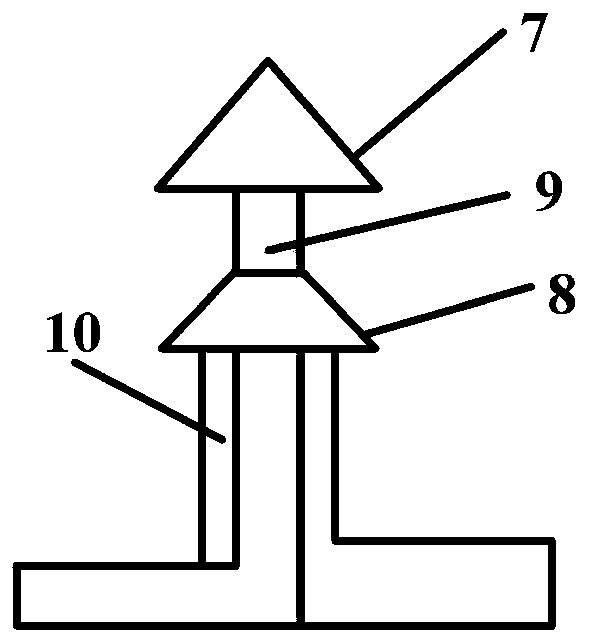

[0078] Step 3, the air flows through the air duct 5 into the lower hood pipe 10 of each hood 1, and is discharged from the lower air outlet 12; the discharged low-temperature air exchanges heat with the high-temperature solid material to cool the high-temperature solid material;

[0079] Step 4, the air and the high-temperature solid material are heated after heat exchange, and the heated air is passed into the circulating hot air pipe 4 from the circulating hot air inlet 2 as circulating hot air;

[0080] Step 5, the circulating hot air flows through the ci...

Embodiment 3

[0086] to combine figure 1 , image 3 and Figure 4 As shown, the present embodiment adopts a circular gas-solid heat exchange device 6, and there are 5 hoods 1 in total, among which the hood 1 at the center is larger, and the other 4 hoods 1 are smaller, and the 4 smaller hoods 1 are evenly distributed. Distributed around the wind cap 1 of large size in the central position. First, the high-temperature granulated slag at 900°C enters the gas-solid heat exchange device 6, and the circulating hot air at 150°C and the air at 20°C enter from the circulating hot air inlet 2 and the air inlet 3 respectively, wherein the circulating hot air goes through the circulating hot air pipe 4, and the air Go through the air duct 5, and the two ways of air are respectively discharged from the upper air outlet hole 11 on the upper air cap tube 9 and the lower air outlet hole 12 on the lower layer air cap tube 10 and exchange heat with the high-temperature granulated slag, and the air is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com